11. Input device

Hero Shot

Group assignment:

- probe an input device’s analog levels and digital signals

Individual assignment

- measure something: add a sensor to a microcontroller board that you have designed and read it

for this job i will use Kicad, in version 8 to design the board. and flatcam do design edge cut for milling machine. at lab we will use candy to milling our pcb on the CNC machine. And soldering all necessary to the board.

For this assignment i work on my final project intput board. so i will use XIO ESP32C3 board; my project is an 360 degre camera, with speaker, and light. So for output i wille have:

-

1 sound sensor (microphone).

-

1 camera

-

1 ultra sonic sensor

-

1 motion sensor

-

2 E2C ports

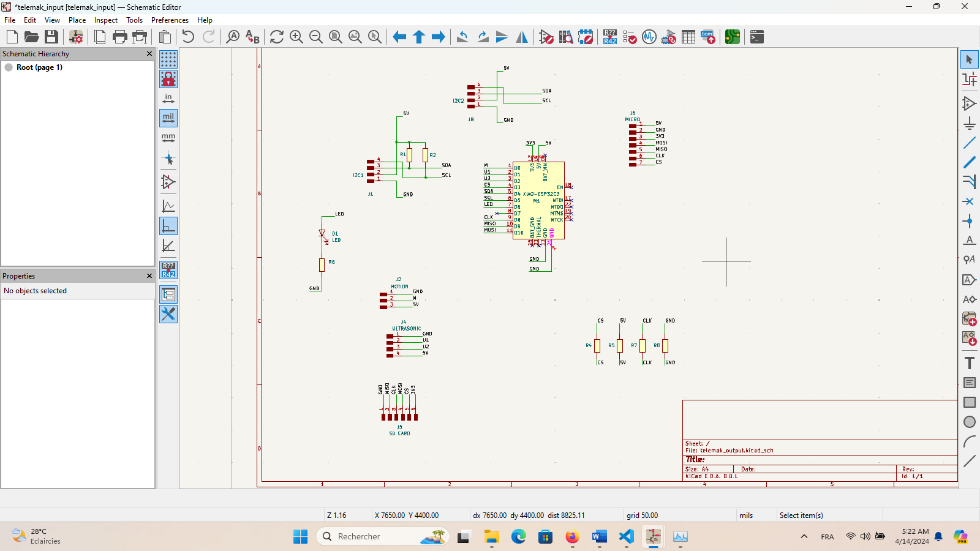

kicad schematic editor

Start designing click on the schematic editor symbol below to open your schematic.

Then I started searching and placing components. To do that just click on the symbol below:

That takes you to the symbol libraries as you can see below. And there you can type and search for any component symbol you want. Scroll up and down to select from different components available on the list. Note that you can only pick one component at a time.

Once satisfied with the component Click OK at the bottom to get the component to your schematic. And just click anywhere on the schematic to drop it down. Highlight it and press M to move it and R to rotate it ino-rder to position it to its location. Press control D to duplicate the component if you want more of the same.

You can see the example how I placed components below.

So, to connect components together you can press on W on your keyboard to add a wire, or click on the Add wire symbol below on your schematic symbol editor.

Another way of connecting components together is by using labels that can be used to name connection points.

To use labels simply press L on the keyboard or you can click on the I con symbol on the schematic shown below.

To join the components using net label flags you just have to name the connecting points with the same name eg. RR or LED LED. See below.

After connecting everything dont forget to click on electrical rules checker. It is also important to add power flags to our circuit as this helps the software to identify where the power is coming from. See below.

You can find esp32c3 specs here

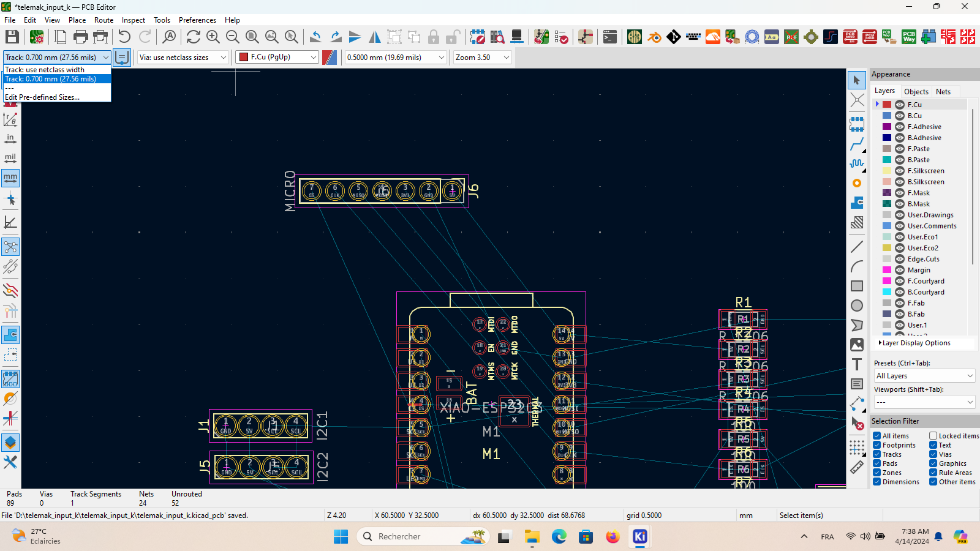

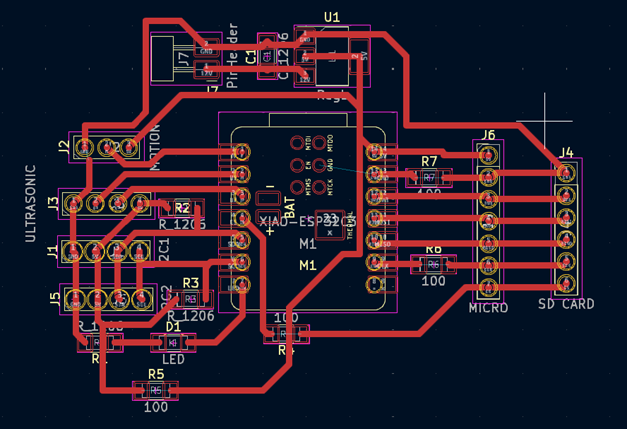

PCB Editor

After finishing with the schematic click on open PCB in board editor symbol shown below.

And then click on update PCB with changes made to schematic.

Then finally you can start routing the traces.

Below you can see how the circuit looks like after routing the traces in my Kicad PCB editor window with the components shown in my schematic.

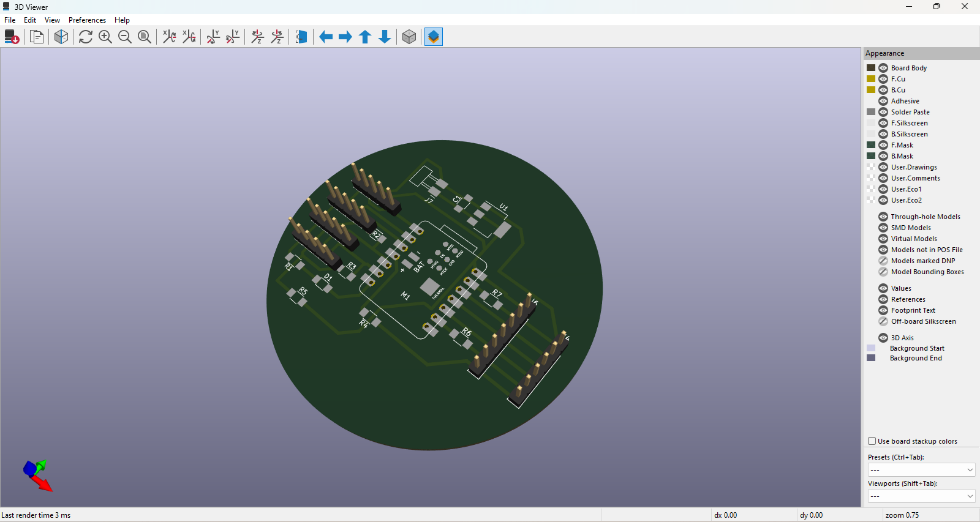

You can click on view 3D viewer Icon on top and see it in 3Dmode as you can see below.

After being satified with the view I can export the file in gerber format for for further processing with a different software.

To do that, go to file>Fabrication Outputs>Gerbers(.gbr)

That will take you to this document below.

Click on plot to generate your F_cu and Edge_cut gerber file format. Remember to select the output folder for your gerber files. Then get back on the same document and click on generate drill File. That is excellon file for holes.

Below you can see I have generated gerber files. But there three important ones that I have circled. For copper traces, Edge cutting and holes. Those are the ones we are going to use for creating G-Code for the cnc machine.

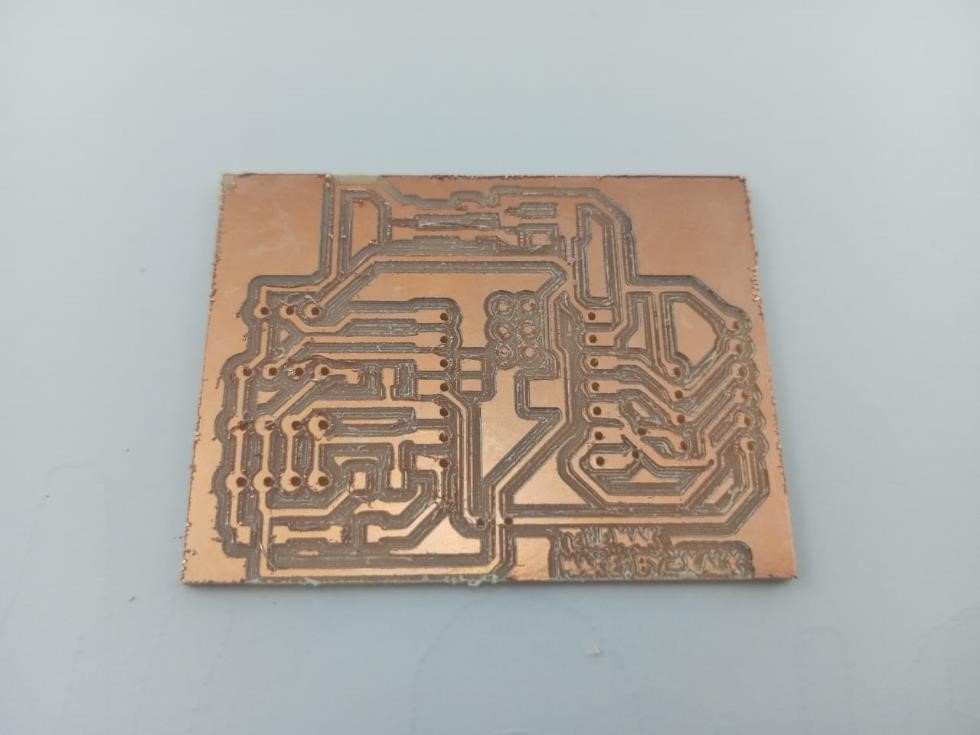

Milling

To proceed with milling processes first we need to create G-Code for our machine.

G-code is a type of computer code that instructs machines on how to perform certain tasks. It is widely used in manufacturing and can control everything from the speed of a machine to the temperature of its heater.

FlatCam

A software that converts Gerber and Excellon (Drill) files to G-Code.

So, open your FlatCam software. Go to file>Ope gerber. That will let you import gerber files to to your flatcam project. And again File>Open Excellon to import the hole file.

For milling the Traces we used the following sizes.

Tool diameter = 0.33mm, tool depth = 0.08mm, Feed rate = 90mm, spindle speed = 1000, travel Z = 5mm, cut Z =0.08mm.

Then after generating the G-Code with FlatCam you export the G-Code for milling processes.