System Integration

Objectives for Week 16

- Design and document the system integration for the final project

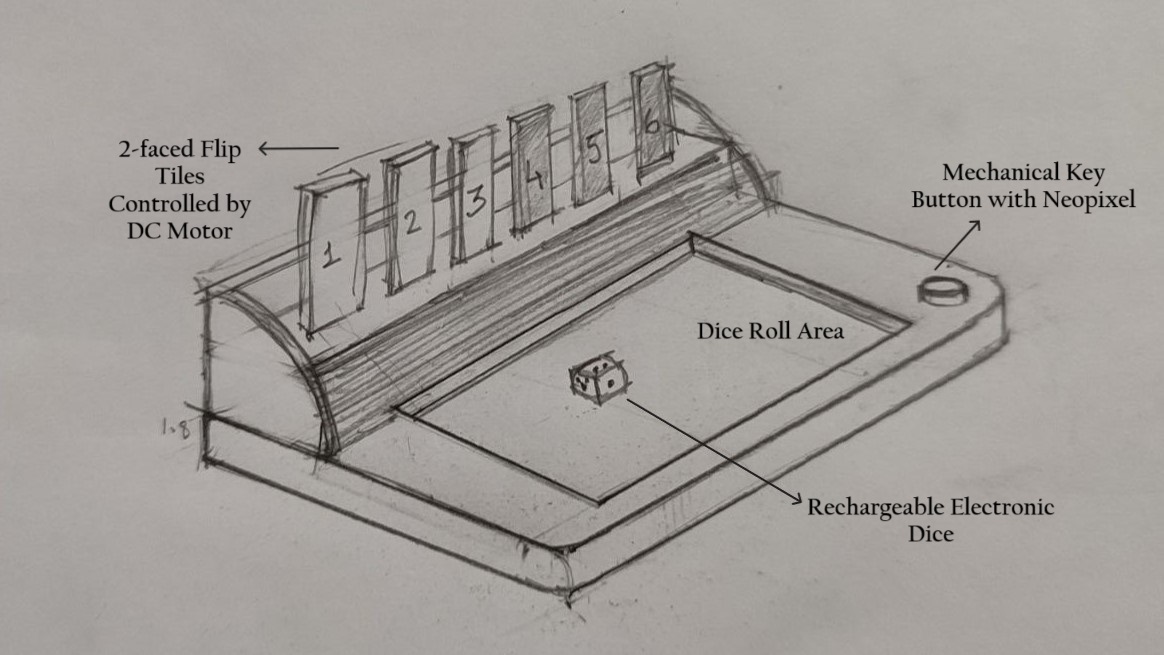

This week was quite challenging/confusing. I exactly don't know how to explain. As I'm getting closer to the final project presentation, I have started getting jittery. Throughout the previous weeks, I hadn't started my final project, only just some of the input and output devices were used. Since, I had changed my project in between, first thing I did was to create a sketch. Kalyani, my fellow fab mate, helped me during this process.

Right after sketching, as instructed by my instructor, Saheen, I listed out the highlighted features of my project as well as its possible production methods.

Features

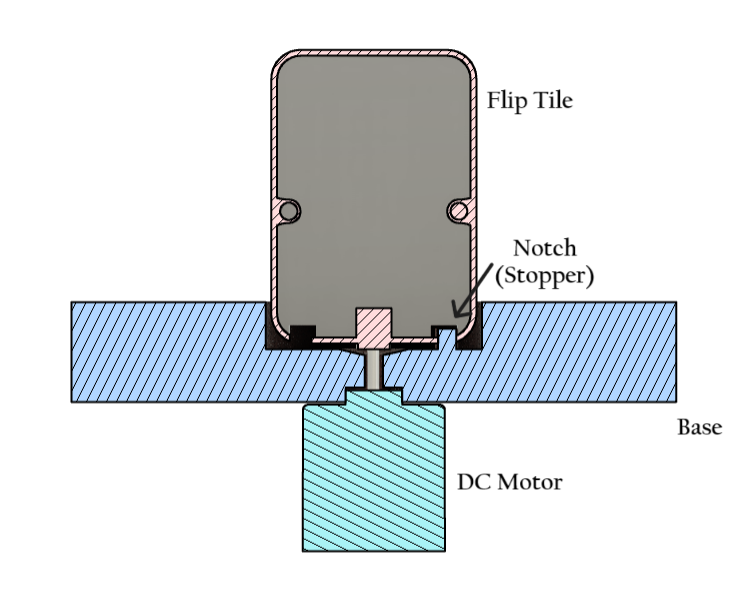

• Flip Tiles

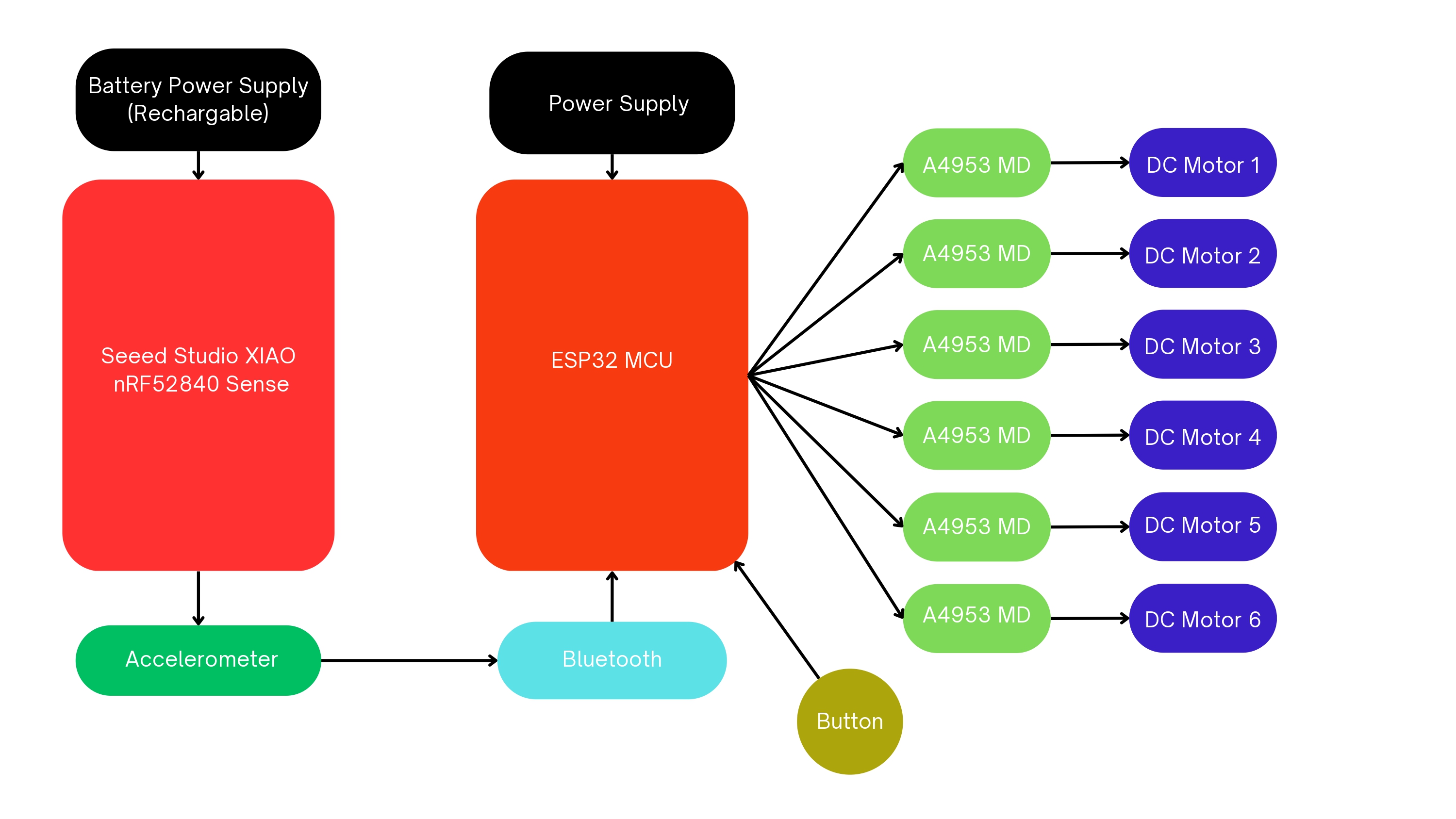

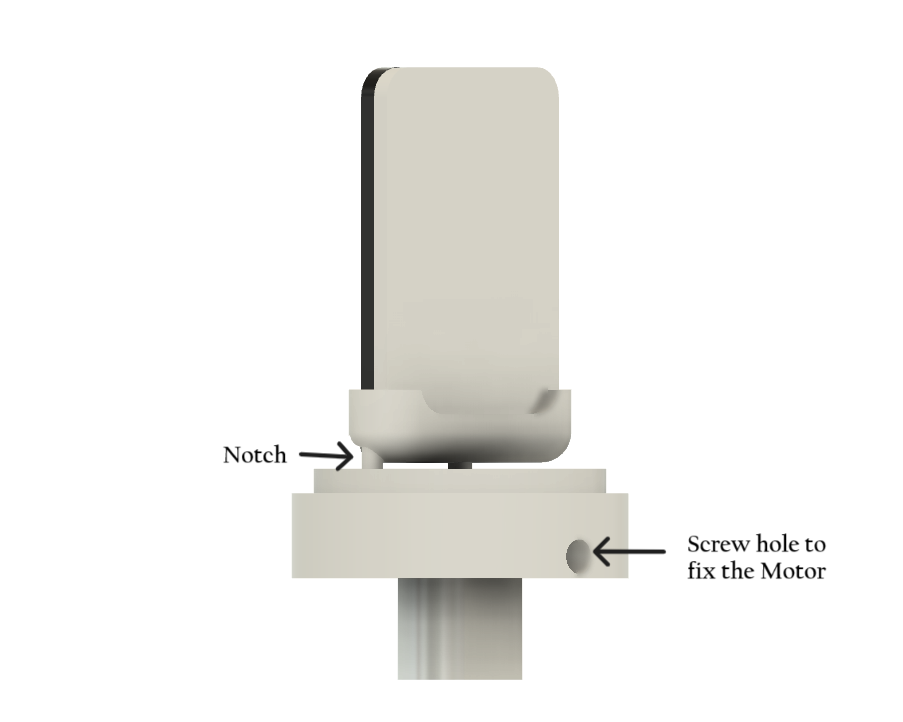

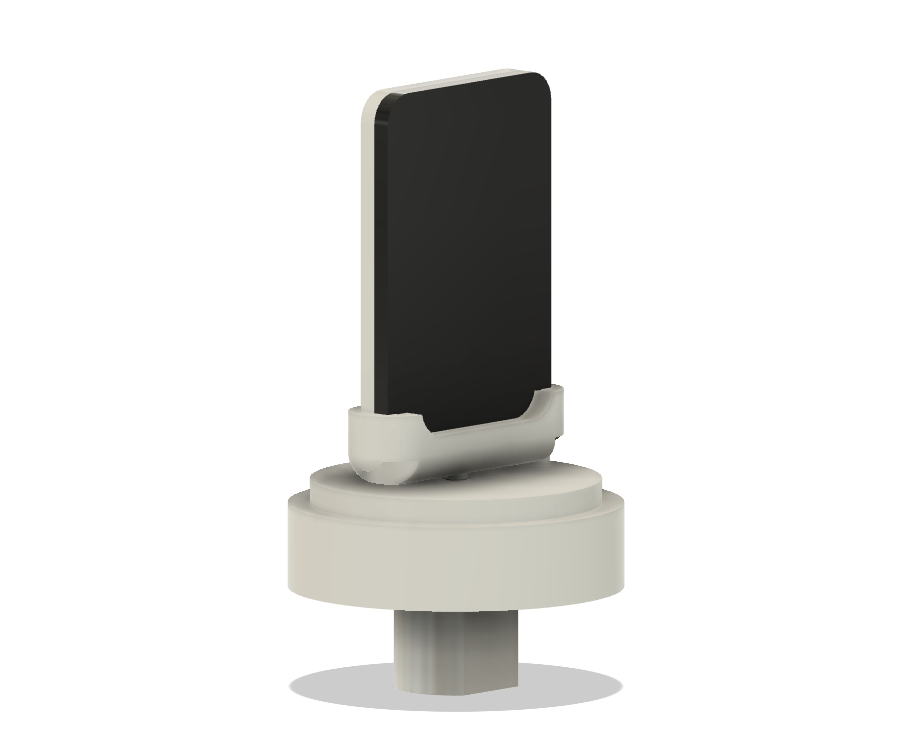

Two-faced tiles numbered from 1 to 6. The tiles are flipped using DC Motors. There will be 6 DC Motors connected to each tiles. This week I designed one module for testing the DC Motor limiting. A notch is provided on the base to stop the motor. The motor will turn 180° clockwise and counter-clockwise for the flipping action. Each DC Motor is controlled by A4953 motor driver in ESP32 WROOM 32E Microcontroller board.

• Dice

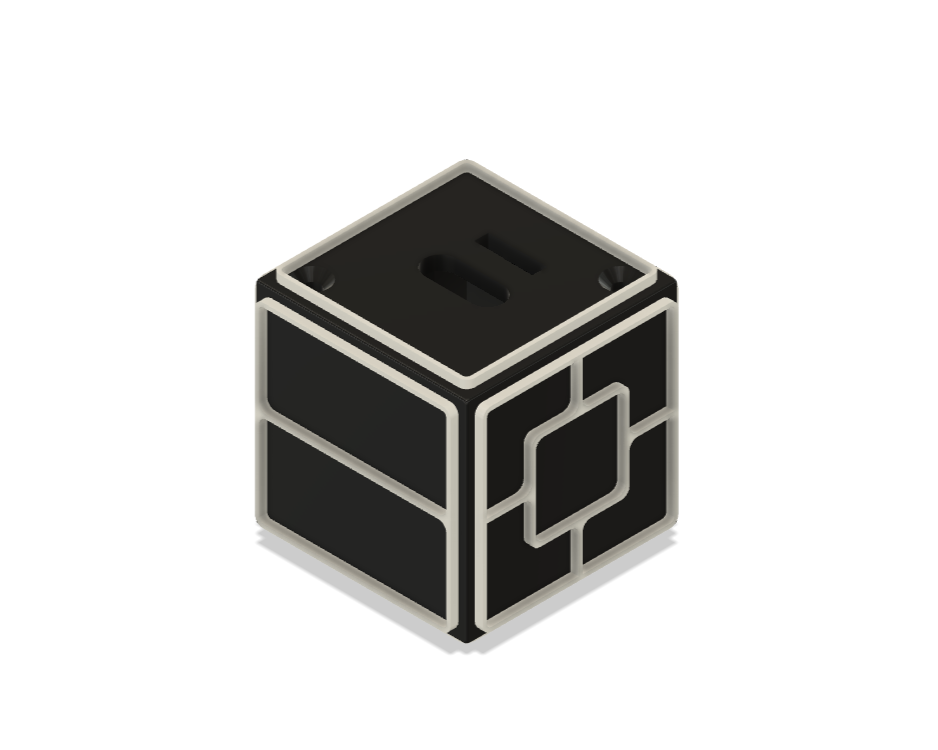

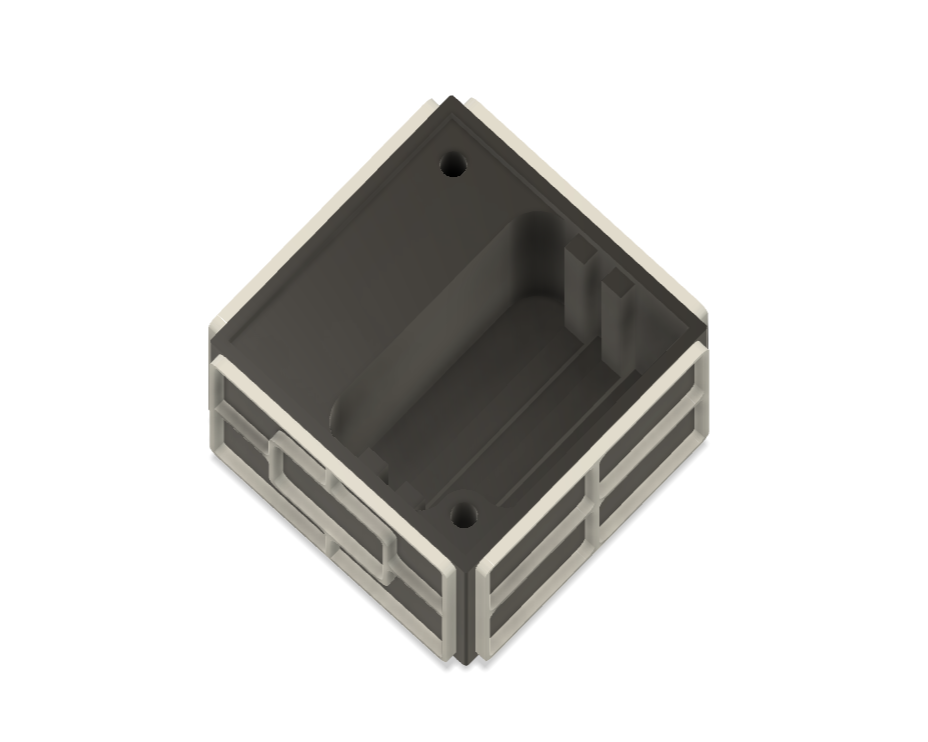

The dice is equipped with XIAO nRF52840 Sense and a rechargable battery. The Seeed Studio nRF52840 Sense features a 6-axis inertial measurement unit (IMU), specifically the LSM6DS3, which combines a 3-axis gyroscope and a 3-axis accelerometer. I use the accelerometer to determine the orientation of the die and send the data to the other board via bluetooth to run the corresponding motor to flip the tile.

• Button

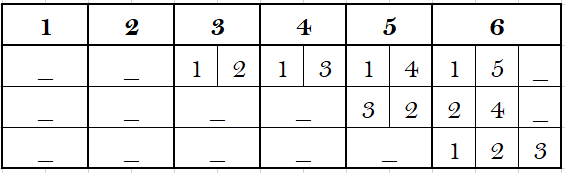

A Mechanical keyboard switch will be provided as a button so that it shows different possible combination for each die roll (if). Below image shows the different possible combinations. By pressing on the button it shows the next combination by flipping the respective tiles if available and if finalized on the combination all you have do is to lift the dice.

Production Method

- Laser Cutting: Cutting all the 6 tiles (Black and White 3mm thickness acrylic sheets), front panel (White 6mm thickness acrylic sheet), side panels (White 6mm thickness acrylic sheet) and back panel (Black 6mm thickness acrylic sheet) using Trotec Speedy 400 flexx.

- Wood CNC Milling: Milling plywood for the enclosure using Zund.

- PCB Milling and Soldering: Generate the PCBs required for the project using Roland Modela MDX20

- Designing: 3D designing of the final project using Autodesk Fusion.

- 3D Printing: 3D printing the holders, base using Prusa i3 MK3 and dice using Bambu Labs.

- Vinyl Cutting: Vinyl cutting black stickers for Dice using Roland GX-24 Camm-1 Servo.

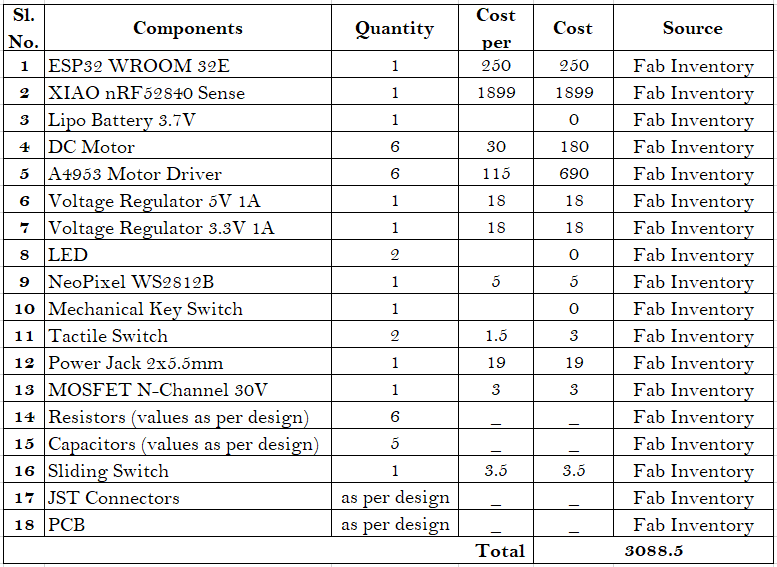

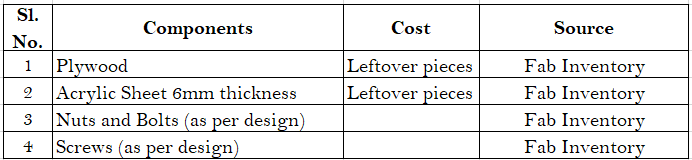

Bill of Material

• Material List

• Electrical and Electronics Components