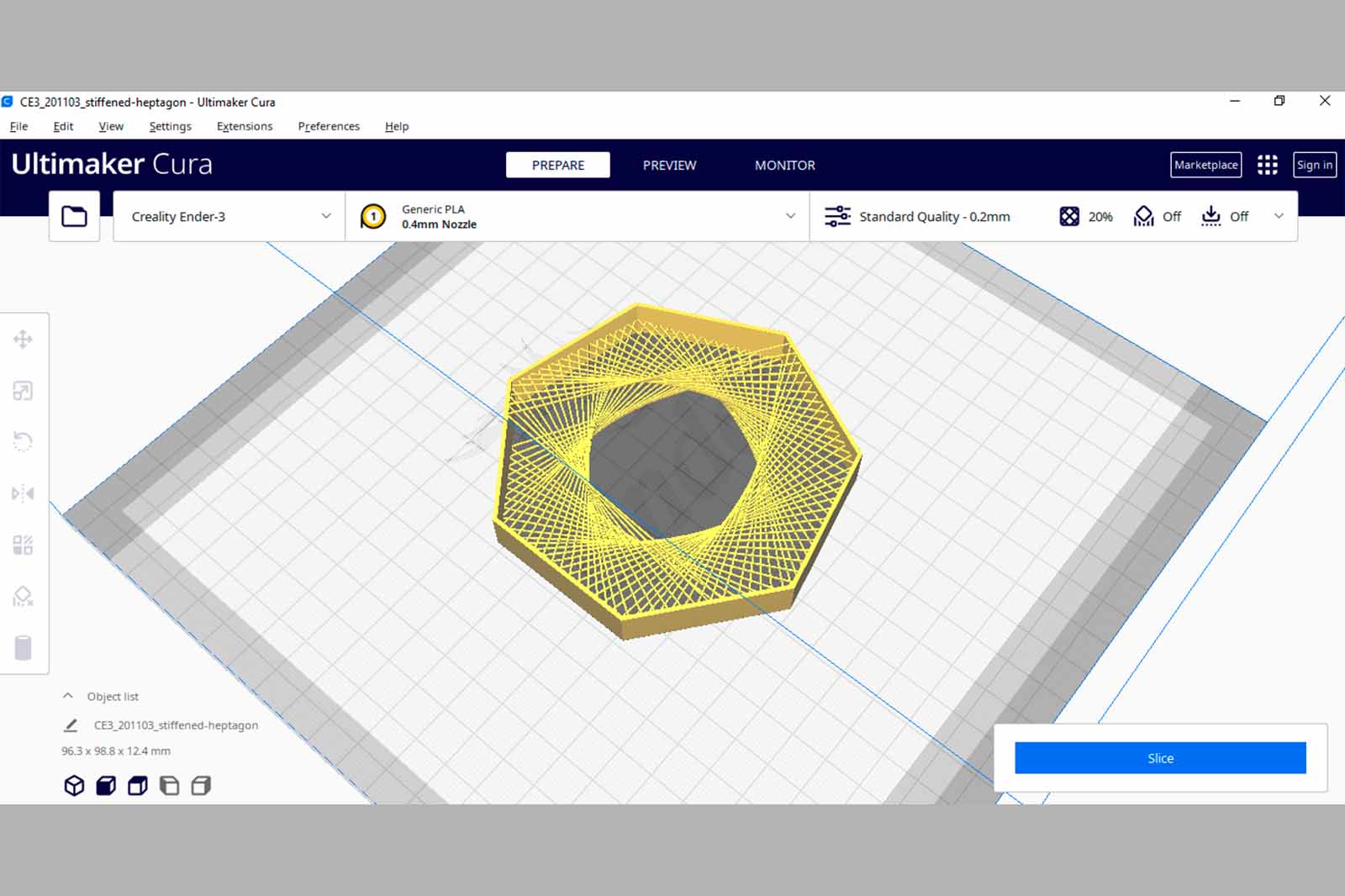

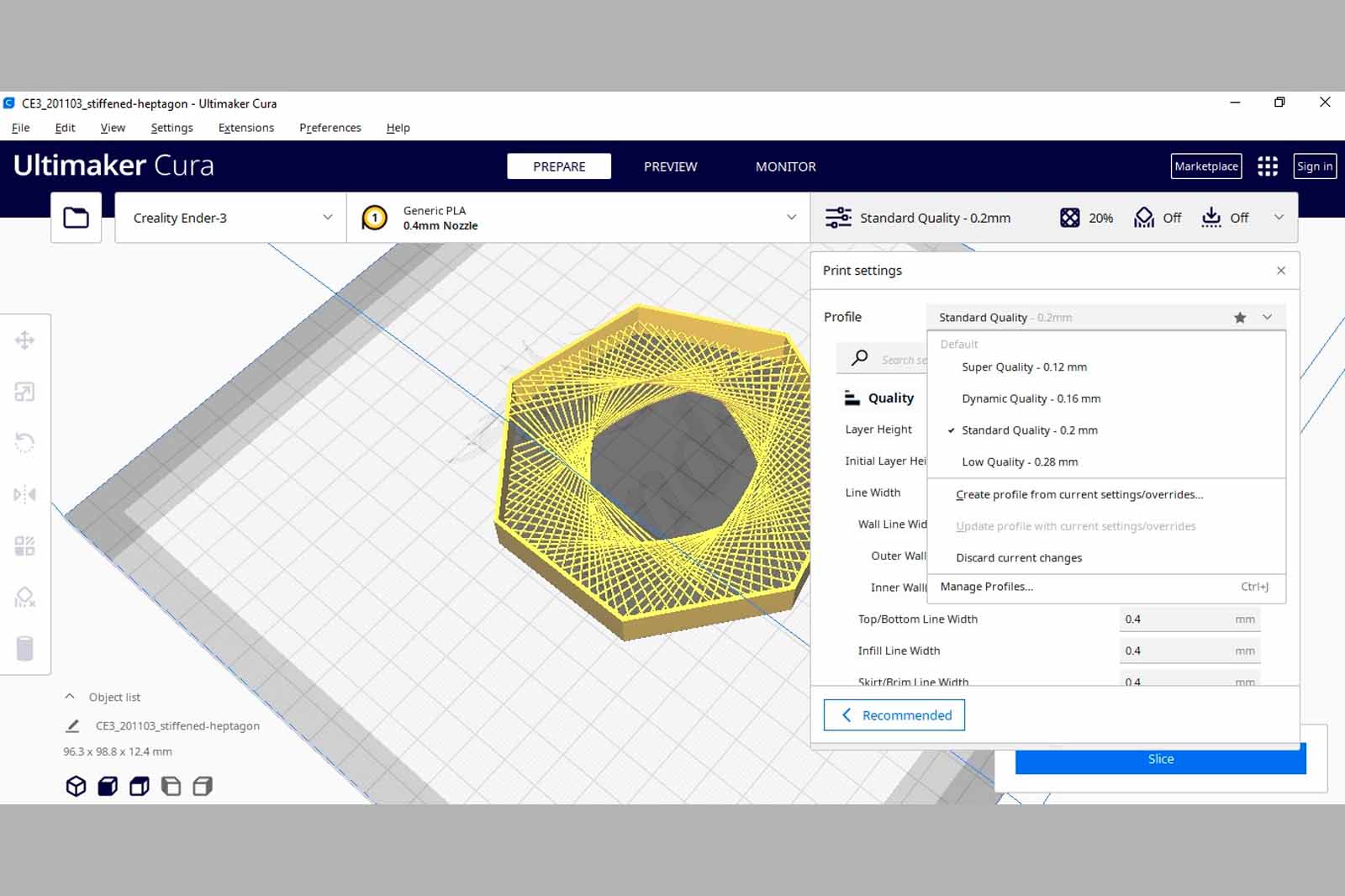

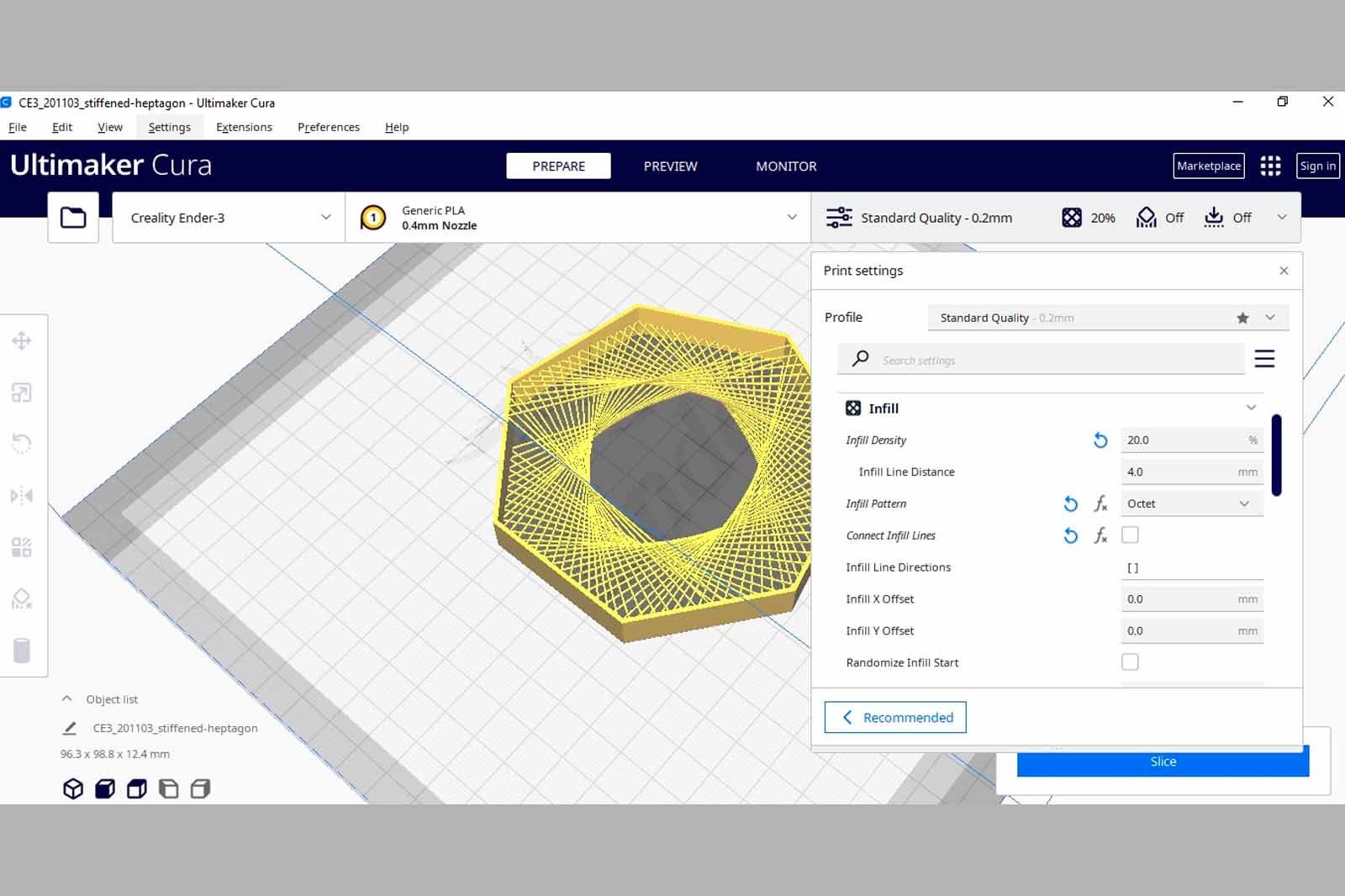

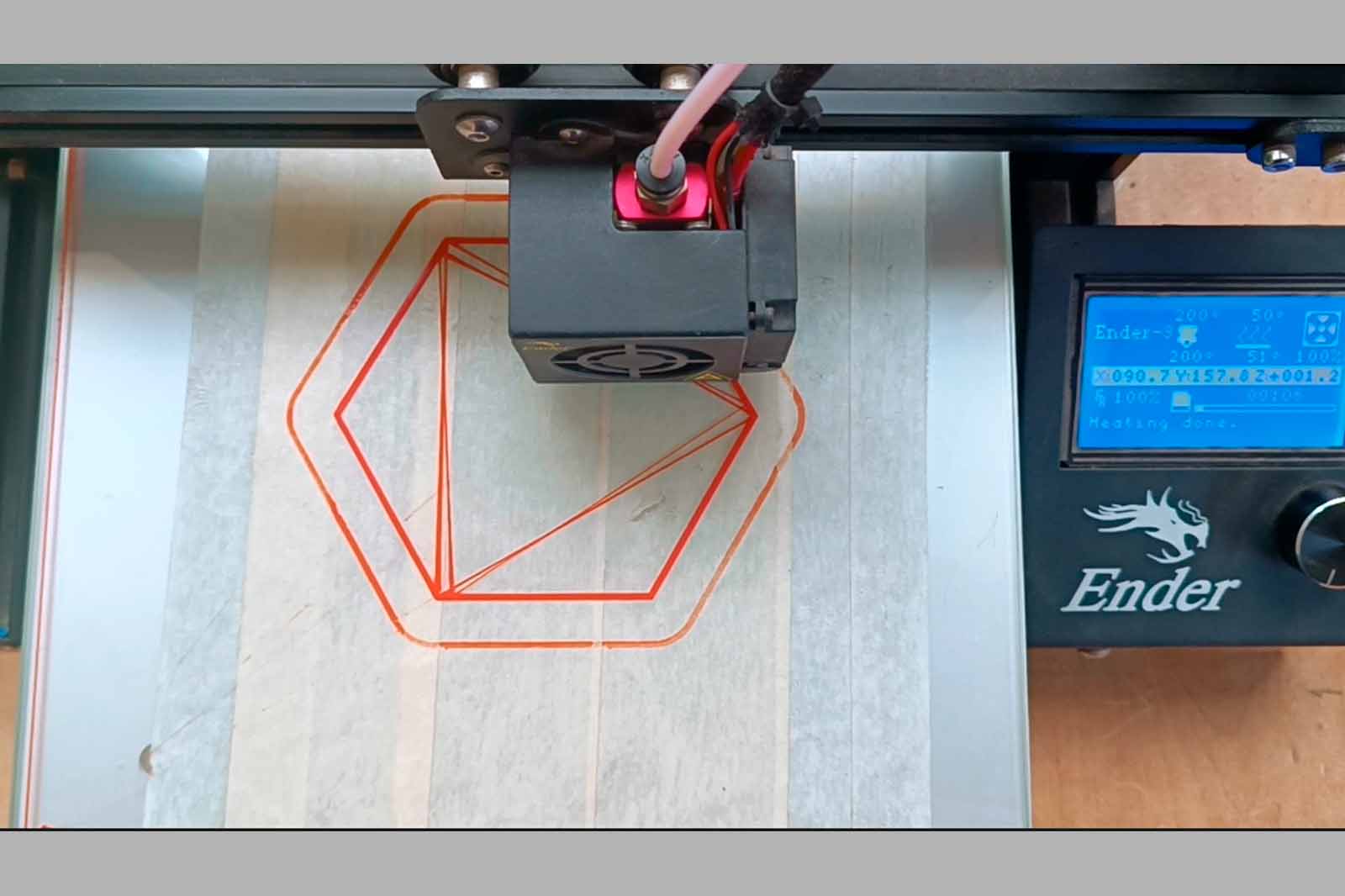

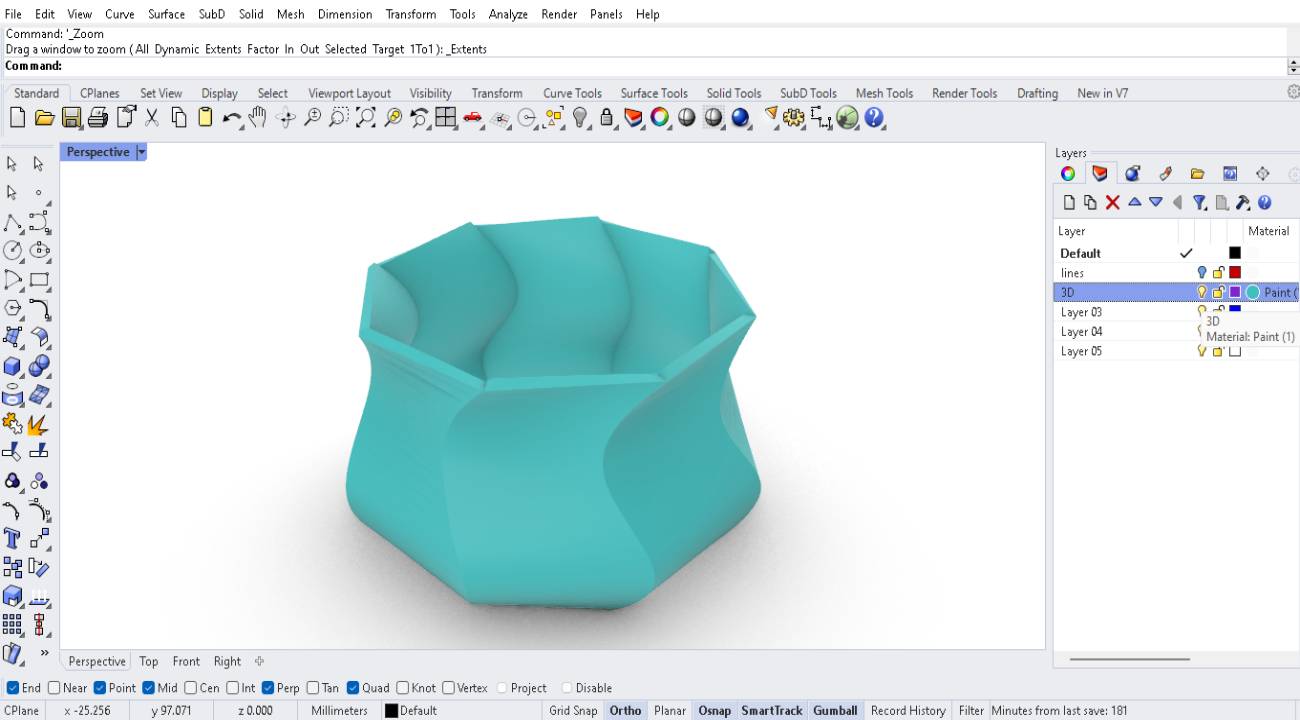

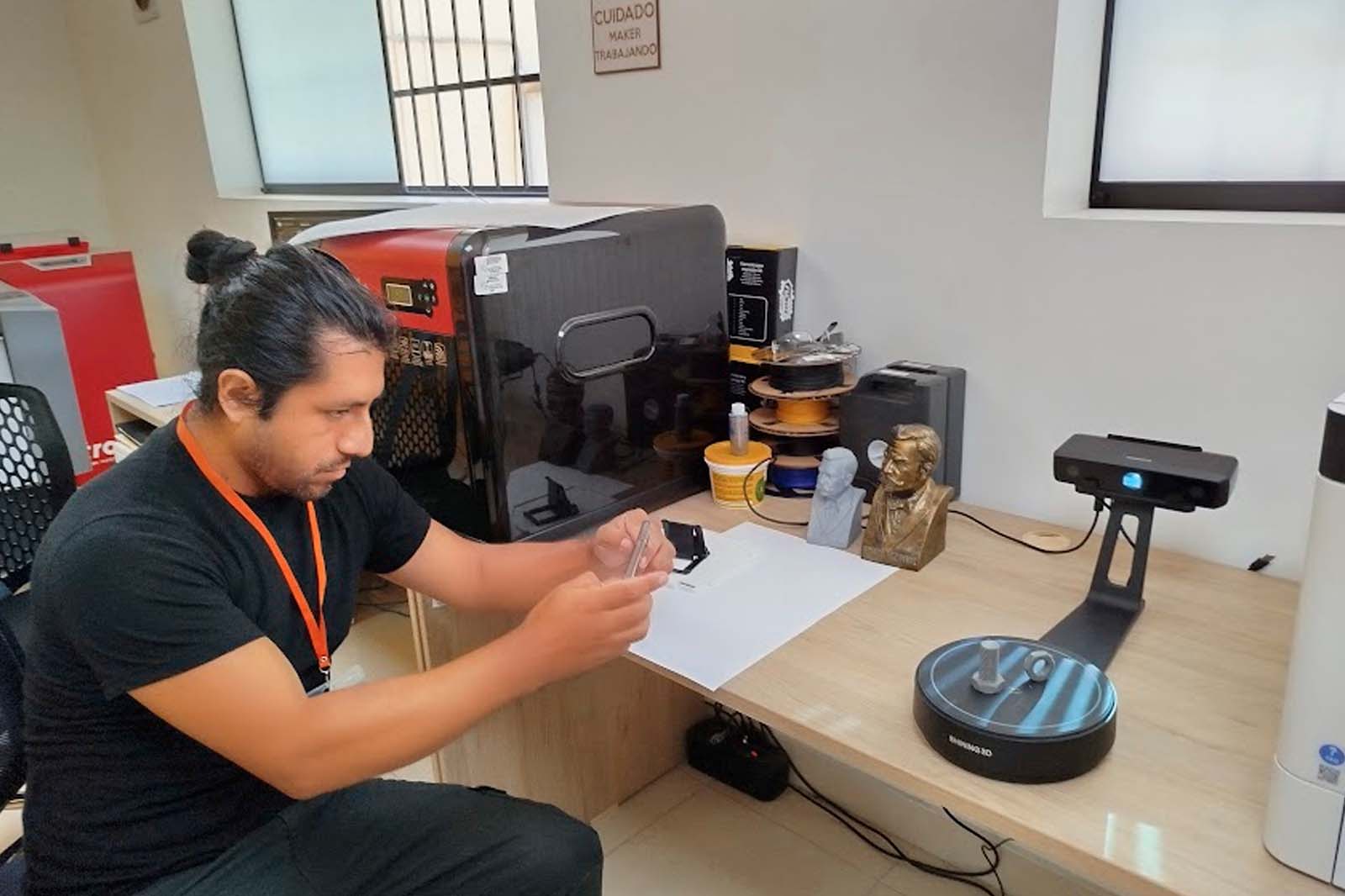

3D Scanning and Printing

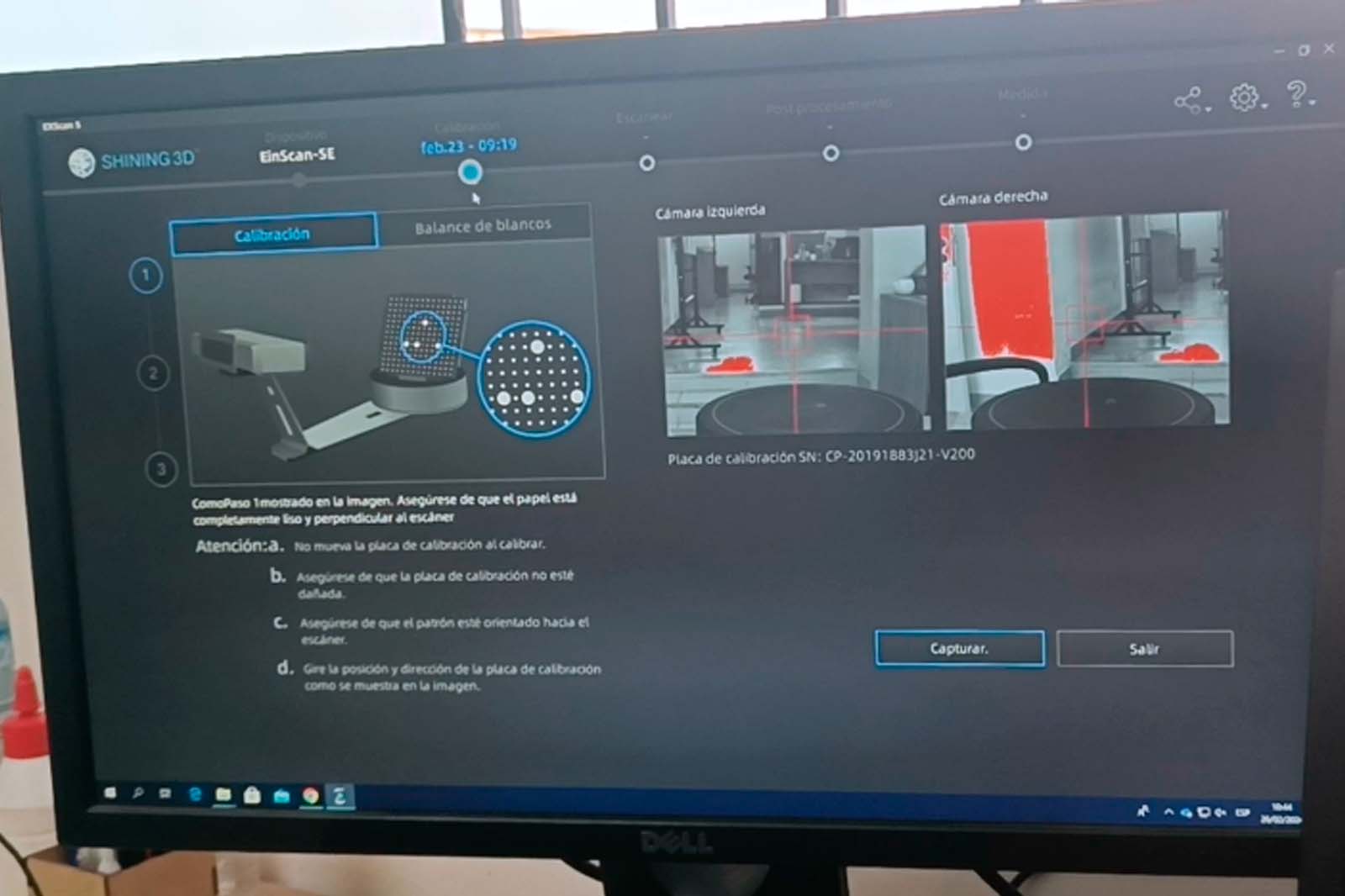

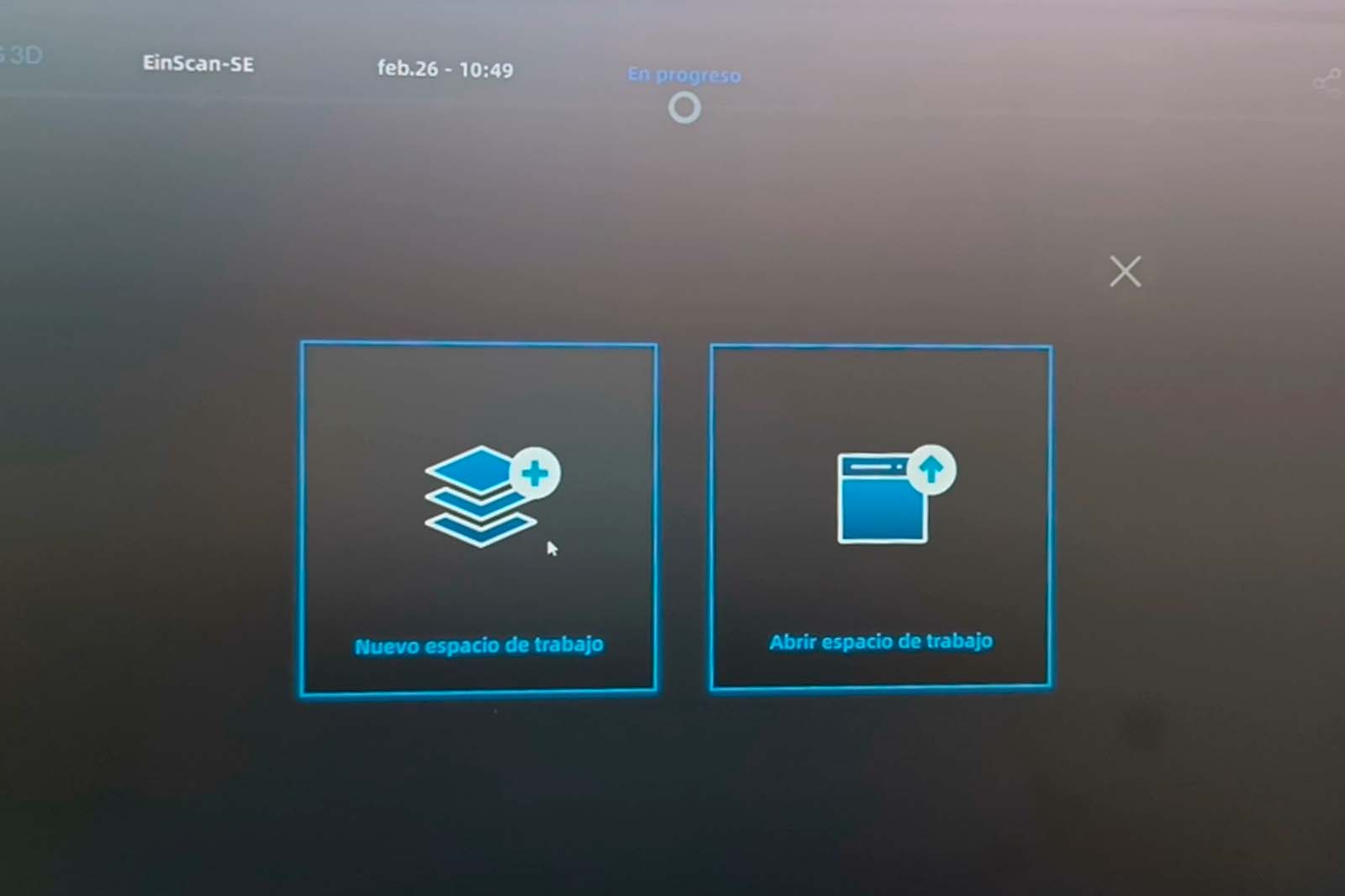

This week we focus on the procedures for using a 3D Scanner and printing tests of objects with different characteristics.

the assignment was:

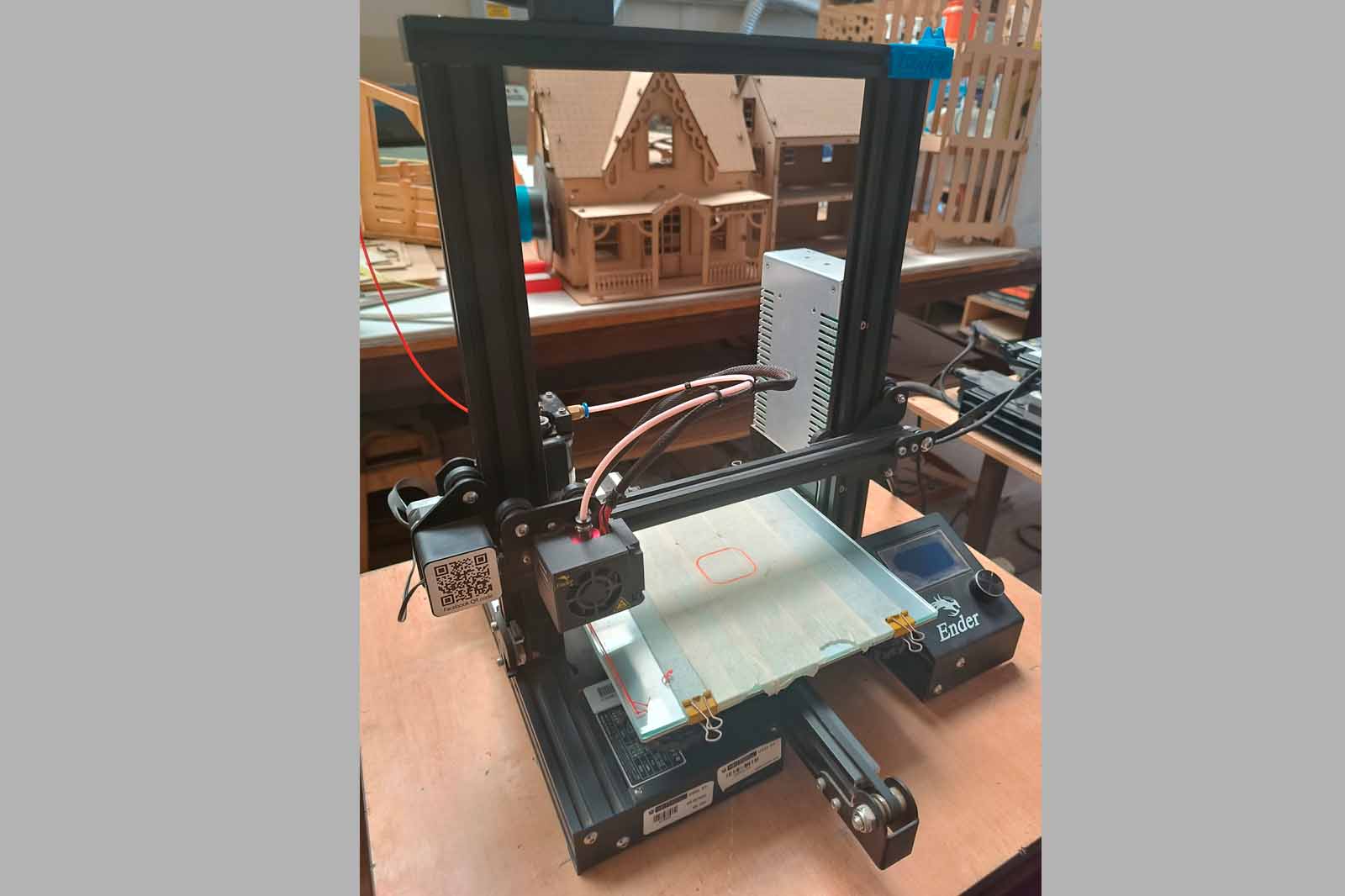

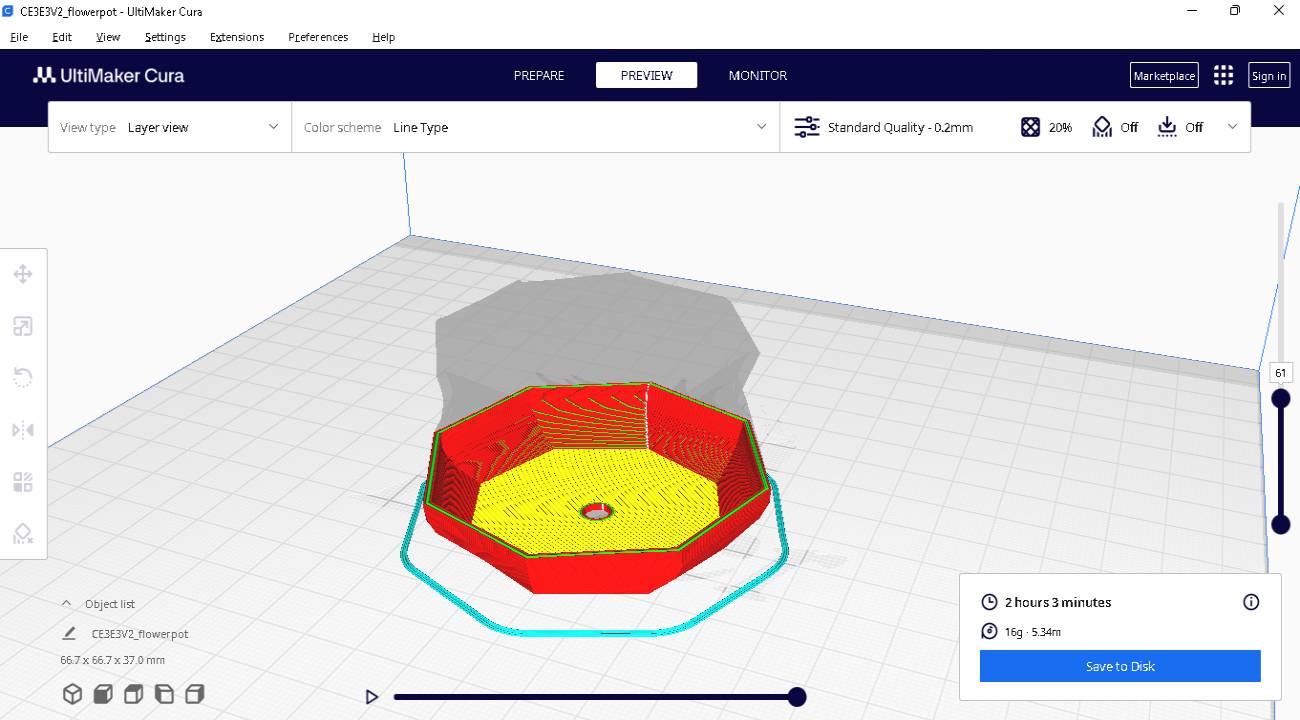

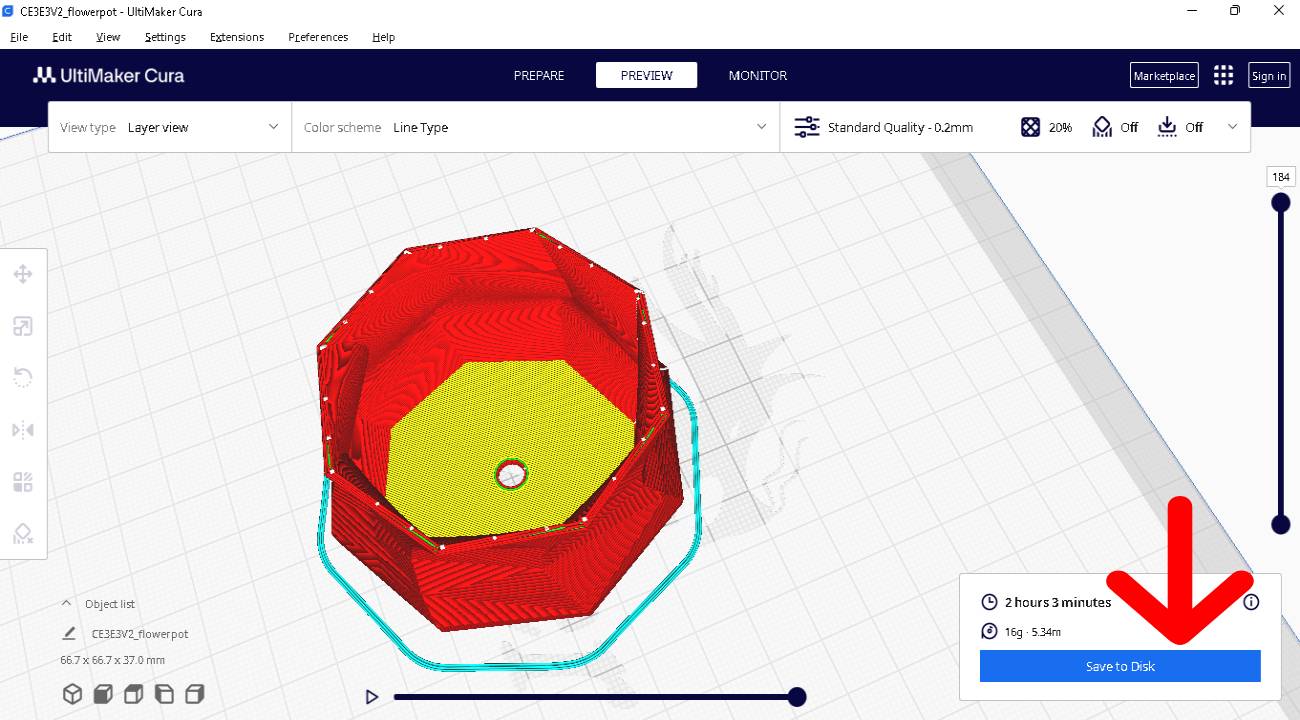

group assignment: test the design rules for your 3D printer(s)

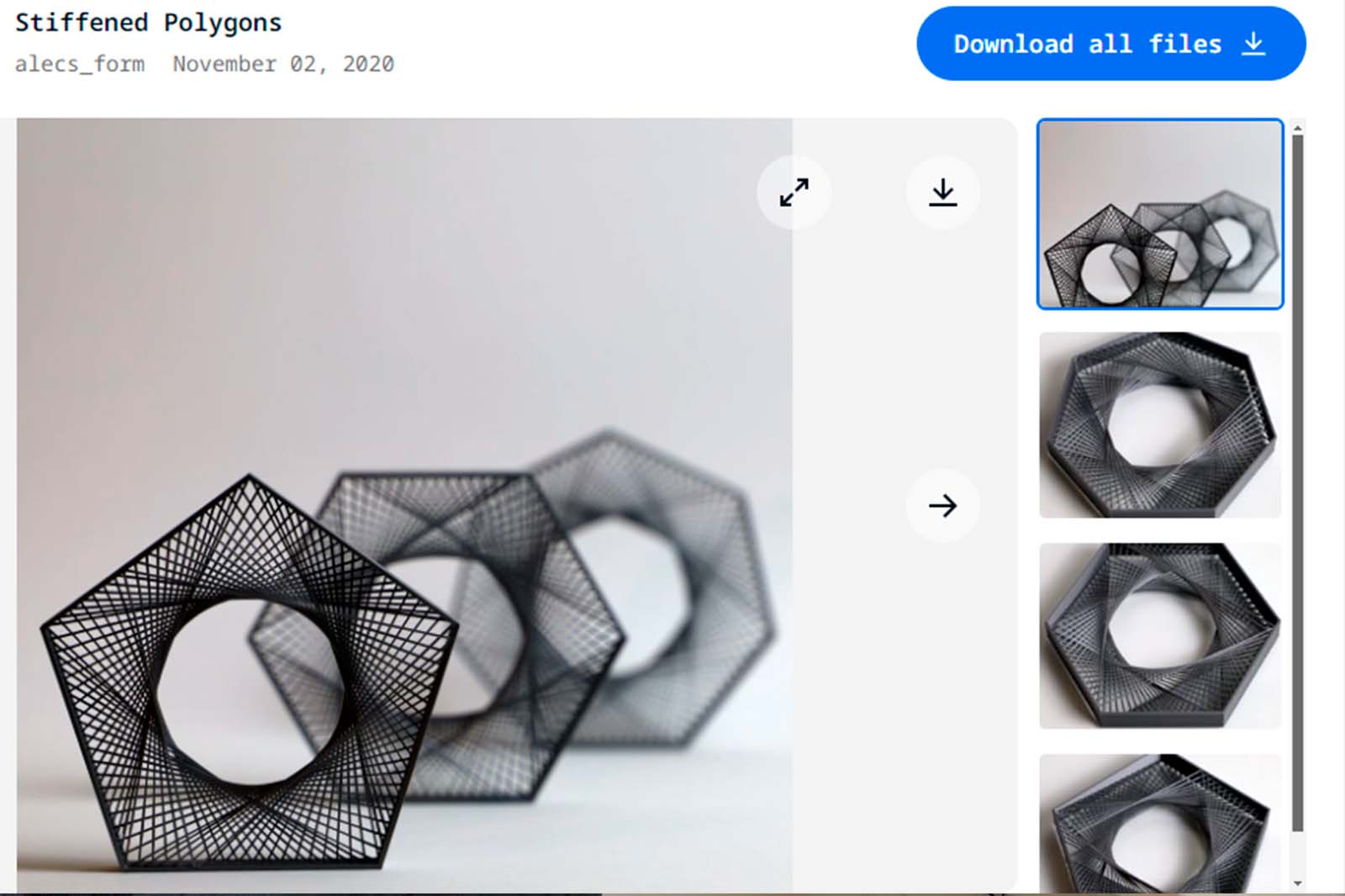

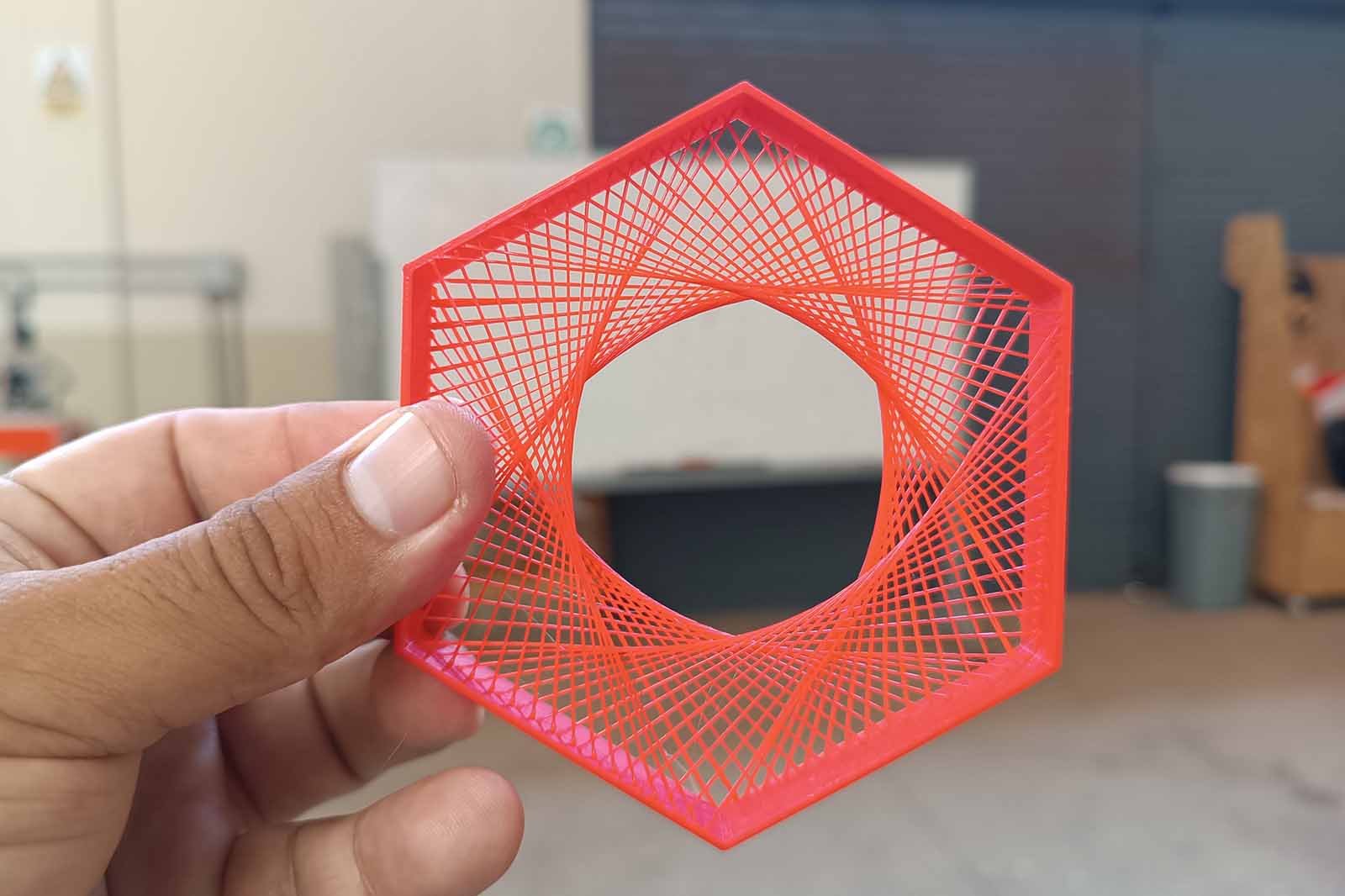

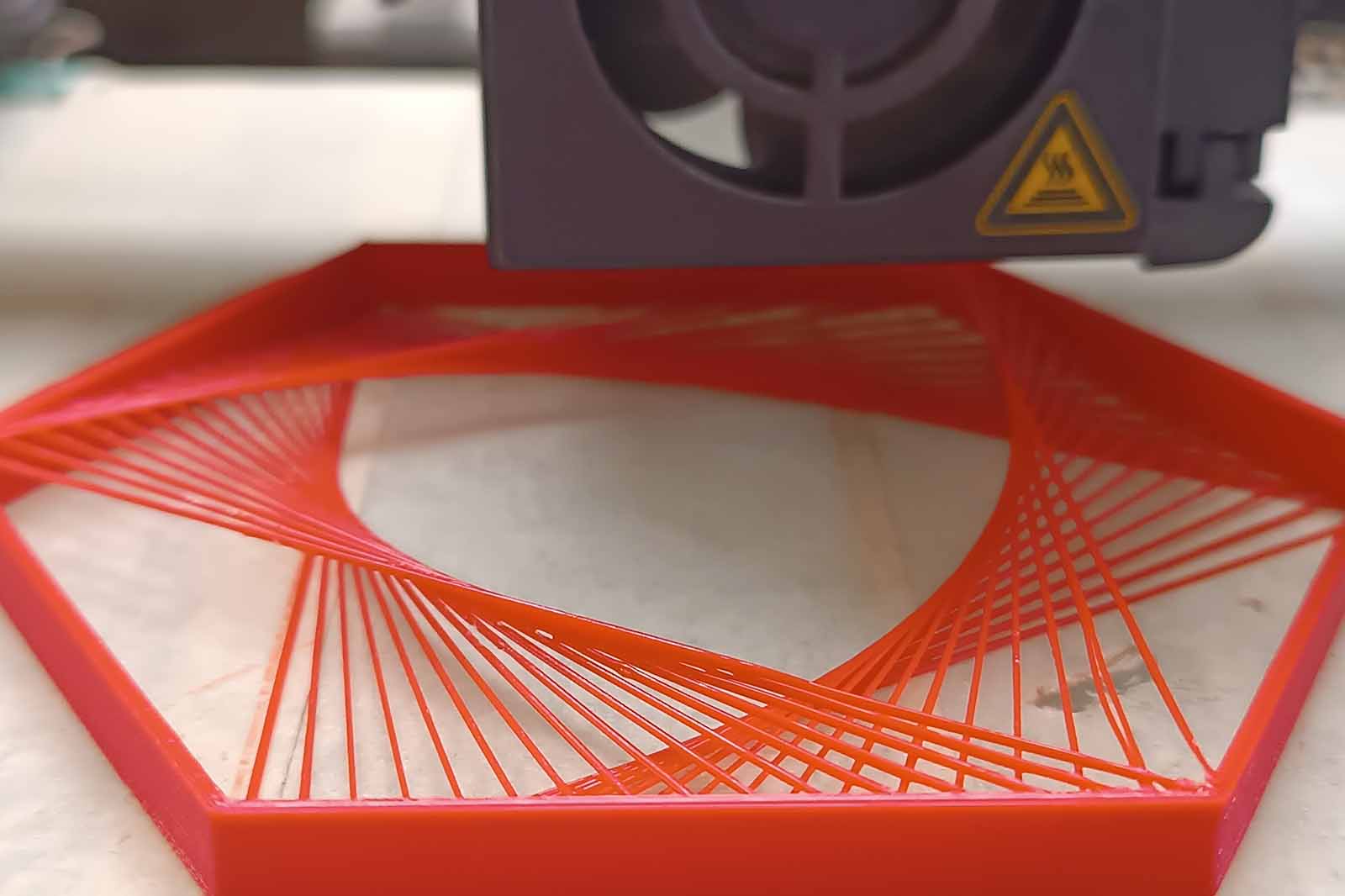

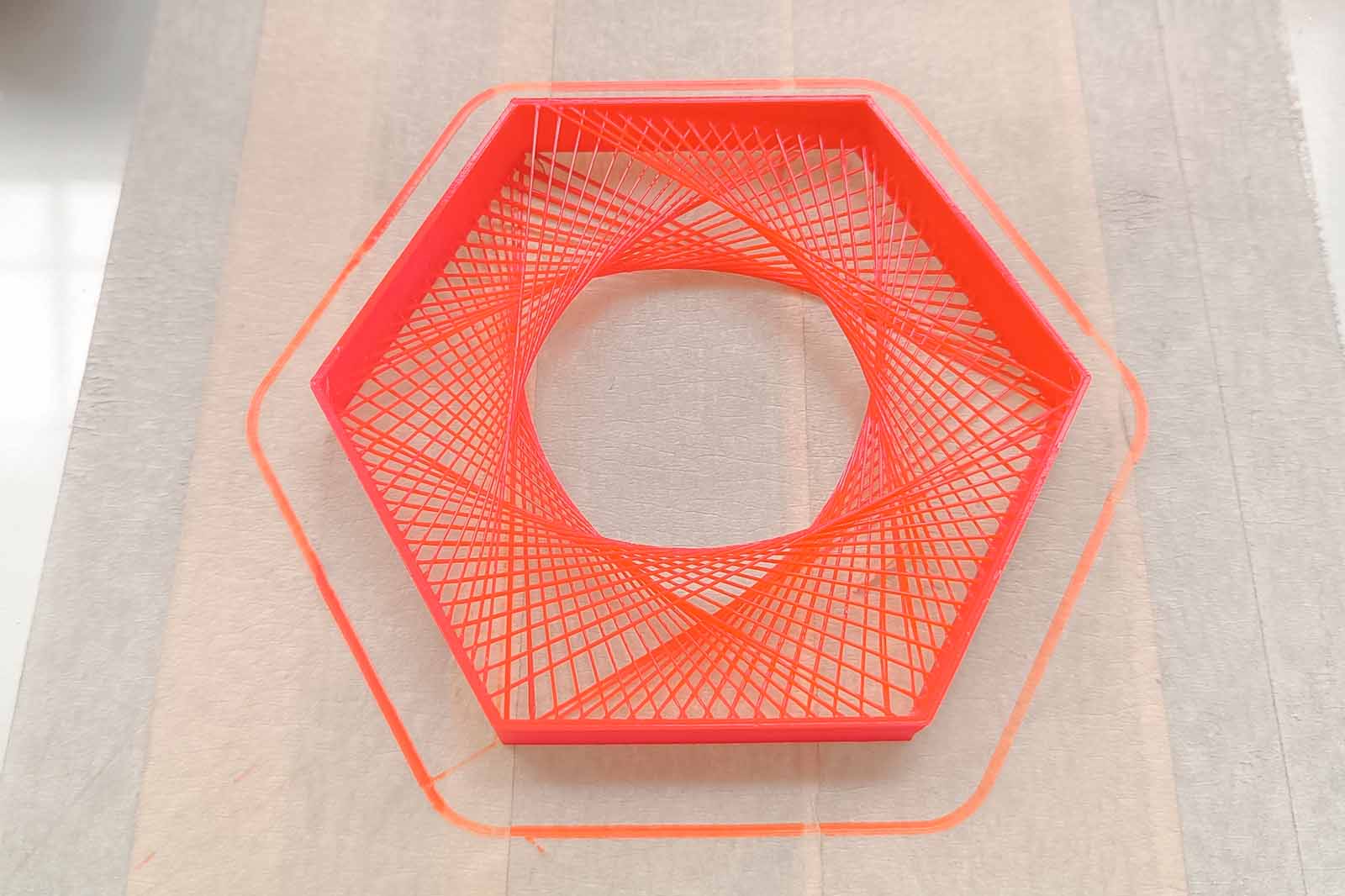

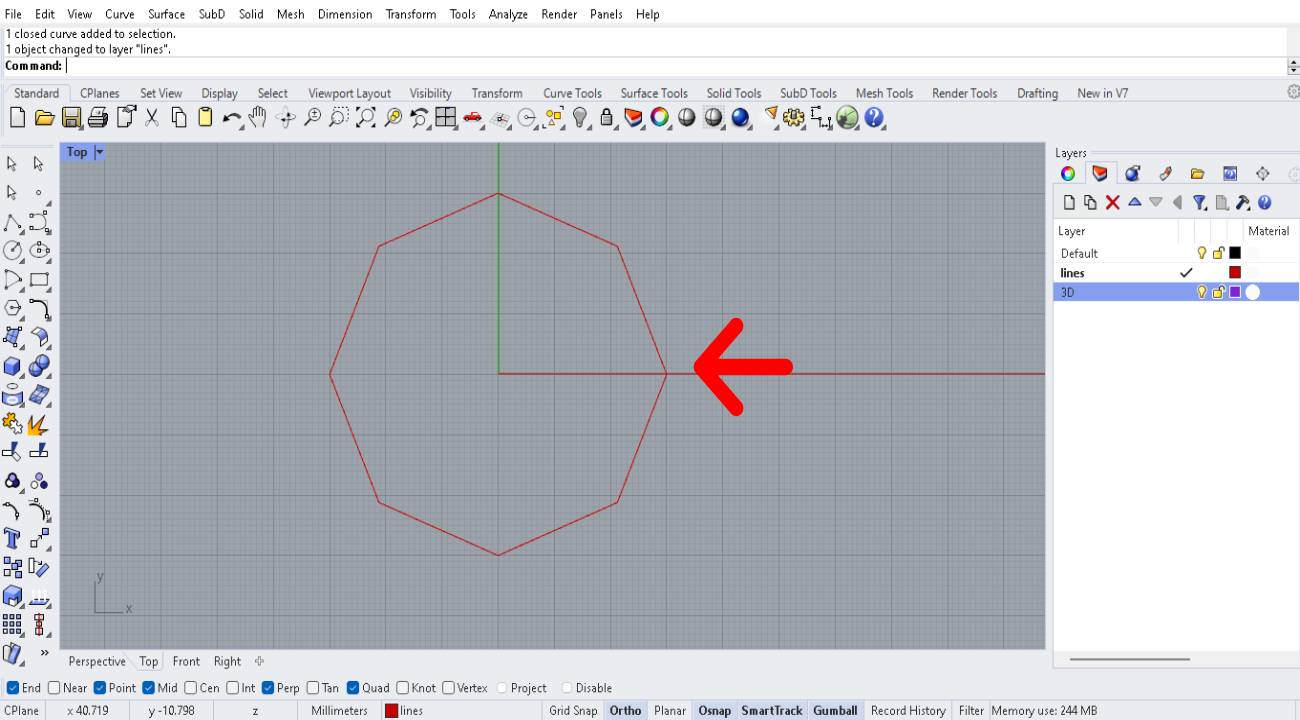

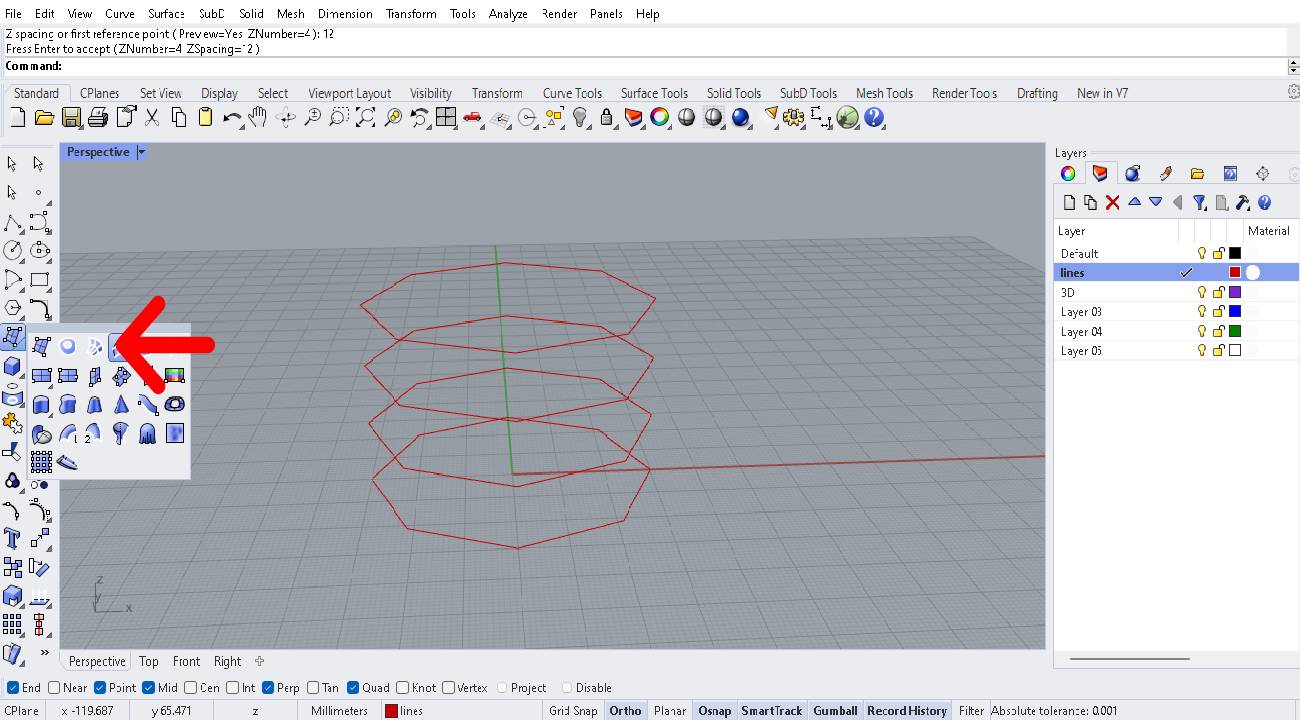

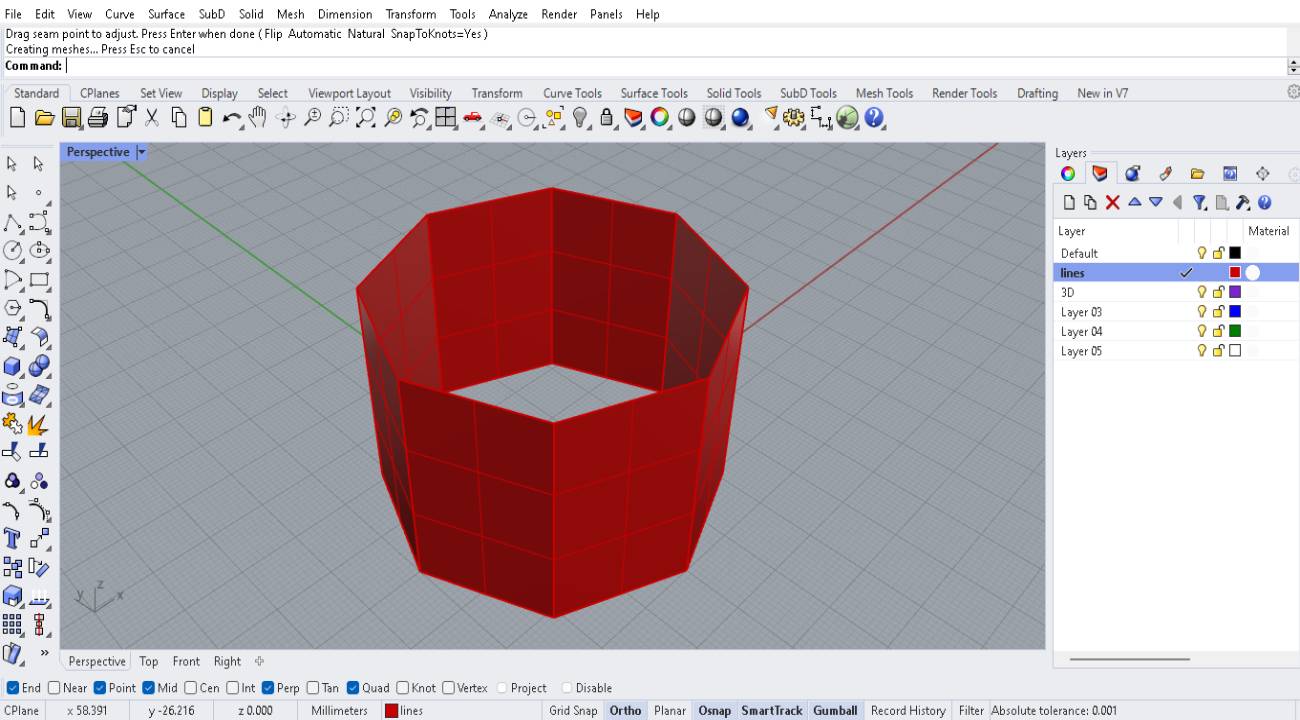

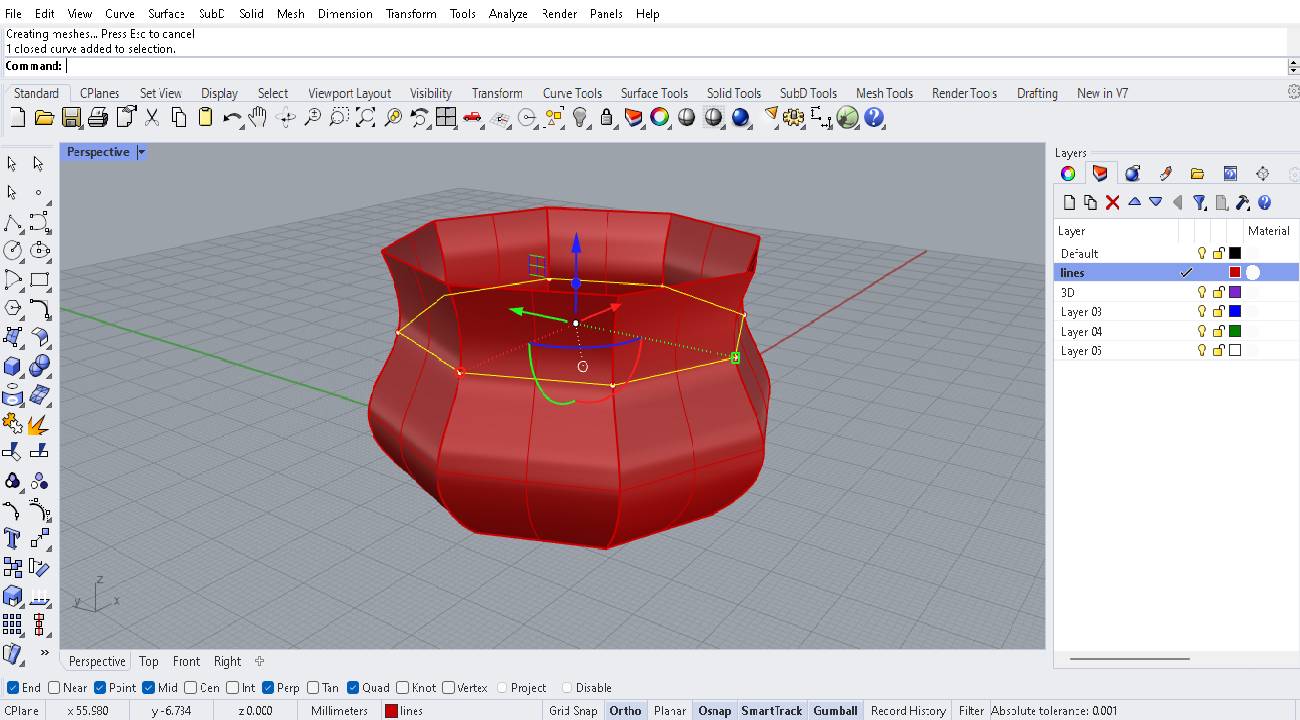

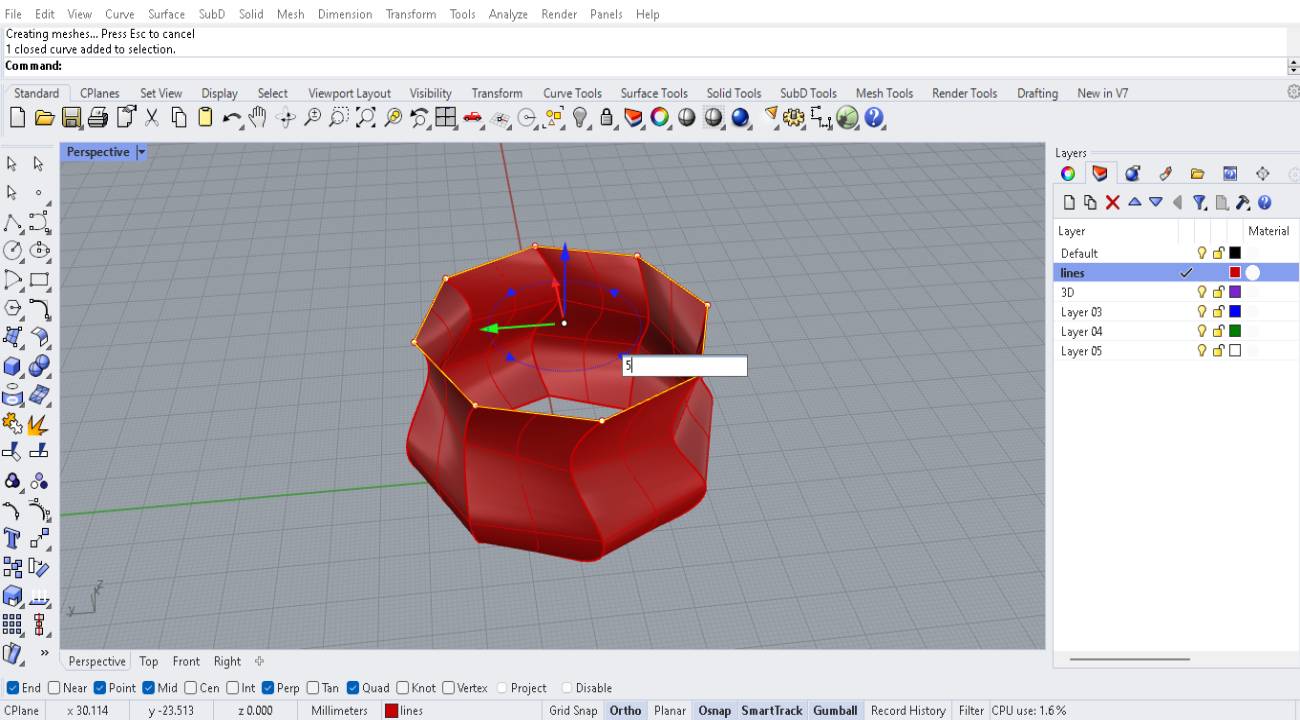

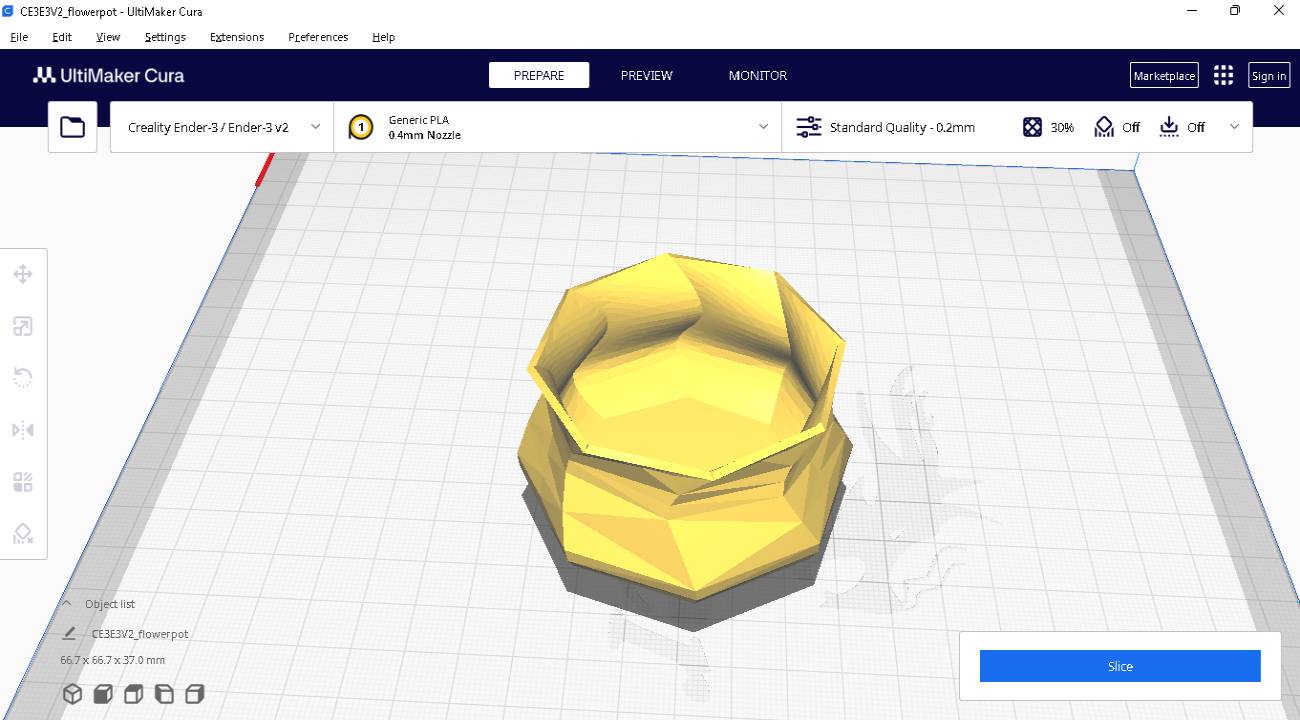

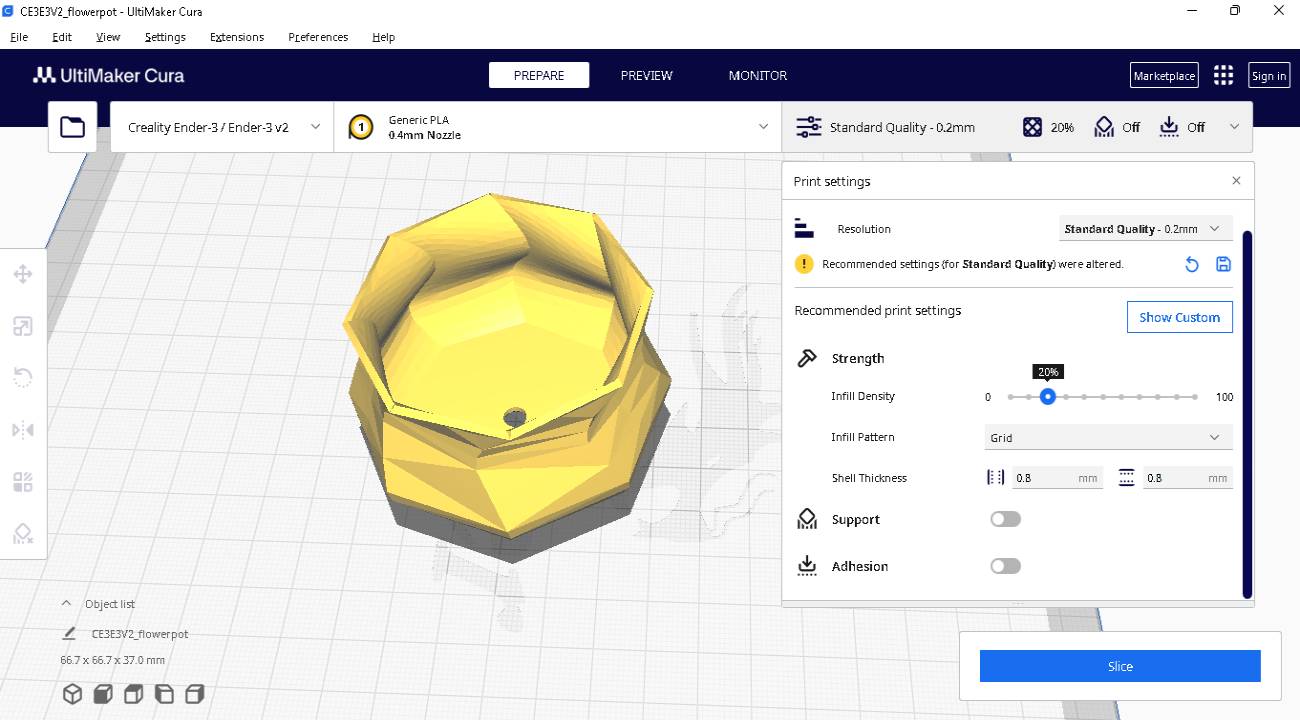

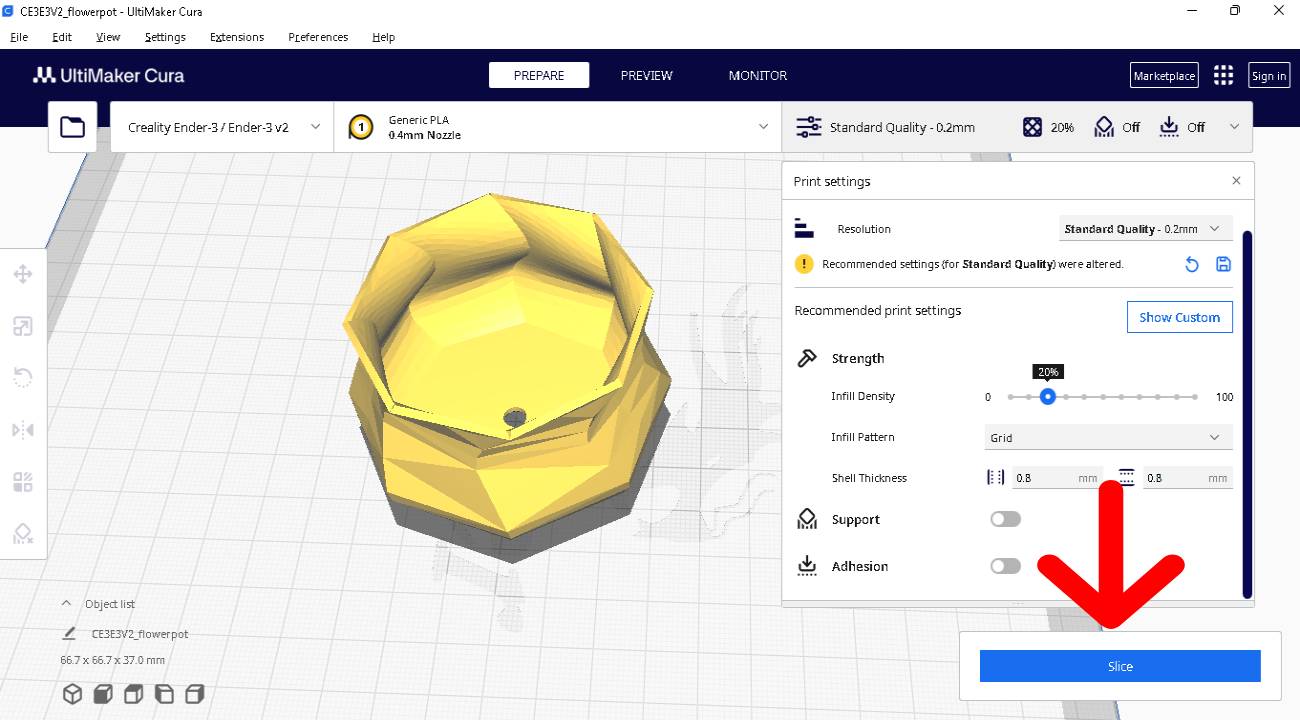

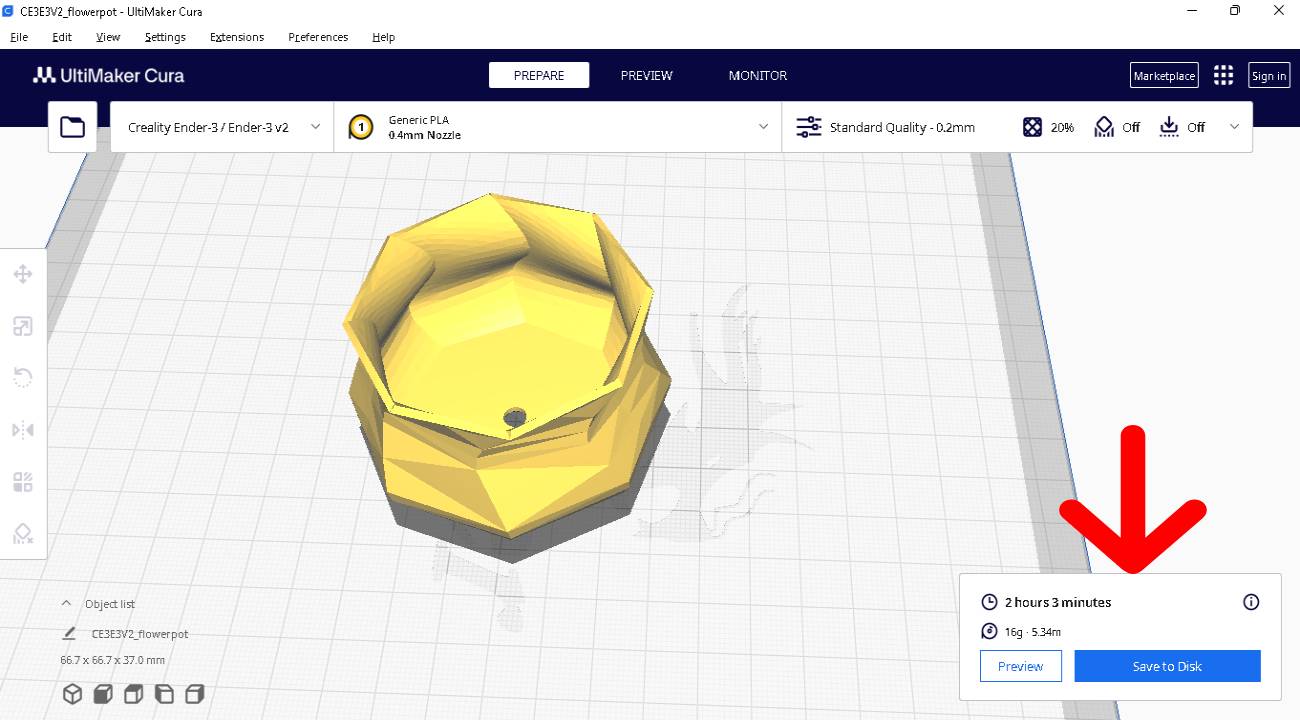

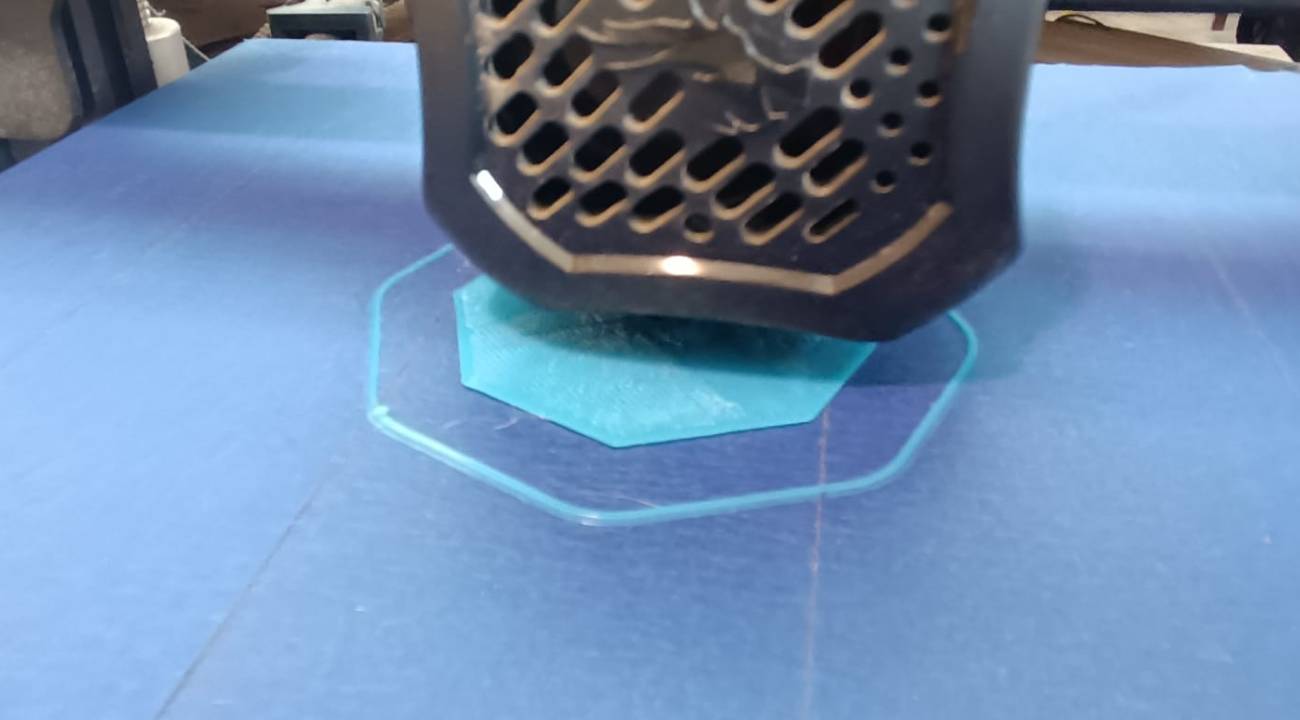

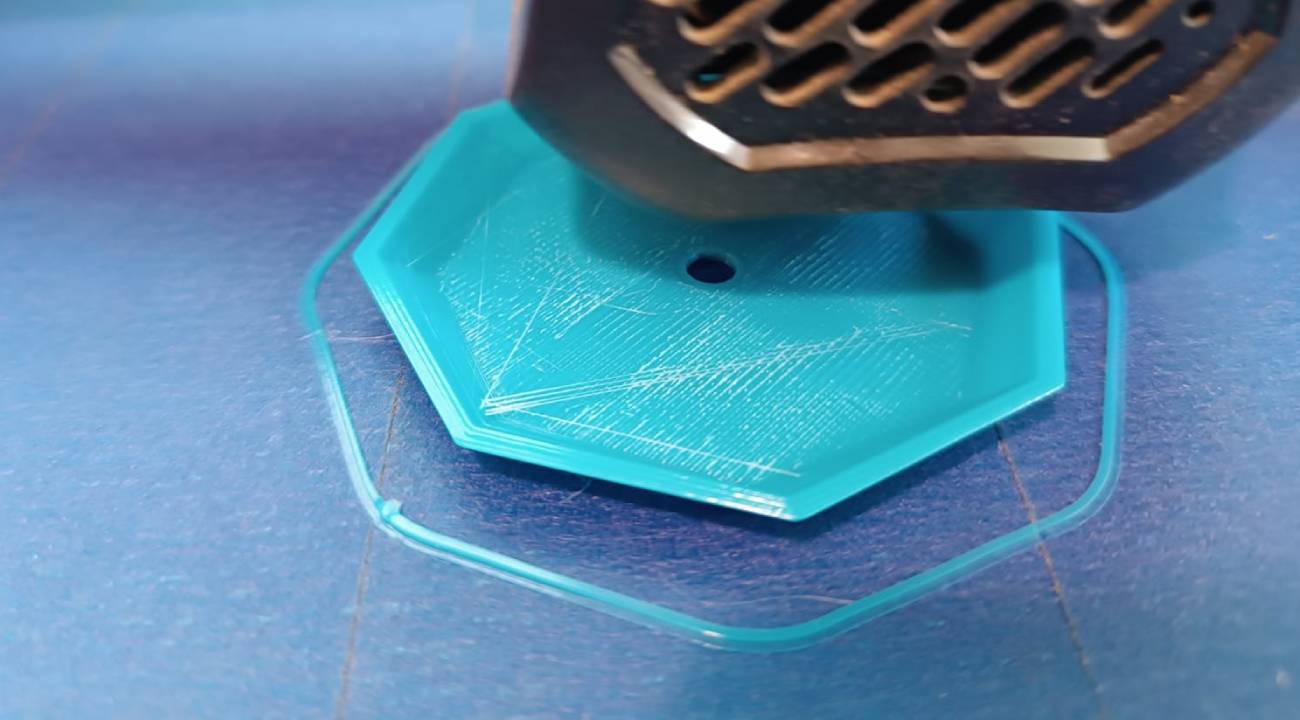

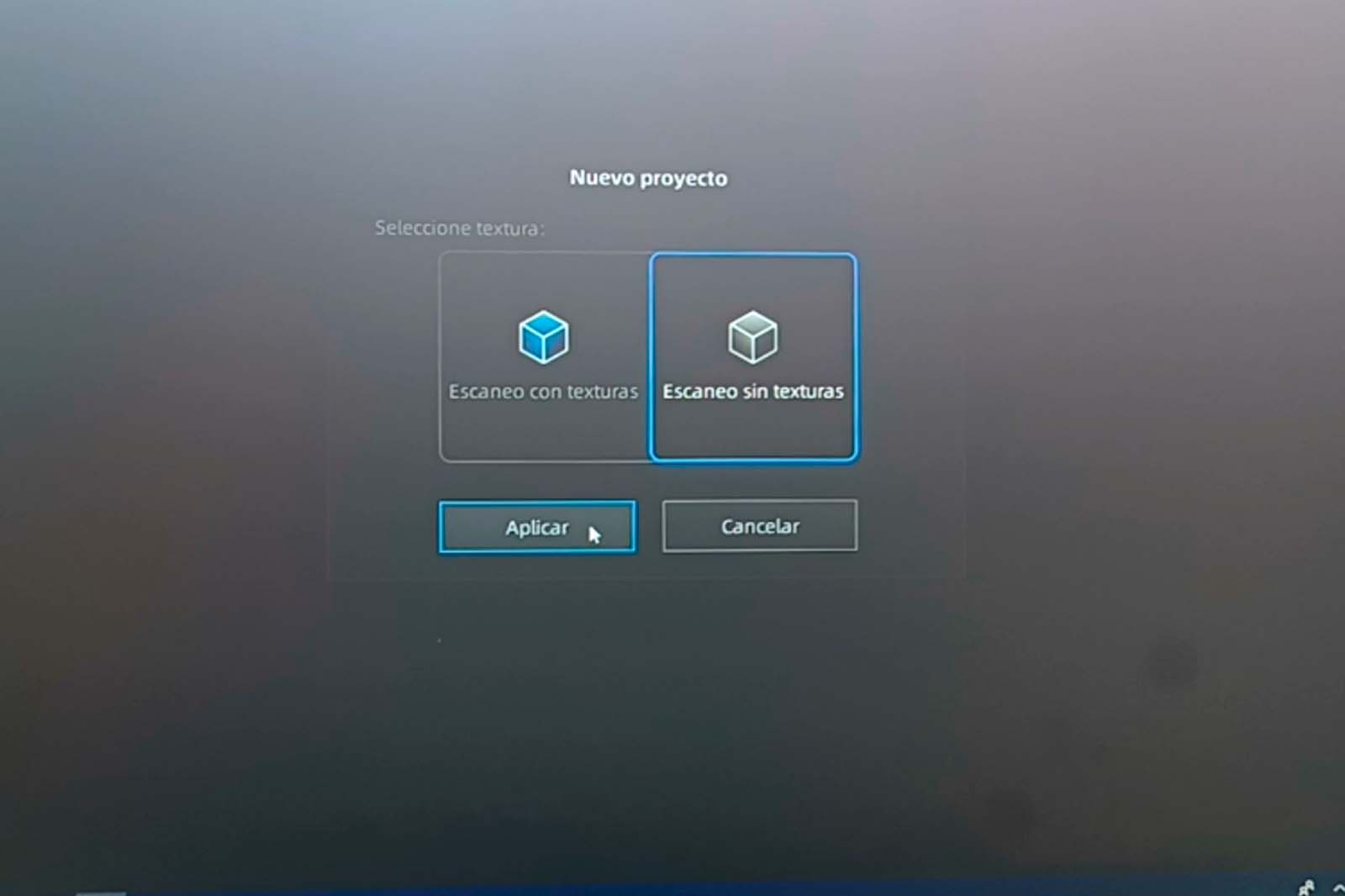

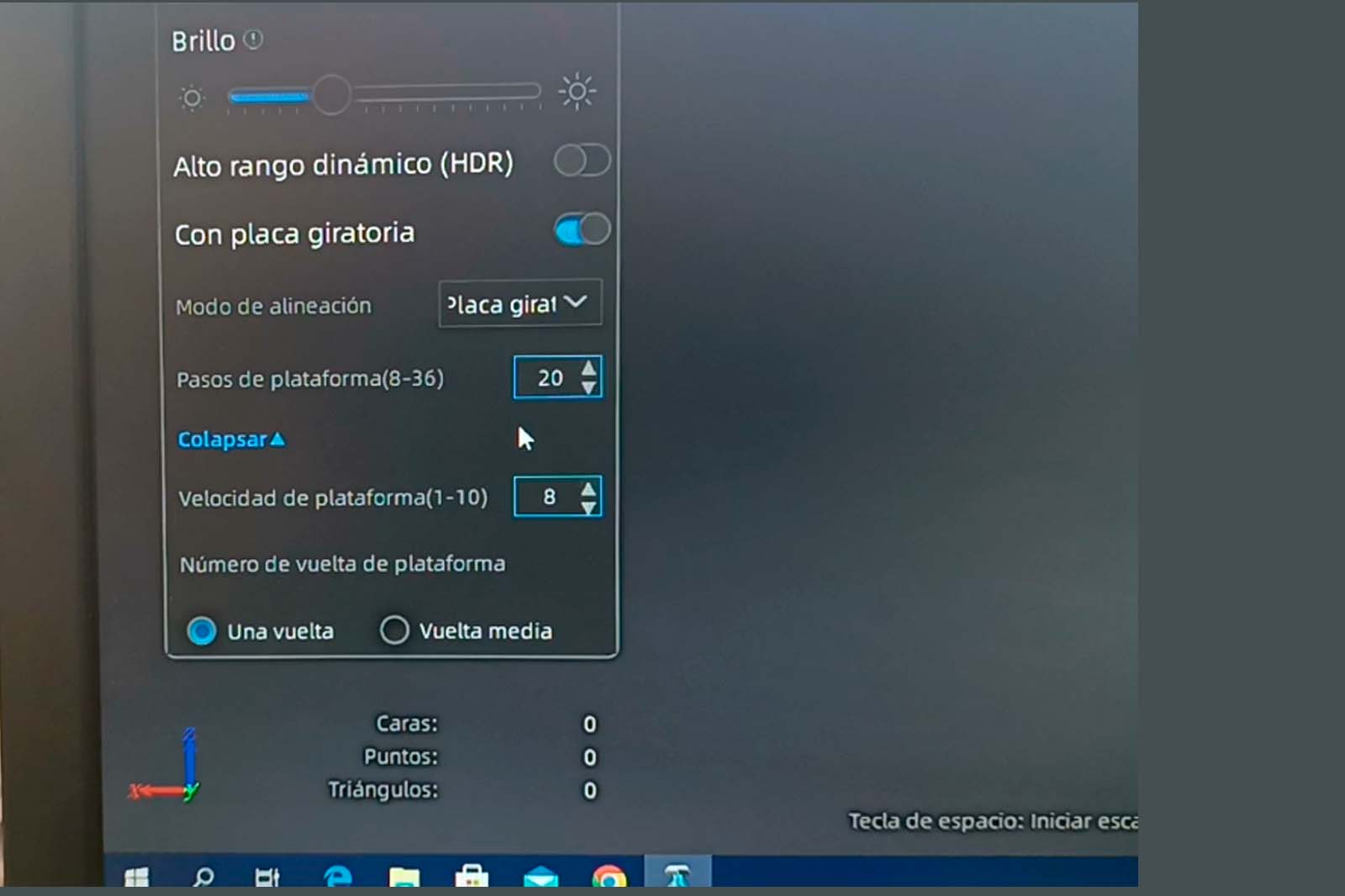

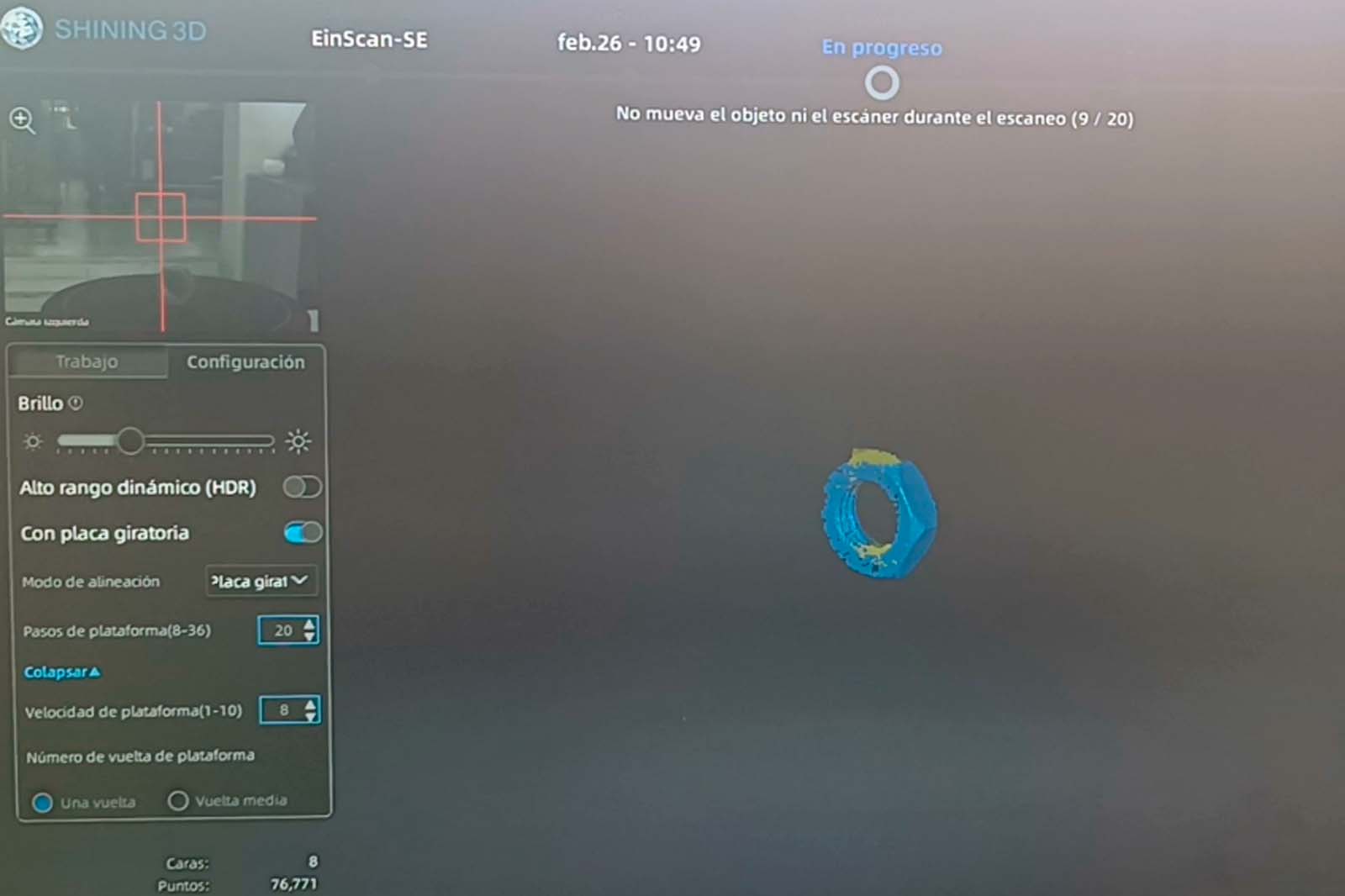

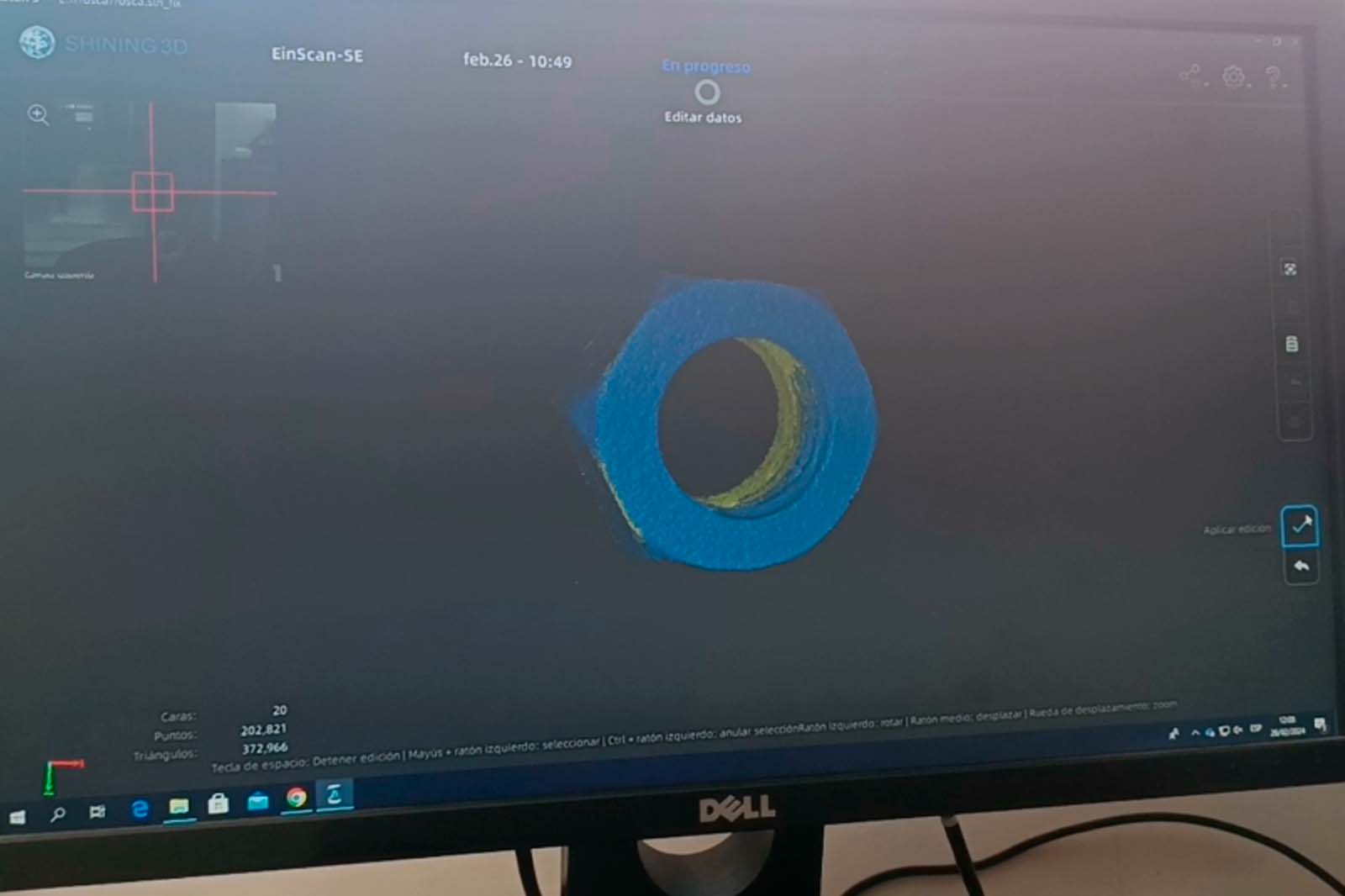

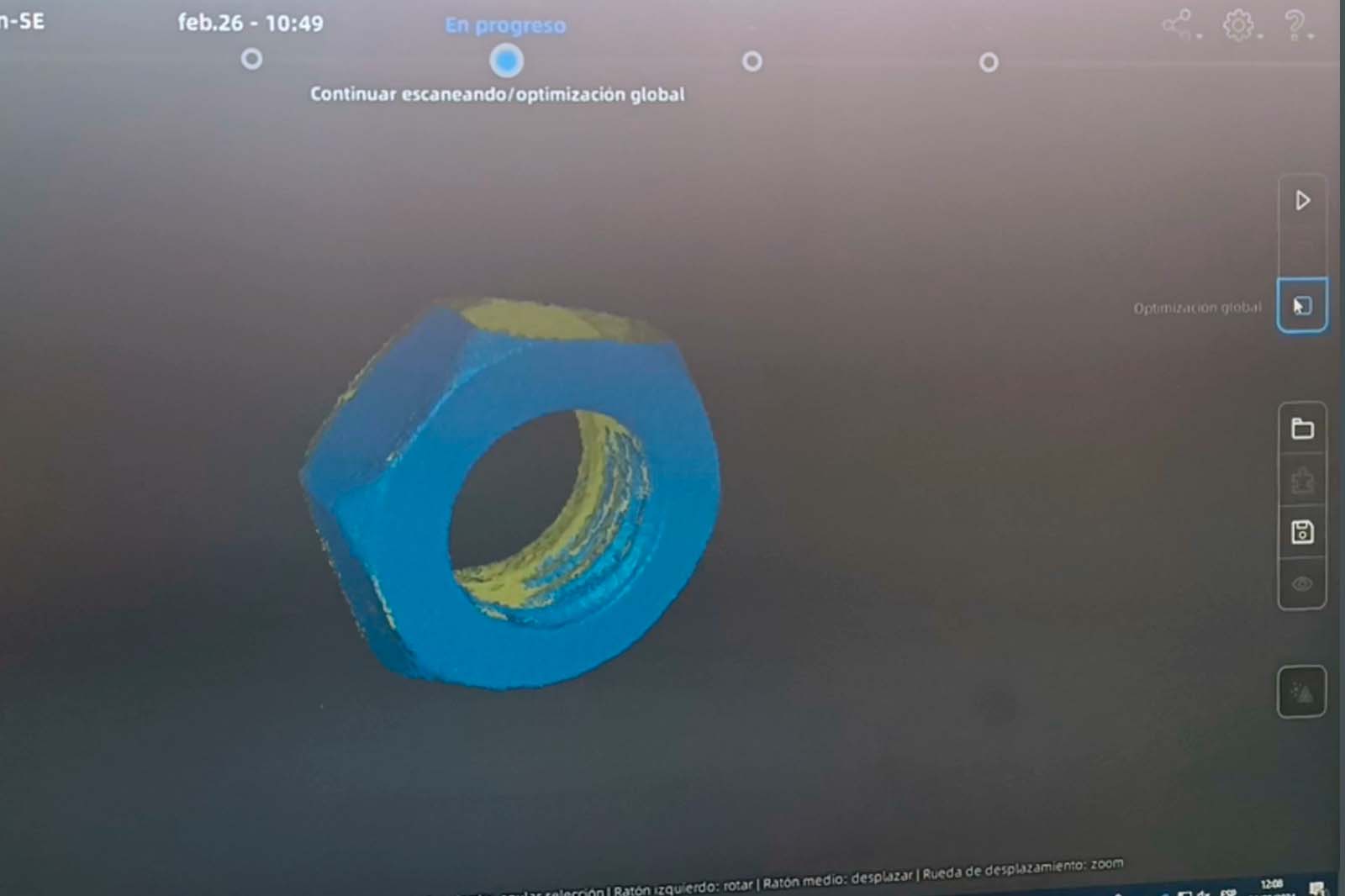

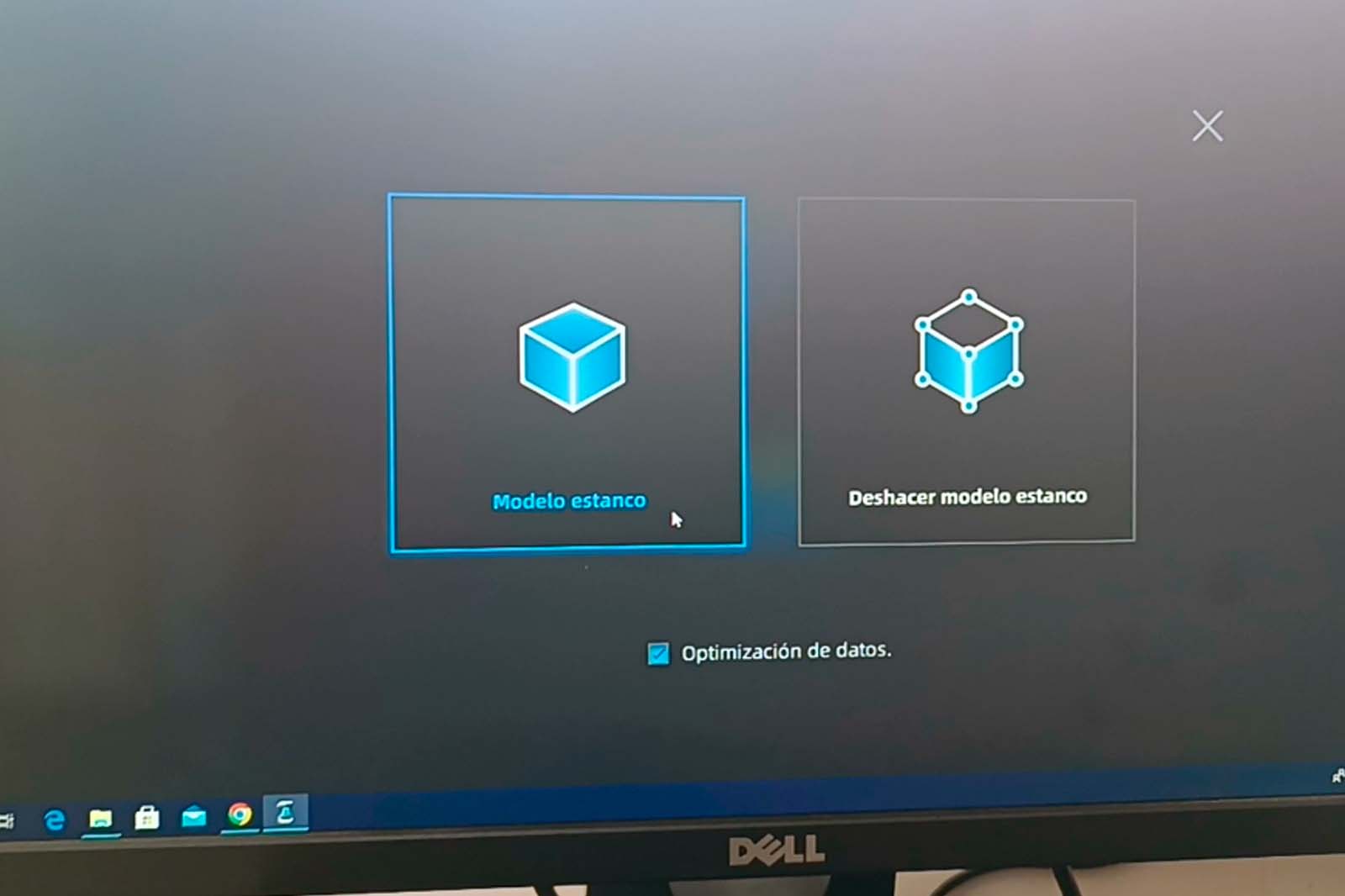

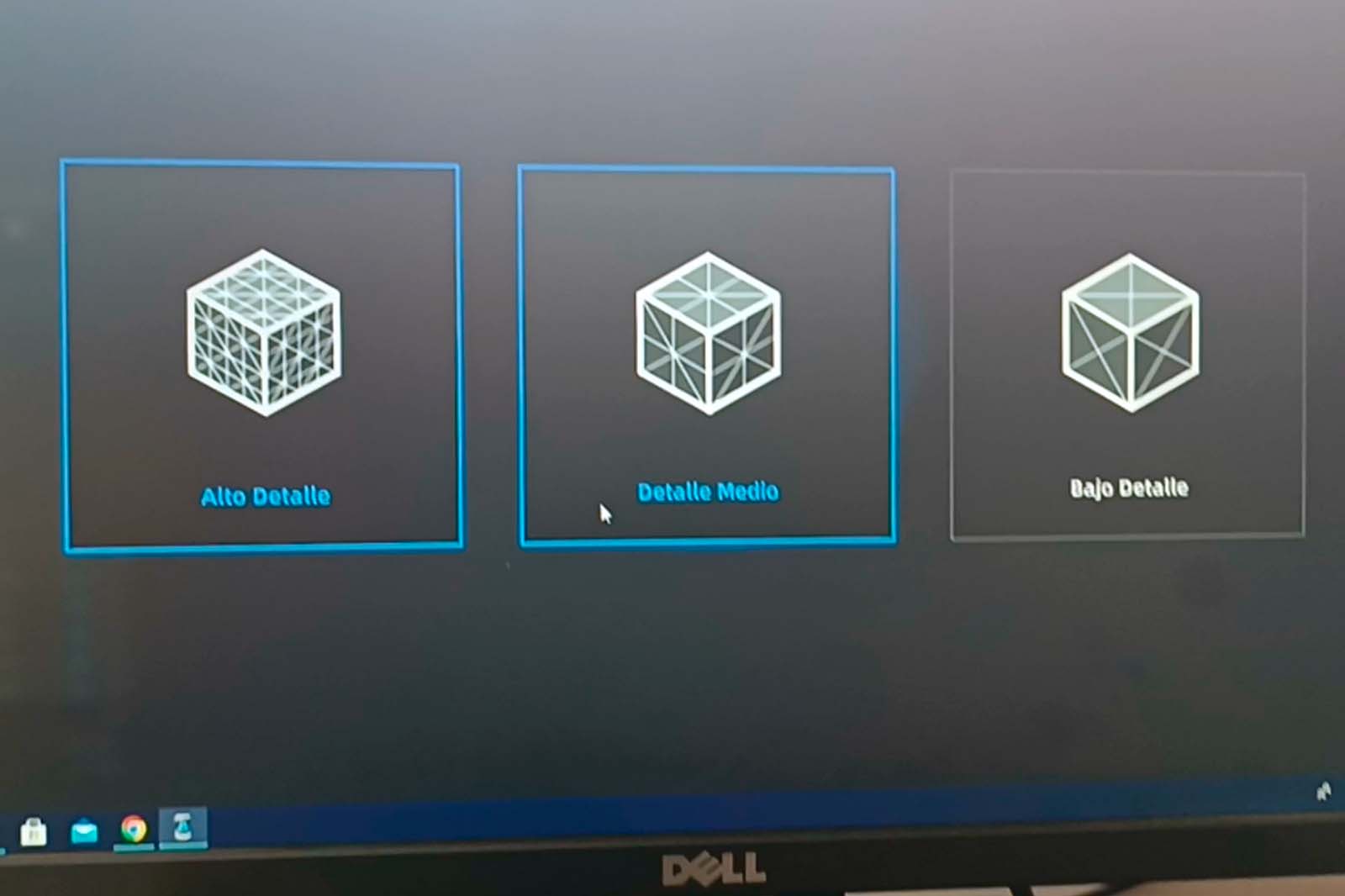

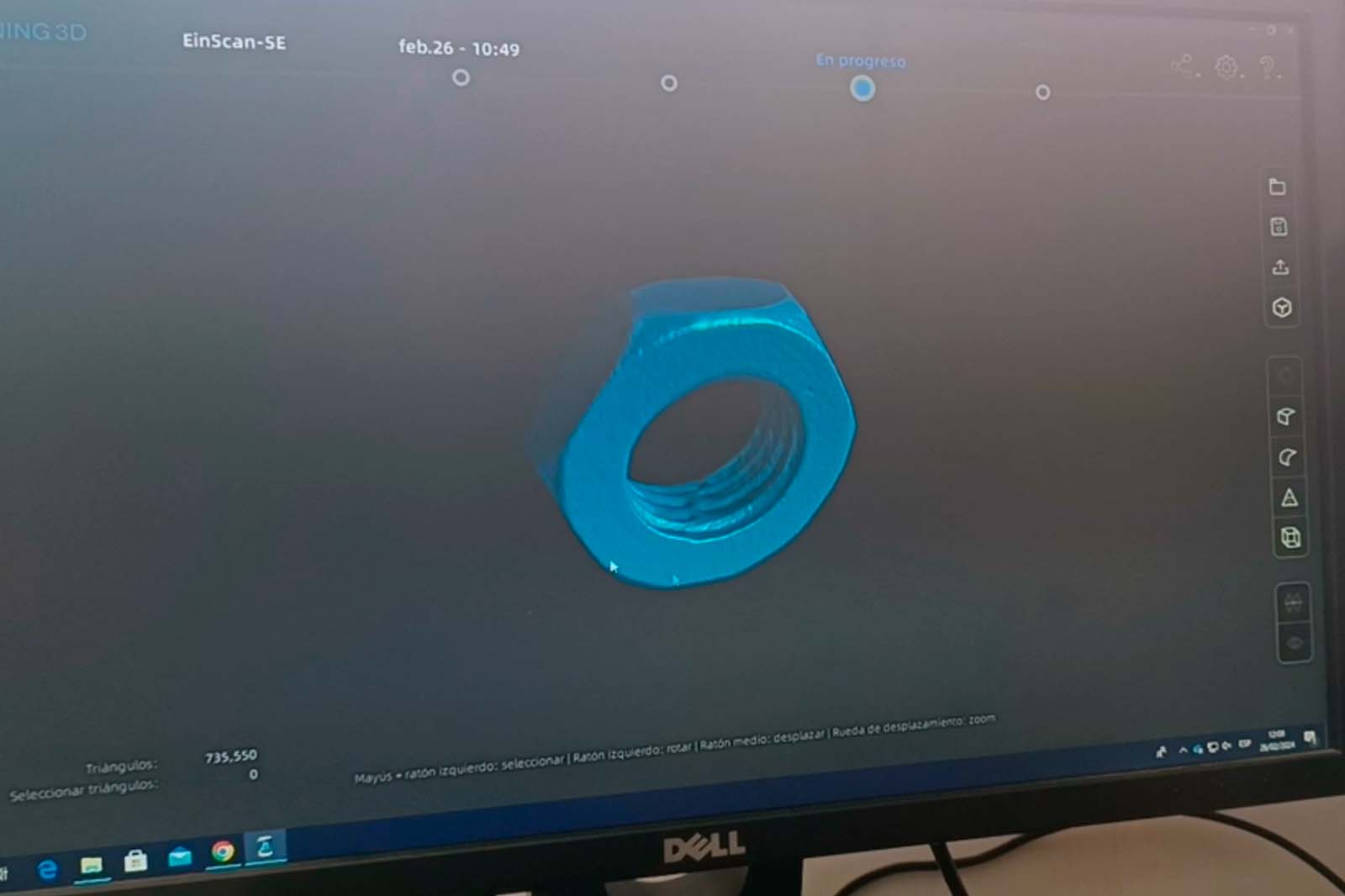

individual assignment: design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively. 3D scan an object (and optionally print it).

Group assignment

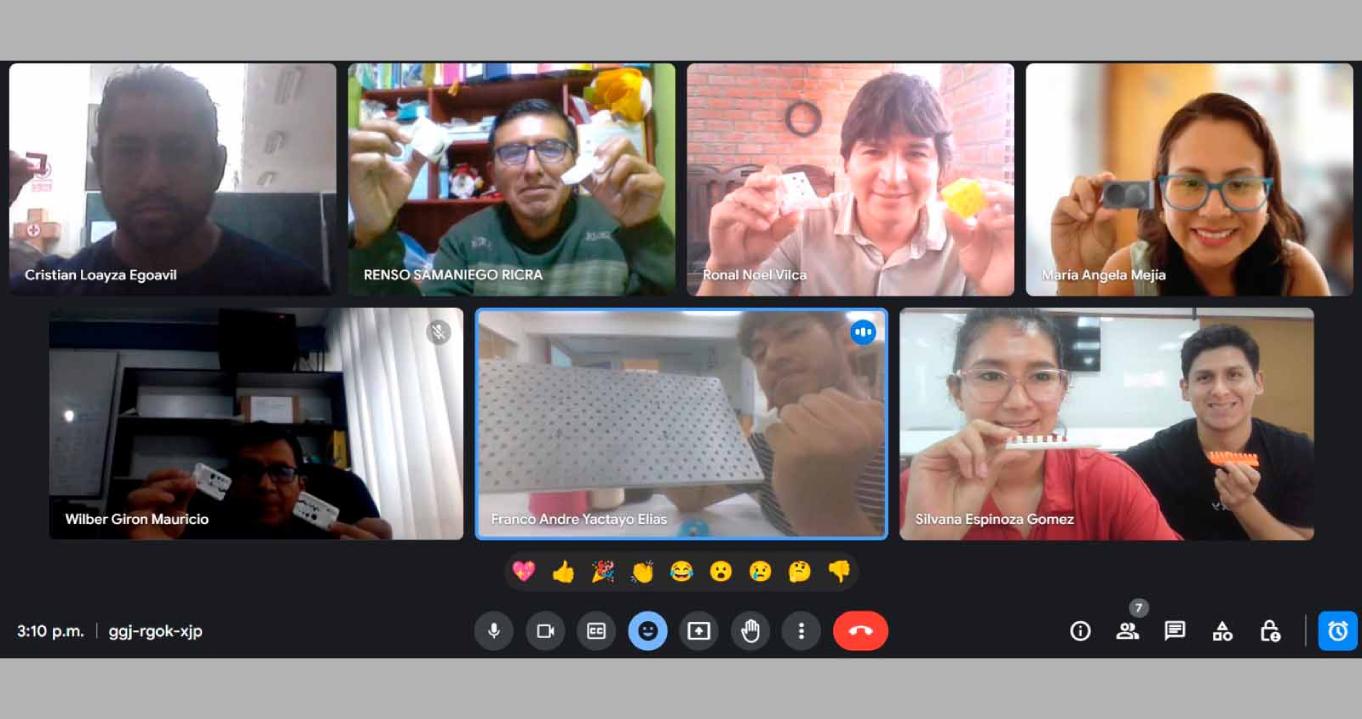

To perform this group assignment, we printed on different locations and 3D printers in a distributed way, and then we could evidence and compare the results.

By testing different materials and printers we can notice that there is variation in the results given by the different configurations.

We were able to optimize the printing time of the models since they were printed at the same time.

You can see the complete documentation on the group's web page