Equipment Details

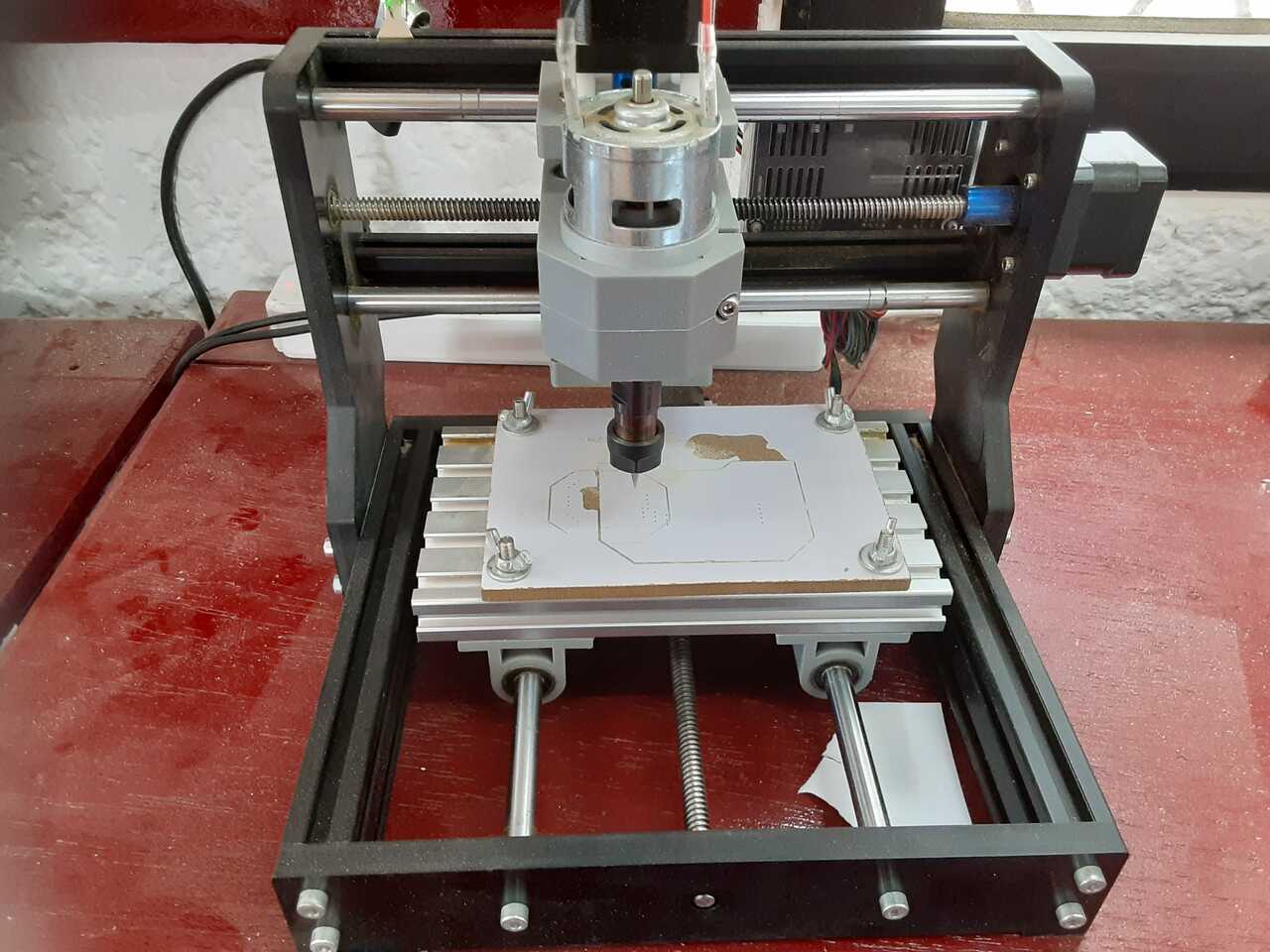

Pinnochio is our micron precision benchtop CNC machine that is designed for PCB milling. Pinnochio was another one of the major workhorses of the lab. It is as Funwill 3018 Pro that was purchased on Amazon. Details regarding the machine can be found here. A photo of a similar machine as well as the machine specs are included below.

| Funwill CNC 3018 Pro Engraving Router Maching | |

|---|---|

| Material | Aluminum and plastic |

| Working area | 300 x 180 x 40 mm |

| Frame size | 420 x 355 x 280 mm |

| Spindle | 775 spindle motor |

| Spindle chuck | ER11 |

| Stepper motor | 1.3 A / 0.25 N.m |

| Power supply | 24V / 5.6A (110V - 240V) |

| Supported System | Windows |

| Supported format | jpg/bmp/png/gerber/gcode |

| Communication port | Micro USB |

Offset of gerber files

This video provides an example of how to re-define the coordinate systems of a gerber file in the case that the board is located outside the size of the cutting area.

Z zeroing method using multimeter continuity

This is a method to accurately zero the z-axis by using a multimeter set to the continuity function with one clip on the spindle and the other on a screw that is in contact with the top copper.

ADEOKE AND OUSIA TO ADD THIS HERE

Z height mapping

This is a height mapping method to account for uneven copper plates to ensure the machine accounts for variations in height throughout the course of the milling process. Below is a video that explains the process.

ADEOKE TO ADD WORKFLOW AND DOCUMENTATION FOR OUR MACHINE HERE

Milling parameters

Below is a list of the milling parameters to use as a function of the type of bit

| Bit | Type of cut | Diameter | z-depth | Feed (Plunge) Rate | Pass Overlap |

|---|---|---|---|---|---|

| V-bit | Traces | 0.03 mm | - 0.08 mm | 60 mm/min | 5 |

| Endmill (0.8 mm) | Edge Cut | 0.8 mm | - 1.6 mm | 60 mm/min | 0 |

| Drill bit (XX mm) | Dill Holes | 0.8 mm | -1.6 mm | 60 mm/min | N/A |

Double sided milling

Another option using the equipment in our lab is double-sided PCB milling. This requires making registration holes. The video below explains the process for making a double sided PCB using Eagle, FlatCam, and Candle.