Molding and casting

This week we will work on molding and casting, I have no previous experience with this but it seems to be interesting...

The assignment was:

group assignment: review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them compare printing vs machining molds

individual assignment: design a mold around the process you'll be using, produce it with a smooth surface finish, and use it to cast parts. extra credit: use more then two mold parts

Group assignment

For this assignment we visited the Fab Lab of the Cientifica del Sur University.

We use the shopbot cnc router to mill a block of wax.

You can see the complete documentation on the group's web page

What did I learn?

I understood the manufacturing process of positive and negative molds and the fine finish that must be achieved to have good results.

Read and apply the safety advice on the handling of chemicals for molding and casting using safety equipment such as glasses, gloves, mask, long sleeves, aprons, etc.

work with exact measurements to achieve a mixture that allows us to do the job.

Individual assignment

First we will establish some design criteria:

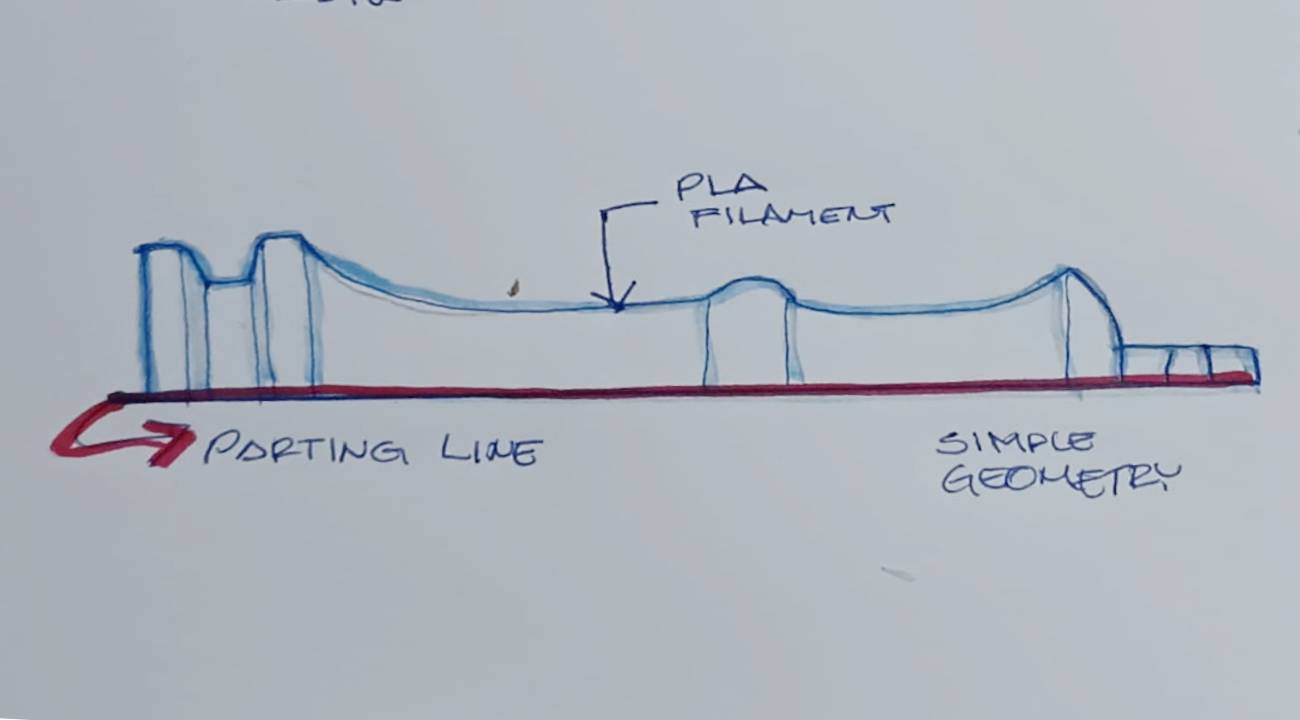

1. Draft angle: All vertical surfaces will have a draft angle of at least 1-3 degrees to facilitate mold removal.

2. Radius at the vertices: all vertices should have a radius for ease of removal.

3. Simple geometry: The geometry of the object should be as simple as possible. Complex shapes are difficult to unmold.

4. Compatibilidad con silicona: El filamento PLA es un material compatible con la silicona.

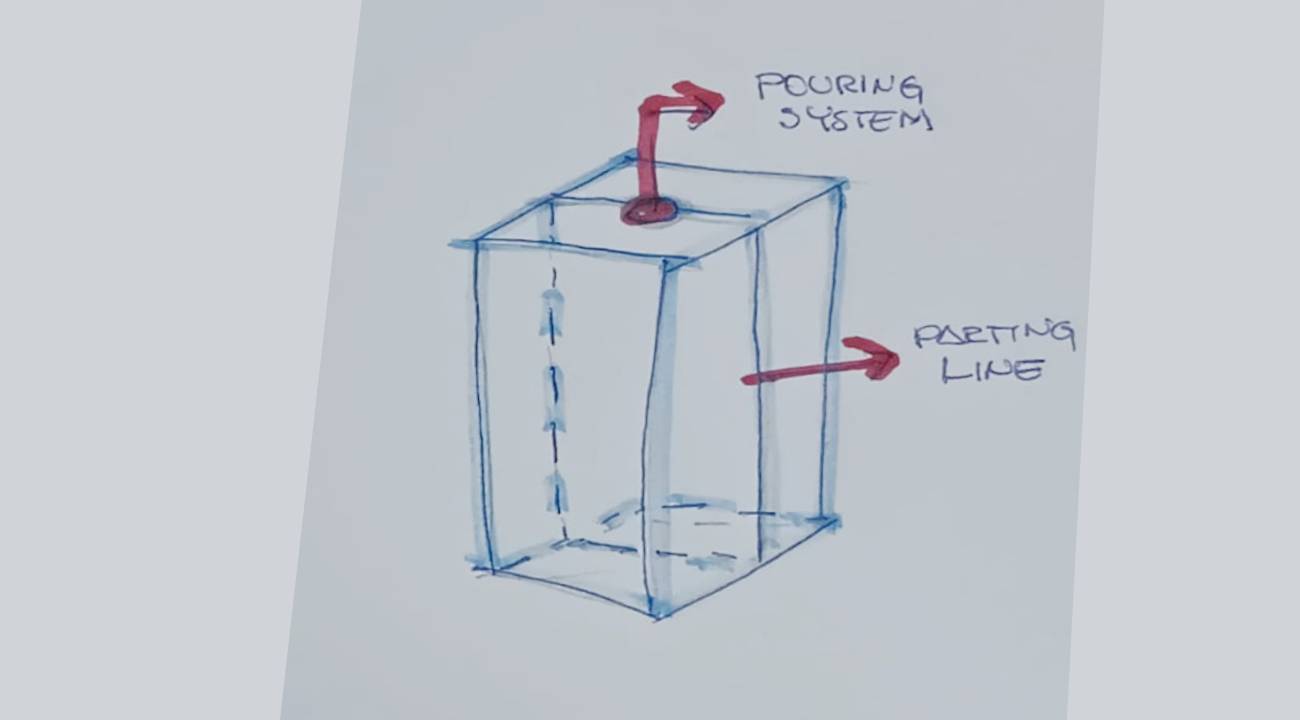

5. Parting line: should be located where it minimizes visible marks on the final product and allows easy demolding.

6. Pouring system: A suitable inlet will be designed for pouring the silicone, ensuring a smooth flow and avoiding bubbles.

7. Post-processing: Surface finishing (sanding, polishing) should be considered to obtain a smooth surface finish on the final object.

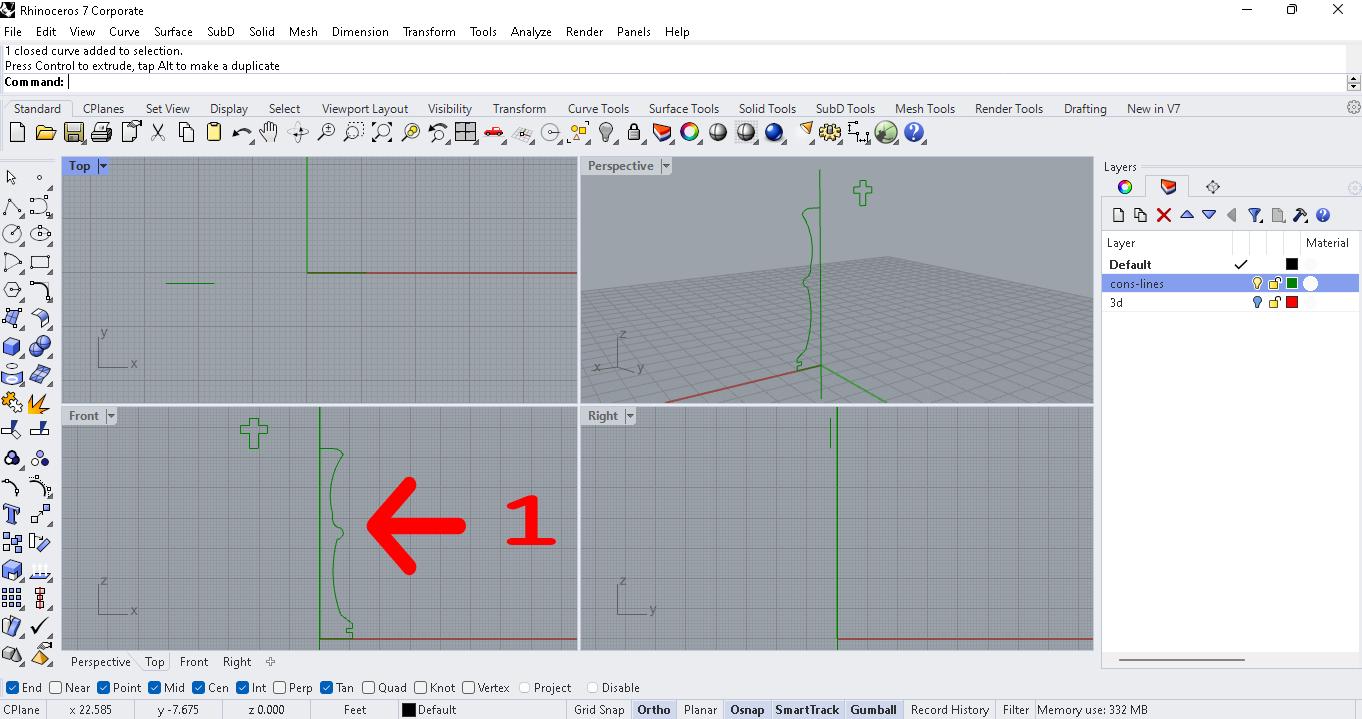

I started modeling a simple object "the King", the most important piece in chess, which is one of my passions. use Rhinoceros 7.0 software.

1. Draw a curve to make a revolution at 360

Modeling of the King finished.

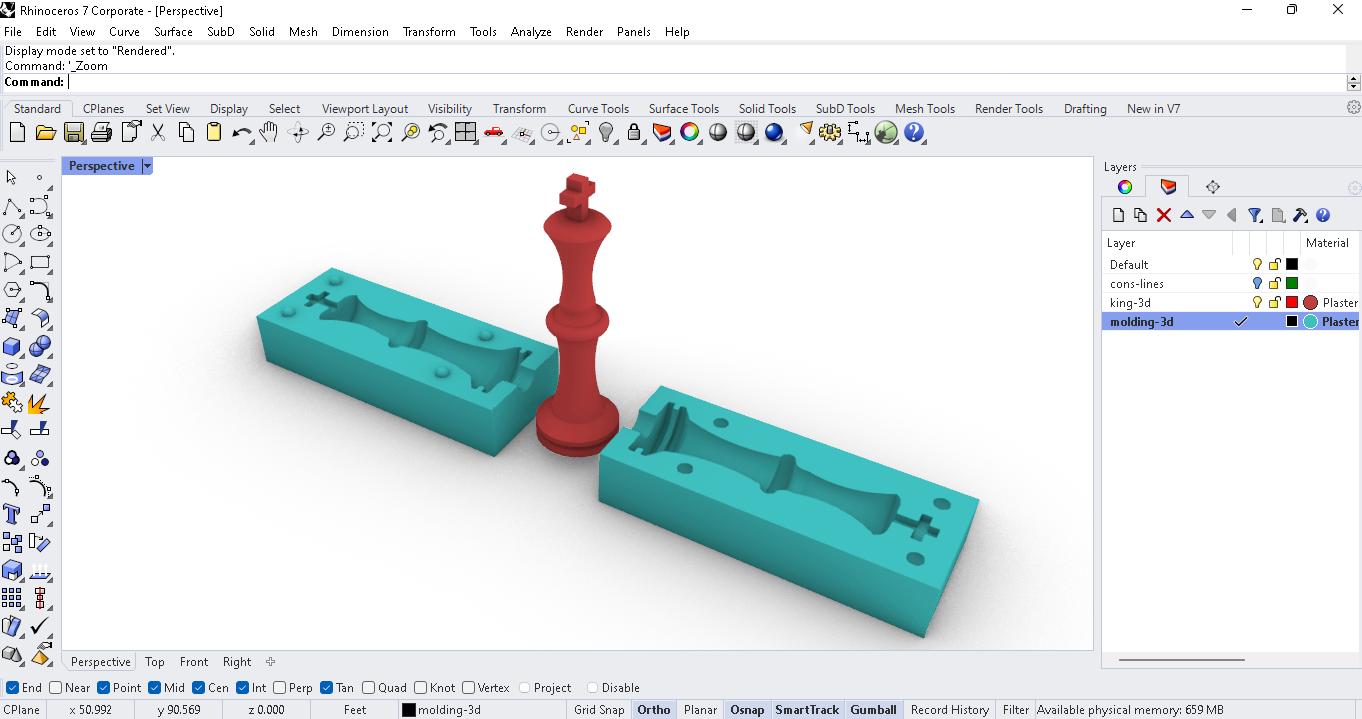

We generate the two pieces that will make up the mold for the casting.

This is the way if you want to use direct 3D printing as a mold, one of the problems that this technique entails is that the mold is very hard and does not allow for easy manipulation.

This is the way to design and manufacture a model that will be used to cast the final mold that will be in silicone.

we print on the Ender 3 3D printer using PLA filament.

The printing time is 2 hours 19 minutes each piece and there are two pieces.

Parts printing process.

Parts printing process.

Result of the manufacture of the negative of the mold.

This is a test of how the silicone mold should look once poured.

We carry out a simple post-processing by hand using No. 120 water-based sandpaper to remove imperfections, then we use No. 600 water-based sandpaper to polish and at the end No. 1000 water-based sandpaper to leave the negative soft and smooth.

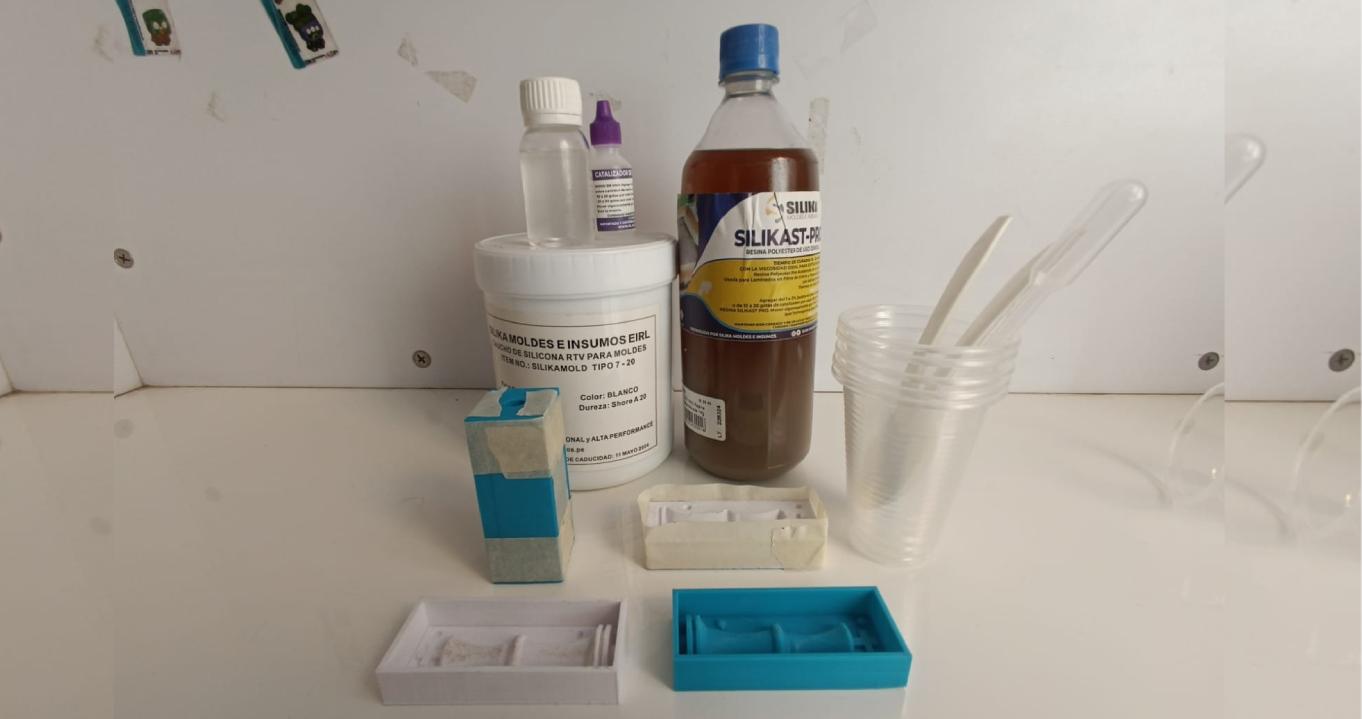

supplies for the mold and casting, RTV Silicone Rubber for the negatives and Polyester Resin for the casting.

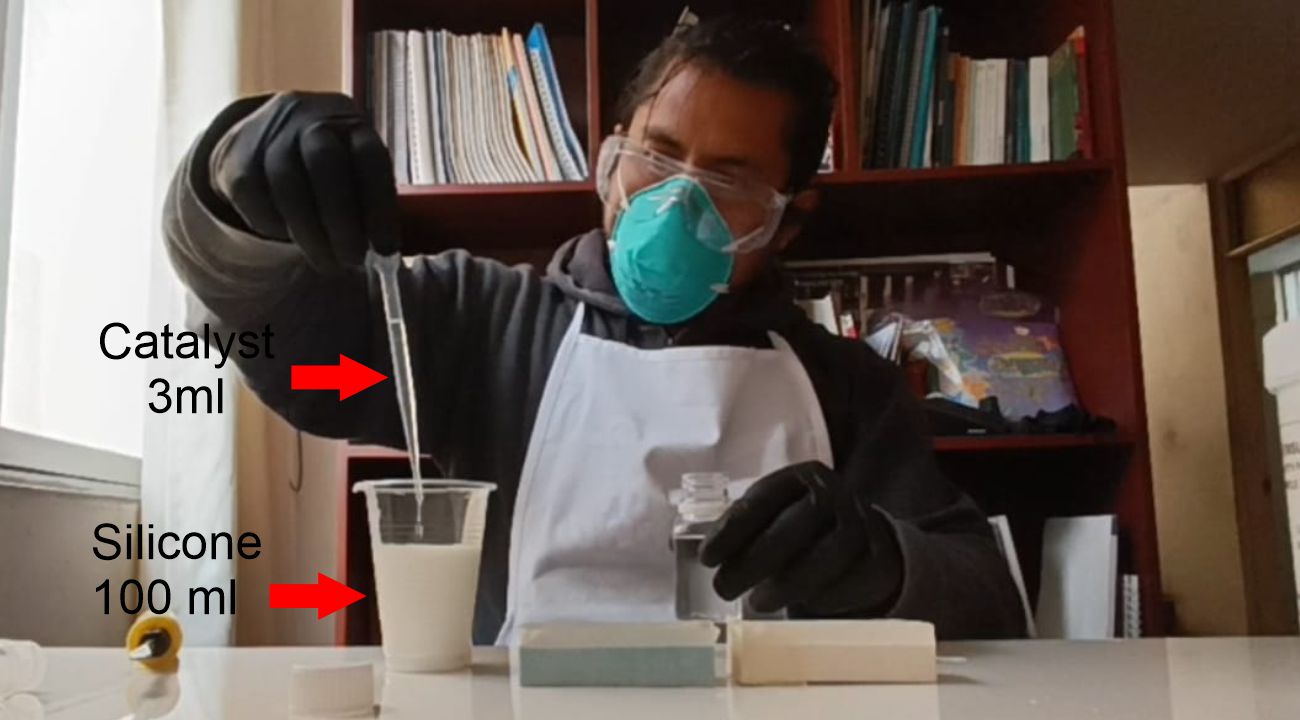

For the negative of the mold we will use RTV silicone rubber.

The proportion will be: 100 ml of silicone and 2-3% catalyst, it should be moved slowly to avoid generating bubbles.

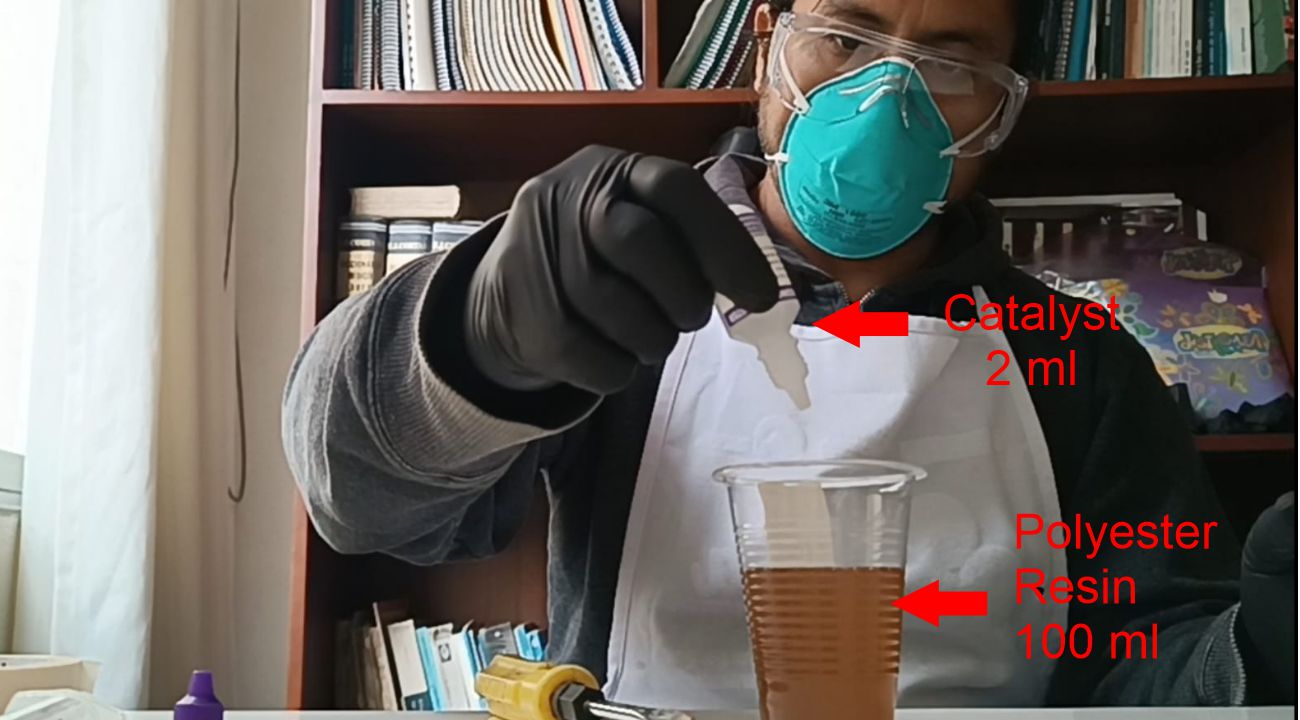

For the final piece the King, we will use Polyester Resin, the proportion indicated by the supplier is 100 ml of Resin and 2% catalyst.

To handle chemicals for molding and casting we must use safety equipment such as glasses, gloves, mask, long sleeves, aprons, etc.

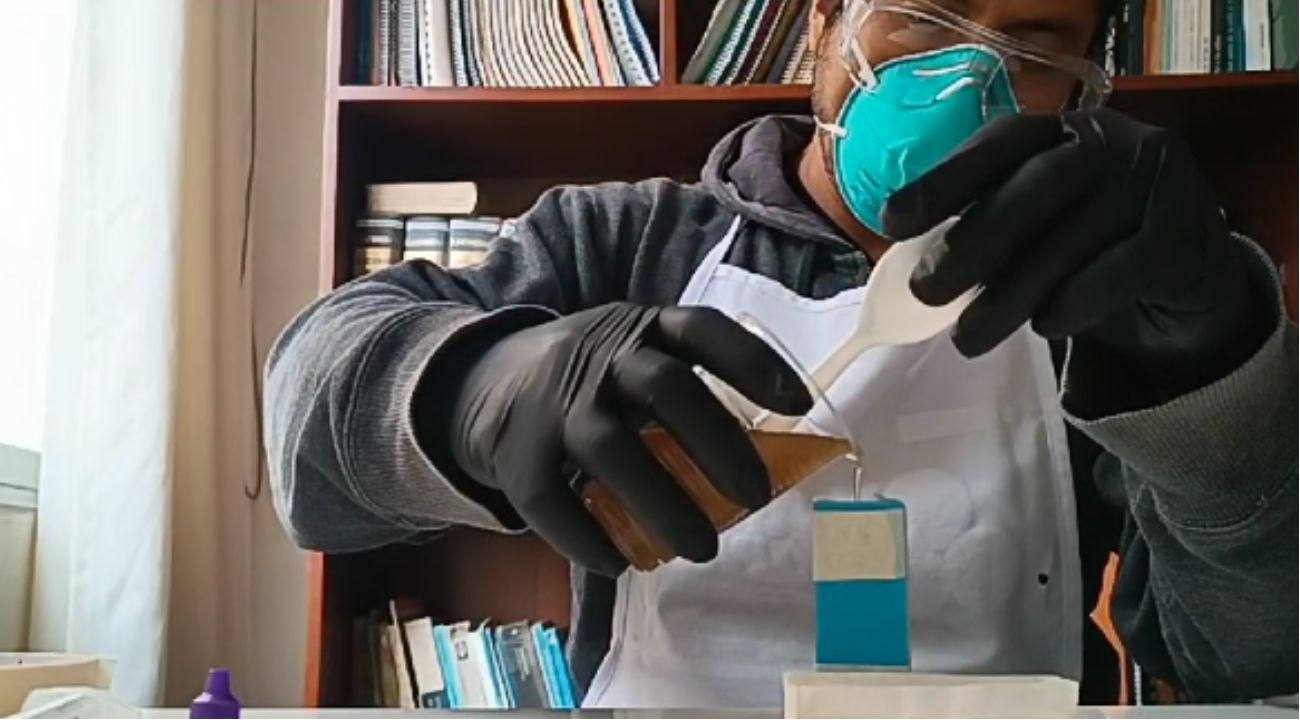

For the negative of the mold we mix with the indicated proportions: 100 ml of Silicone and 3 ml of catalyst.

The total amount required to cast the negative from the mold is: 52 mm3.

The calculations are carried out in design software with the Analyze tool -> mass properties -> volume.

Para el vaceado del Rey realizamos la mezcla con las proporciones indicadas 100 ml de Resina Poliester y 2 ml de catalizador.

La cantidad total que se require para el vaceado del Rey es de: 7.5 mm3

The calculations are carried out in design software with the Analyze tool -> mass properties -> volume.

unmolding

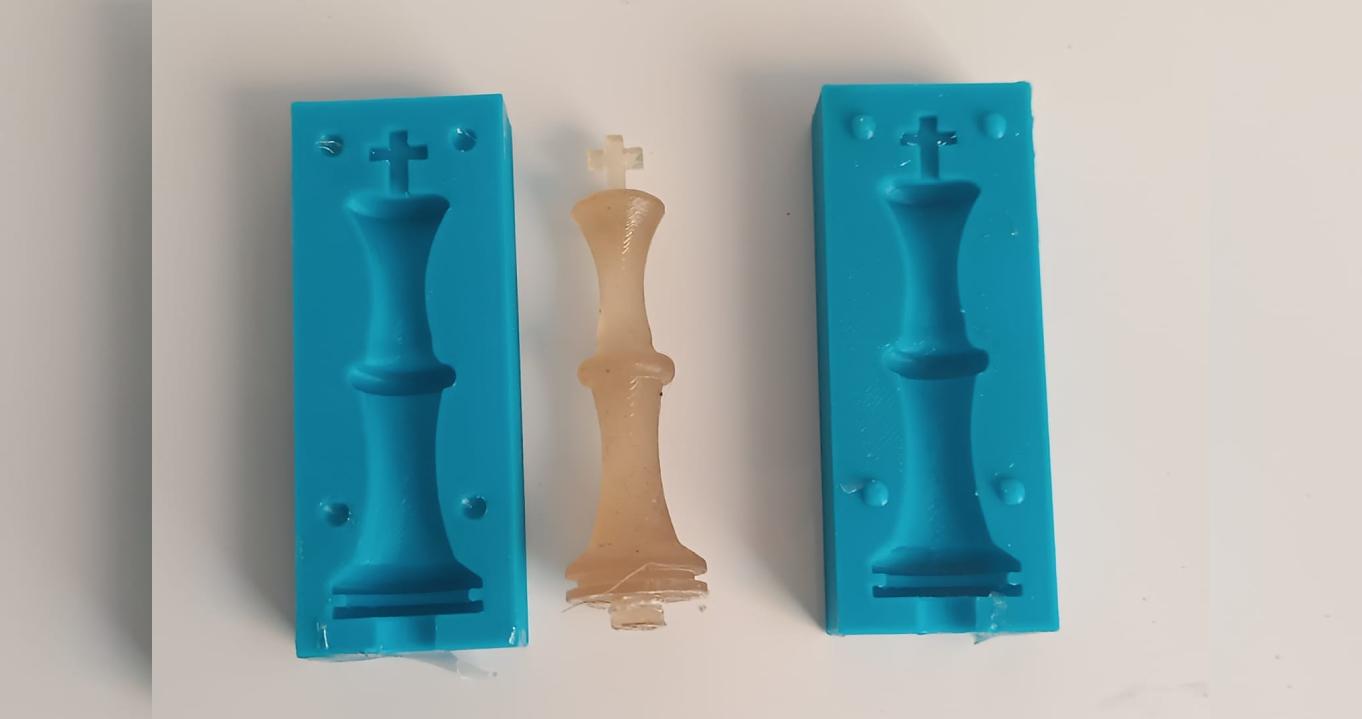

Final result, mold with 3D printing in PLA and cast piece in polyester resin.

Final result, mold cast in RTV type 7 silicone rubber and piece cast in polyester resin.

Download files

Here we can find and download the design original files