Group assignment:

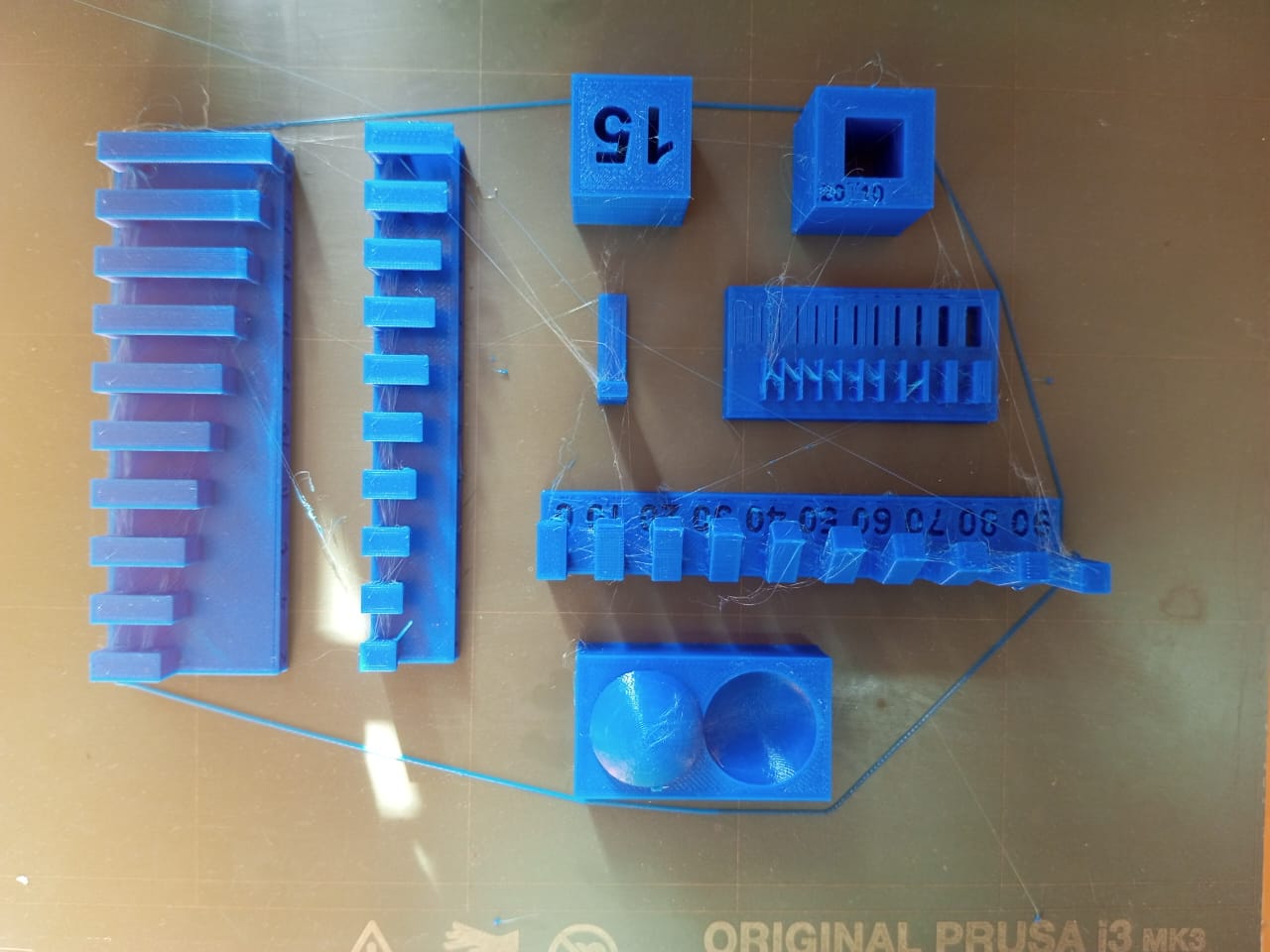

For this group assignment, we used our Prusa 3D printer, whose specifications can be found here

After a very interesting discussion about 3D printers and their characteristics, we also talked about some very important parameters to take into account when printing. Here are just a few .

1- Dimension

Dimensions in 3D printing are crucial to the accuracy and functionality of printed parts. Particular attention must be paid to printer calibration, model design, and print parameters to ensure accurate, specification-compliant dimensions.

2- Angle

Angle plays a critical role in the 3D printing process and in model design. Effective management of these angles not only optimizes print quality, but also minimizes the need for supports and simplifies the post-processing process.

3- Anisotropy

Anisotropy is a crucial factor to consider in 3D printing, influencing the strength, durability and overall performance of printed parts.

4- Bridging

Bridging is a crucial technique in 3D printing, enabling the creation of complex structures with open spaces and no underlying supports. Mastering bridging requires attention to print parameters, cooling, and model design to achieve optimal results.

5- Infill

Infill is a crucial element in 3D printing, enabling the mechanical properties, weight, printing time and material consumption of printed parts to be adjusted. Choosing the right type of pattern and infill percentage is essential to optimize the performance of the final object according to its intended use.

6- Overhang

In 3D printing, an “overhang” refers to a part of a model that protrudes without being directly supported by the layer below. Overhangs pose challenges because the printer deposits the material layer by layer, and without adequate support, the material risks sagging or not adhering properly. For overhangs up to around 45 degrees, 3D printers can often handle them without additional support, but for steeper angles, temporary support structures are required. Optimizing the model, reducing print speed, adjusting extrusion temperature, and using cooling fans are common techniques for improving overhang printing.

7- Surface finish

Surface finish is a crucial aspect of 3D printing, influenced by various factors related to technology, materials and printing parameters, and often enhanced by post-processing techniques.

8- Wall thickness

Wall thickness is a crucial parameter in 3D printing, directly influencing the strength, surface quality, impermeability and production costs of printed parts. Careful attention to print technology, material and part design can optimize this parameter for optimum results.