Molding and casting

This week, I learned how to make molds and created some fun earrings.

[Hero Shot]

1.1 Assignments of the Week

- Group assignment:

1.Review the safety data sheets for each of your molding and casting materials

2.Make and compare test casts with each of them

3.Compare printing vs milling molds

- Individual assignment:

1.Design a mold around the process you'll be using, produce it with a smooth surface finish, and use it to cast parts

1.2 Group Work

We studied three materials: food-grade silicone, epoxy resin, and plaster. We are very grateful to our colleagues in the studio for providing us with the datasheets for these three materials.

Material 1: Food-grade Silicone

DatasheetsToxicity: Low toxicity

Color: Translucent

Curing time: About 8 hours

Weight mixing ratio: 1:1

Reaction status: No significant heat generation

Advantages: Safe, non-toxic, suitable for food-contact molds, good elasticity

Disadvantages: Long curing time, surface details may not be very clear

Safety precautions: Wear gloves, avoid contact with eyes and skin

Usage process: Stirring may produce bubbles, defoaming process is slow

Bubble level: Medium bubbles

Defoaming level: Defoaming is slow

![]()

![]()

Material 2: Epoxy Resin

DatasheetsToxicity: Moderate, may release volatile organic compounds

Color: Transparent, can add colorants

Curing time: About 24 hours

Weight mixing ratio: 3:1

Reaction status: Slight heat generation

Advantages: High transparency, suitable for making detailed molds or accessories

Disadvantages: Strong odor, long curing time, high hardness

Safety precautions: Operate in a well-ventilated environment, wear gloves and a mask

Usage process: Few bubbles during stirring, uniform stirring has a significant impact on curing results

Bubble level: Low bubbles

Defoaming level: Good defoaming

Material 3: Plaster

DatasheetsToxicity: Low

Color: White

Curing time: About 1 hour

Weight mixing ratio: 10:3 (mix with water until no granules)

Reaction status: Slight heat generation

Advantages: Quick curing, low cost, suitable for rapid forming

Disadvantages: Brittle, not suitable for detailed mold making

Safety precautions: Wear a dust mask, avoid inhaling dust

Usage process: Stirring tends to produce bubbles, rapid curing affects defoaming

Bubble level: Medium-high bubbles

Defoaming level: Poor defoaming

Comparison Ranking

1.3 Individual Work

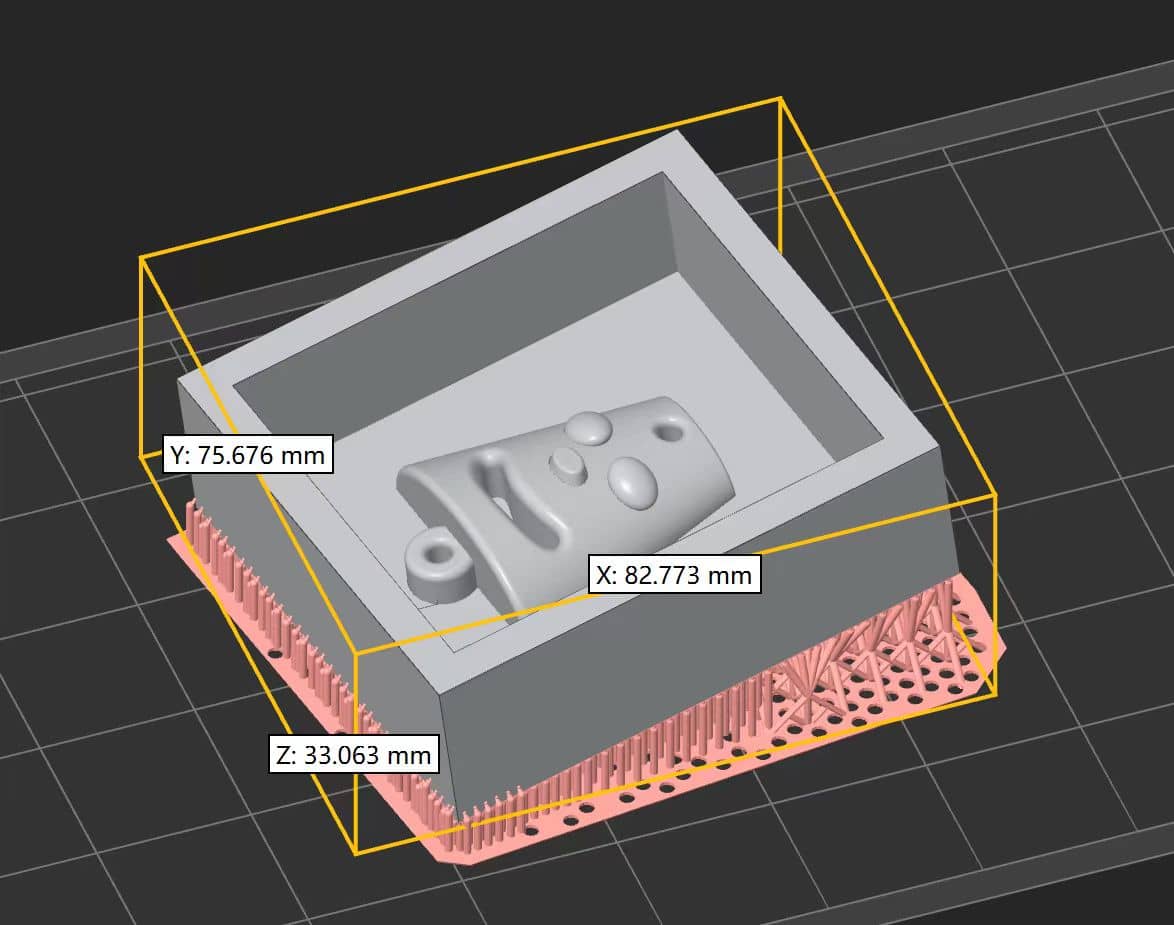

- Select branch, configure printing settings, total time required is 5h18min35s.

- "Start curing! Use ultraviolet laser or UV LED light source to irradiate liquid photosensitive resin, curing layer by layer to create the object."

- After printing is complete, tilt and drain the resin for half an hour.

- Add industrial ethanol (above 98 degrees) and place it in an ultrasonic cleaner for 5 minutes.

- Air dry in a ventilated area.

- Remove supports and polish the surface.

- Place in a secondary curing machine for 35 seconds.

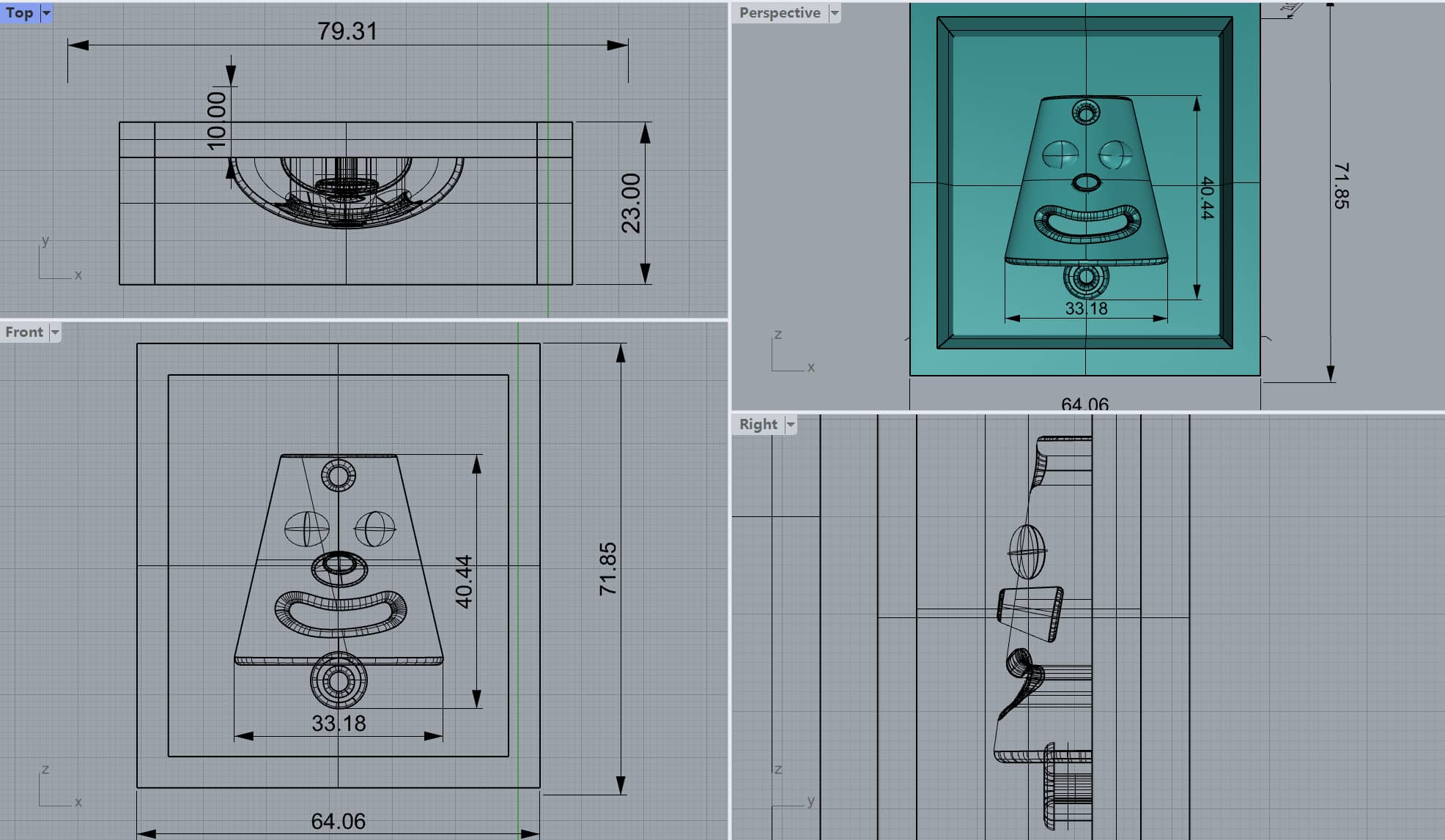

1.3.1 Design

This is the final model.

1.3.2 printing

In Week 05, I learned and used an FDM printer and noticed that the printed objects, while sturdy, had noticeable layer lines and the quality wasn't as good. So I chose to use LCD for manufacturing. Here is a comparison of the printing results between FDM and LCD.

The process of LCD involves the following steps:

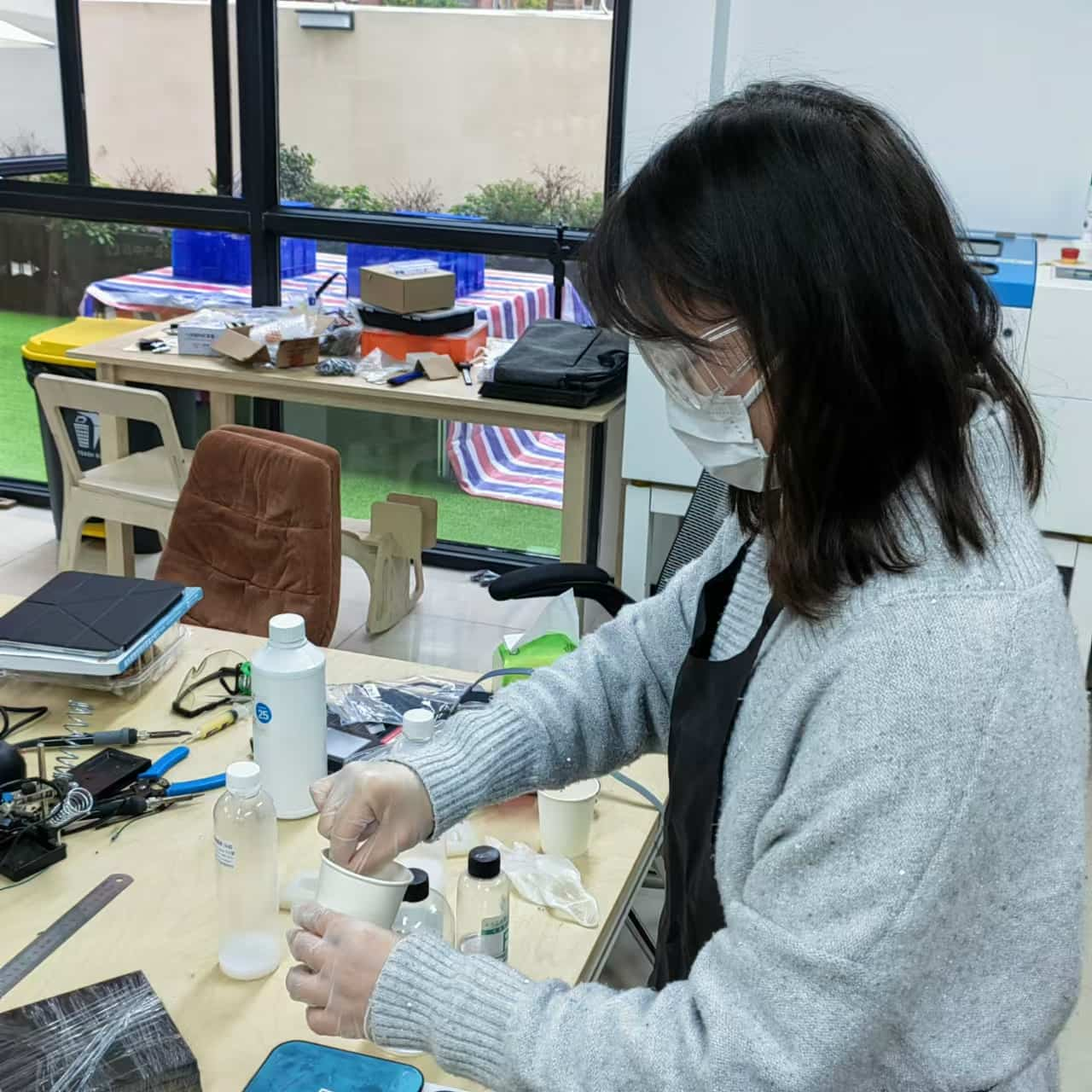

1.3.3 Molding and Casting

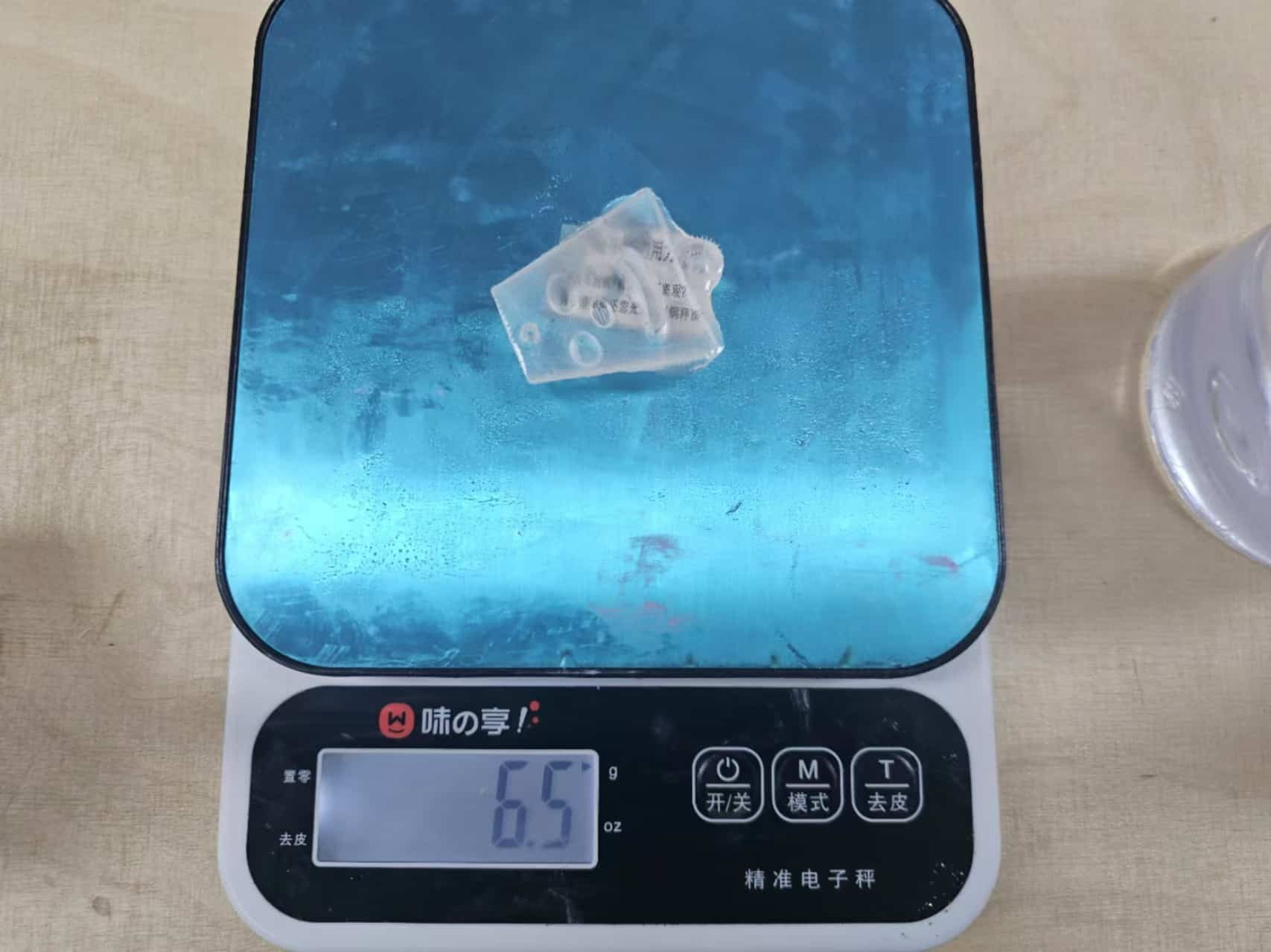

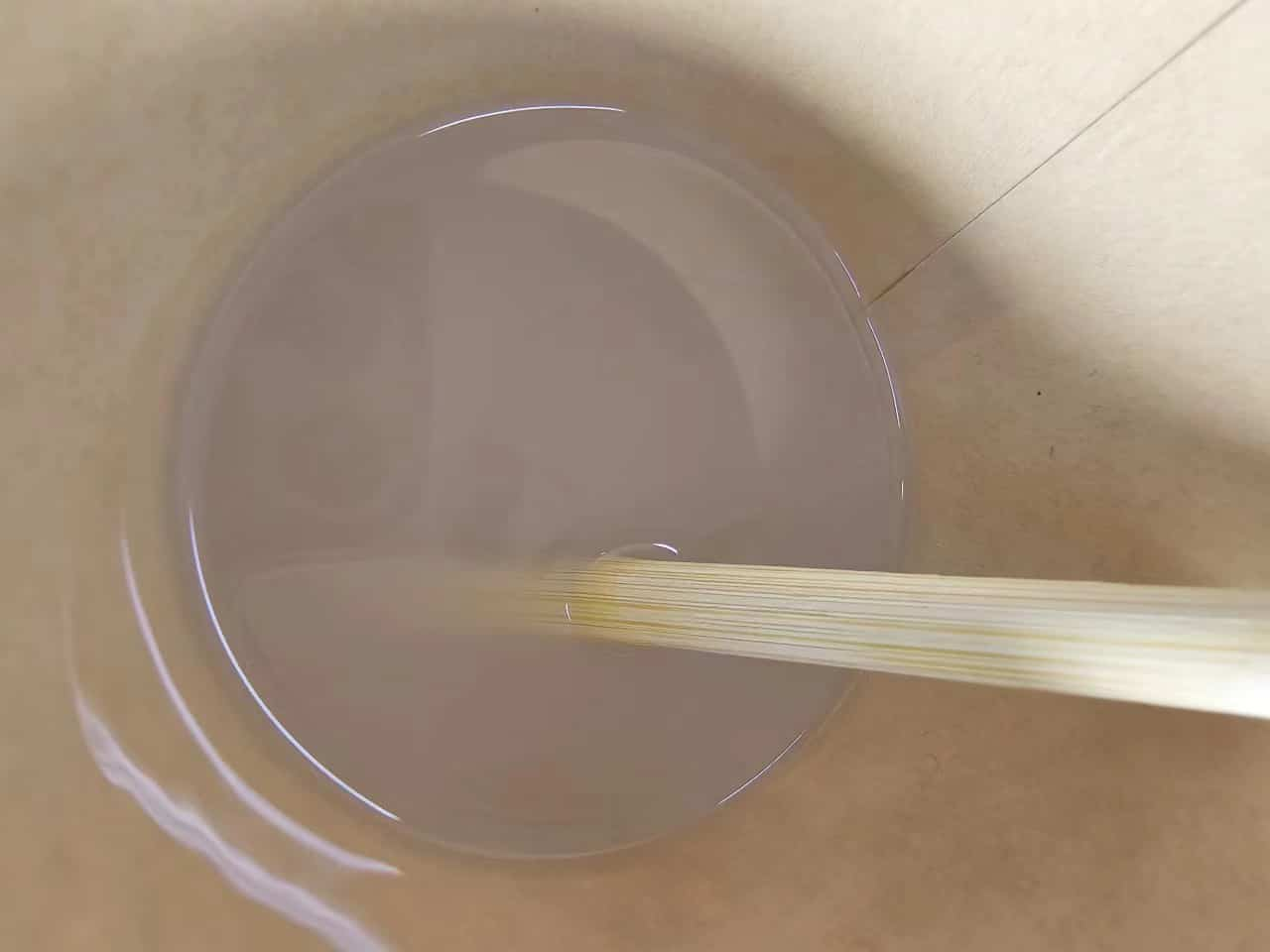

- I mixed components A and B of the silicone in a 1:1 ratio, removing 3g of the cup's weight, resulting in a total weight of 66g for the combined AB mixture. Then, I stirred slowly to prevent bubbles from forming.

- Allow to stand for 8 hours , wait...

- After pouring the silicone mold, I'm use plaster powder to make the earrings. Here are the materials I'm getting ready:

- The ratio of plaster powder to water is 10:3. I slowly mix the appropriate amount of material and then pour it into the silicone mold.

- Let it stand for one hour.

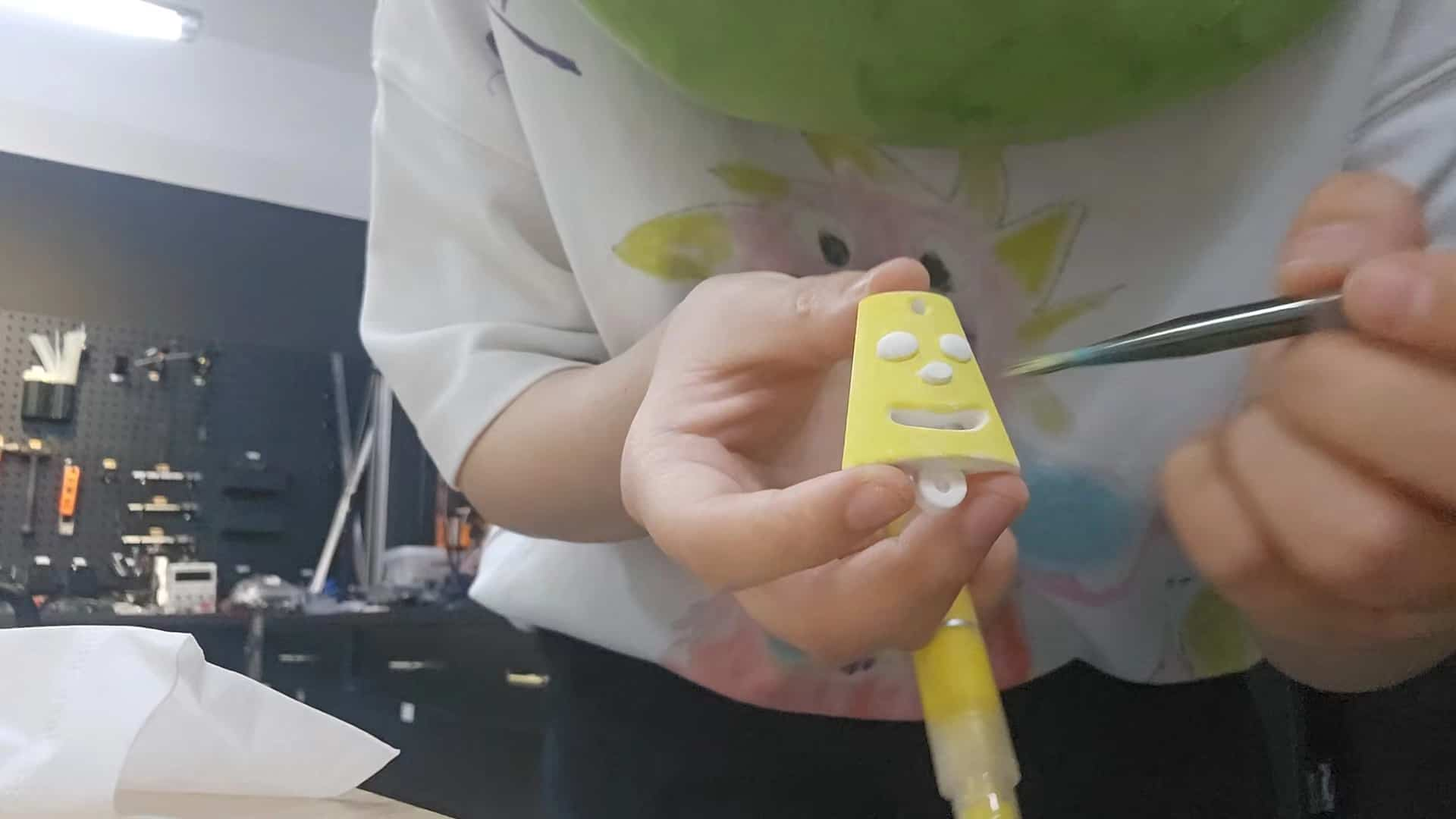

- To color it.

- Attaching earring components, including clips (for friends without pierced ears), connectors, etc. I previously designed some earrings using acrylic cut with a laser cutter in the lab, and they include a pair of yellow accessories that work well.

So pretty! They sway beautifully in the wind! Thanks to my model.