Computer controlled cutting

This week we will focus on the use of computer controlled cutting. We will use the vinyl cutting machine and the laser cutting machine.

the assignment was:

group assignment: do your lab's safety training characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types

individual assignment: cut something on the vinyl cutter, design lasercut and document a parametric construction kit accounting for the lasercutter kerf which can be assembled in multiple ways and for extra credit include elements that aren't flat.

Group assignment

In this assignment we characterize the focus, power, speed, index, kerf, joint clearance of the fablab iFurniture laser cutter.

You can see the complete documentation on the group's web page

Conclusions on the group assignment:

- We must take into account safety and use the necessary attachments for the cutting process.

- The machine must be correctly calibrated on the "Z" axis using the accessory indicated by the manufacturer that measures 7mm in height.

- the file must be worked in layers corresponding to each process (marking, cutting and engraving).

- the final cut file must be exported in DXF format which is the file read by the RDWorks controller used by the laser machine.

Individual assignment

Vinyl cutting

The vinyl cutting plotter I will use is Jinka, model 721 and uses 600mm vinyl.

The plotter uses Artcut 2009 software as a driver.

For the sticker design I used corel draw

I design an artwork with the fab lab logo and the text "Fab Academy 2024"

To use the Artcut 2009 we must export the file in PLT format.

1. File->Import->file name->Open

2. Cut/Out

3. Cut/Plot

4. Start

Vinyl cutting process

Vinyl peeling process

Placement of transfer film

finally the sticker

Laser cutting

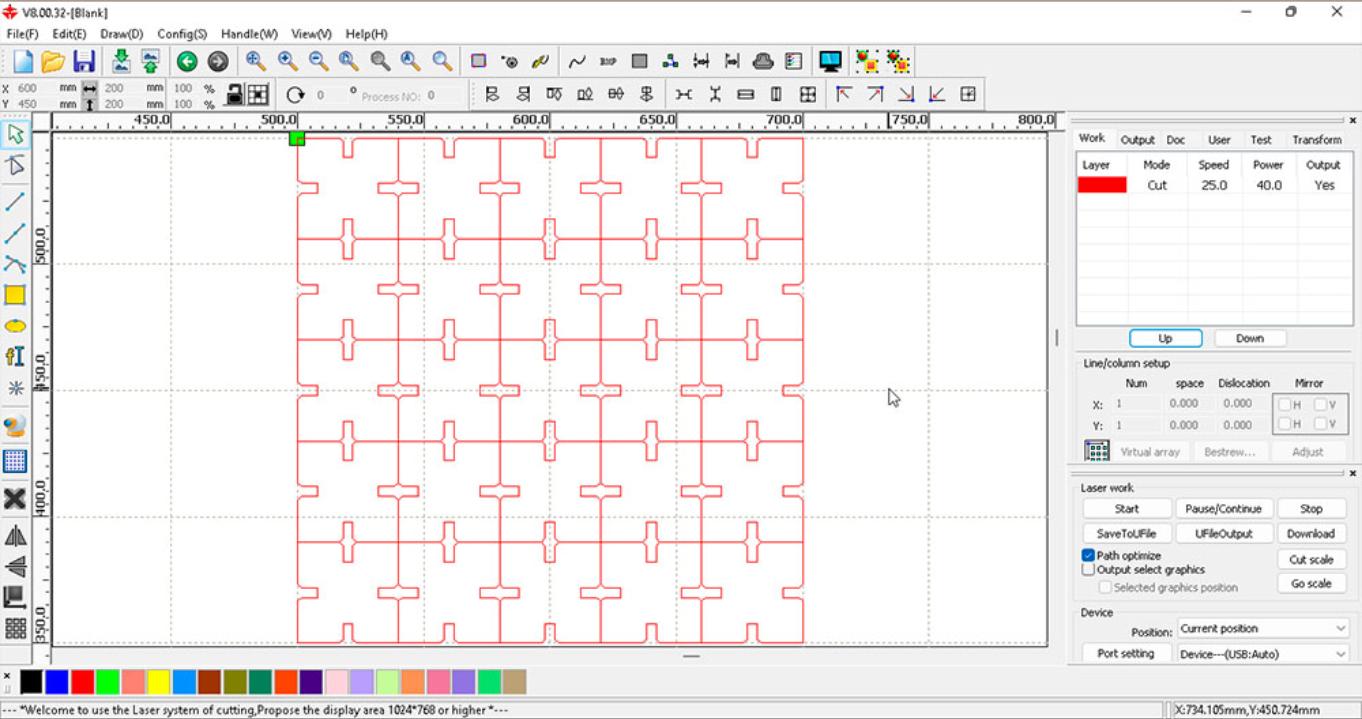

Design of a parametric square using rhinoceros + grasshopper and .DXF export file

I use RDWorks to set up the cutting on the laser machine

Cutting process with the laser cutting machine

setup cut process, speed:25mm/s and power:40%

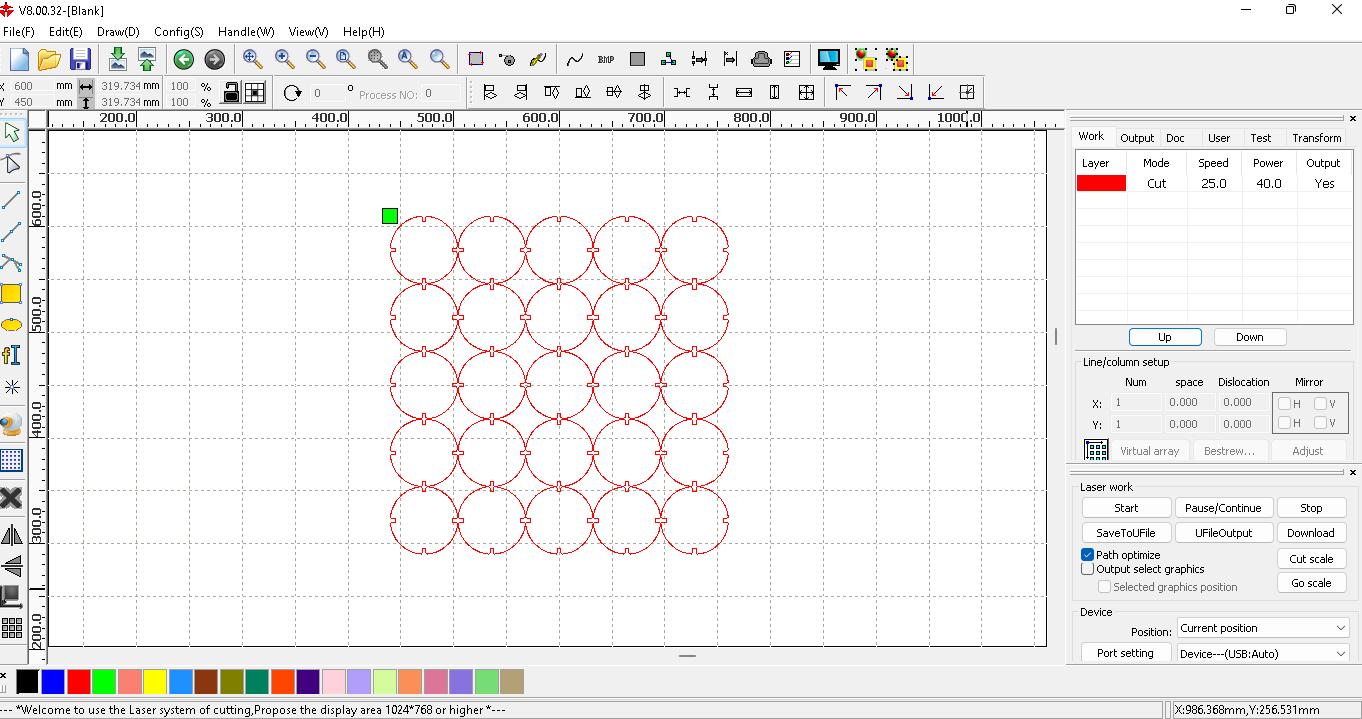

Design of a parametric circle using rhinoceros + grasshopper and .DXF export file

I use RDWorks to set up the cutting on the laser machine

Cutting process with the laser cutting machine

setup cut process, speed:25mm/s and power:40%

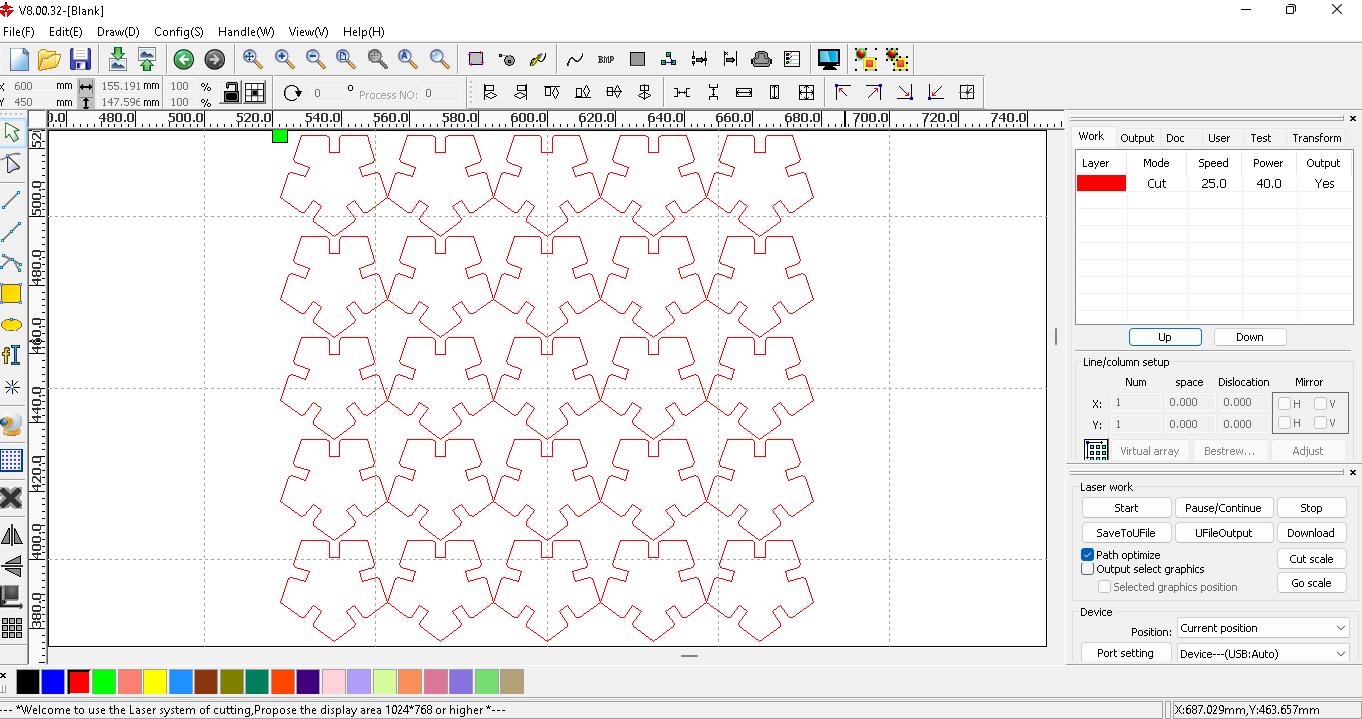

Design of a parametric pentagon using rhinoceros + grasshopper and .DXF export file

I use RDWorks to set up the cutting on the laser machine

Cutting process with the laser cutting machine

setup cut process, speed:25mm/s and power:40%

Kit result

final result: an animal shape

Download files

Here we can find and download the design original files