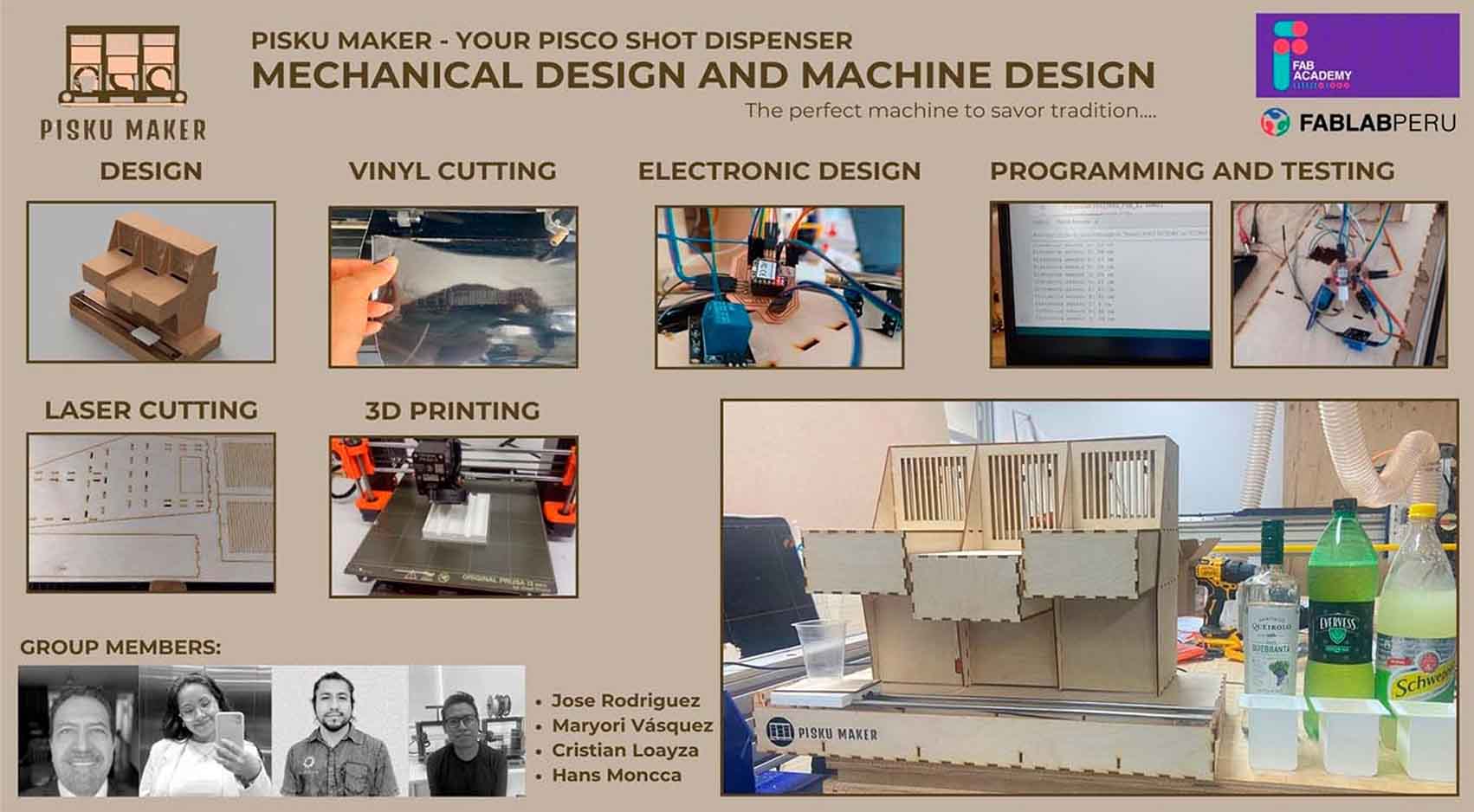

MECHANISM

Our group was divided into all the tasks that we were going to develop this assignment. I was responsible for the 2D and 3D design, and since I was going to be in charge of the design, I was in charge of the assembly of the machine and finally, I was also part of the testing for its development.

CONCEPT

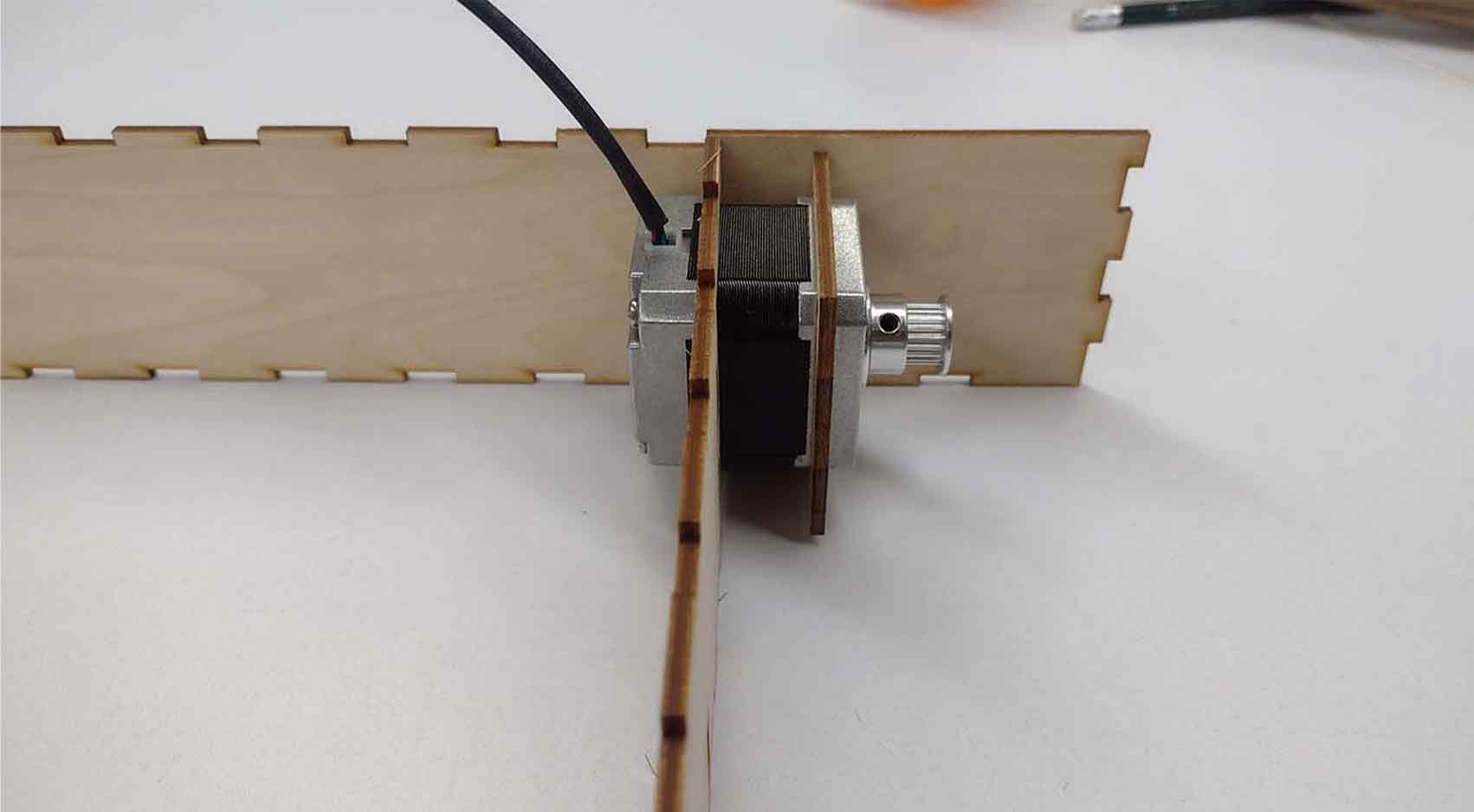

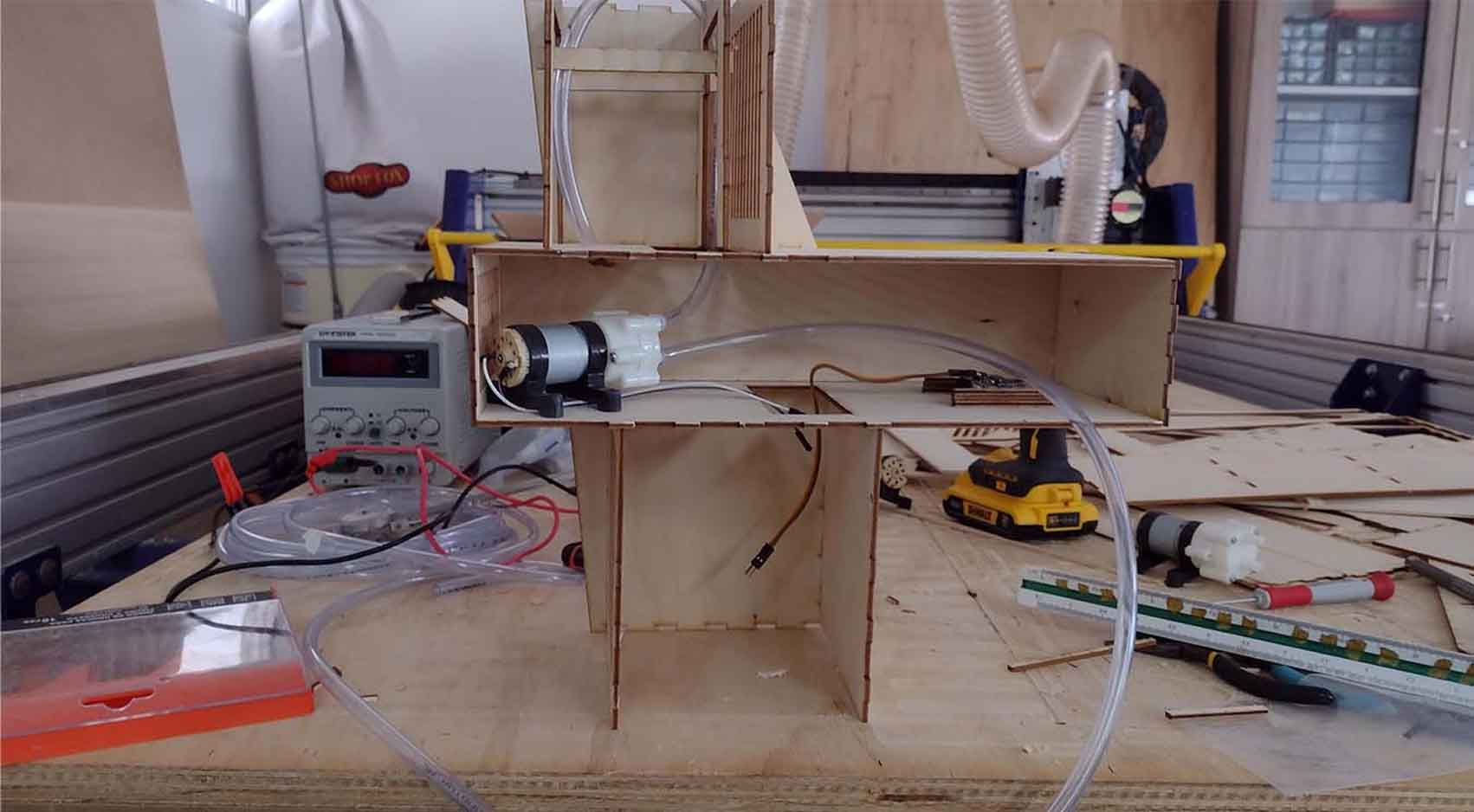

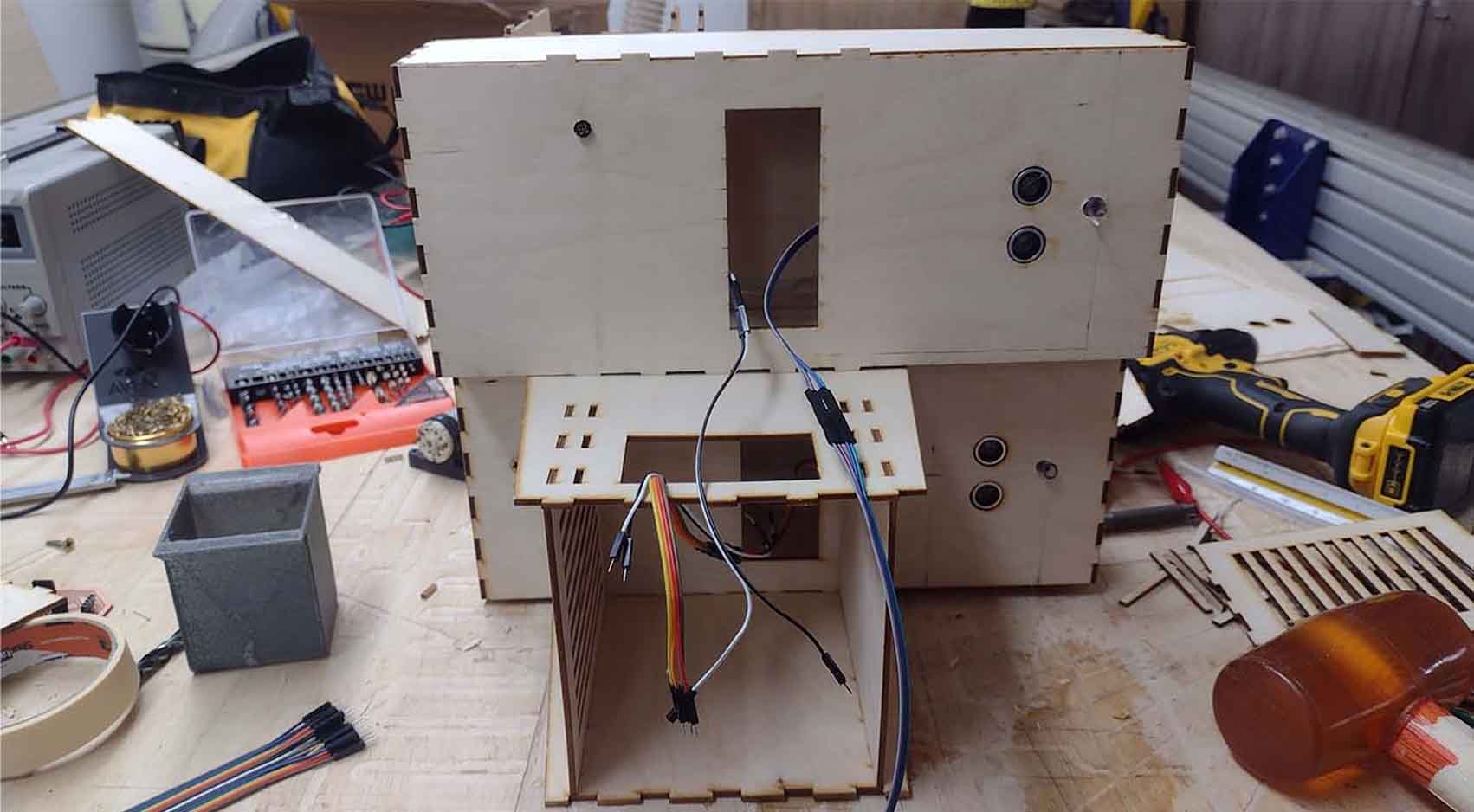

To design the machine we thought of many ways in which it could work. The truth is that we were afraid of how to start and what we were going to develop. Therefore, when recapitulating the entire FAB ACADEMY and what was done each week, we concluded that the machine should be all PRESS FIT to avoid using screws or other components since we had 3mm PLYWOOD as material. From this, we developed design sketches and what was left was one that looked like a building. The majority of the group are architects and we liked the mix between machine and architecture so much that we developed an architectural model-type machine.

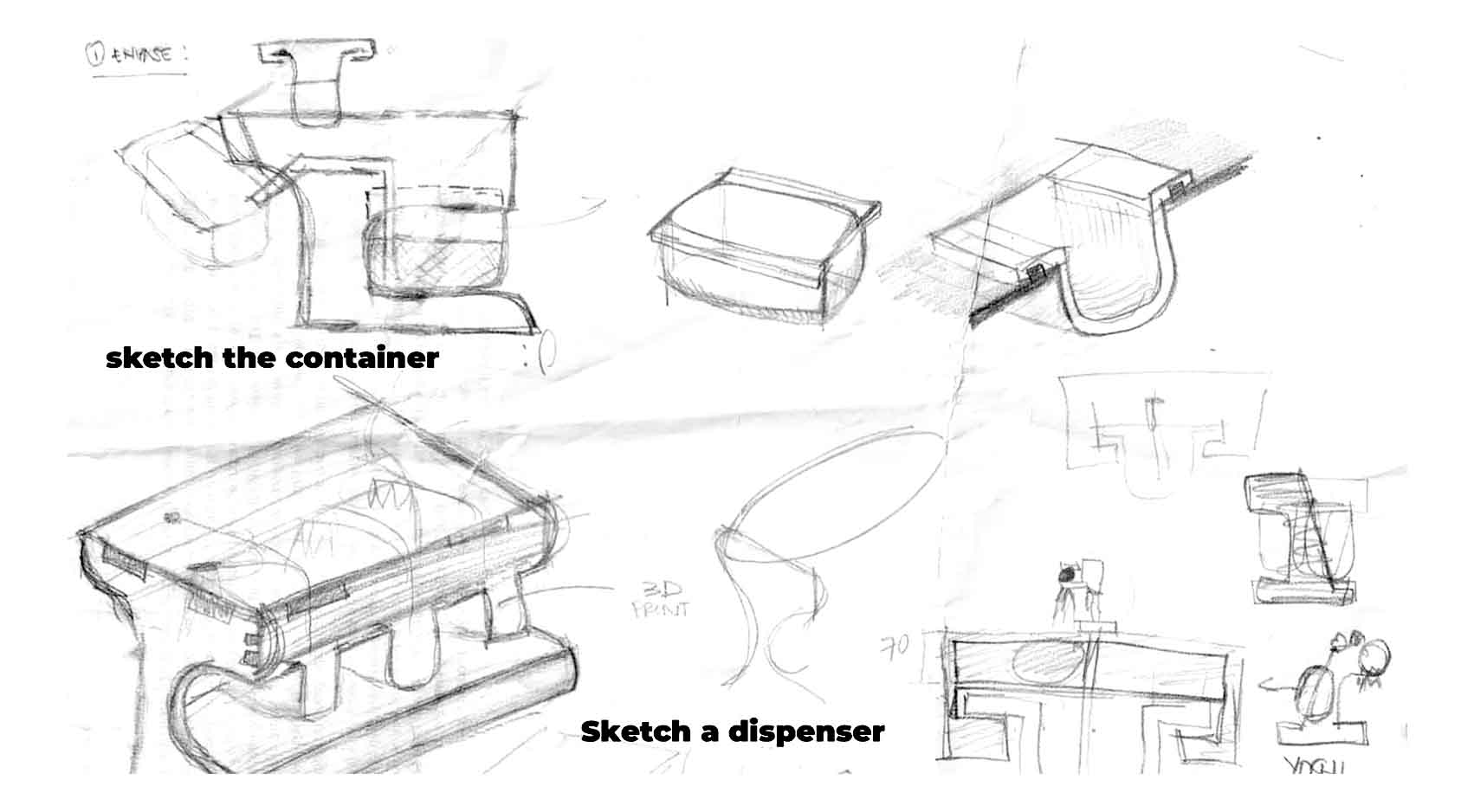

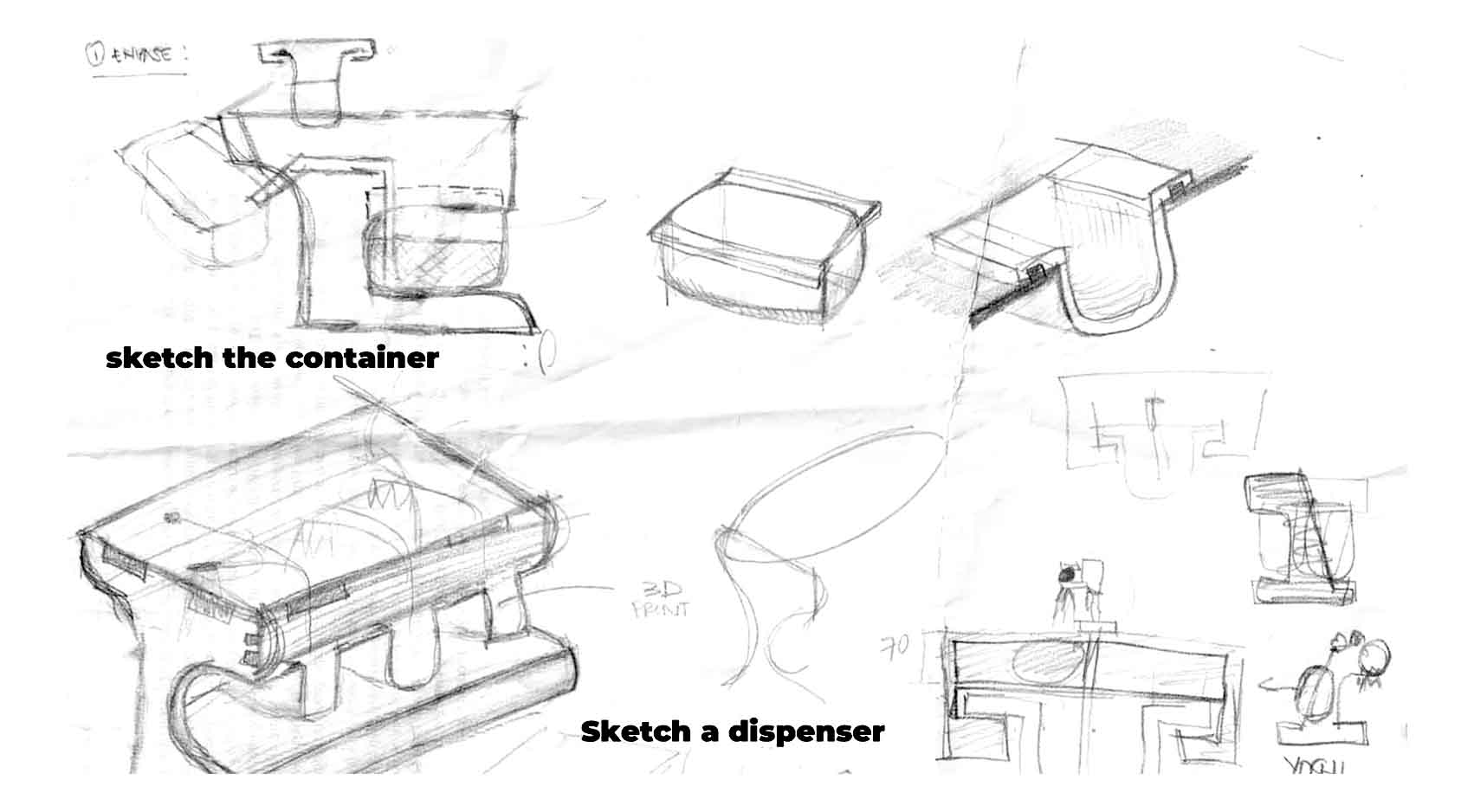

SKETCH

To begin the design of the machine, we began to make sketches to understand how it was going to work and how to place the components that we were going to have. Here are some photographs of sketches that I was able to recover at the time of design.

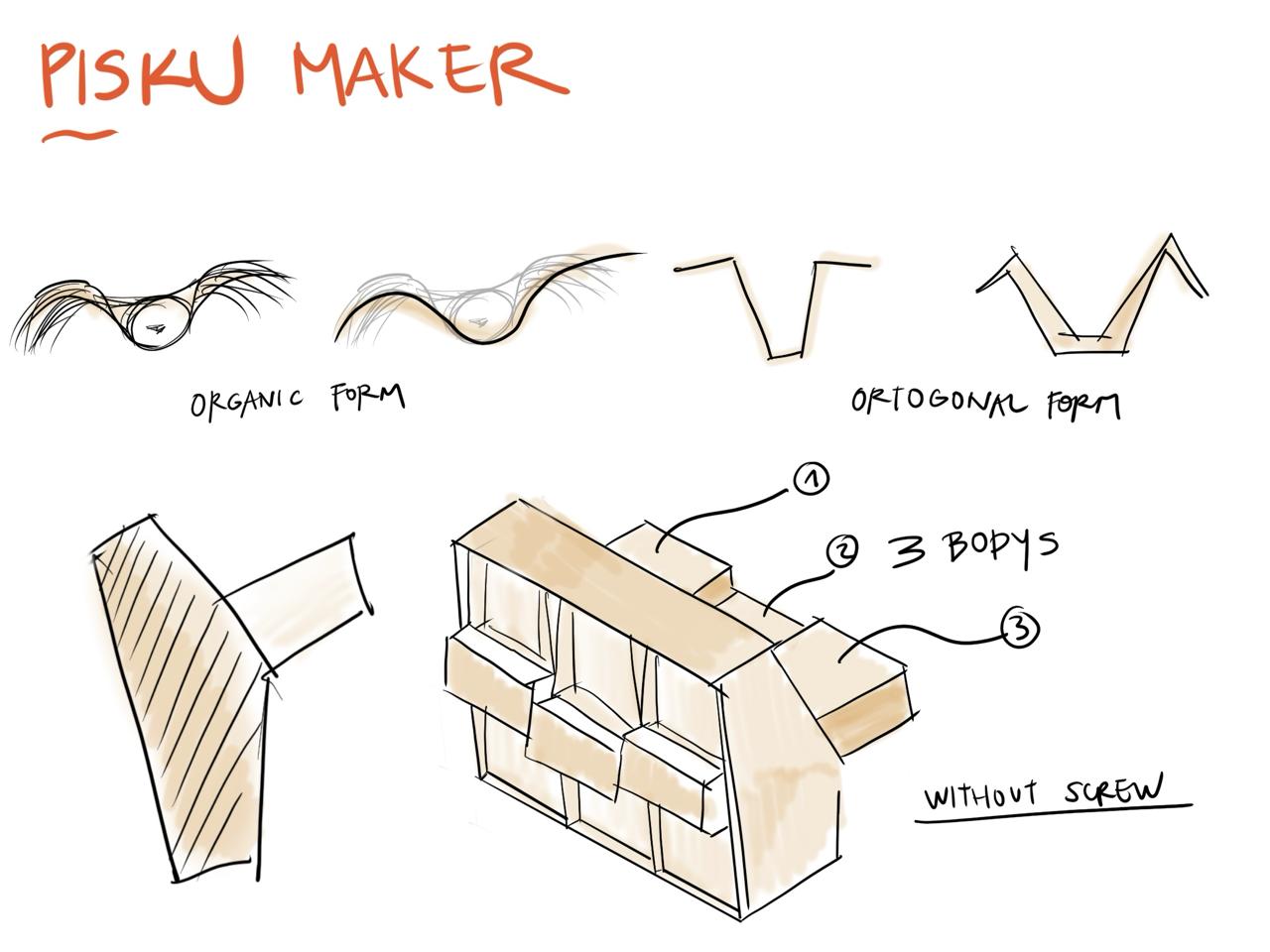

DESIGN AND INSPIRATION

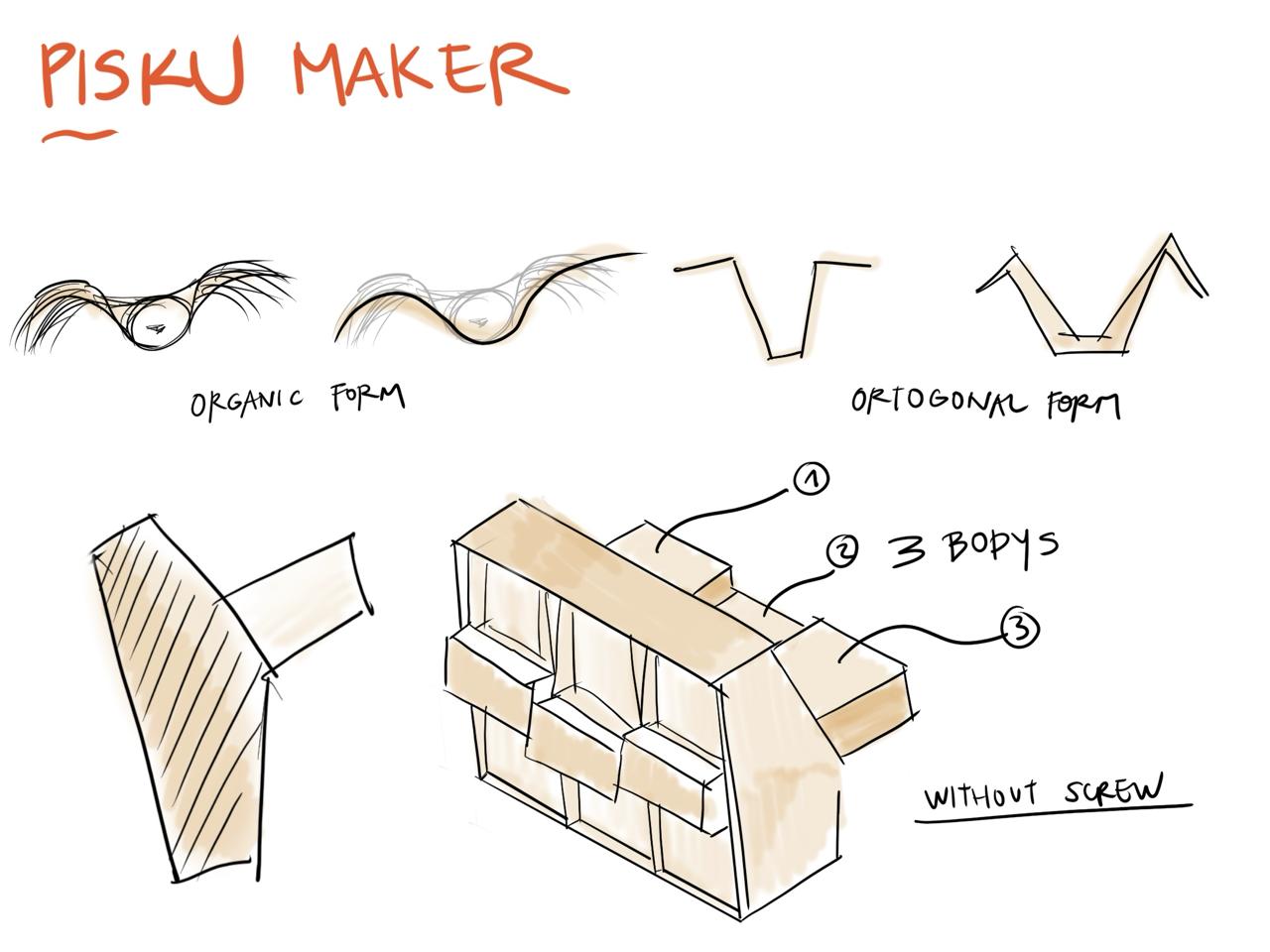

The 3D model is inspired by the meaning of the word Pisku, which in Spanish translation is "Pisco", a legendary Peruvian drink that comes from the distilled grape, is a flagship drink of our country.

Therefore devising the meaning of Pisku in Quechua, is "Little Bird" or "small bird", thanks to this we could conceptualize our design based on rigid and strong lines, alluding to its meaning.

3D MODEL

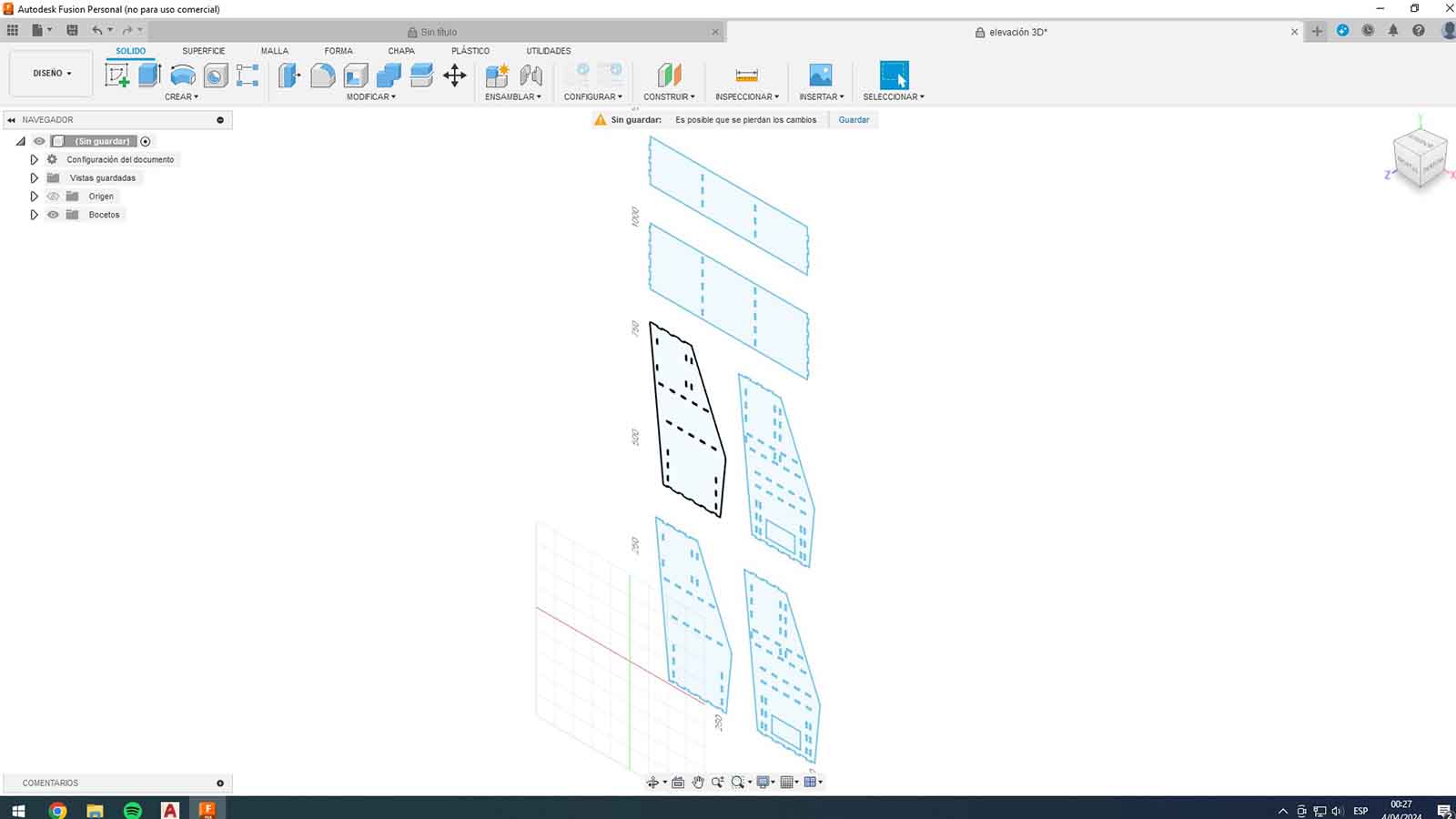

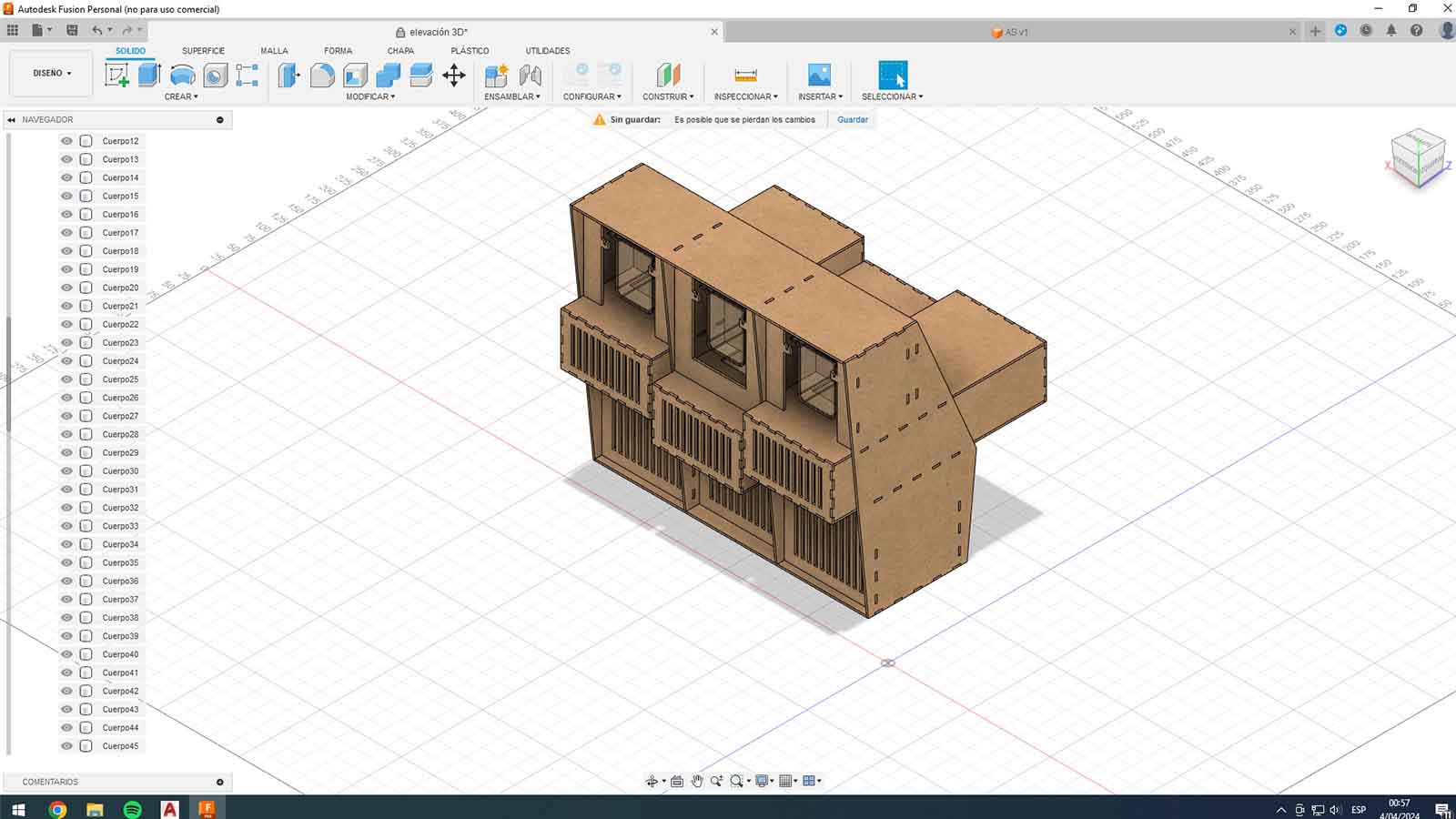

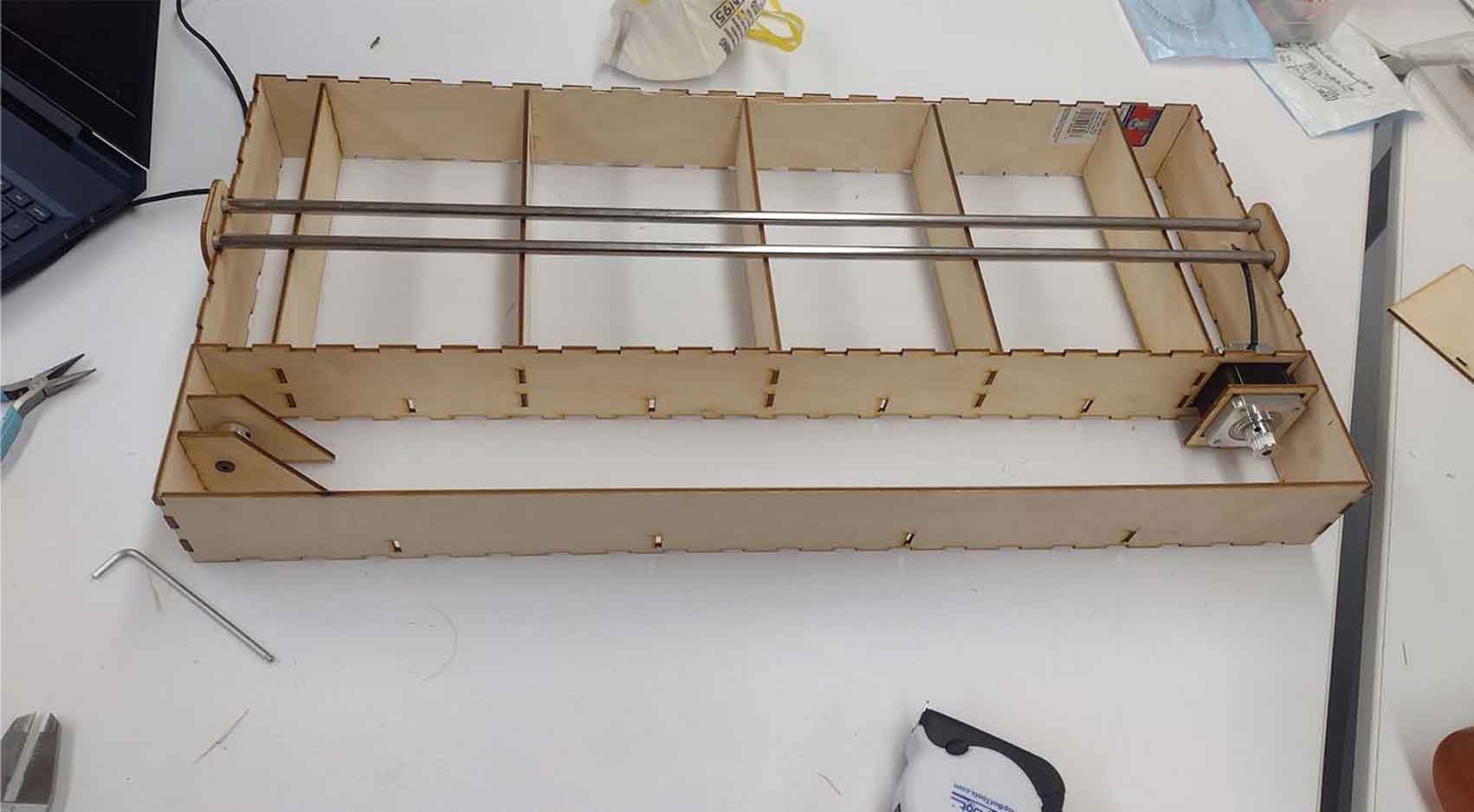

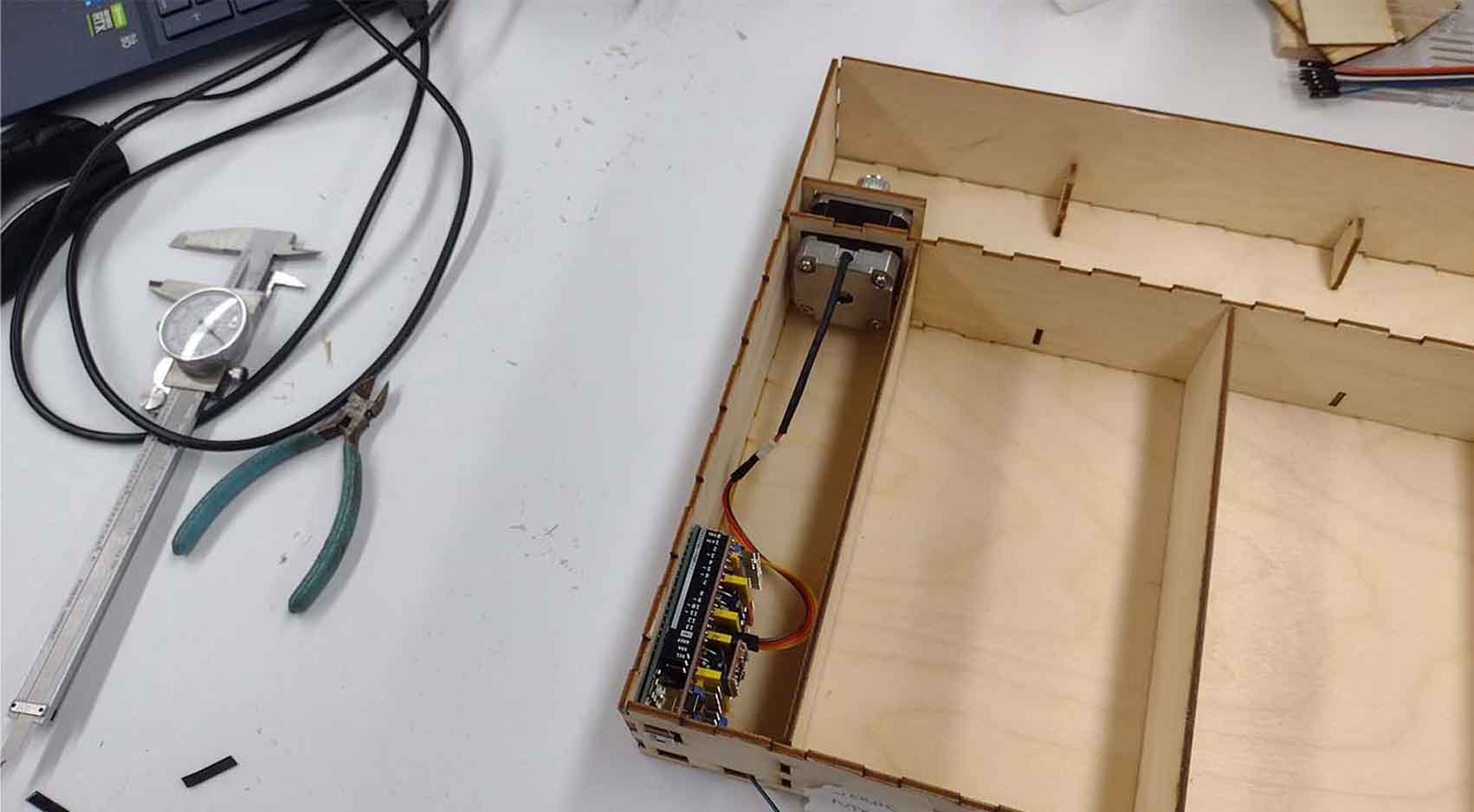

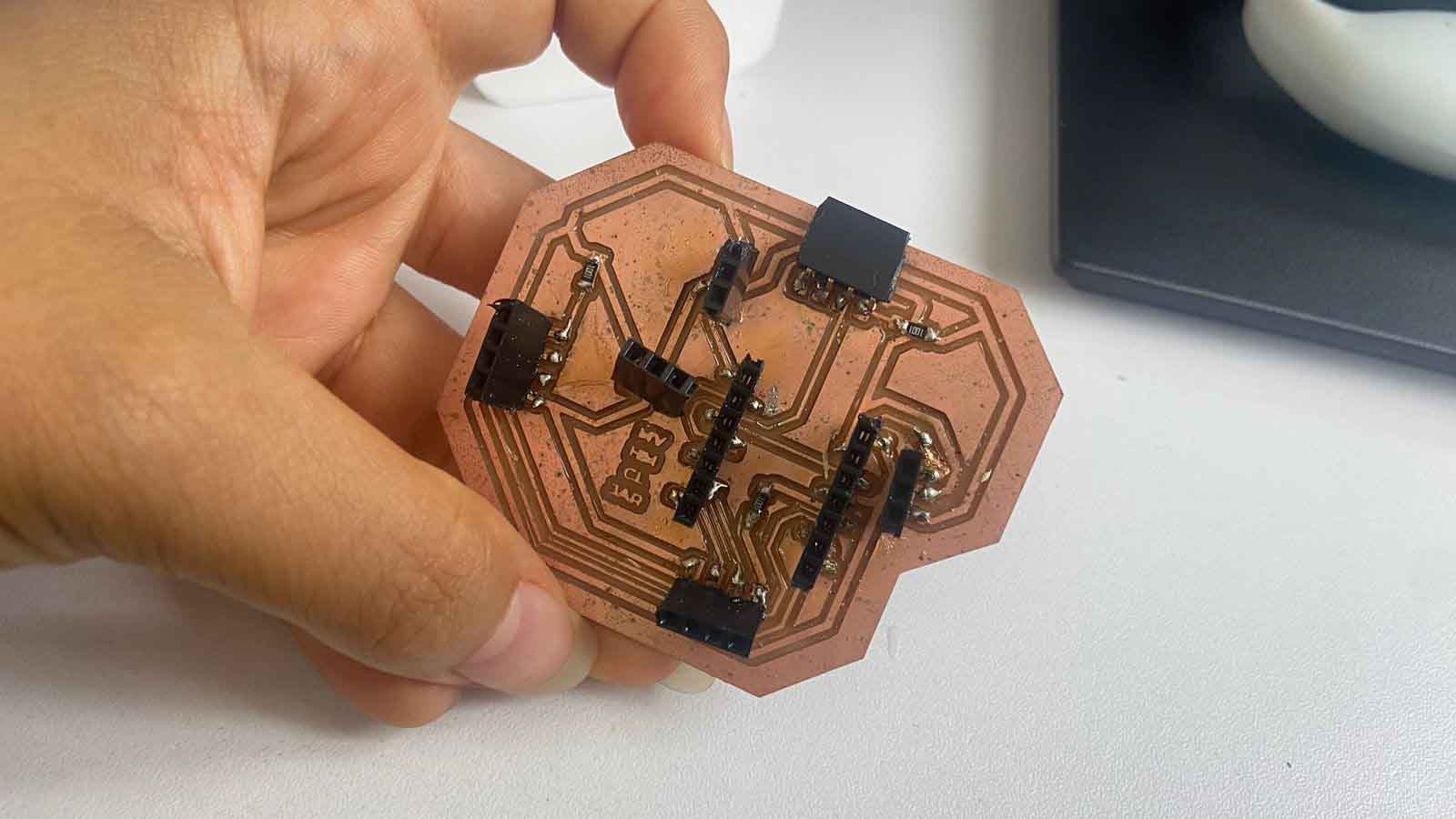

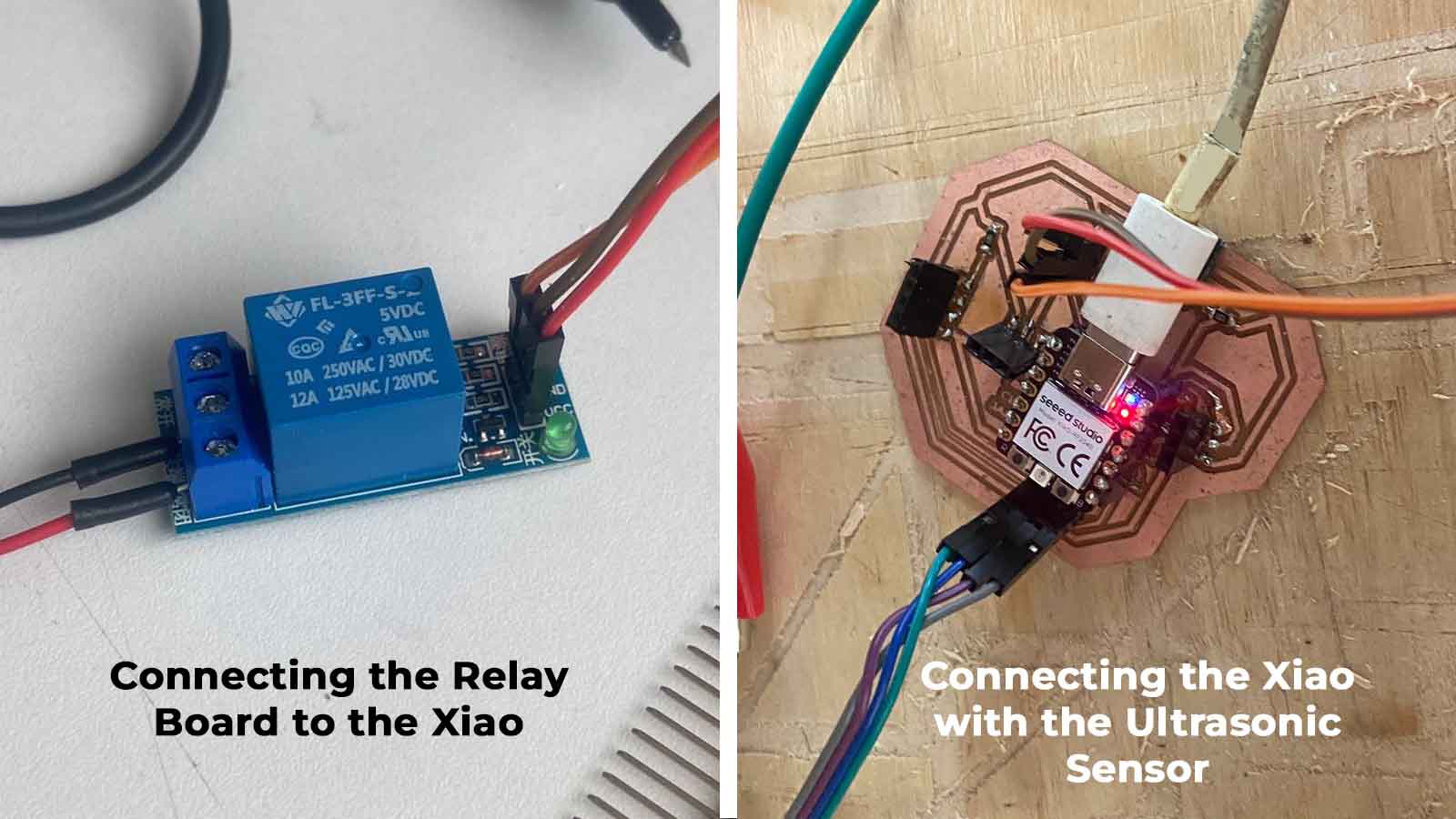

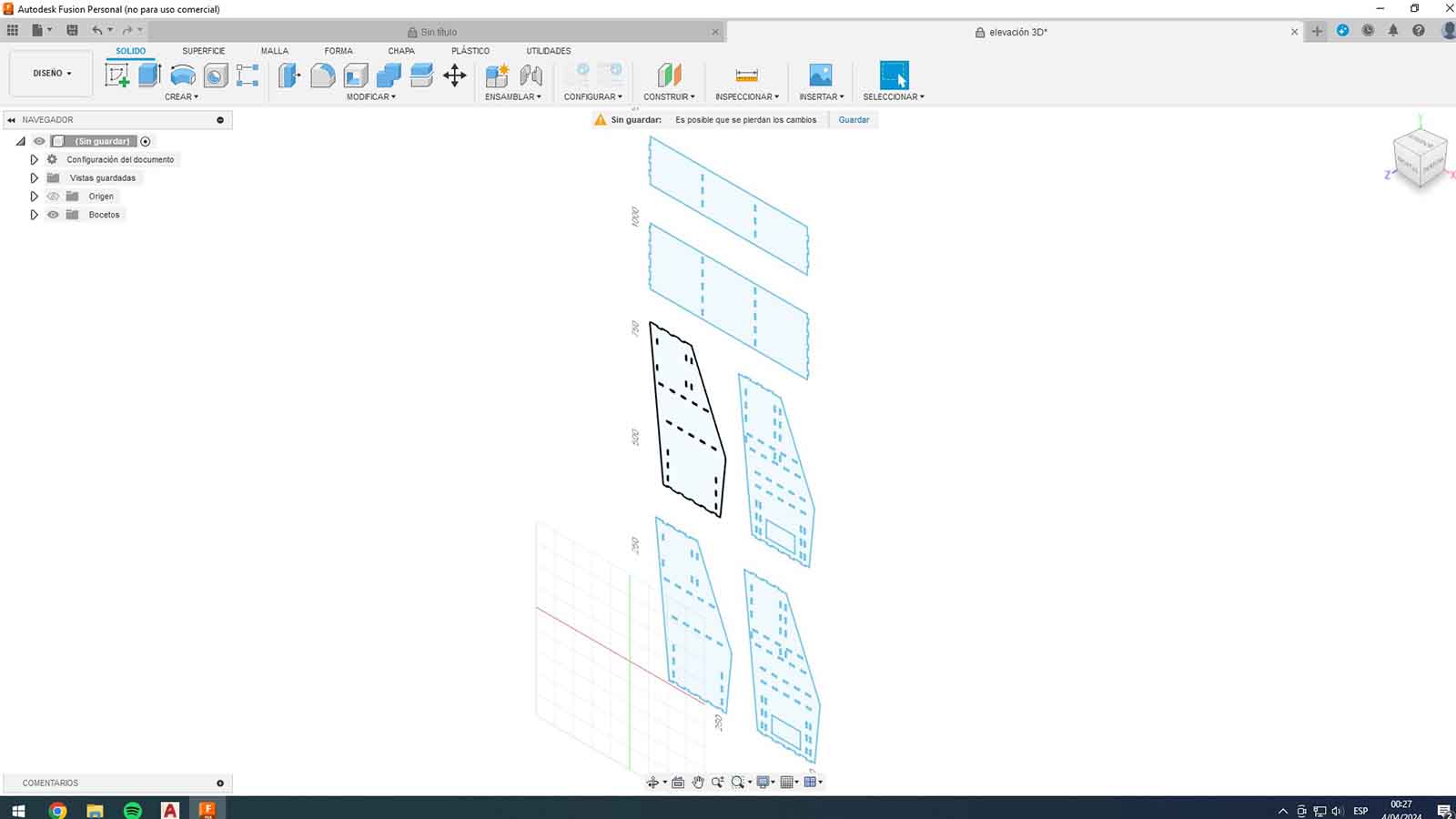

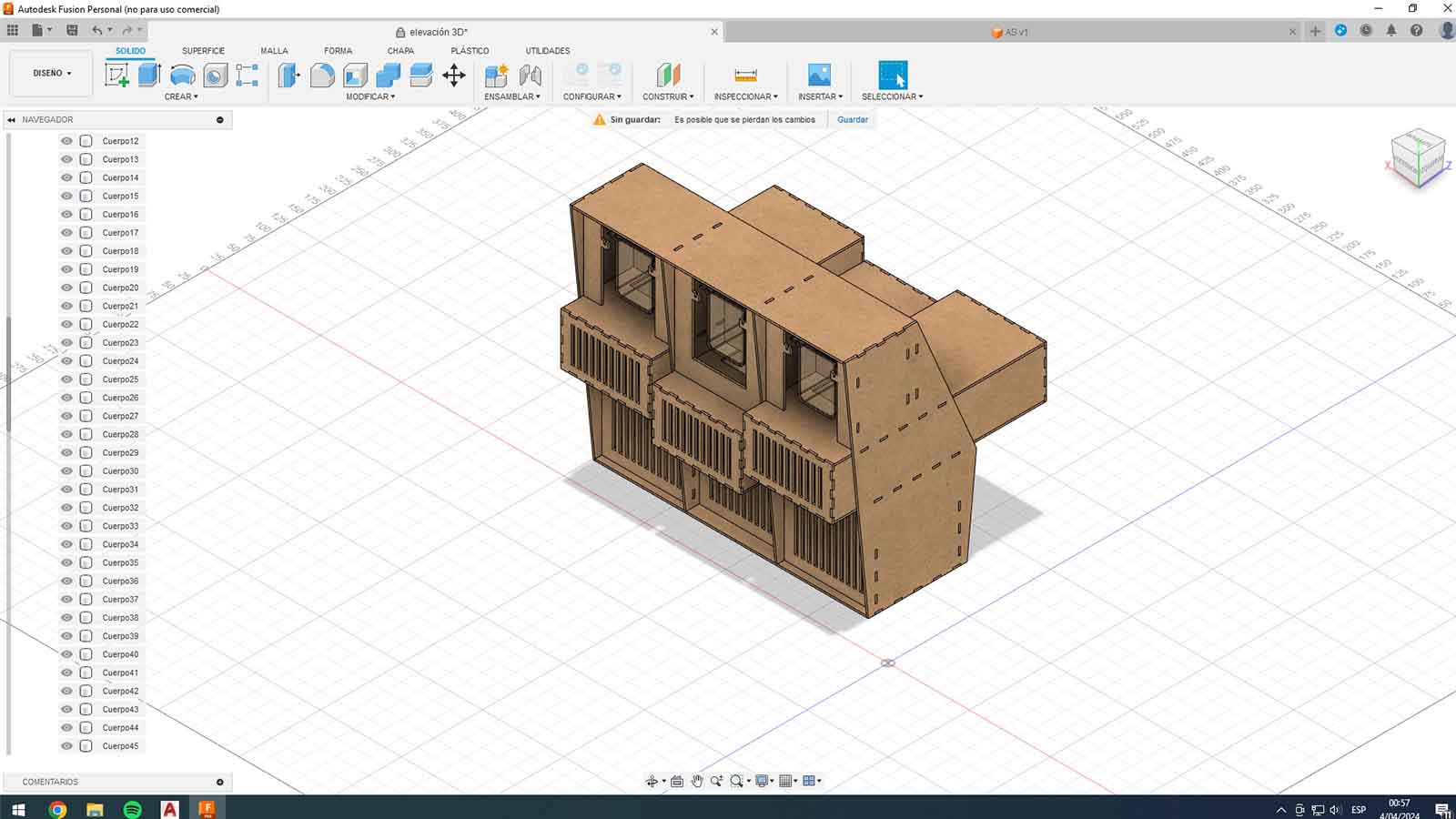

We started to make the parts in AutoCAD and we were passing them to Fusion 360 to see the final armature of the machine.

From here we start the modeling in Fusion to have a final idea, and then we move on to laser cutting to start building the structure.

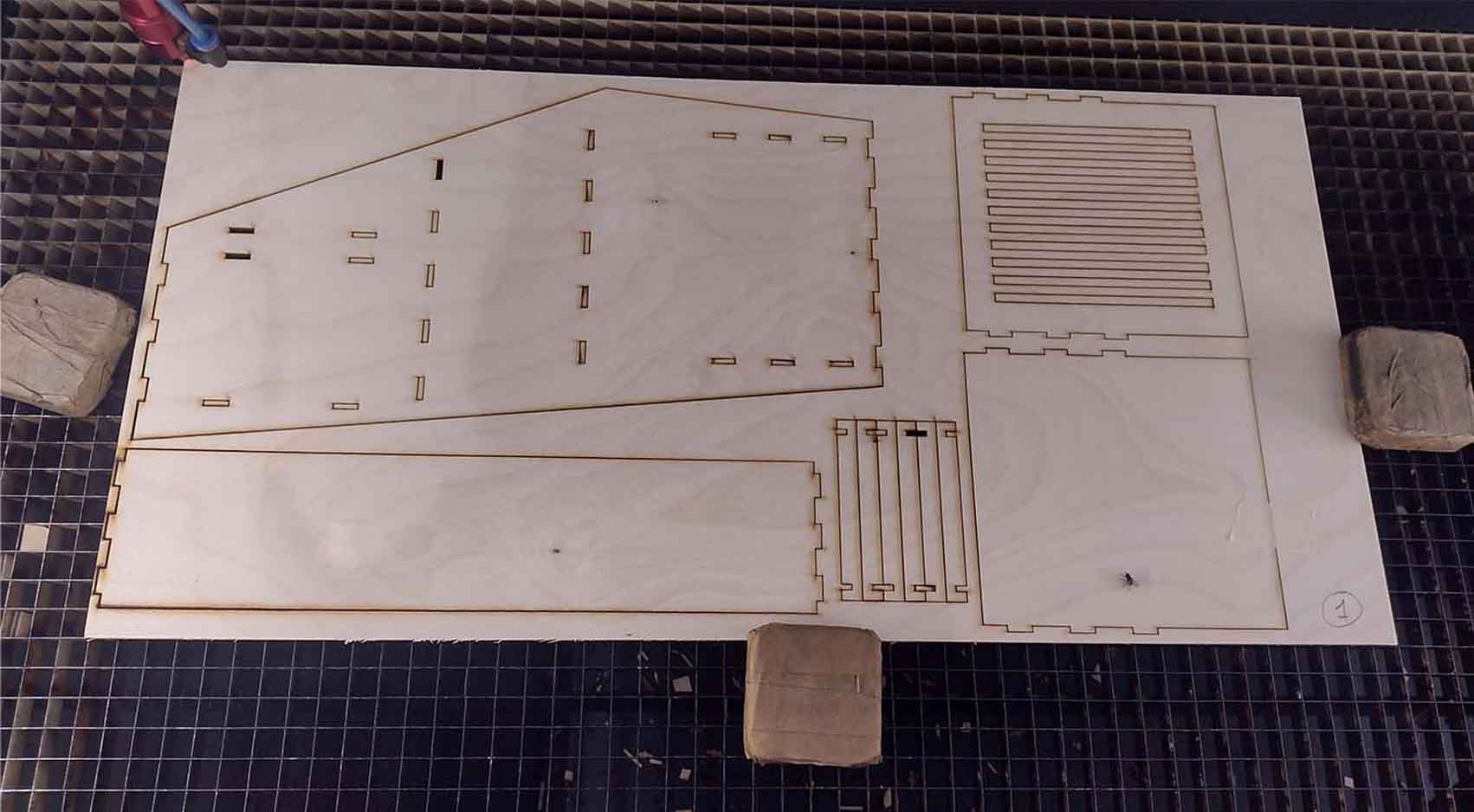

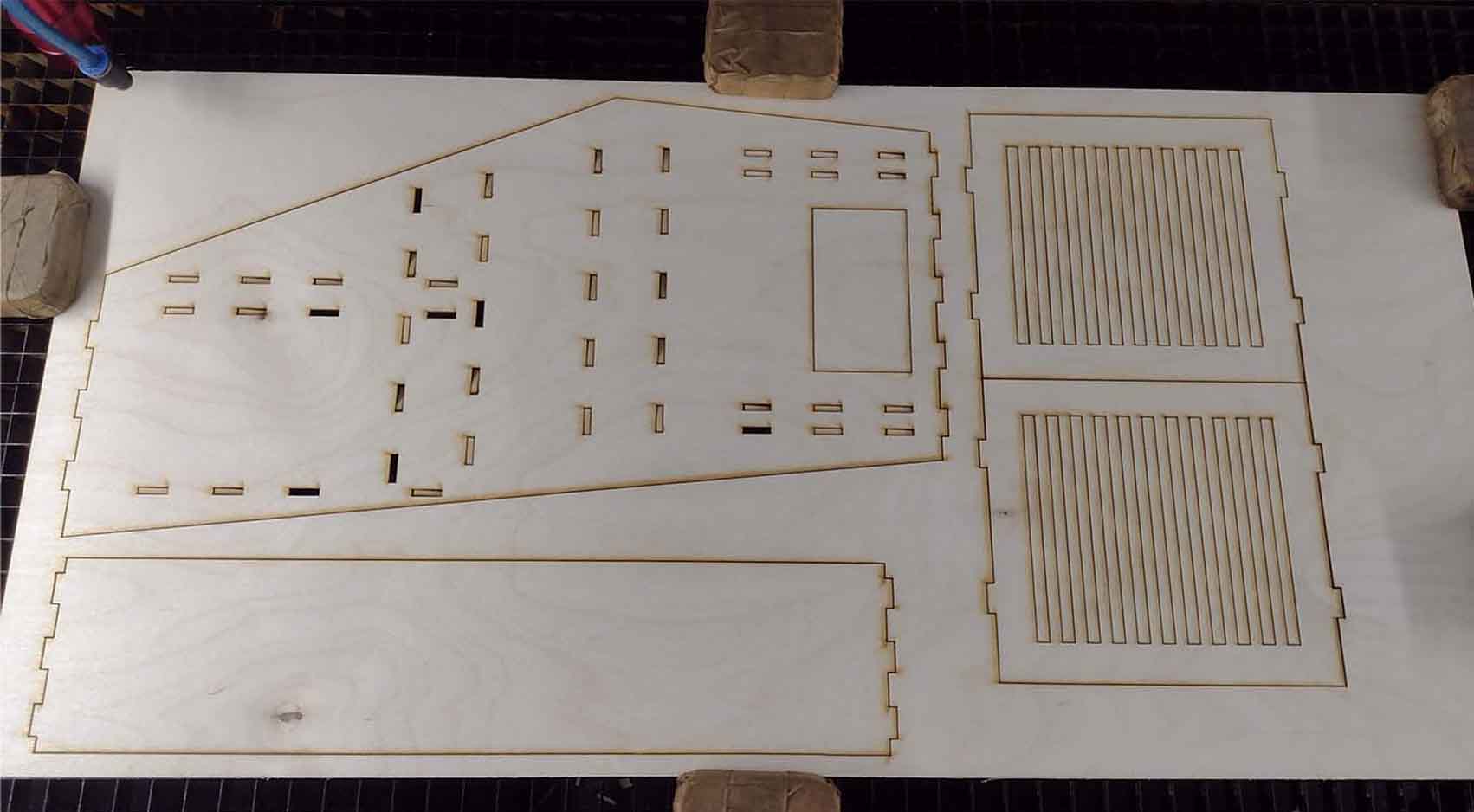

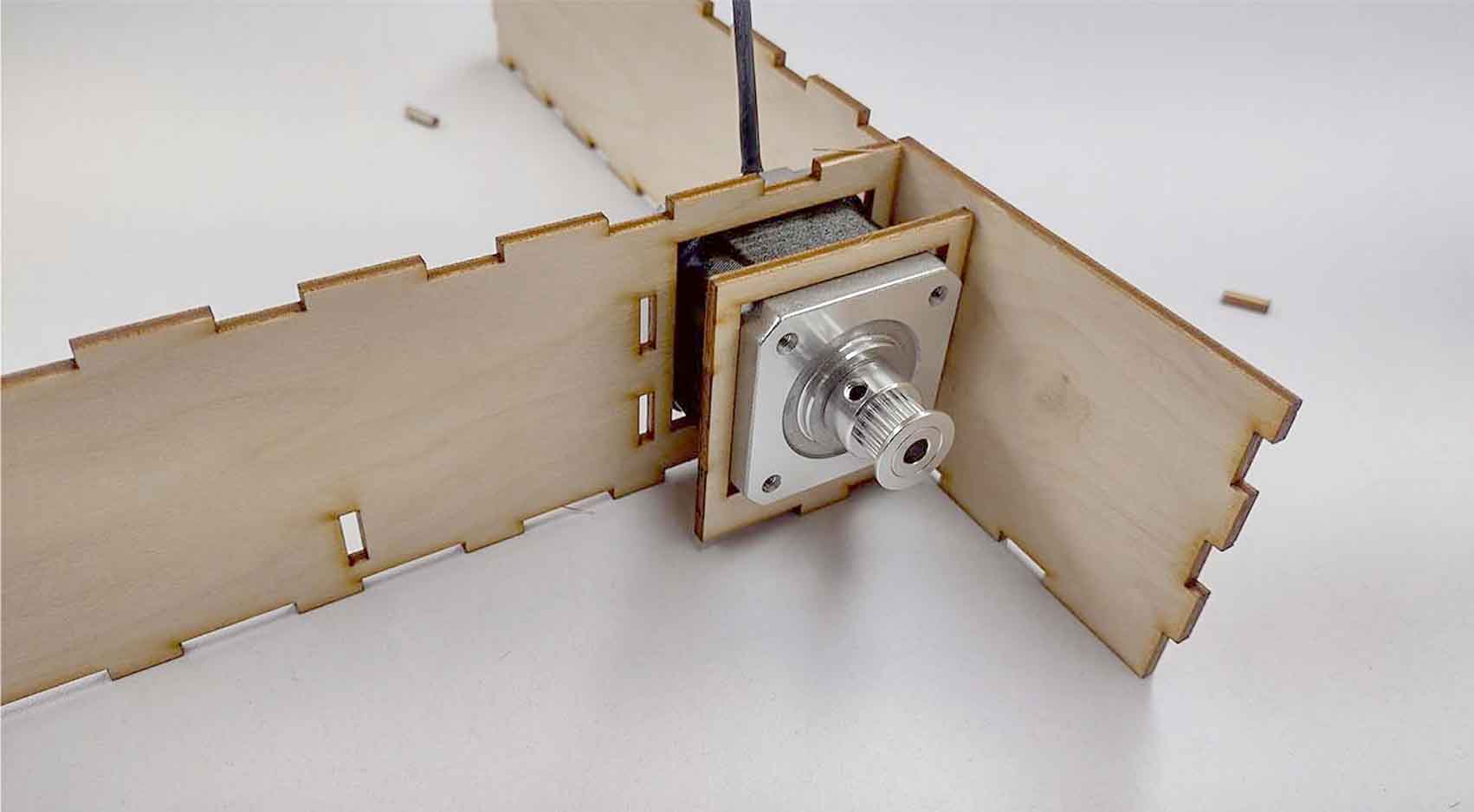

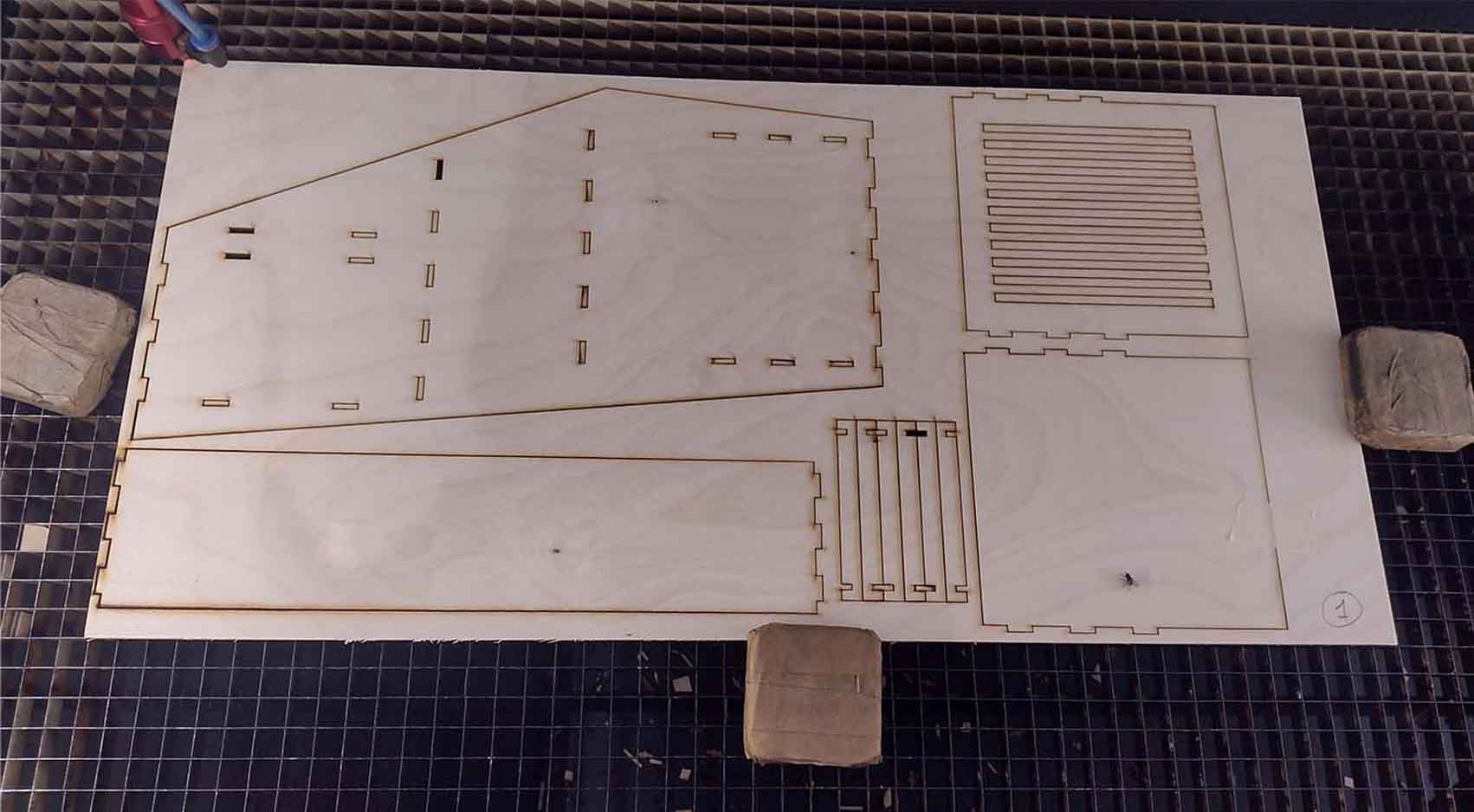

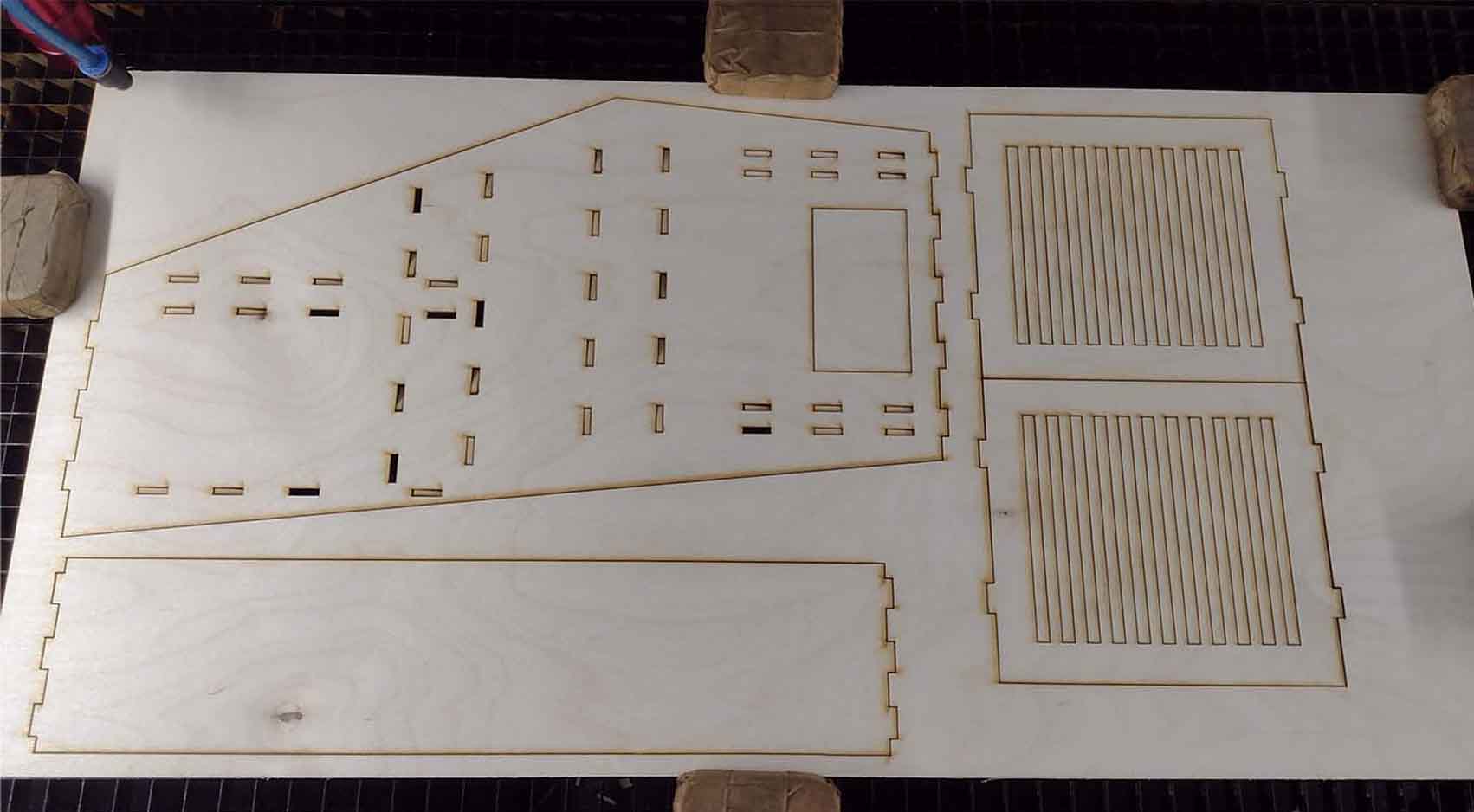

We proceeded to the quartering of the entire machine, using 3mm Plywood, the sockets were made at 2.75mm and we grouped the cuts in 9 plates.

Below are some screenshots of the cuts of all the pieces of the machine developed to send it to laser cut the PLYWOOD boards.

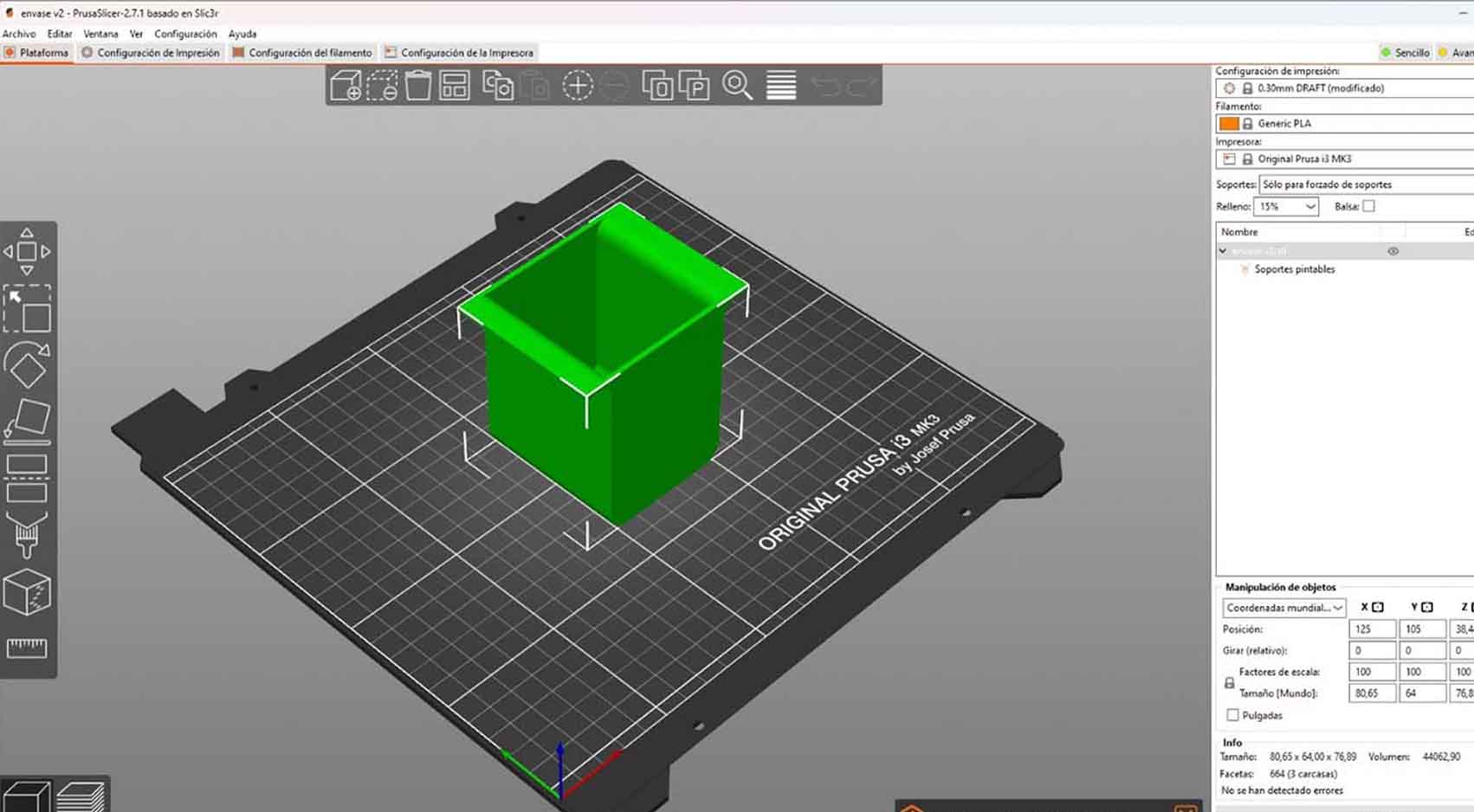

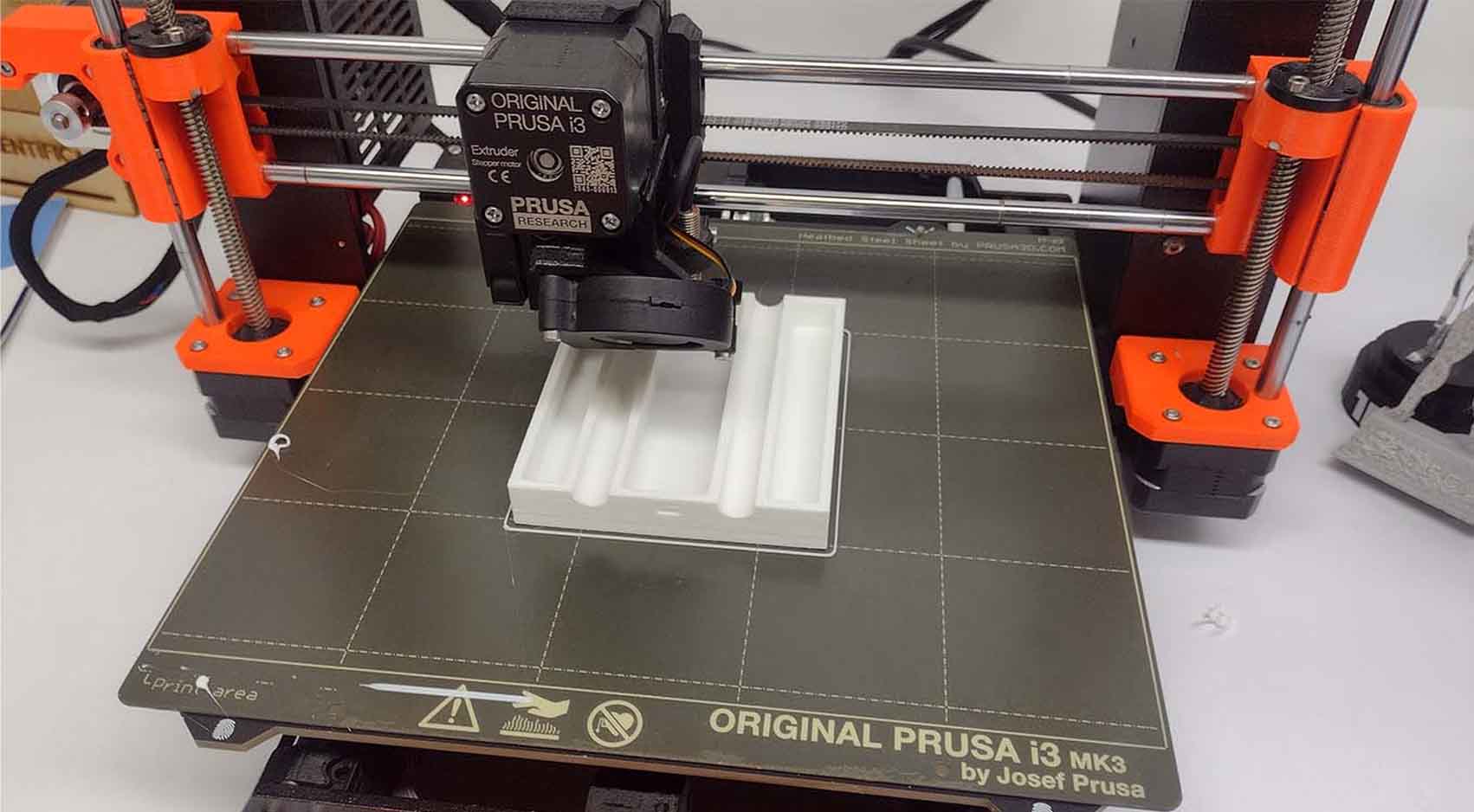

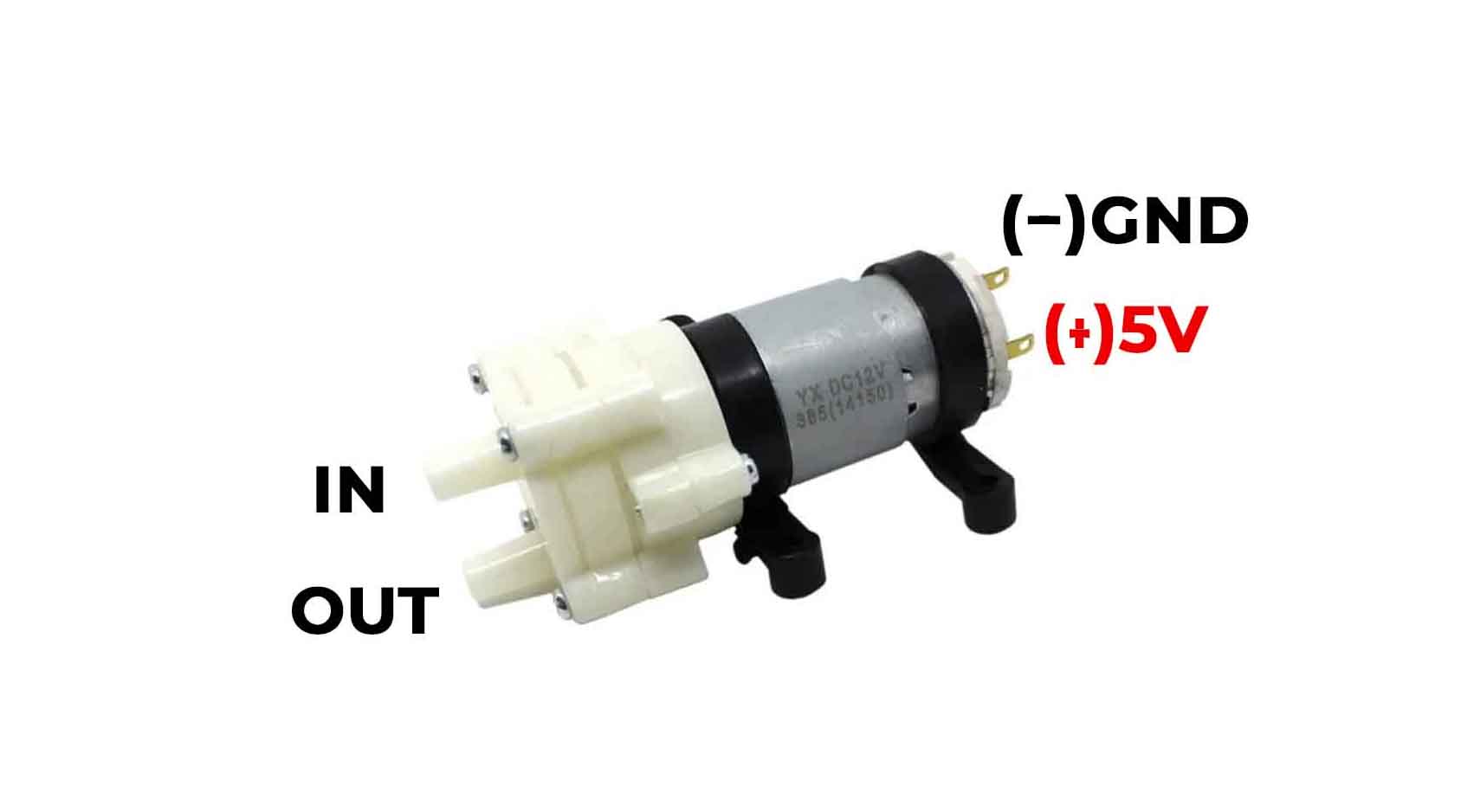

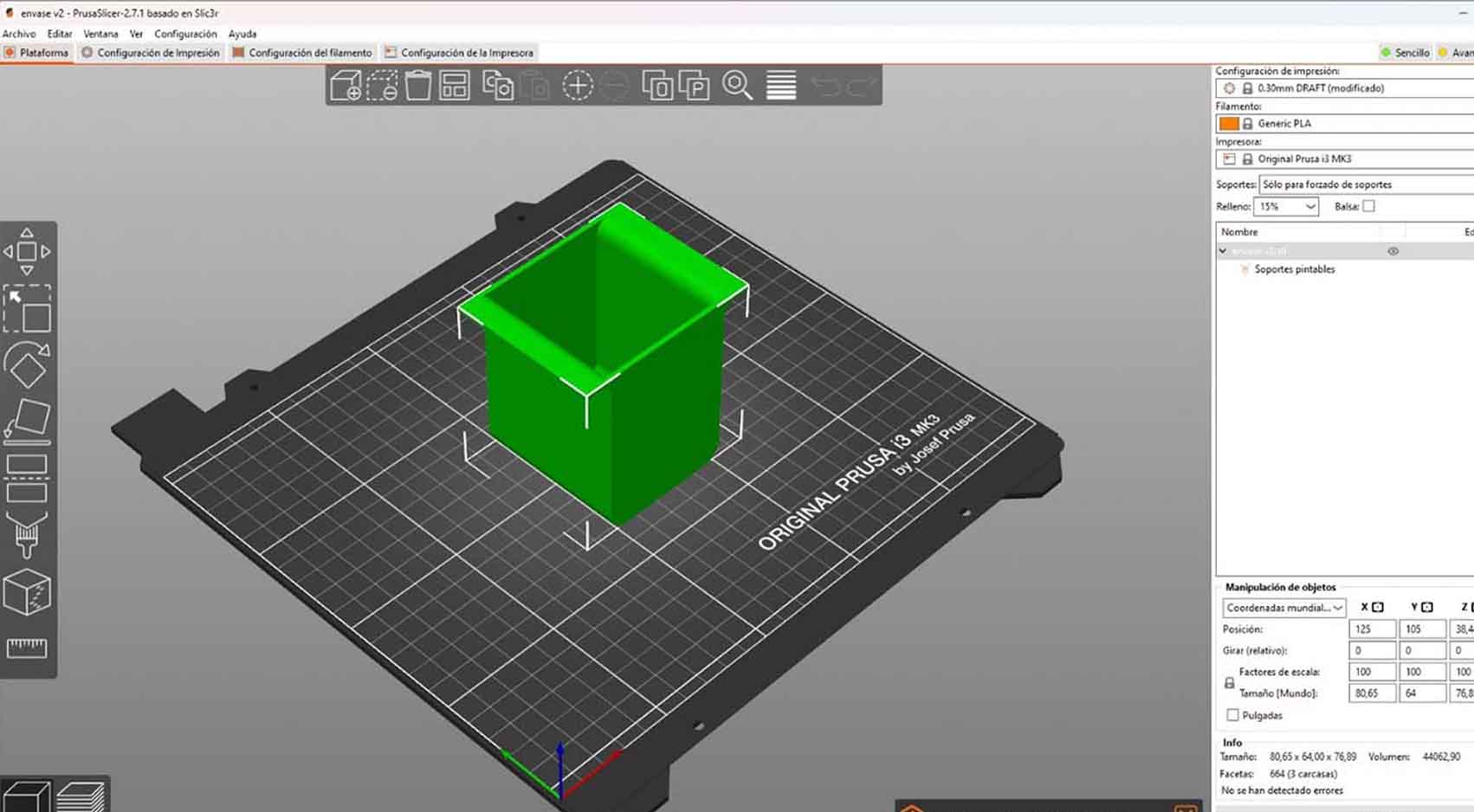

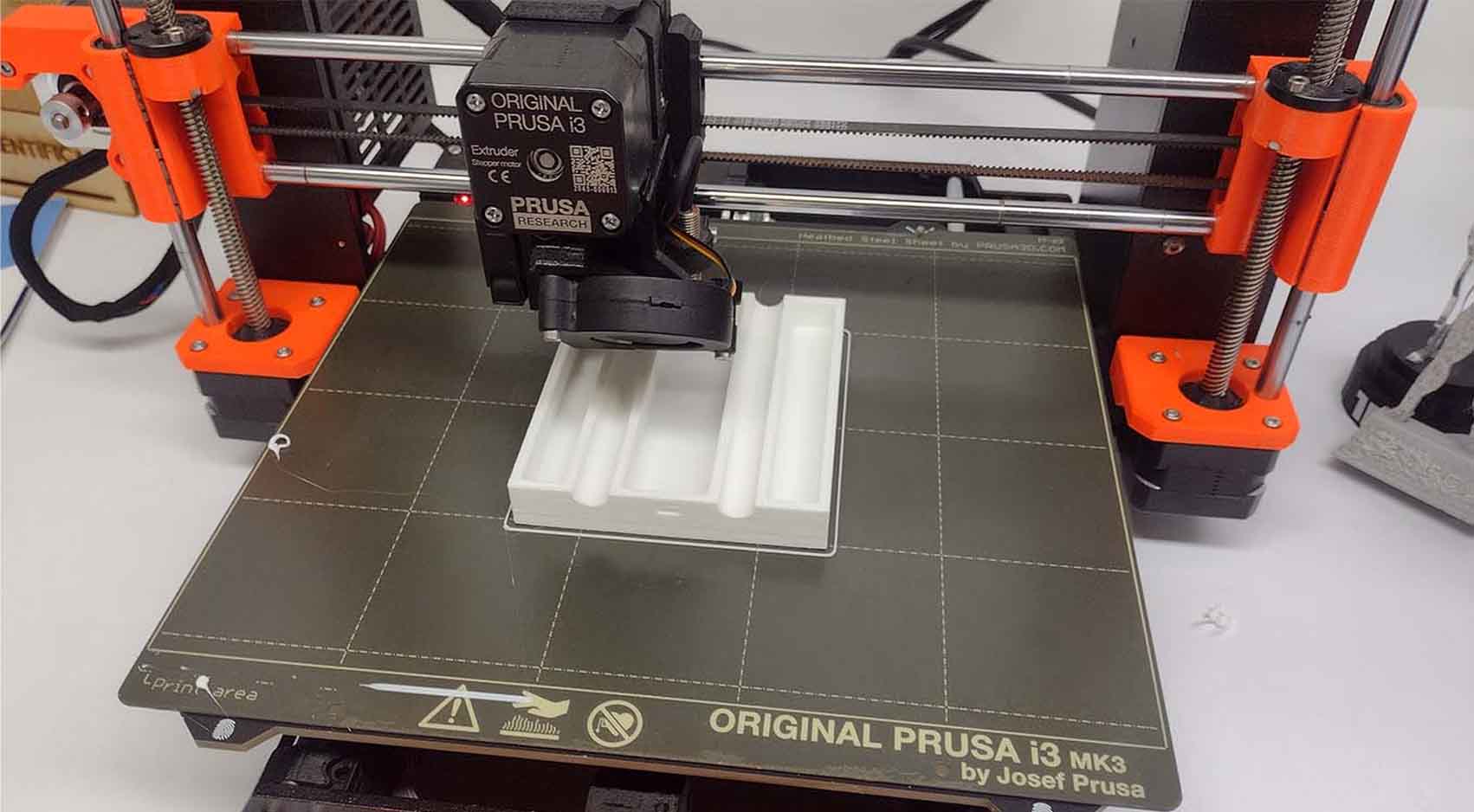

Likewise, I had some components that we were going to need 3D printed, such as the base of the glass and the liquid containers. Here are some screenshots of the procedure.

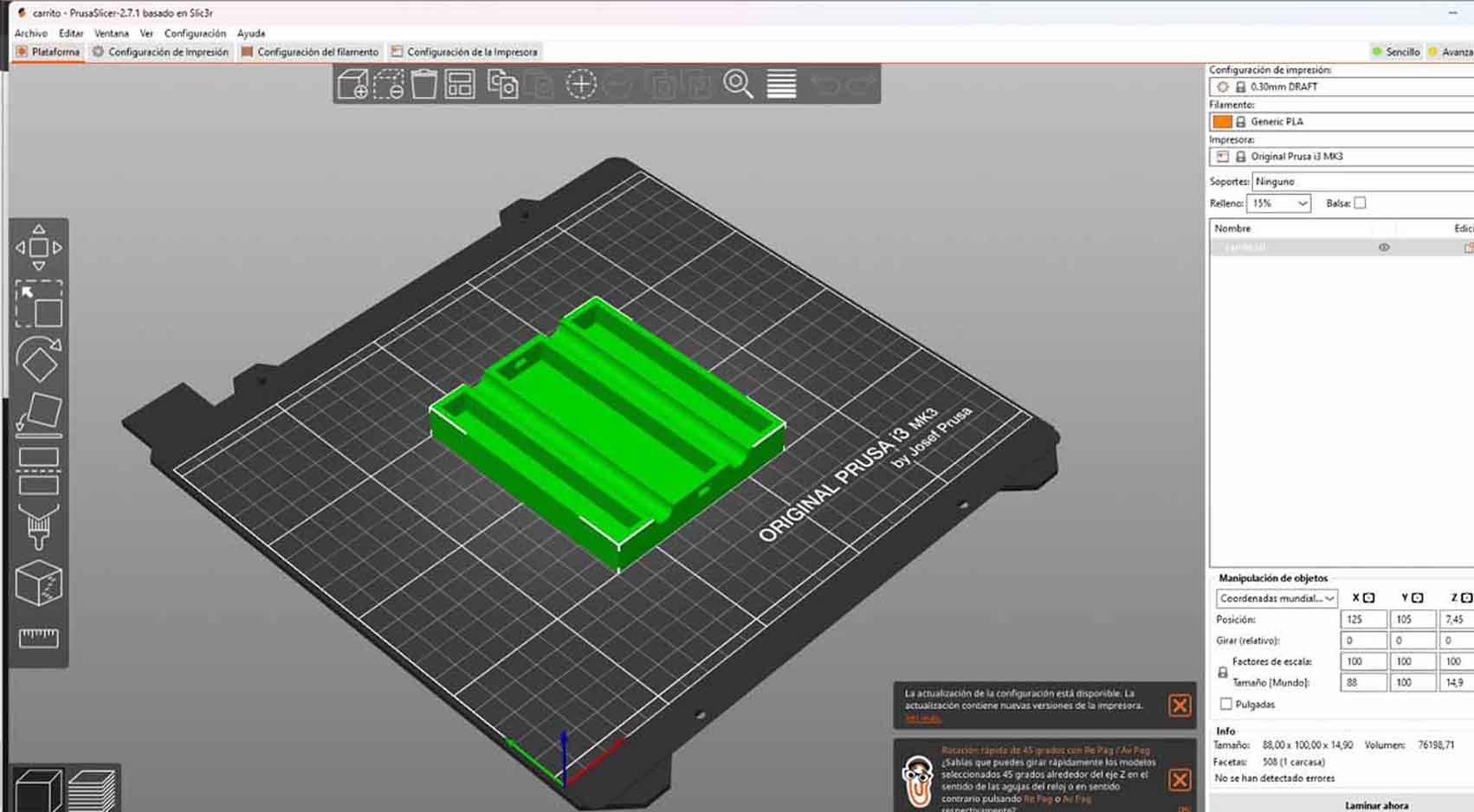

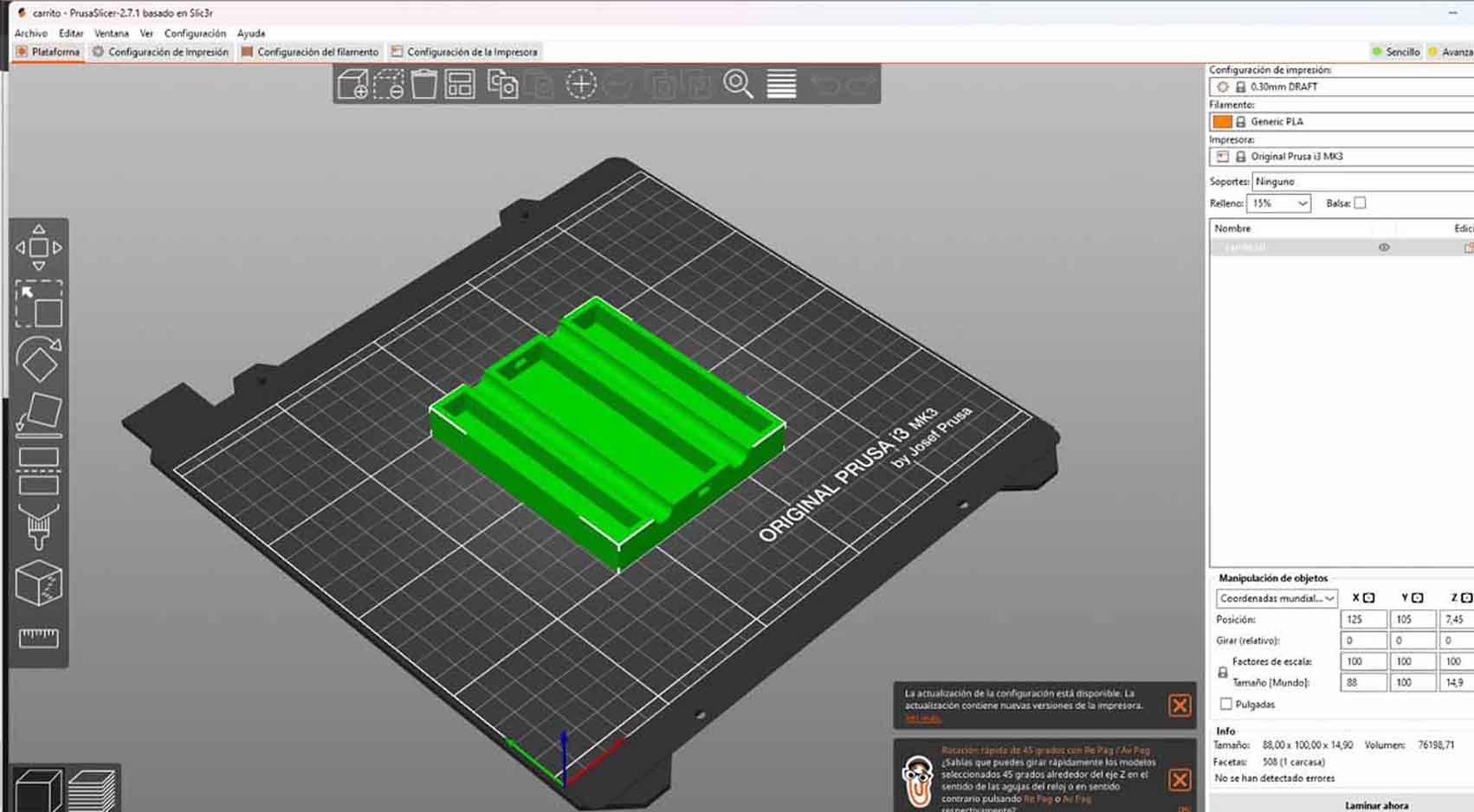

On the other hand, I also had the base where we were going to put the glasses that were going to receive the liquids to be 3D printed. This support was going to move throughout the machinery.

THE LOGO

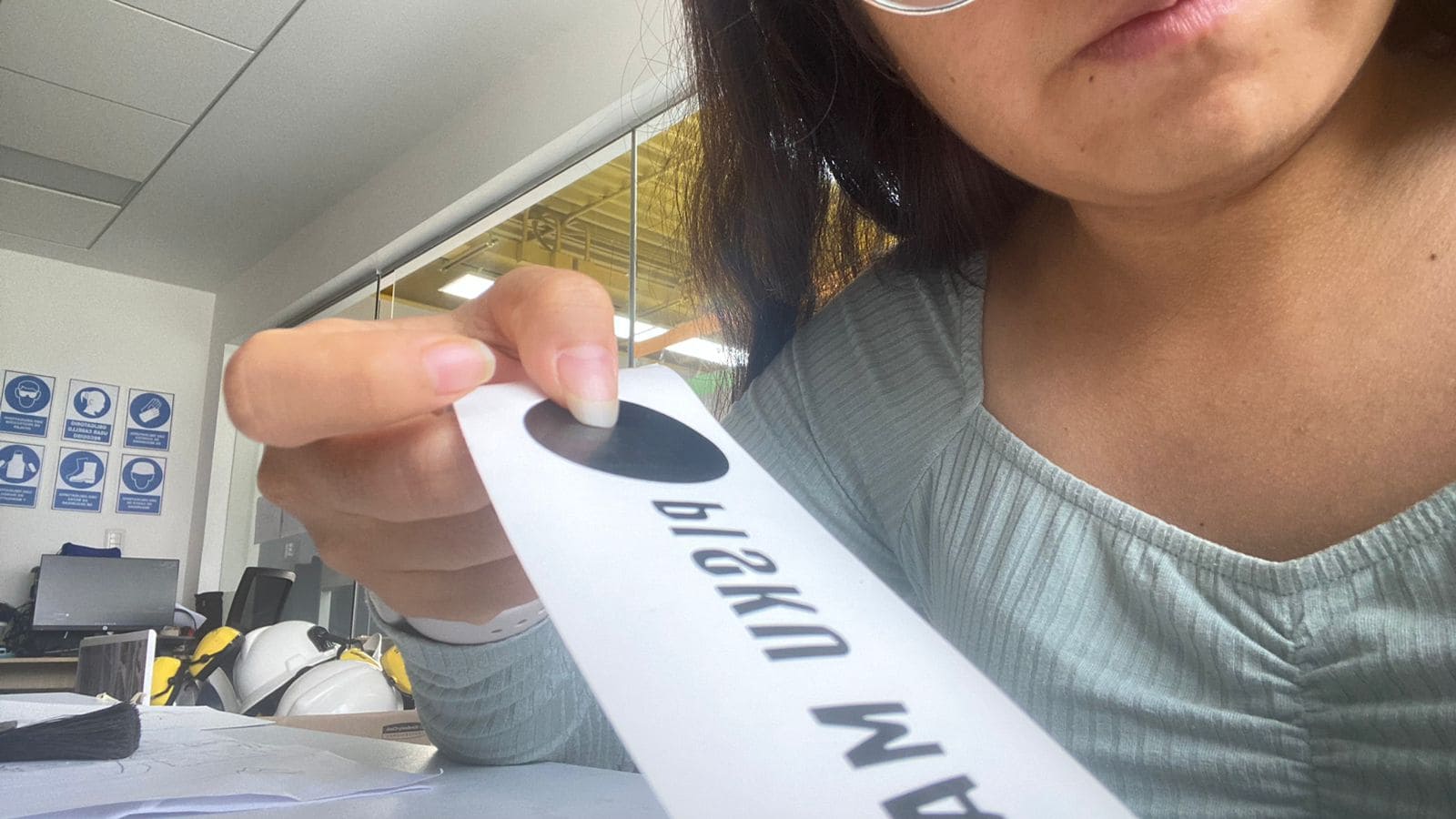

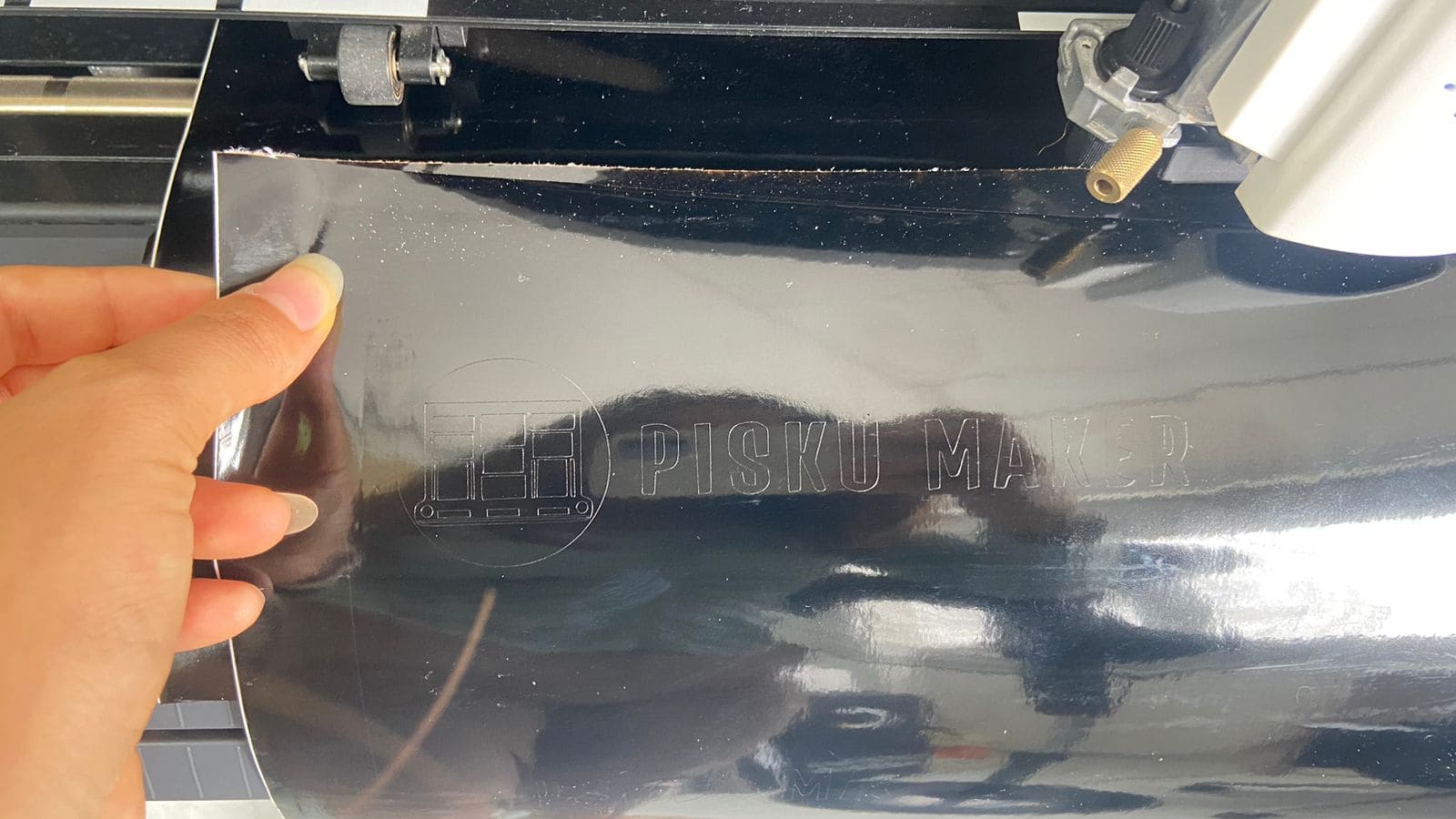

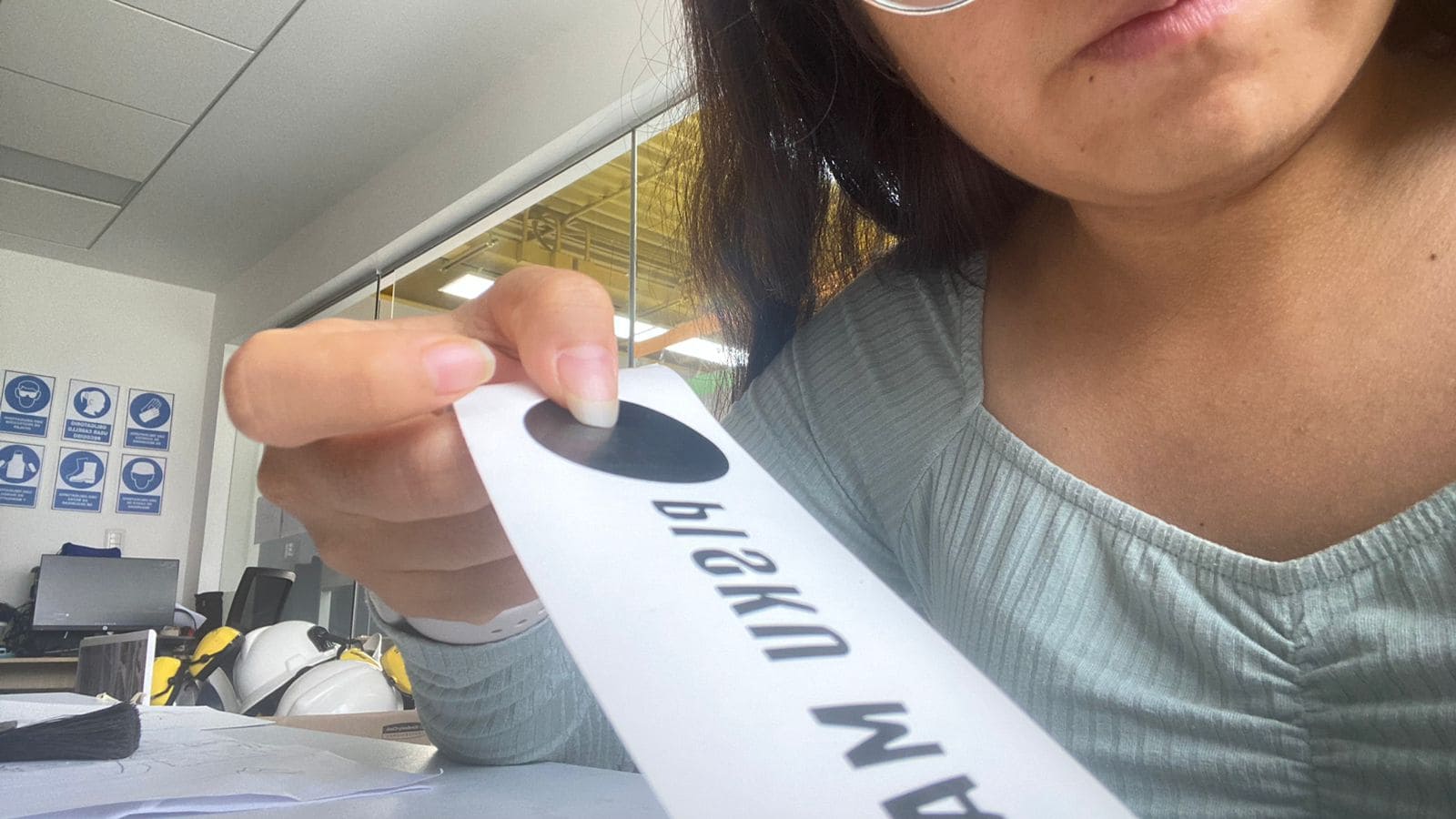

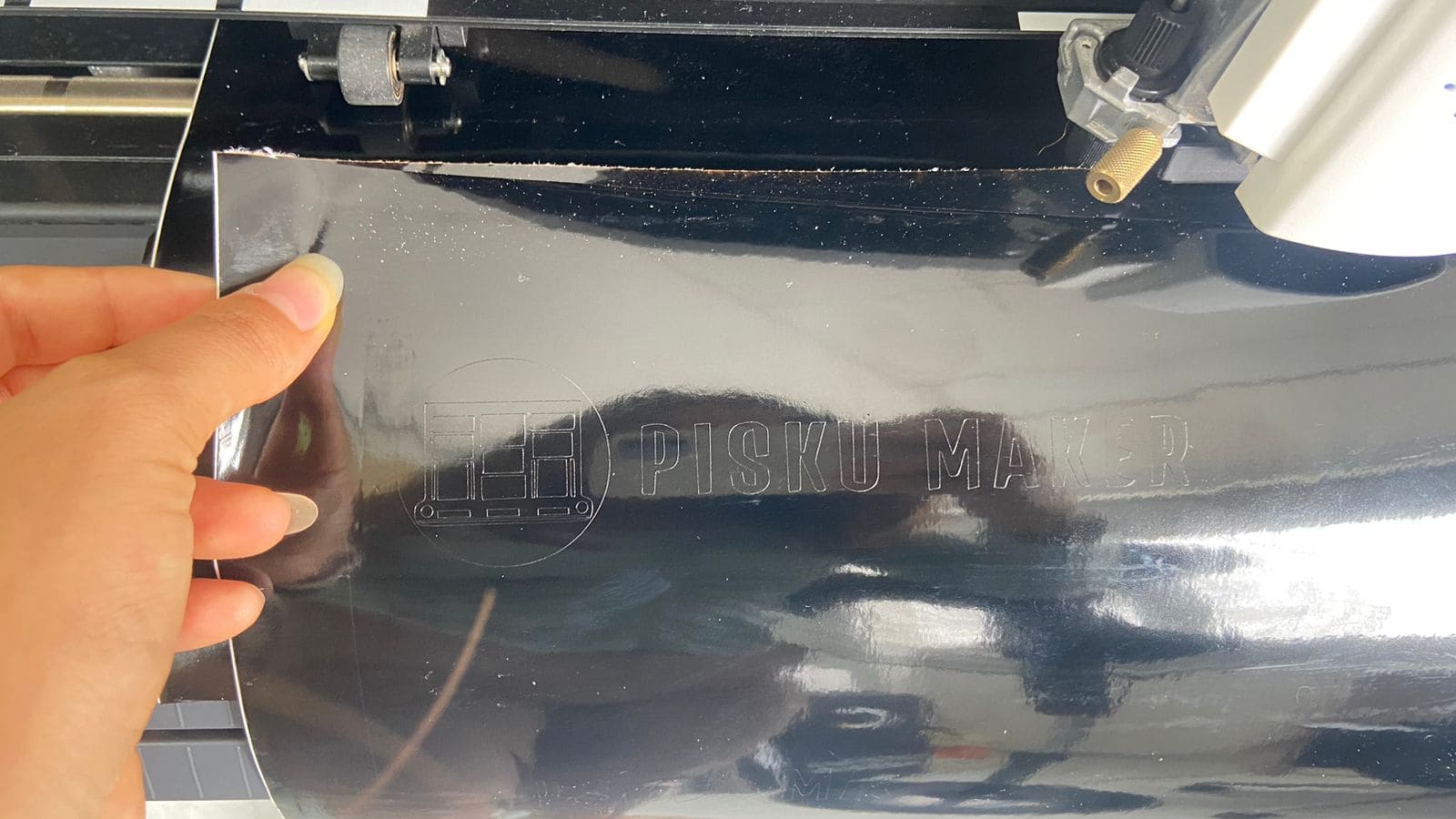

The logo is inspired by the abstraction of the machine, it was made in Illustrator, going first through the color and then being in black and white to be cut in vinyl and placed on the machine.

The logo was cut in black vinyl, we transferred the logo to the Cut Studio program and from this point we cut and pasted it on the machine.

Pisku Maker Video

Pisku Maker Video