Computer-Controlled Cutting

This week I was introduced to lazier cutting. I started looking to the shapes and ideas that I might need to try before start doing my final project.

Tasks

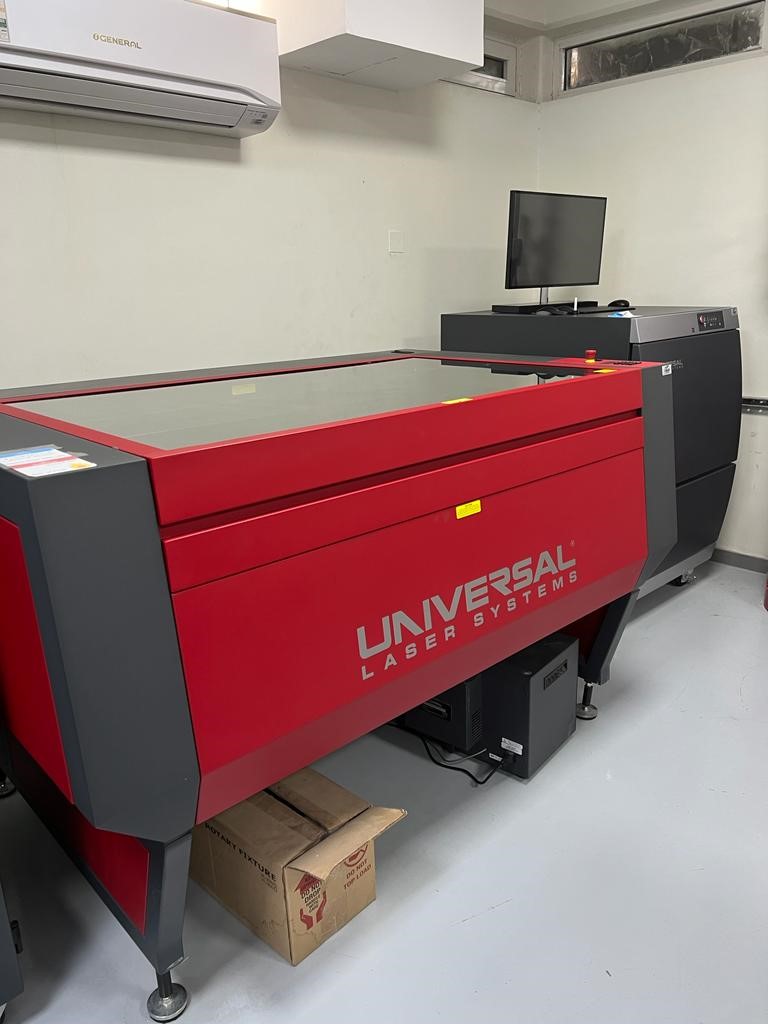

Also, we were introduced to the machines that they use in UAE fab lab as you can see in the bellow pic.

The machines are almost similar. They have miner differences such as size of the ares that every machine can work with.

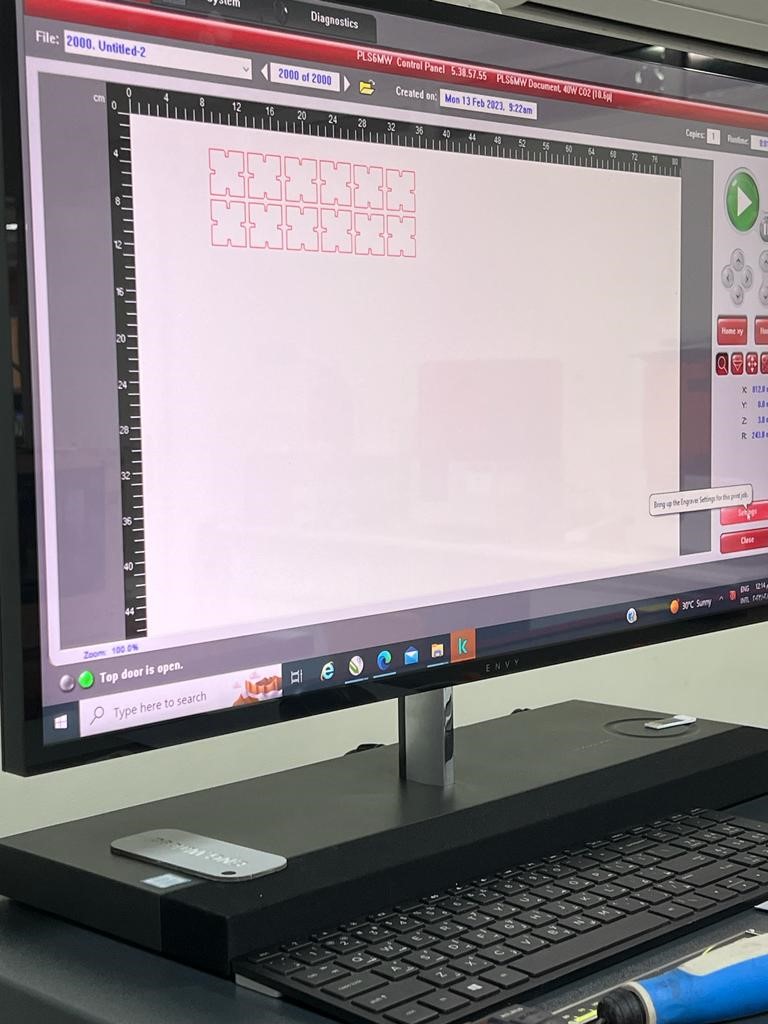

The instructor suggested that we try the a one with a medium size machine it can cut any material with a dimension lower than 16*120 cm. I started learning about the feature that the software provides. Is you can see in the picture here. The dimensions of the operation area are visible around the white screen.

On the right side of the screen, there are different buttons that help to move the laser beam location and determine the exact location of the laser beam and where it’s going to start cutting the object, at what angle.

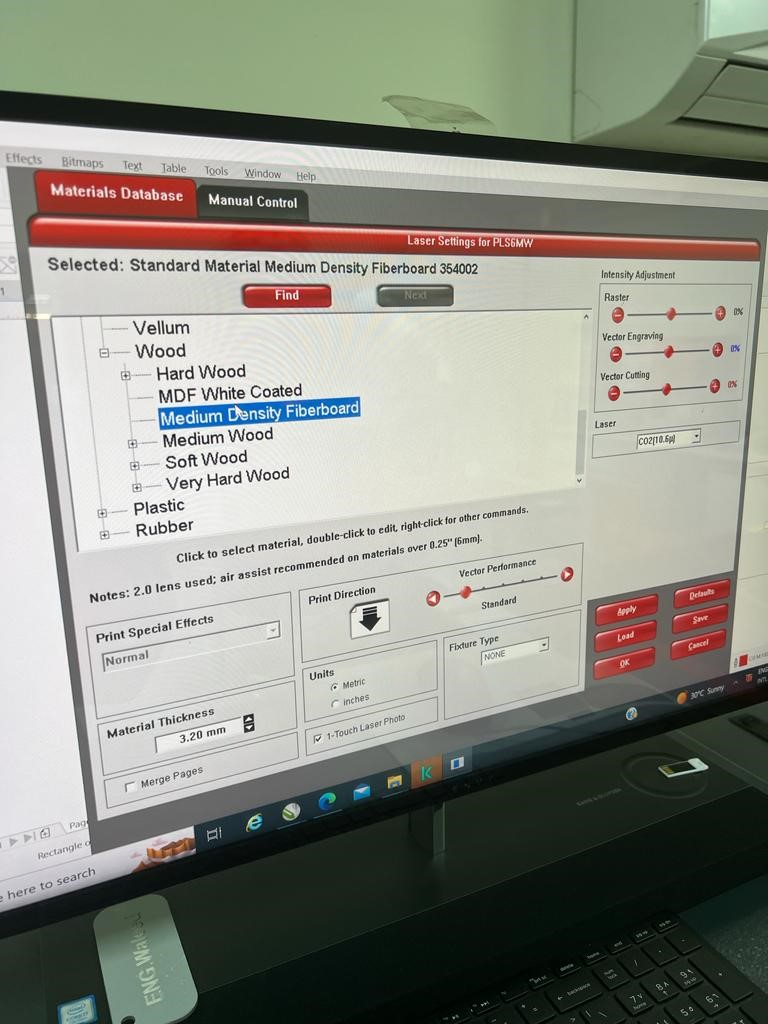

Using the software, we can select the material that we will be working with, the speed, the thickness, and the PPI. These variables differ depending on the shape we need.

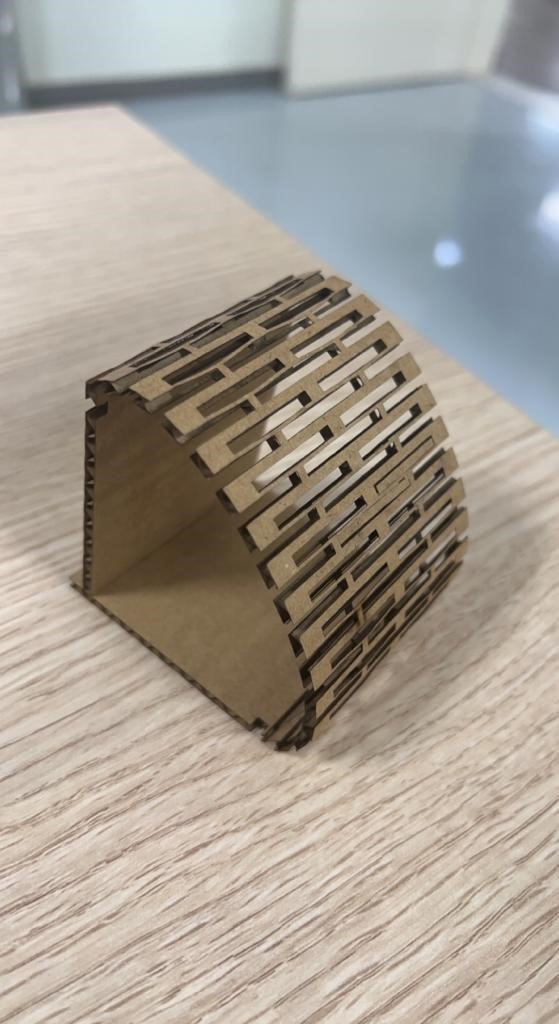

As you can see below we have two different shapes that I cut in the lab using different variables.

Material: Cardboard Thickness: 2.8 mm - Right: • Ppi:500 • Speed:15 - Left: • Ppi2: 10 • Spread: 1

Two last not that the instructor repeated a couple of time: Before closing the led: - never leave the machine when your cutting a cardboard because it might Couse a fire - never forget to open the filter to get rid of the dust.

After knowing all the details of the software I started looking for an idea of a cad design that might help me execute the final project so I made this:

I don’t want my final design to look good, So I tried to make this shape that will help me make smooth edges.