WEEK 10 / MECHANICAL DESIGN AND MACHINE DESIGN

This week was about machine and mechanical design. The assignment was to create a machine in a group. My group made a pottery wheel and the full content of the process can be found in our group page.

I participated mostly during the early stages of our pottery wheel project, since I was absent during the midterm break - which was the second week of development for this project. We began our design journey by assessing the materials available in our lab. The starting elements were the motors and the rubber belts. We chose the largest rubber belt available in the lab and started designing the gears based on its tooth structure. This feature became the cornerstone of our design, imposing constraints on our decisions, especially regarding gear size dictated by the belt's length.

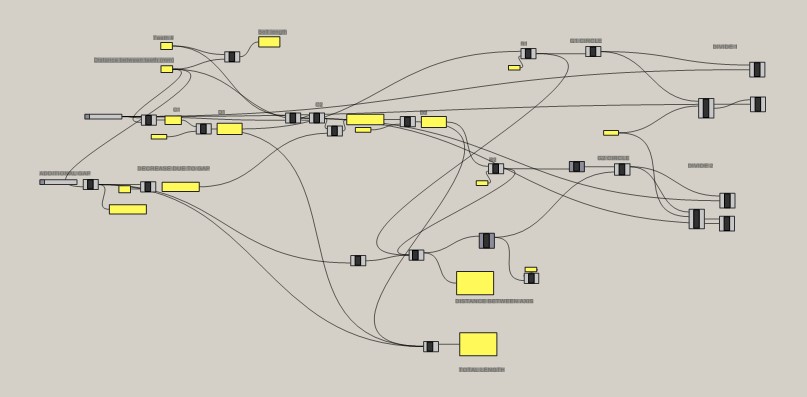

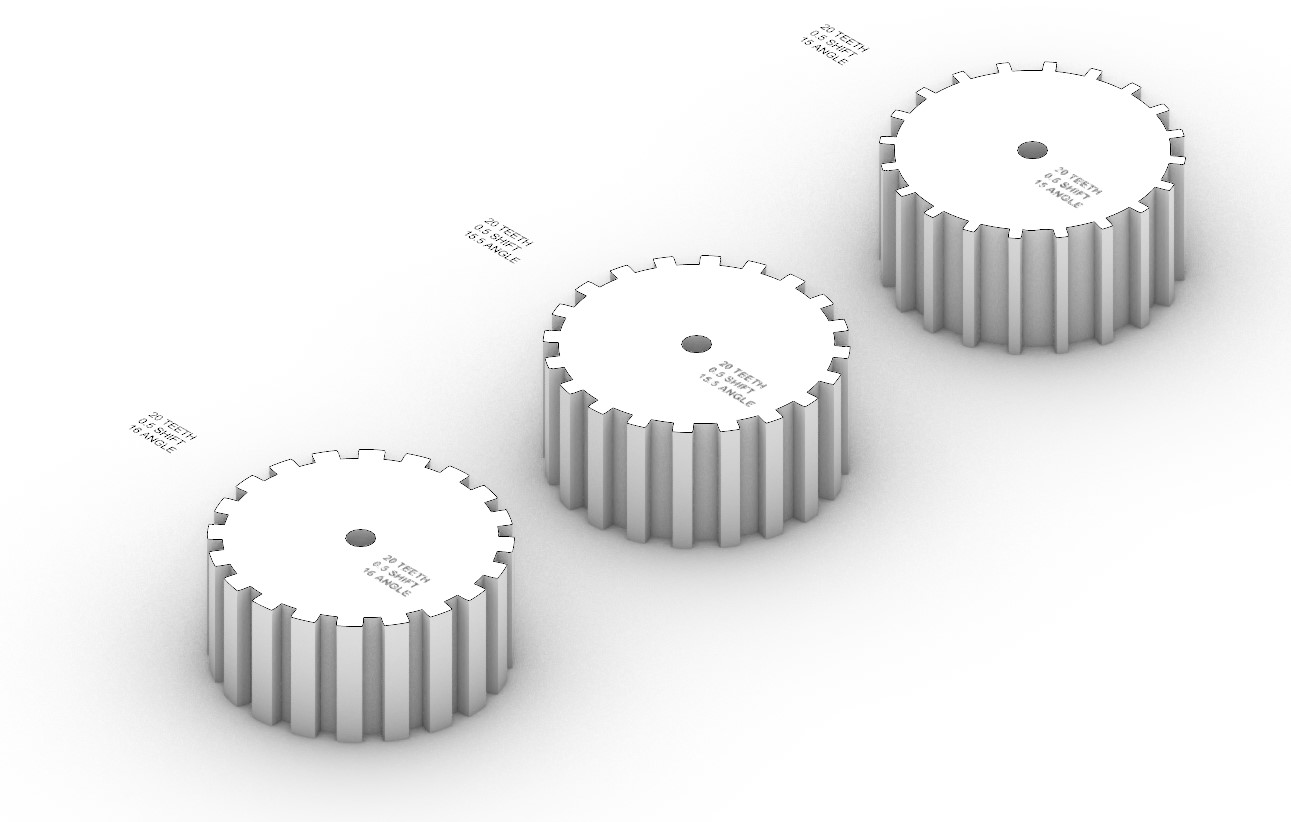

With Grasshopper I developed a parametric model for the gears. The primary objective was to optimize torque output by experimenting with various gear sizes and ratios. This model served as a valuable tool, allowing us to iteratively refine our design by manipulating parameters and evaluating different configurations.

In addition to conceptual work, I participated in the fabrication process, contributing to both the 3D printing of initial gears and the subsequent laser cutting of acrylic counterparts, turning the initial ideation into a tangible start.

Above are the script I created to set up the gear geometries, which are constrained by the belt length. The script allows to change the teeth angles and thickness, and to modify the gears ratios.

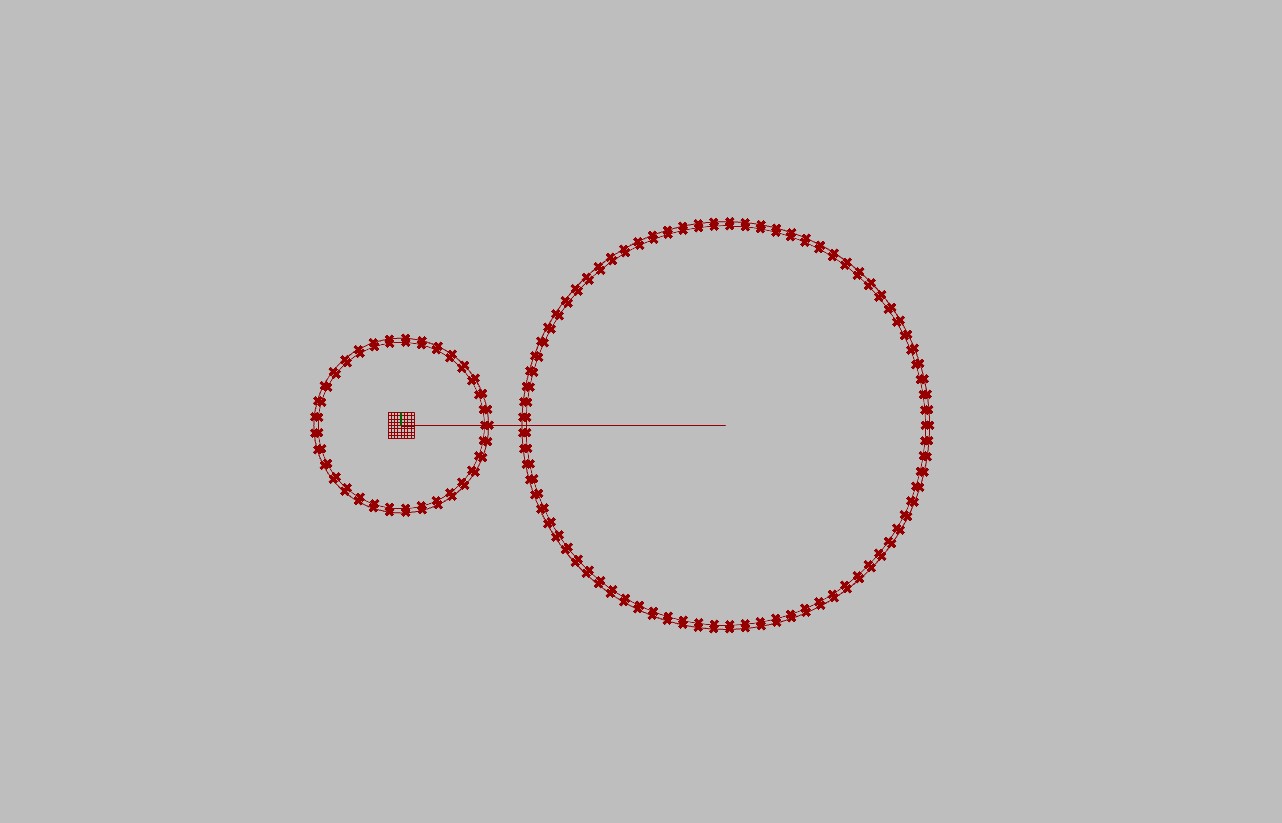

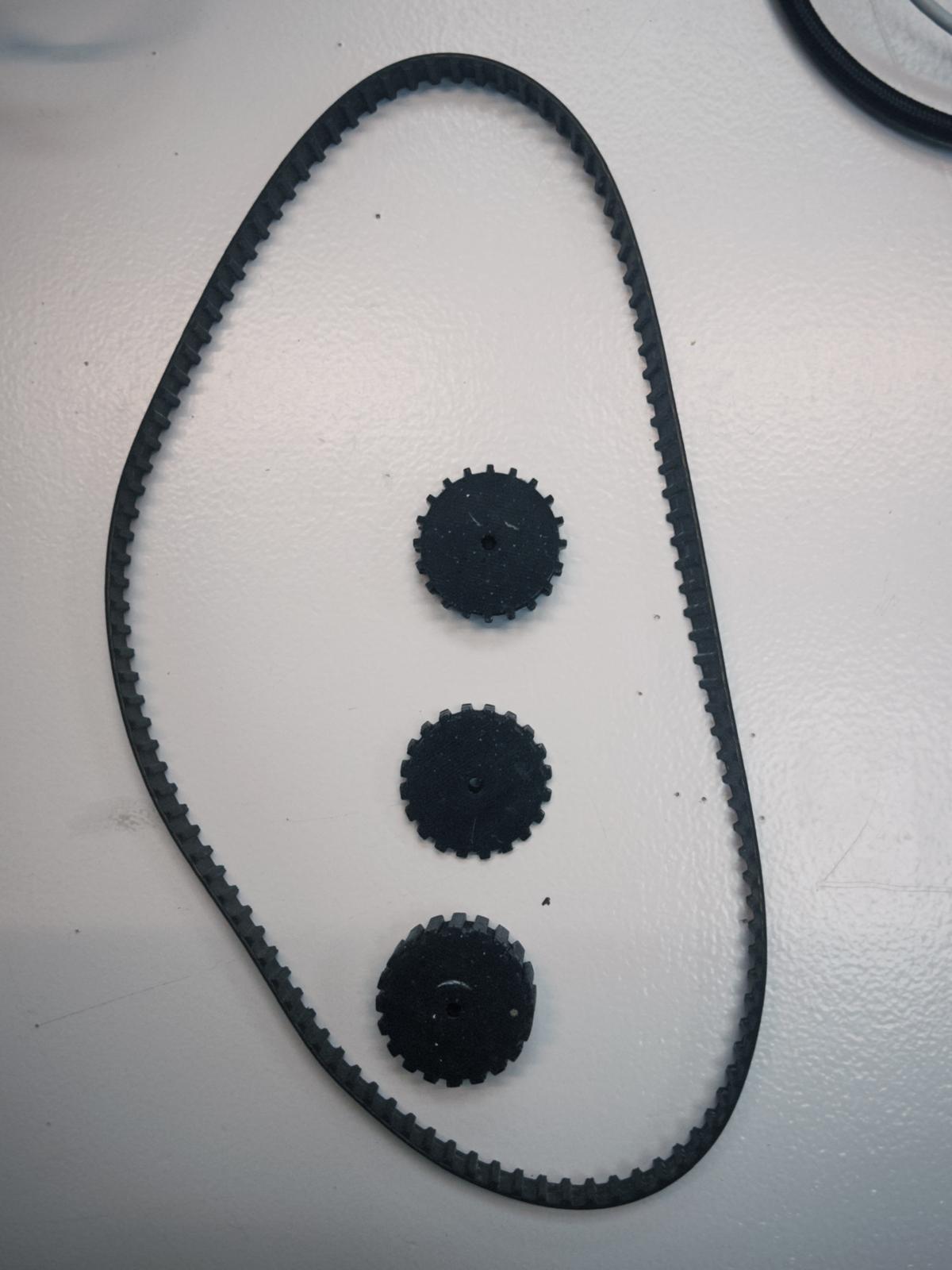

Below is the model of a few tests we did to test how thick the teeth had to be to allow a good grip between the gear and the belt.

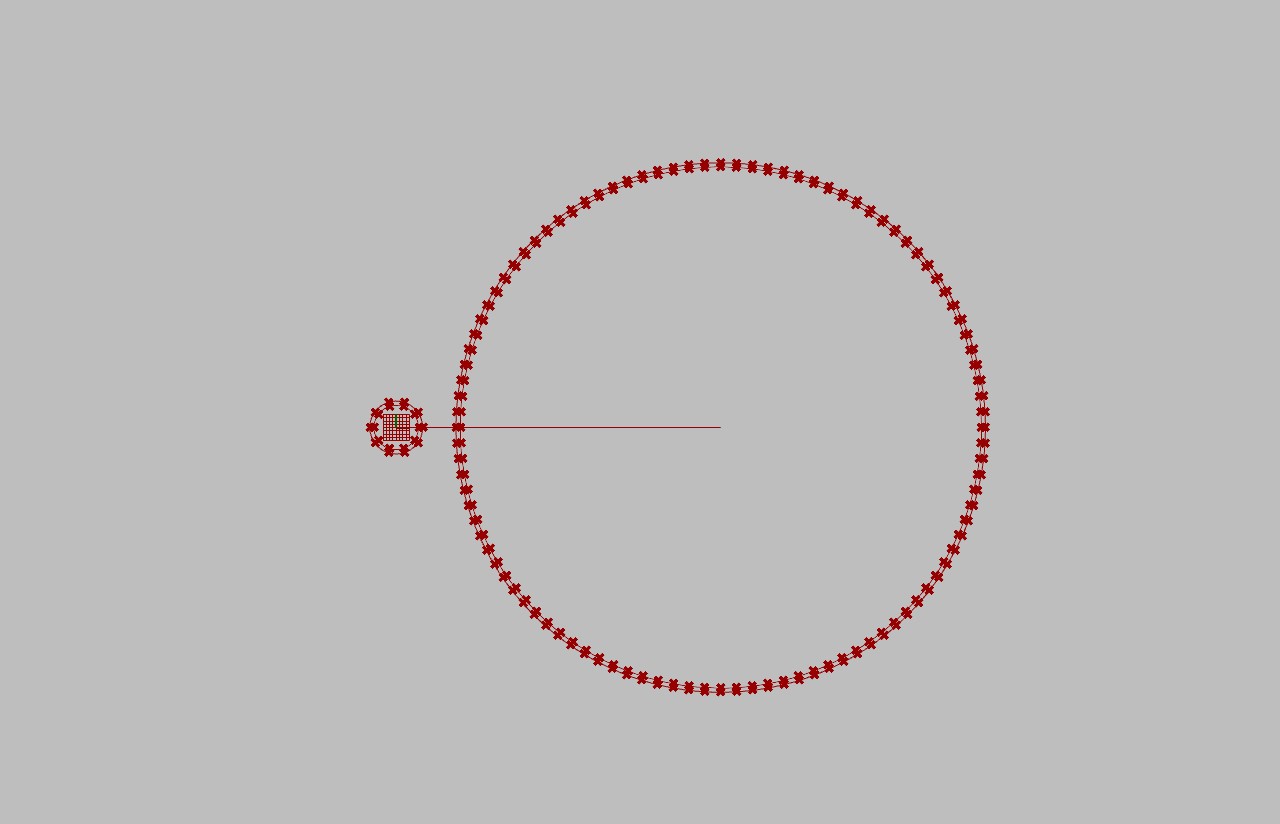

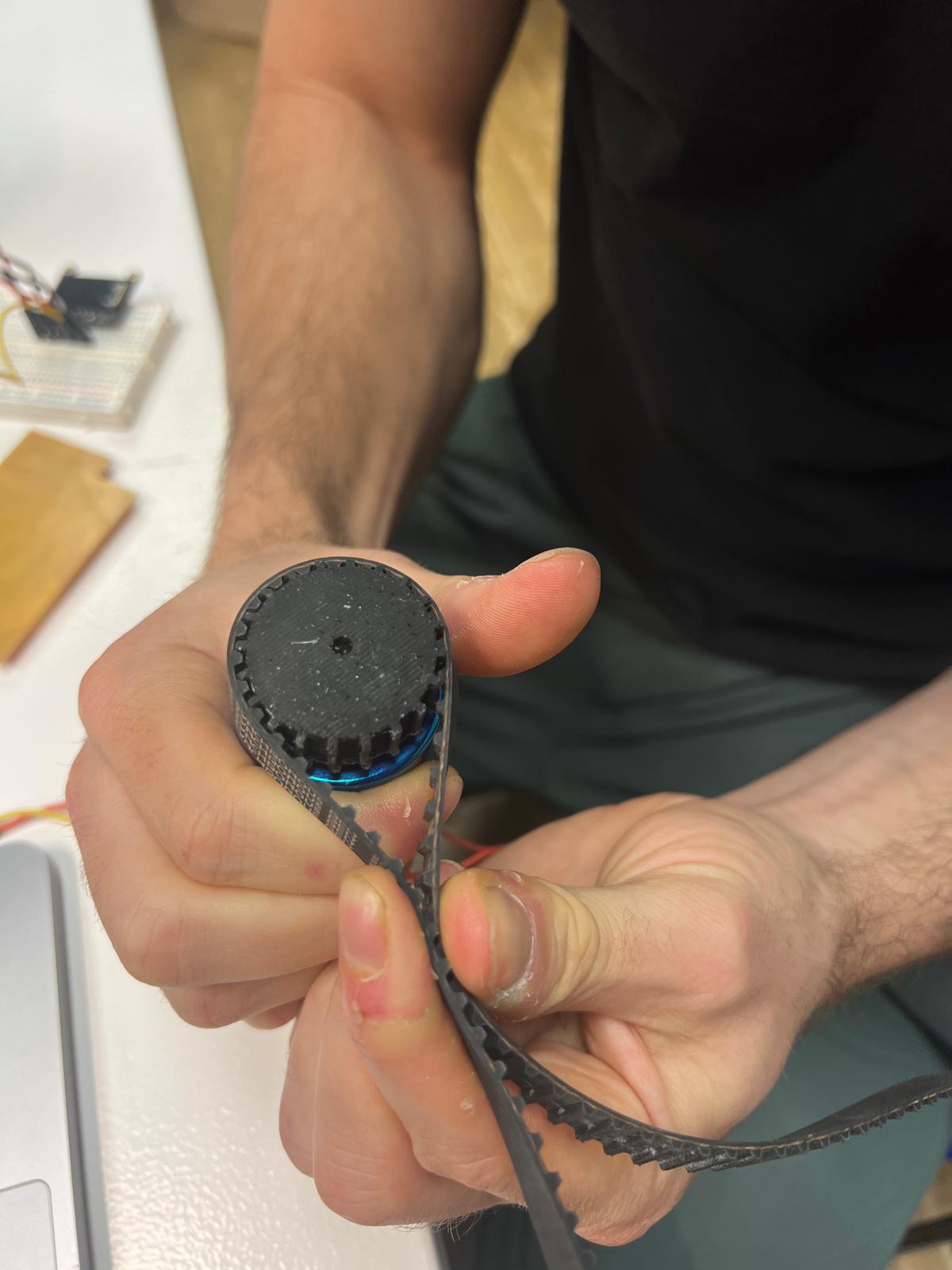

Below on the left is the belt we used with its model number. On the right is the outcome of the gear we tested and thought presented the best result in terms of grip.

Above on the left are Tony, me and Niels, laser cutting the first large gears we would test with out little motor. On the right is the result. Below is a video of us testing that with the belt and the little motor, and finding out that the motor wasn't strong enough and that our gear setup had to present some sort of boundary so it wouldn't easily slip away.

+ FILE: gears.gh