Week 17 - Applications & Implications

What does it do?

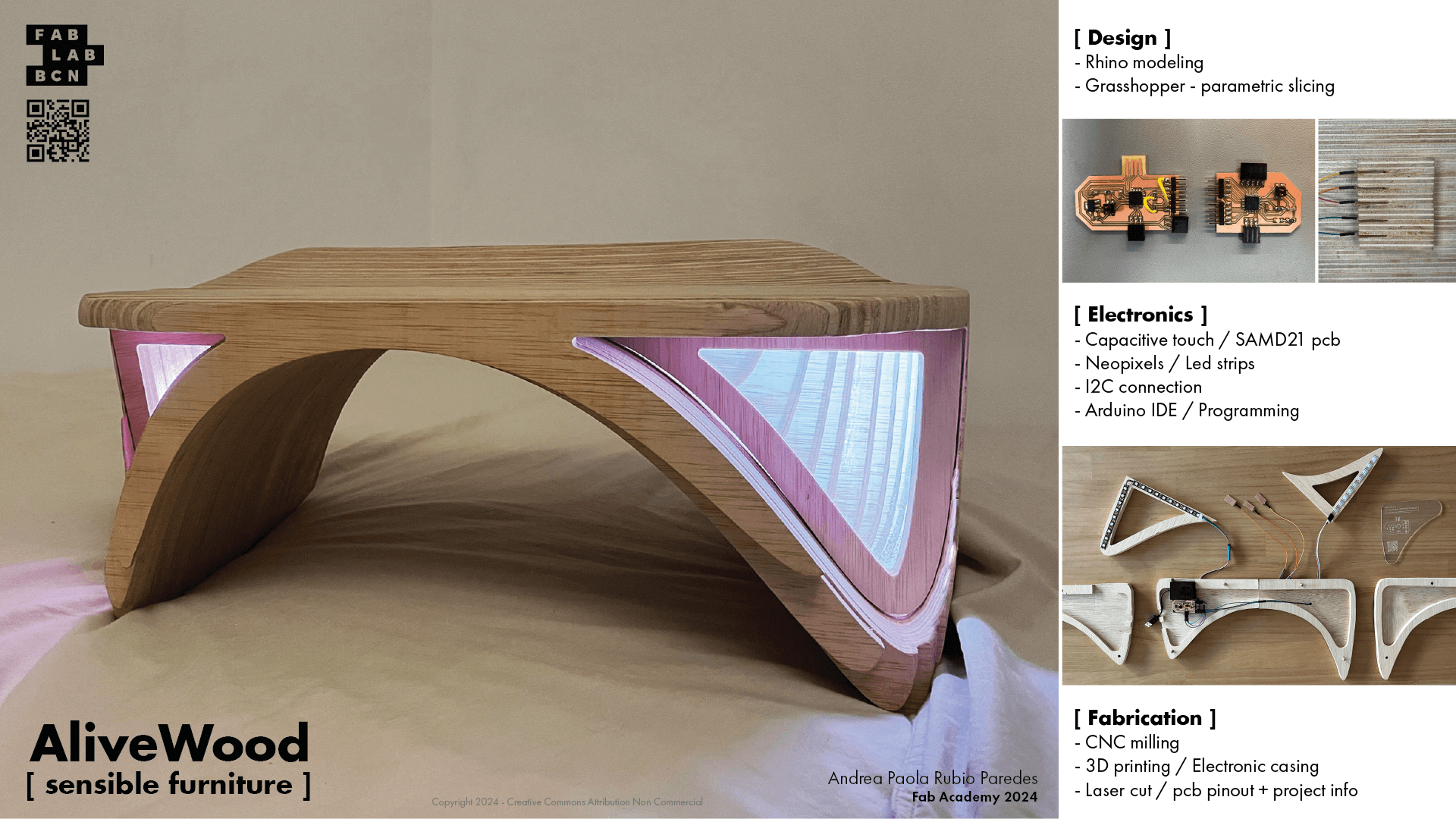

AliveWood is the beginning series of sensible furniture that integrates capacitive touch sensors and LED lighting to create an interactive and aesthetically pleasing object. Combining advanced design and fabrication techniques to create furniture that responds to seamless touch inputs, providing a dynamic lighting experience.

Who's done what beforehand?

Prior projects have explored either sensors, moving mechanisms and sustaintability principles. Here are some references:

Smart table // Interactive LED table

Benjamin Scott // Fab Lab Barcelona

Open desk // Furniture company

What did you design?

The project involved designing the entire furniture piece, considering the structure, electronics, and programming. This included modeling in Rhino, creating parametric slices with Grasshopper, designing the PCB for touch sensors and its casing, while integrating the LED strips.

What materials and components were used?

Materials and components used in the project include:

- Plywood for the main structure

- Neopixels LED strips

- Copper boards for capacitive touch sensing

- SAMD21 microcontroller PCBs

- Various electronic components and connectors

- 3D printed casing & engraved acrylic

Where did they come from?

Materials and components were mainly sourced from Fab Lab Barcelona. The lab is usually supported from various suppliers, such as Bricomat, Digikey and Leroy Merlin.

How much did they cost?

What parts and systems were made?

What processes were used?

What questions were answered?

The project aimed to answer subjects related to the integration of touch-sensitive controls in furniture, the aesthetic impact of interactive lighting, and the feasibility of using advanced fabrication techniques in furniture design.

What worked? What didn't?

Worked:

Stopped working:

Could improve:

How was it evaluated?

The project was evaluated based on its functionality, aesthetic appeal, and the effectiveness of the interactive elements. Feedback from users and peers was also considered to assess the success of the design.

AliveWood aimes to demonstrates the potential for integrating advanced electronics and interactive elements into everyday furniture. This approach can enhance user experiences and open new possibilities in furniture design and smart home applications.