Week 16: APPLICATIONS AND IMPLICATIONS

1. What will it do?

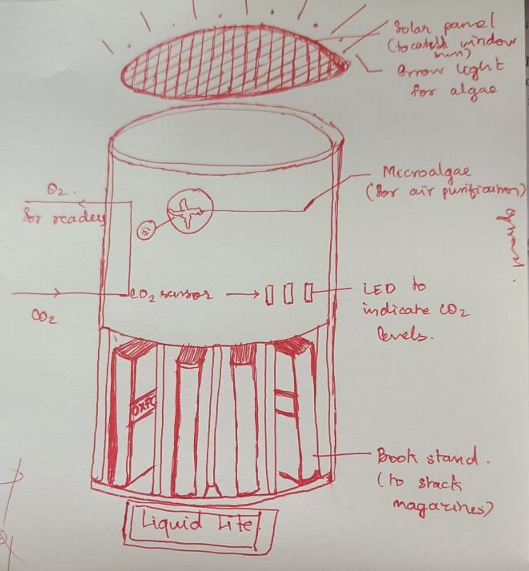

The "Breathing Library - Swasa" project is designed to be a multifunctional, sustainable installation that integrates various features beneficial to a library environment. It will act as a bookshelf, provide a relaxing reading light, purify the air, facilitate CO2 removal, offer a community reading spot, and produce algal protein feed. Additionally, it will incorporate advanced manufacturing and monitoring techniques such as 3D printing, CNC machining, laser cutting, electronics production, Web UI, and real-time monitoring.

2. Who's done what beforehand?

There have been various initiatives and projects focusing on integrating sustainable technologies into community spaces. Examples include:

- Urban vertical gardens for air purification and CO2 removal.

- Multifunctional furniture designs for public spaces.

- Community-focused projects that combine technology and sustainability, such as smart libraries and green buildings.

- Fab lab projects incorporating 3D printing, CNC machining, and electronics production for educational and practical applications.

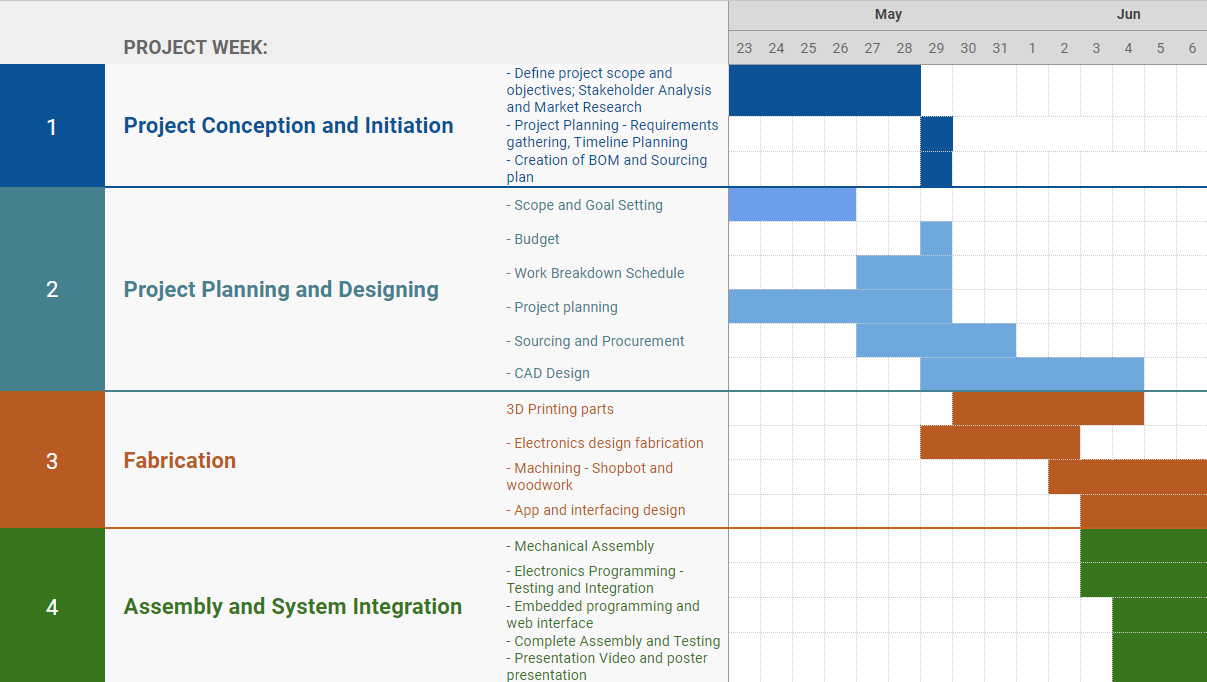

Specific example that inspired me to work on this project is Liquid tree from Serbia.

It’s a living product design that becomes an oxygen source for the environment and a community installation that can be utilized by people. I wanted to create a community installation that’s good for the environment and a living product design.

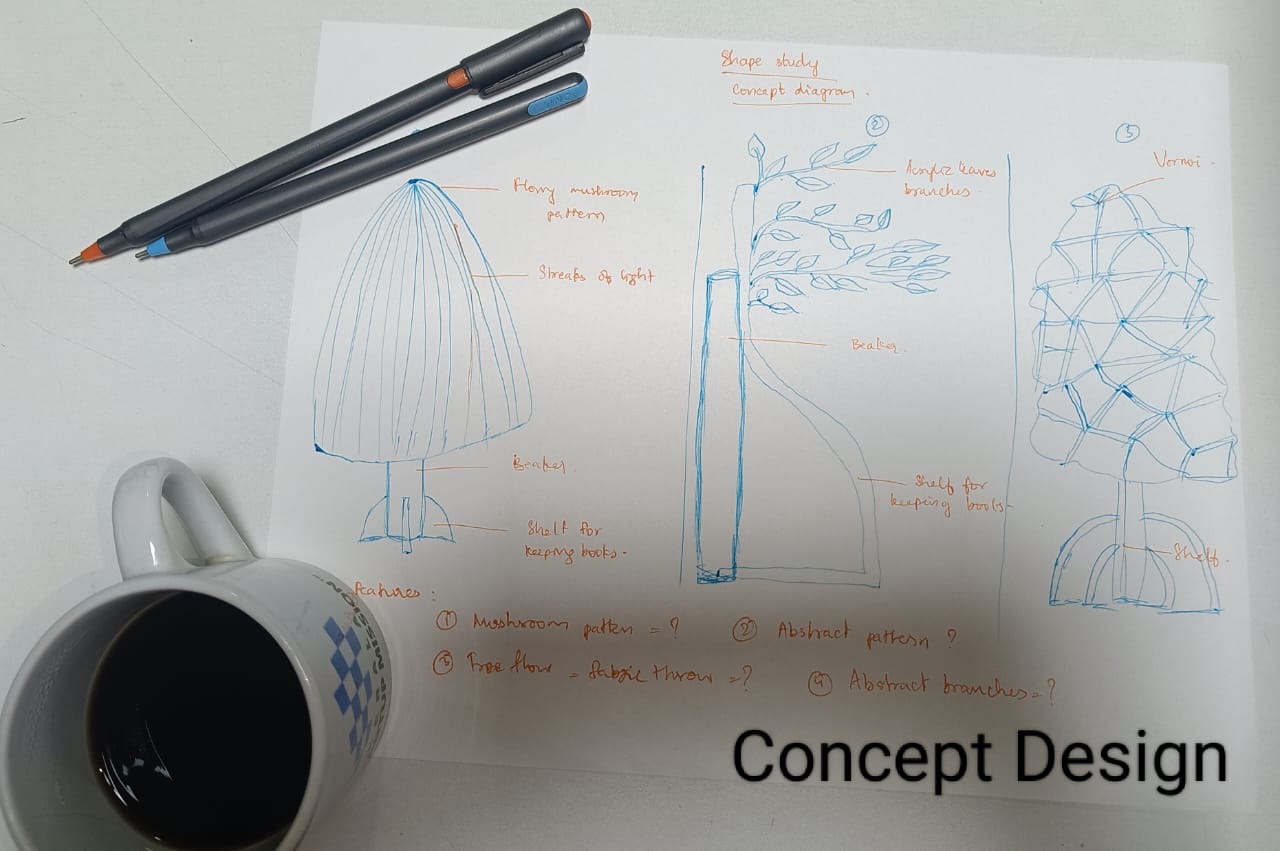

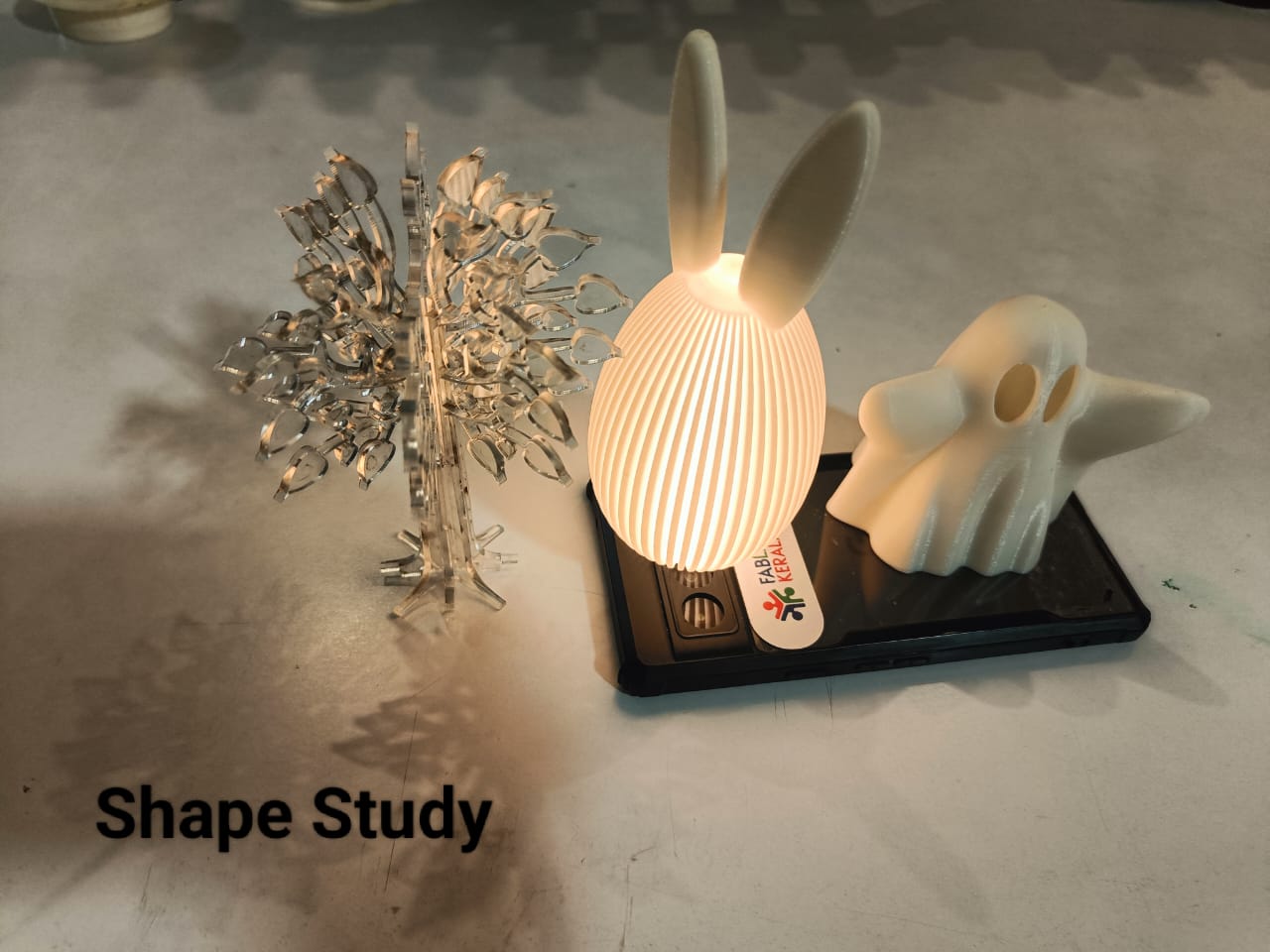

3. What will I design?

The design will include:

- A bookshelf structure that also acts as a reading light.

- An air purifier integrated with CO2 removal capabilities.

- A structure to grow algae for protein feed.

- A community reading spot with embedded electronics for monitoring air quality and other parameters.

- Aesthetic and functional design elements using 3D printing and CNC machining.

4. What materials and components will be used?

Materials and components will include:

- Biodegradable and recycled materials for 3D printing (e.g., PLA filament).

- Wood and acrylic for CNC machining and laser cutting.

- Electronic components such as sensors, microcontrollers (e.g., ESP32), and LEDs.

- Algal growth medium and containers.

- Components for air purification (e.g., activated carbon filters).

5. Where will they come from?

- Filament for 3D printing can be sourced from local suppliers or online stores.

- Wood and acrylic sheets can be purchased from hardware stores or specialized suppliers.

- Electronic components can be sourced from electronics stores or online platforms like Mouser, Digikey, or Seeed Studio.

- Algal growth materials can be sourced from scientific supply companies.

| Material/Component | Source | Example Suppliers |

| Filament for 3D Printing | Local suppliers, online stores | Amazon, MatterHackers, 3D Prima |

| Wood Sheets | Hardware stores, specialized suppliers | Home Depot, Lowe's, Woodcraft |

| Acrylic Sheets | Hardware stores, specialized suppliers | TAP Plastics, Delvie's Plastics, Acme Plastics |

| Electronic Components | Electronics stores, online platforms | Mouser, Digikey, Seeed Studio, SparkFun, Adafruit |

| Algal Growth Materials | Scientific supply companies | Carolina Biological Supply, Fisher Scientific, Sigma-Aldrich |

6. How much will they cost?

A rough estimate of costs:

- 3D printing filament: INR 400

- Beaker - INR 600

- Wood and acrylic sheets: INR 1600

- Electronic components: INR 200

- Air purification materials: INR 300

- Algal growth materials: INR 2000

- Miscellaneous (connectors, wires, adhesives): $50

Total estimated cost: INR 700

7. What parts and systems will be made?

- The bookshelf structure with integrated reading light.

- The air purifier unit.

- The CO2 removal system with algae growth setup.

- The electronic system for monitoring and control (including Web UI).

- The structural components for the community reading spot.

8. What processes will be used?

- 2D and 3D design using CAD software.

- 3D printing for structural components.

- CNC machining and laser cutting for parts.

- Electronics design and production for sensors and microcontroller interfacing.

- Programming for embedded systems and Web UI development.

- System integration and packaging to combine all components.

9. What questions need to be answered?

- How effective will the air purification and CO2 removal systems be?

- What is the optimal design for integrating all features without compromising functionality or aesthetics?

- How will the electronics system handle real-time data monitoring and user interface?

- What are the best materials to use for durability and sustainability?

10. How will it be evaluated?

- Functionality: The project should perform all intended functions effectively.

- Integration: All components and systems should be seamlessly integrated.

- Sustainability: The project should use sustainable materials and processes.

- User Experience: The design should be user-friendly and enhance the library environment.

- Innovation: The project should demonstrate innovative use of technology and design.

Project Requirements Compliance

- 2D and 3D Design: Both will be utilized in the design of structural and aesthetic components.

- Additive and Subtractive Fabrication Processes: 3D printing (additive) and CNC machining/laser cutting (subtractive) will be used.

- Electronics Design and Production: Sensors and microcontroller interfacing will be incorporated.

- Embedded Microcontroller Interfacing and Programming: ESP32 microcontroller will be programmed for various functions.

- System Integration and Packaging: All systems will be integrated into a cohesive, functional unit.

- Make Rather Than Buy: Emphasis will be on making as many parts as possible in-house using available fab lab resources.

Sourcing Table:

| Material/Component | Source | Example Suppliers |

| Filament for 3D Printing | Fab Inventory | Fablab |

| Wood Sheets | Fab Inventory | Fablab |

| Acrylic Sheets, Cardboard | Fab Inventory | Fablab |

| Electronic Components | Electronics stores, online platforms, Fab Inventory | Thomson Electronics, Amazon, Fablab |

| Algal Growth Materials | Amazon | Amazon |

| Beaker | King’s Aquarium | King’s Aquarium |

| Aerator pump | King’s Aquarium | King’s Aquarium |

Electronics BOM:

| Reference | Value | Datasheet | Footprint | Qty |

| C1 | CP_Elec_D6.3mm_H6.1mm | https://api.pim.na.industrial.panasonic.com/file_stream/main/fileversion/19782 | fab:CP_Elec_D6.3mm_H6.1mm | 1 |

| J1,J4 | Conn_PinSocket_1x03_P2.54mm_Vertical_SMD | ~ | -- mixed values -- | 2 |

| J2,J3 | Conn_PinSocket_1x04_P2.54mm_Vertical_SMD | https://media.digikey.com/pdf/Data%20Sheets/Sullins%20PDFs/NPxCxx1KFXx-RC%2010487-D.pdf | fab:PinSocket_1x04_P2.54mm_Vertical_SMD | 2 |

| J5 | Screw_Terminal_01x03_P3.5mm | www.on-shore.com/wp-content/uploads/ED555XDS.pdf | fab:TerminalBlock_OnShore_1x03_P3.50mm_Horizontal | 1 |

| J6 | Screw_Terminal_01x02_P5mm | https://www.on-shore.com/wp-content/uploads/OSTTAXX0161.pdf | fab:TerminalBlock_OnShore_1x02_P5.00mm_Horizontal | 1 |

| M1 | Module_XIAO-ESP32C3 | https://wiki.seeedstudio.com/XIAO_ESP32C3_Getting_Started/ | fab:SeeedStudio_XIAO_ESP32C3 | 1 |

| LED | Neopixel String Lights | 1 (41 units) | ||

| S1 | MQ 135 | 1 | ||

| S2 | DHT Sensor | 1 | ||

| Power Module | Adapter | 1 |

Material and Machining BOM:

| SL NO | PART NAME | SOURCE | QUANTITY | PRICE | TOTAL |

| 1 | 3D PRINTING | FABLAB INVENTORY | 18 hrs | ₹200 | ₹3600 |

| 2 | M3 NUTS AND BOLTS | FABLAB INVENTORY | 15 | ₹5 | ₹125 |

| 3 | M4 NUTS AND BOLTS | FABLAB INVENTORY | 5 | ₹5 | ₹25 |

| 4 | PCB MILLING | FABLAB INVENTORY | .5 hrs | ₹150 | ₹75 |

| 5 | Card Board | Fablab | 1 | ₹.5 | ₹10 |

| 6 | Aquarium Cost (beaker) | Fablab | 2 | 300 | 600 |

| TOTAL | ₹4435 |

Total Project Cost:

Electronics BOM Total: ₹2000

Material and Machining BOM Total: ₹4435

Overall Total: ₹6435 INR

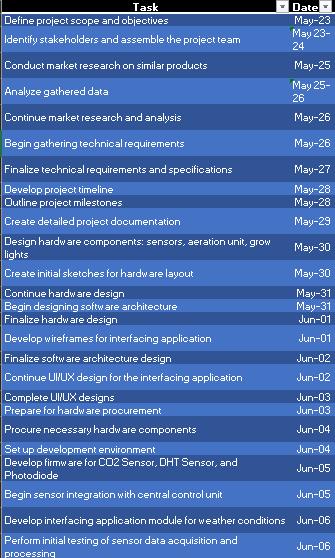

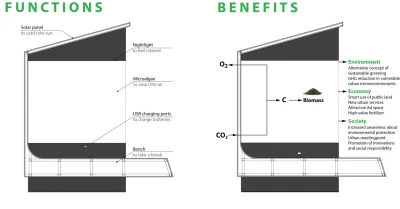

Project Plan