3. Computer controlled cutting

Overview

This transcript summarizes a lecture by Neil Gershenfeld for a digital fabrication course focused on vinyl and laser cutting tools and techniques. It provides an overview of different types of vinyl cutters, materials, and workflows for making stickers, circuits, origami, and more. The lecture then covers laser cutter safety, different laser types, optimal materials like cardboard, parametric design, press fit construction, joints for flat pack furniture, and tips for successful cutting. The group assignment involves laser safety training, characterizing material kerf, and designing a construction kit using parametric offsets. Action items relate to decorating laptops with vinyl stickers and thinking of creative ways to make laser cut kits that assemble in multiple configurations.

Assignment

group assignment:

individual assignment:

WorkFlow

vinyl cutting

Equipment specifications

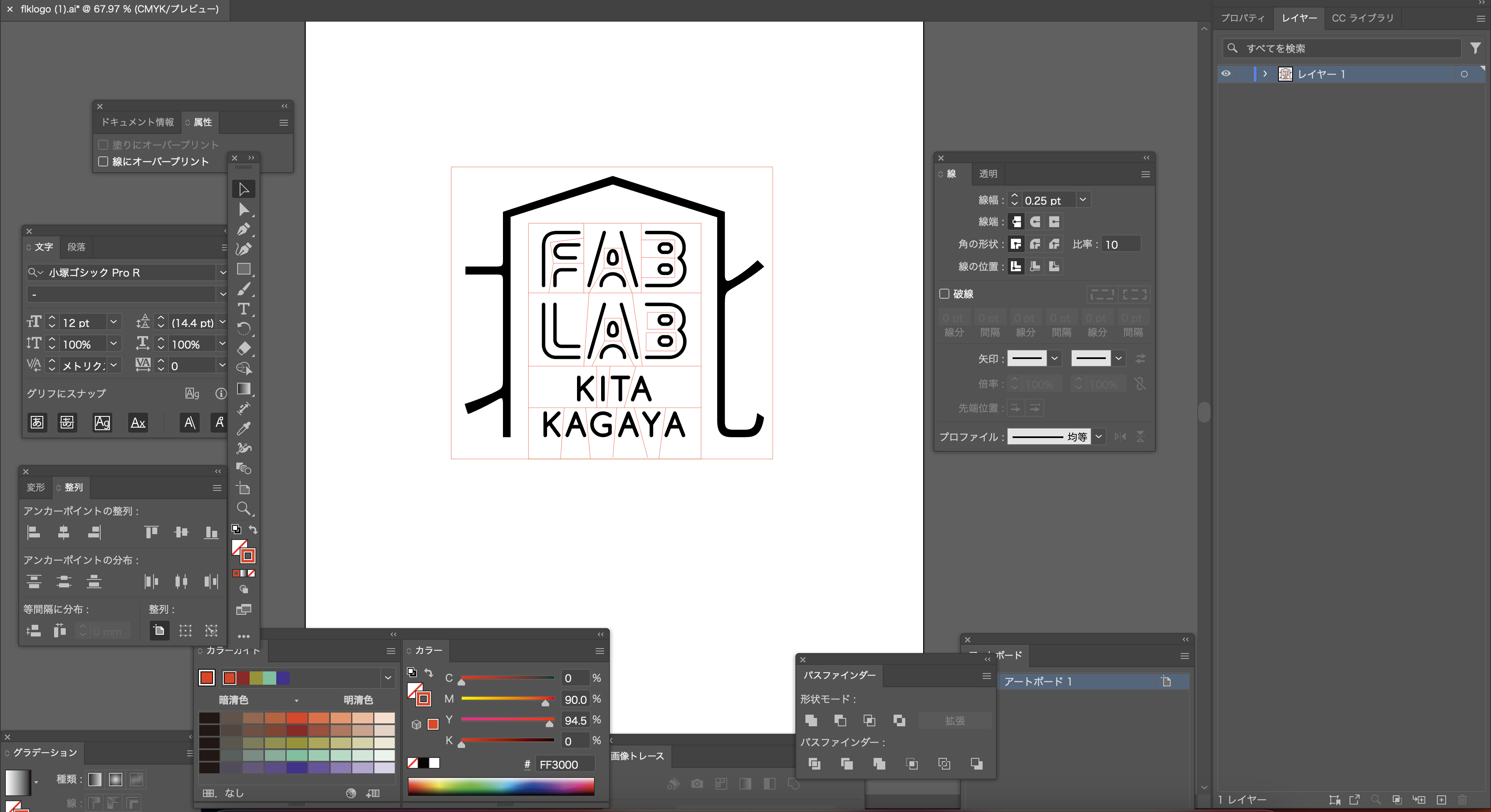

Stickers featuring the FABLAB Kitakagaya logo are desired.

Edit the data in Illustrator to make it suitable for use as a sticker.

The stickers come with a frame that facilitates their removal, making the process easier.

laser cutting

Equipment specifications

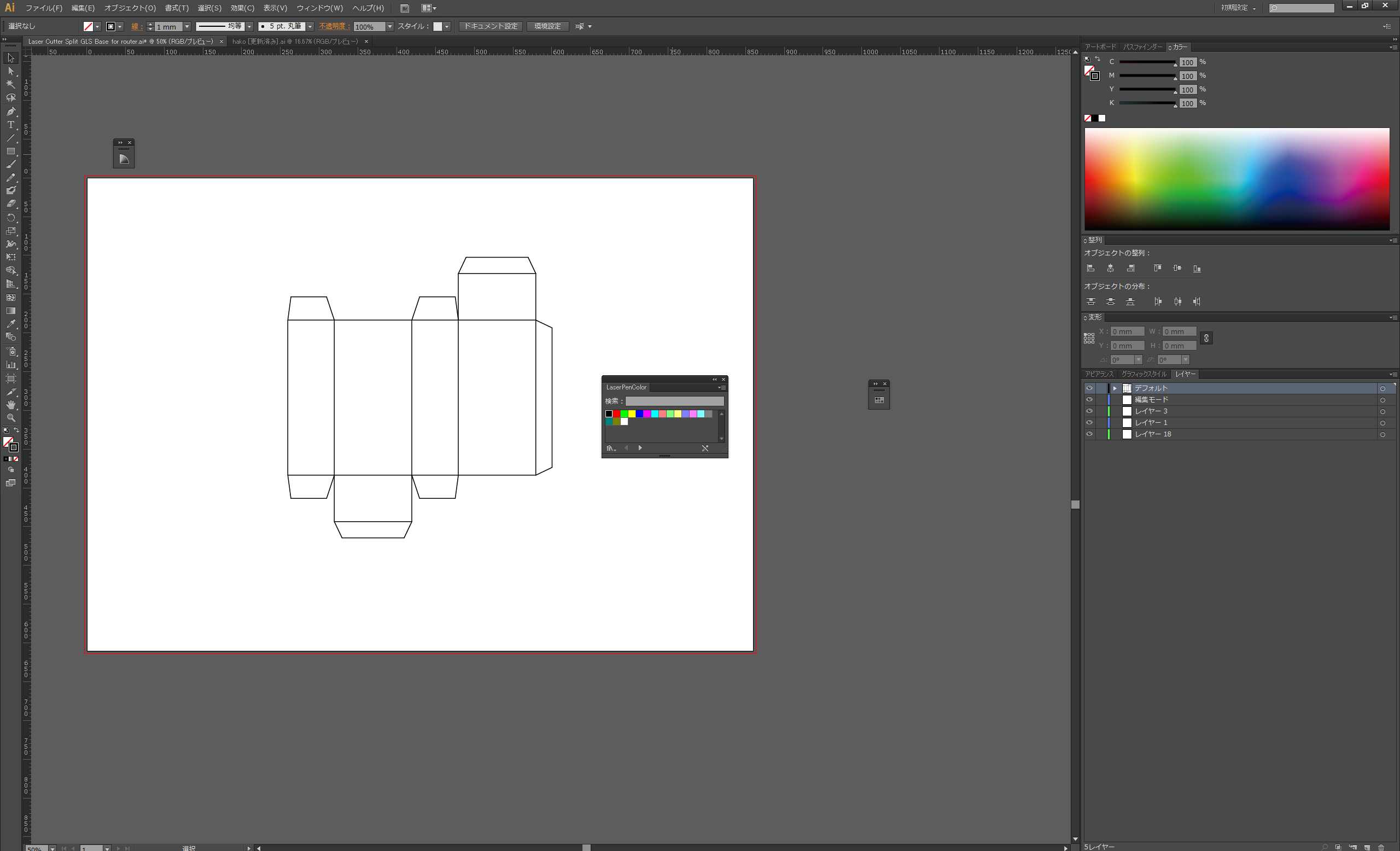

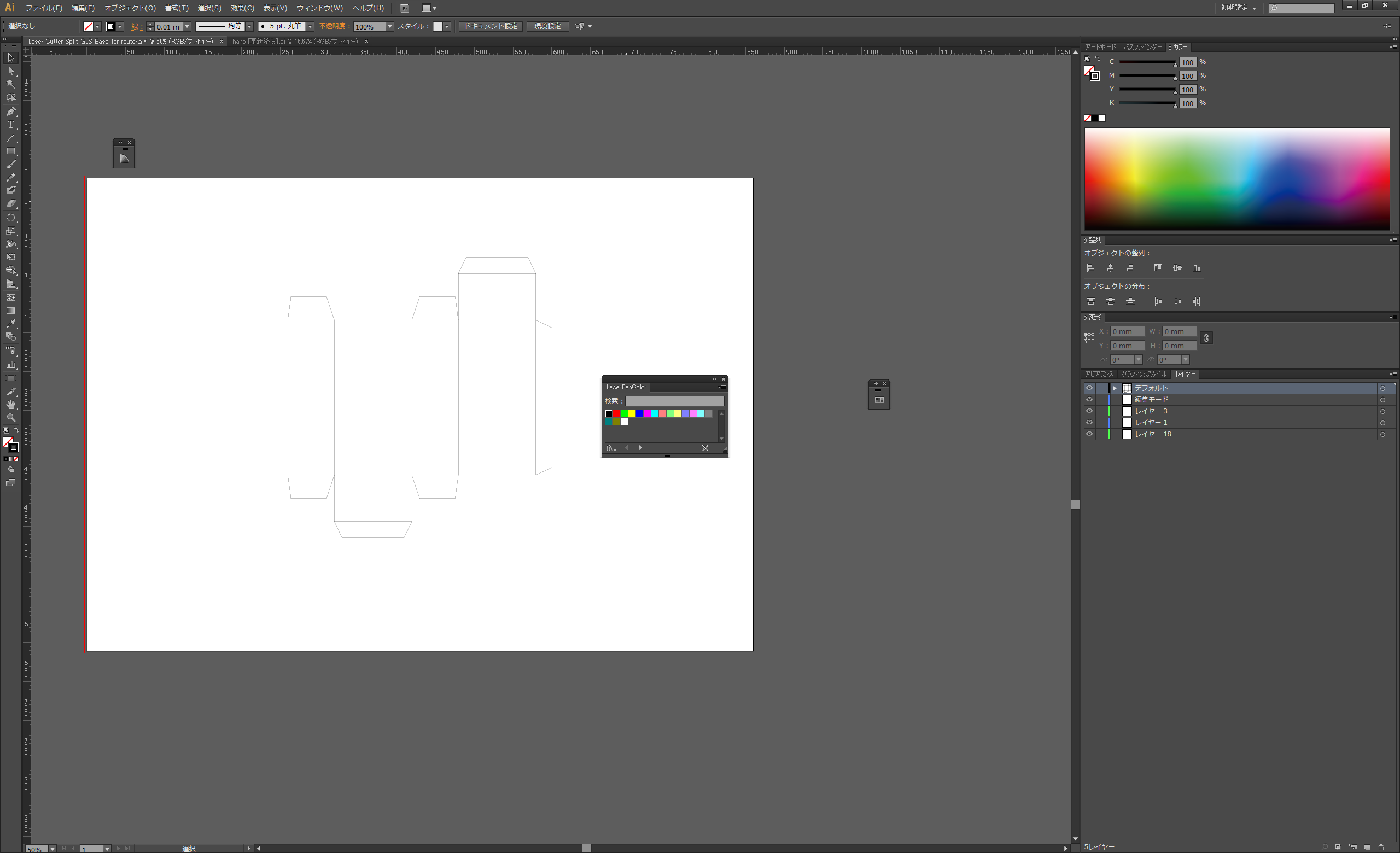

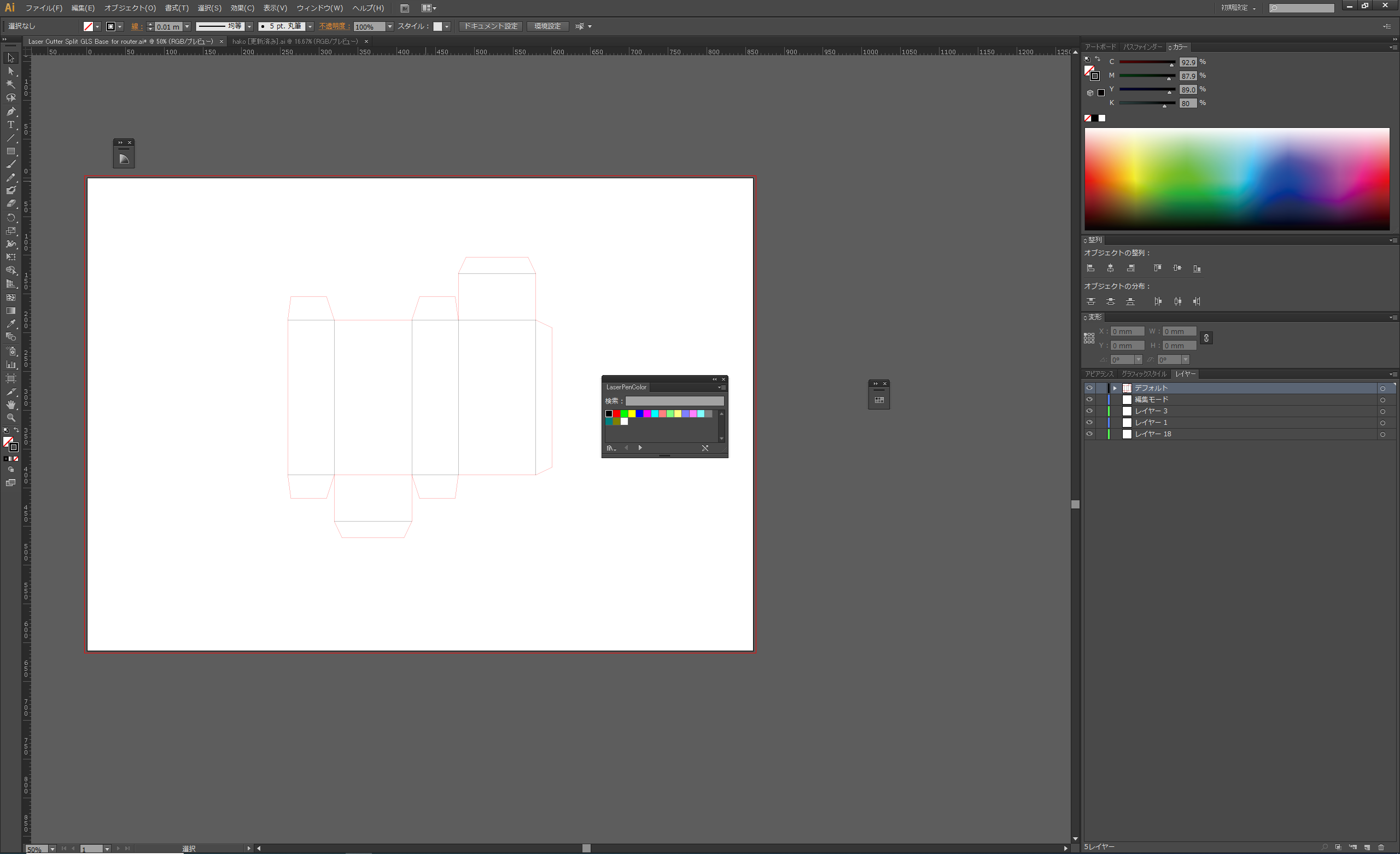

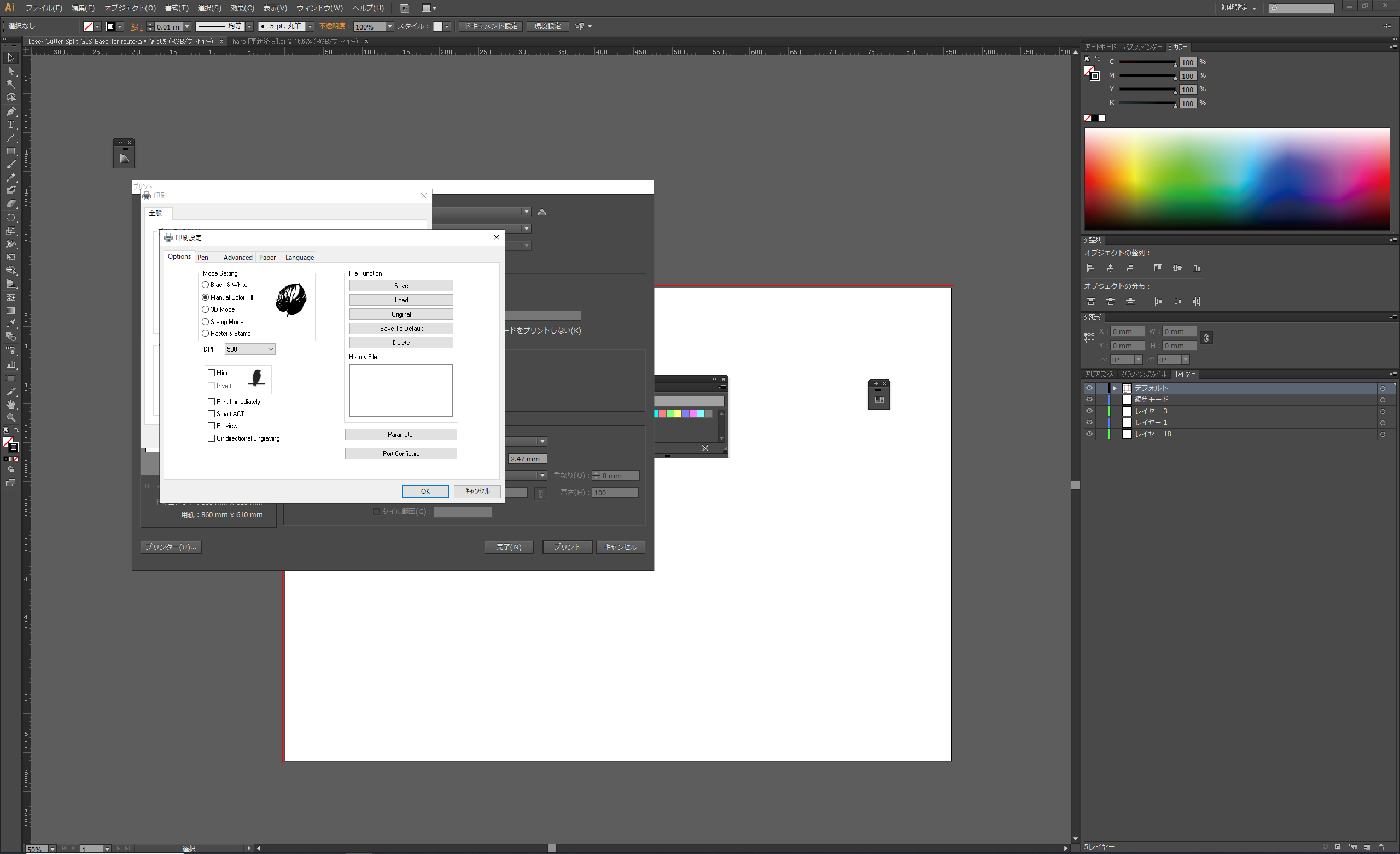

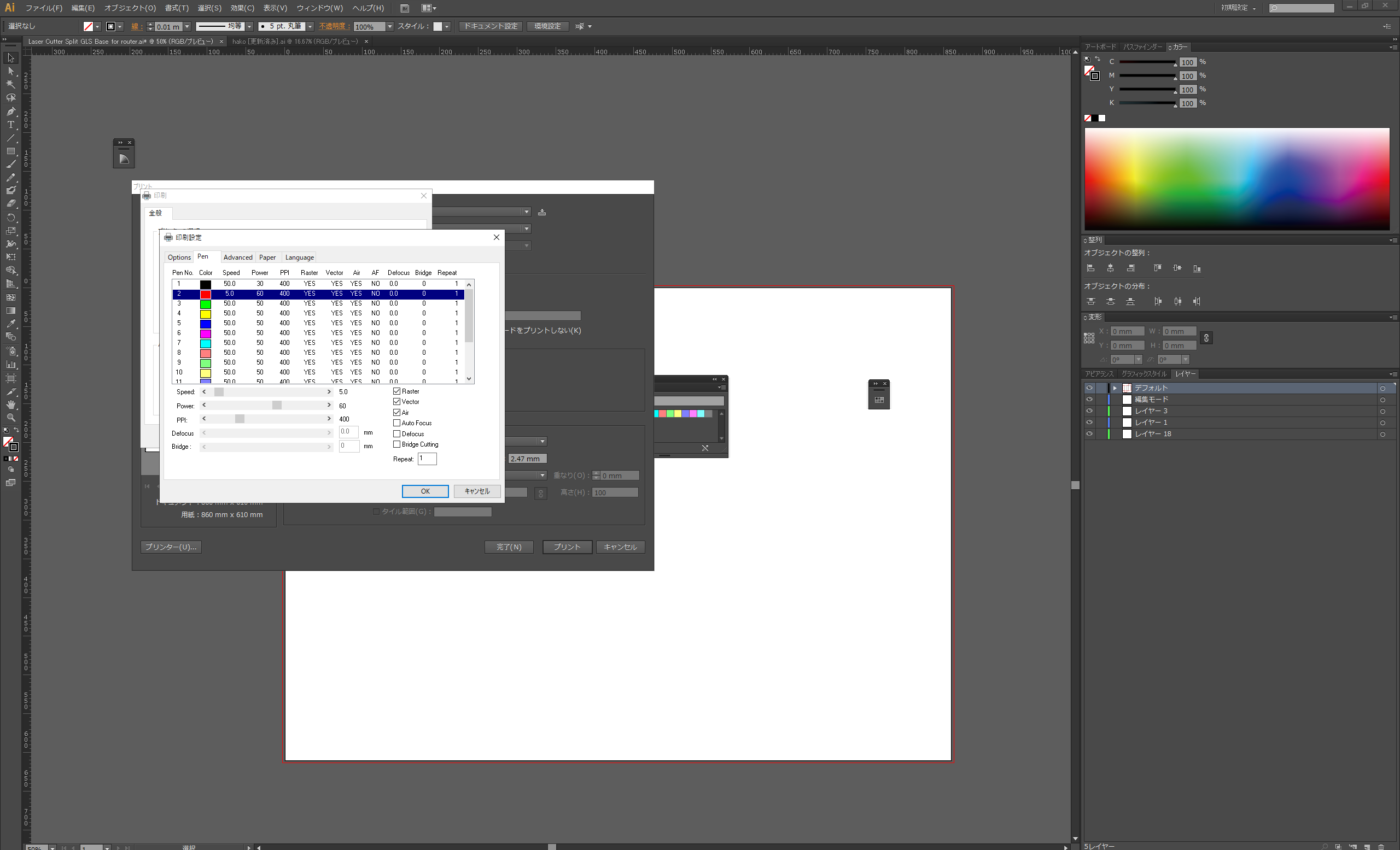

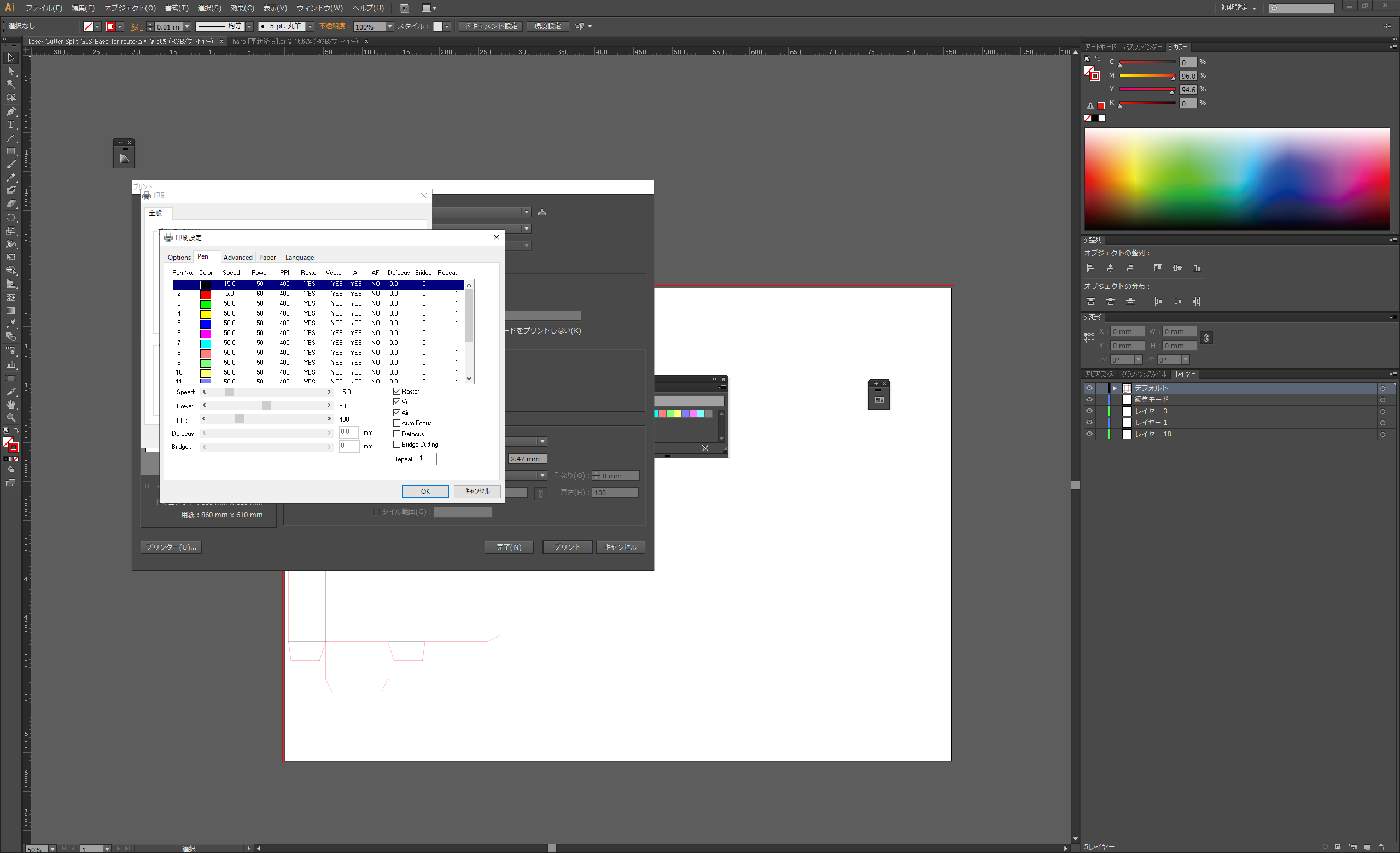

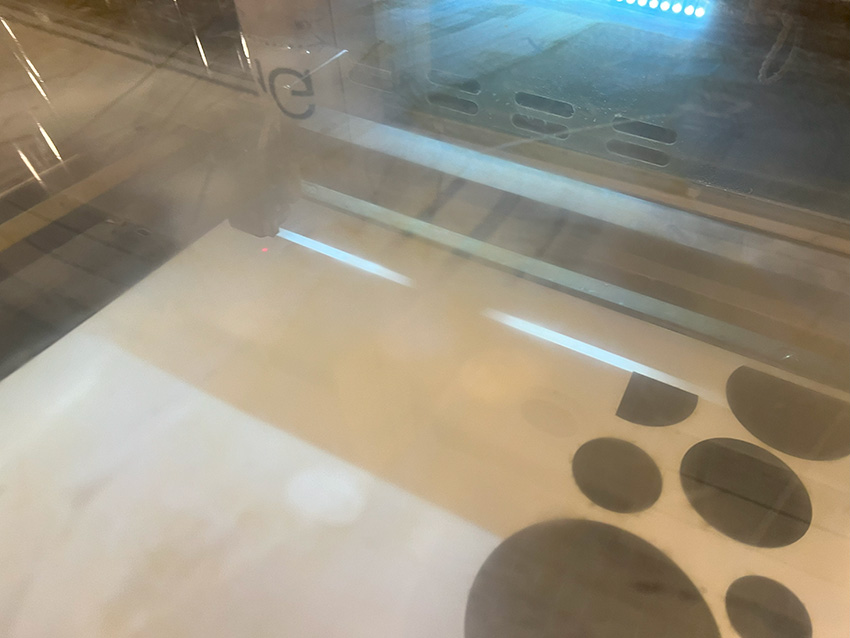

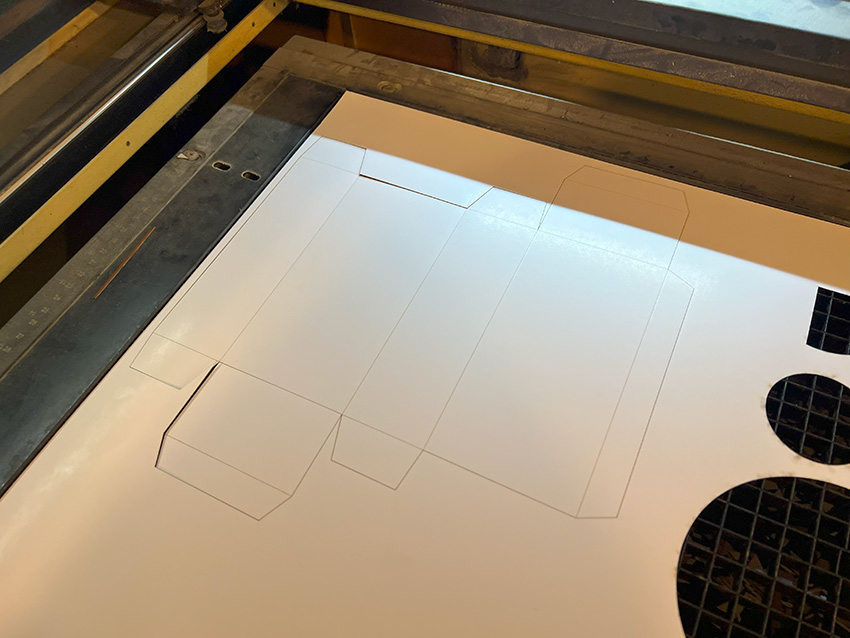

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

The laser cutter utilises CO2 to process the data from the pre-made folded box.

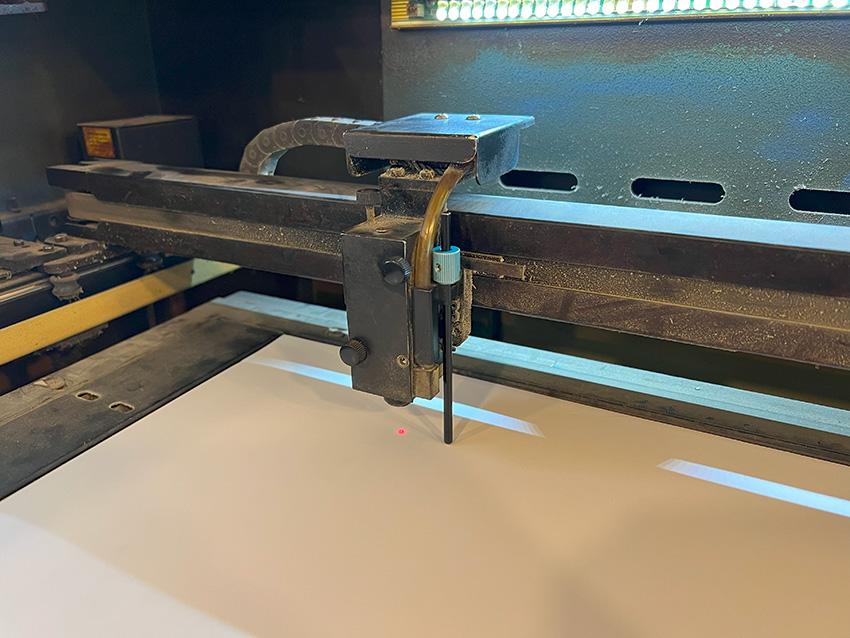

To ensure a consistent distance between the material and the laser head, adjust the focal length using the manual focus pins.

The dust collector and blower must always be switched on before laser processing.

Observe the processing progress without looking directly at the laser beam.

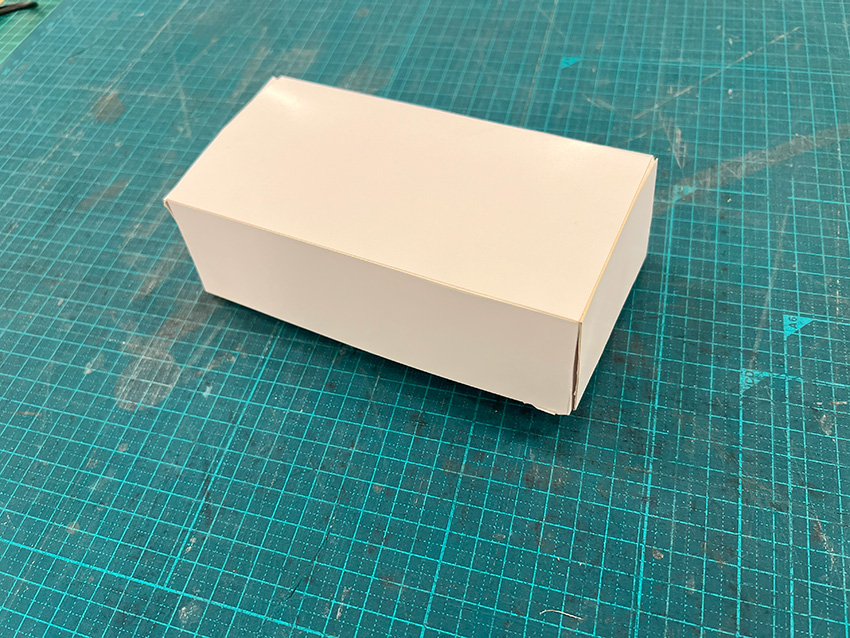

The processed items are then assembled along the folds to complete the process.