Table of Contents

- What will it do?

- Who's done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will they come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

- Project Incorporation Requirements

- Making vs. Buying

- Future Scope

Applications and Implications

Project Development

Applications and Implications

What will it do?

The Aqua Sense smartwatch is designed for swimmers to enhance their training and performance. It will:

1. Allow users to set target time via a dedicated app.

2. Provide real-time data updates on speed, time, and lap counts during swimming.

3. Monitor and track speed and time, counting the number of laps completed.

4. Send vibration alerts if the swimmer’s time has elapsed

5. Use RGB LEDs to change colors based on the swimmer’s performance, providing visual feedback.

Who's done what beforehand?

Previous developments in the field include standard fitness and swimming watches by companies like Garmin and Apple, which track swimming metrics.

What will you design?

1. A waterproof watch case, with strap and a charger.

2. PCB design of electronic components within the watch.

3. Custom firmware for the microcontroller to process sensor data and communicate with the app.

4. A smartphone app interface for setting targets and displaying real-time data.

What materials and components will be used?

| SL No | Material | Amount | Place of Procurement |

|---|---|---|---|

| 1 | Seeed XIAO nRF52840 Sense | ₹1,899.00 | Lab |

| 2 | 0.96 Inch I2C/IIC 4-Pin OLED Display Module | ₹162.00 | Lab |

| 3 | 40 mAh 3.7V single cell Rechargeable LiPo Battery | ₹119.00 | Penta Menaka |

| 4 | LED RGB CLEAR 4PLCC SMD | ₹19.00 | Lab |

| 5 | Coin vibration motor | ₹100.00 | Penta Menaka |

| 6 | eSun ePLA+HS 3D Printing Filament- 1.75mm White | ₹299.00 (3 hours) | Lab |

| 7 | 3D Printing Filament Black PLA | ₹199.00 (2 hours) | Lab |

| 8 | SeSun eTPU-95A 3D Printing Filament-Transparent Purple | ₹99.00 (1 hour) | Lab |

| 9 | M2 nut and bolt x 20mm | ₹200 | Lab |

| 10 | 3mm Waterproof Rubber Sheet | ₹50 | Lab |

| Total | ₹3,146.00 | ||

| Personal Expenses | ₹220.00 | ||

Where will they come from?

Almost all materials and components are available at the lab. The only components I have to purchase explicitly is the battery and the motor. I have procured them from Penta Menaka Shopping Complex, Marine Drive, Kochi. It is a popular mall for all mobile electronics and accessories.

How much will they cost?

| Total | ₹3,146.00 | ||

| Personal Expenses | ₹220.00 |

What parts and systems will be made?

The watch case will be 3D printed.

The electronic system will include the microcontroller, display, battery, LED, and vibration motor.

Custom firmware will be developed for the microcontroller.

A smartphone app will be created to interface with the watch.

What processes will be used?

2D and 3D Design: CAD software for the watch case and component layout.

Additive Fabrication: 3D printing the watch case.

Subtractive Fabrication: Laser Cutting Display glass, Vinyl cutting display sticker, Digital cutting watch strap

Electronics Design and Production: Soldering and assembling electronic components.

Embedded Microcontroller Programming: Writing firmware for the Seeed XIAO nRF52840.

System Integration and Packaging: Assembling all parts into a final product.

What questions need to be answered?

How accurate are the sensor readings in different swimming conditions?

How effective is the waterproofing of the watch case?

How reliable is the BLE connection between the watch and the app?

Can the battery life sustain long swimming sessions?

How intuitive and user-friendly is the app interface?

How will it be evaluated?

Accuracy and reliability of data tracking (speed, time, laps).

Responsiveness and effectiveness of vibration and LED feedback.

Durability and waterproofing of the watch case.

User experience with the app for setting targets and viewing data.

Overall integration and functionality of the smartwatch.

Project Incorporation Requirements

2D and 3D Design: Design the watch case and component layout.

Additive Fabrication: 3D printing the watch case using TPU material.

Subtractive Fabrication: Laser Cutting Display glass, Vinyl cutting display sticker, Digital cutting watch strap.

Electronics Design and Production: Soldering and integrating components.

Embedded Microcontroller Interfacing and Programming: Custom firmware development.

System Integration and Packaging: Assembling and packaging the final product.

Making vs. Buying

All parts of the watch are going to be made using the production processes mentioned above.

Future Scope

I aim to commercialise this project by building upon the prototypes and add more features such as to use it for different sports modes such as running, walking etc.

Project Development

What tasks have been completed, and what tasks remain?

1. Programming to count the number of strokes

✔️

2. Programming to count the number of laps, speed and time

✔️

3. Procurement of all components

✔️

4. Footprint design for side button

✔️

5. TinyML implementation

✔️

6. Schematic and PCB Design

✔️

7. Case design and System integration

✔️

8. 3D printing the Case❌

9. PCB Milling and Soldering❌

10. Waterproofing❌

11. Programming❌

12. Bluetooth communication with the app❌

13. Strap making❌

14. Charger making❌

What's working? What's not?

1. Programming to count number if strokes and thereby count the number of laps and calculate the speed and time taken for each lap has been obtained.

The number of strokes has accuracy of 70% and should be worked upon.

2. Implemented TinyML for gesture movements of the wrist as yes or no. It was found to be inaccurate and although it could be improved upon by increasing the data set samples, the time taken to predict was too much.

Therefore the plan of implementing TinyML so that I could map out the time taken for different strokes were ruled out.

3. Since I'm using 3.7V LiPo battery, I had to refer the datasheet of NeoPixel LEDs and I discovered it wouldn't work because of insufficient voltage.

So, I switched to LED RGB 4PLCC SMD.

4. I designed the PCB with the custom footprint of the button I had designed but while case designing and system integration I realised the difficulty of waterproofing the button.

Therefore I decided to program tapping interrupts to control the watch.

5. The watch display I had bought i.e. the Seeed Studio 1.28-inch Round Touch Display for XIAO and the IMU in XIAO NRF52840 can't work simultaneously. Therefore I am bound to use OLED display for my watch screen.

6. The hollow cup vibration motor I had purchased turned out to be much bigger than I anticipated and therefore I had to purchase the coin vibration motor for smaller packaging.

7. However irrelevant to this context, I had named the watch Aqua Sense but due to the size limitations of the PCB, I had to choose a

smaller name to mill. Upon discussion with my FAB mates, ChatGPT and Gemini and came to the name DOLFIN.

What questions need to be resolved?

1. Waterproofing of the watch is still under discussion. For now the plan is to have print the watch case in two parts and print the casket in flexible resin, and use screws to tighten the gap.

For the transparency of the display, the top part will be printed with transparent filament.

2. To make waterproofing easier, button and USB port has to removed. But the alternate solution has to be discussed and tested.

Button problem may be resolved by tap interrupts however untested that is. USB port for charging maybe replaced by POGO pins but the suitable pins from the microcontroller has to be found out by refering its datasheet.

3. BLE connection while swimming has to be discussed.

4. For long-life of the battery, the implementation of deep sleep mode must be tested.

5. Development of the App

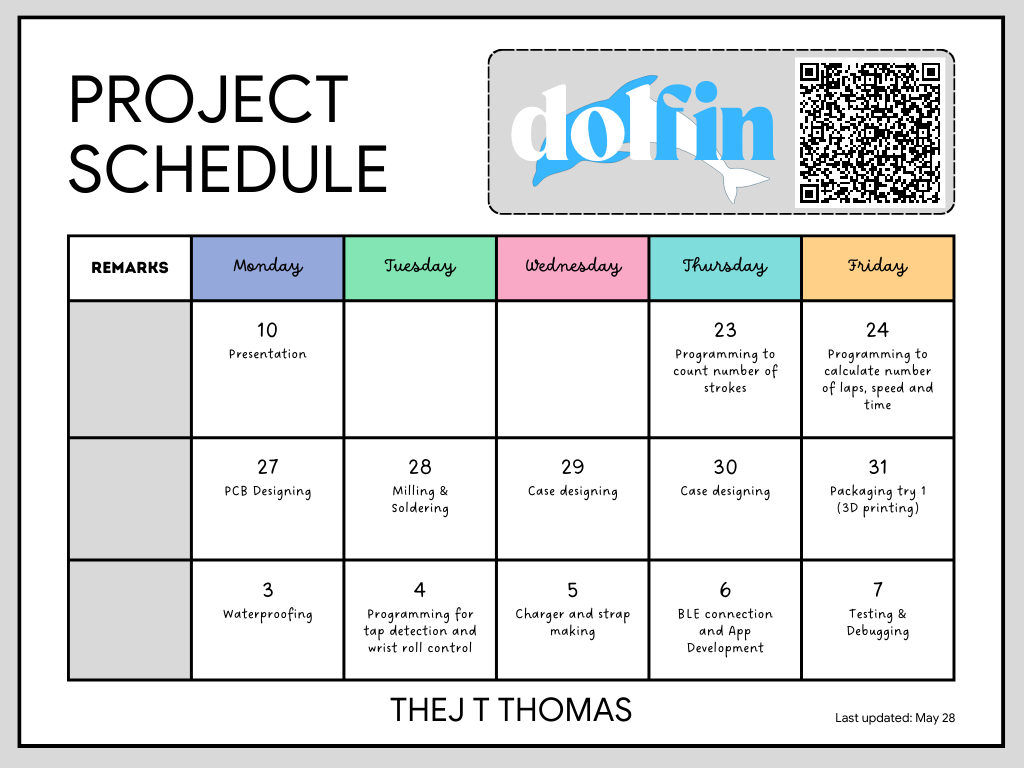

What will happen when?

What have you learned?

Since watch requires the minimum packaging and size possible, I had to tone down my expected features and the its functionality. Not only this, waterproofing of the watch comes with immense challenges of cutting down button and USB charging abilities of the watch. However thanks of my instructors I was able to come upto a satisfiable functions and pleasant design of the watch. There are much more unresolved problems but I have the confidence to overcome them through this journey.