more detail will shown on class link

furter description for group assignment you can find the link of our group plat form.

here there is more description on work on this group web page:Group work description is on hereBuilding a hive that can conserve and protect bees while also being manufactured using a CNC machine can be an innovative and sustainable solution. The idea may have stemmed from a desire to address the ongoing decline in bee populations and the need for more eco-friendly manufacturing processes. Using a CNC machine can allow for precision cutting and efficient use of materials, while also reducing waste. The hive design may also incorporate features such as insulation to protect the bees from harsh weather conditions and ventilation to prevent the buildup of harmful toxins. By combining technology and environmental consciousness, this idea can potentially make a positive impact on both the bee population and the planet.

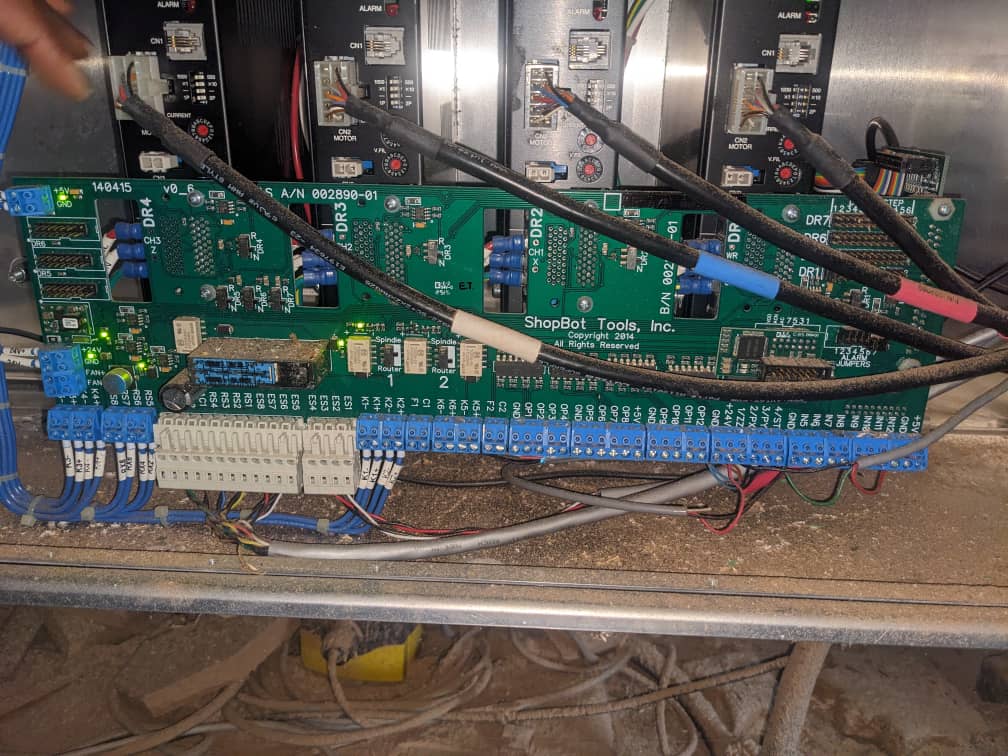

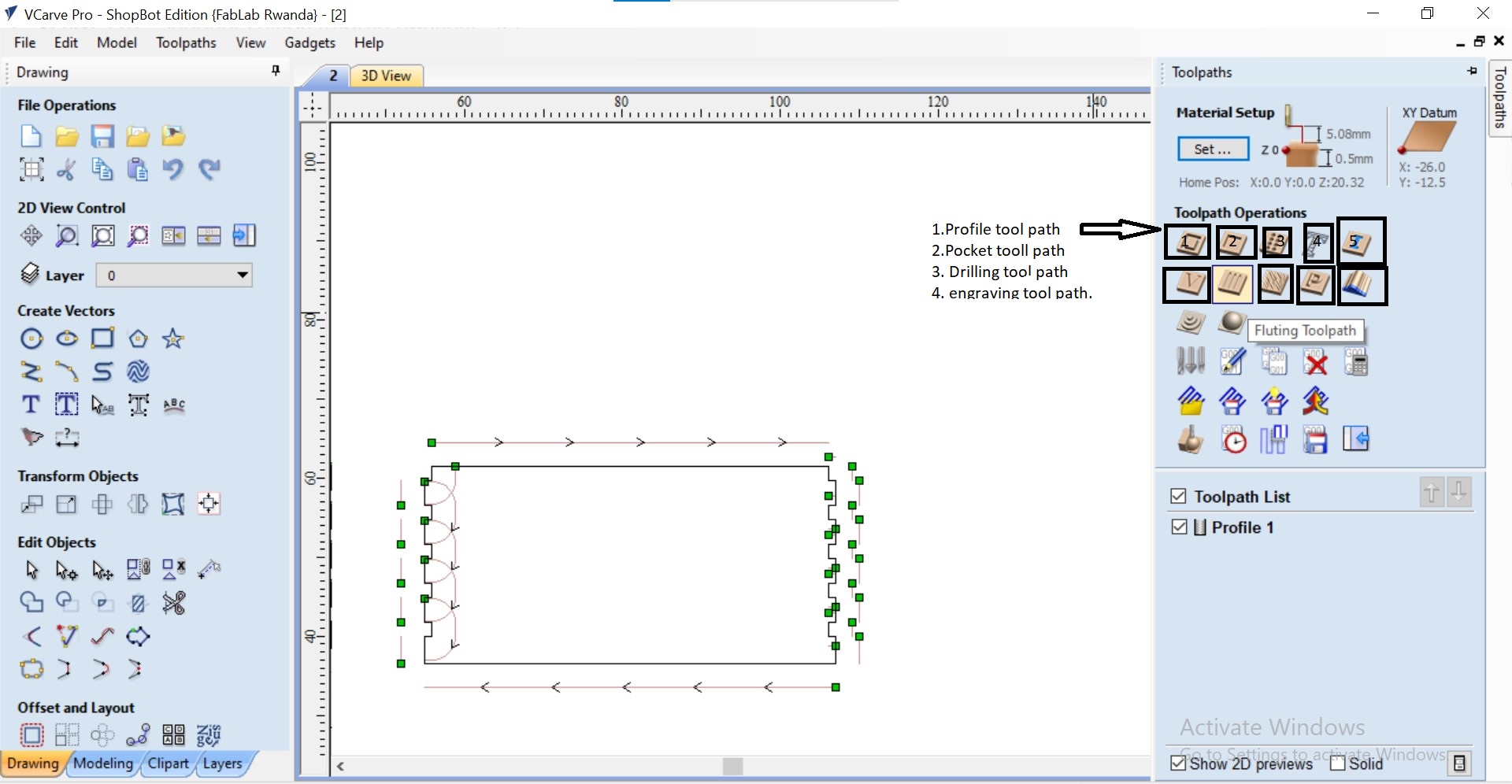

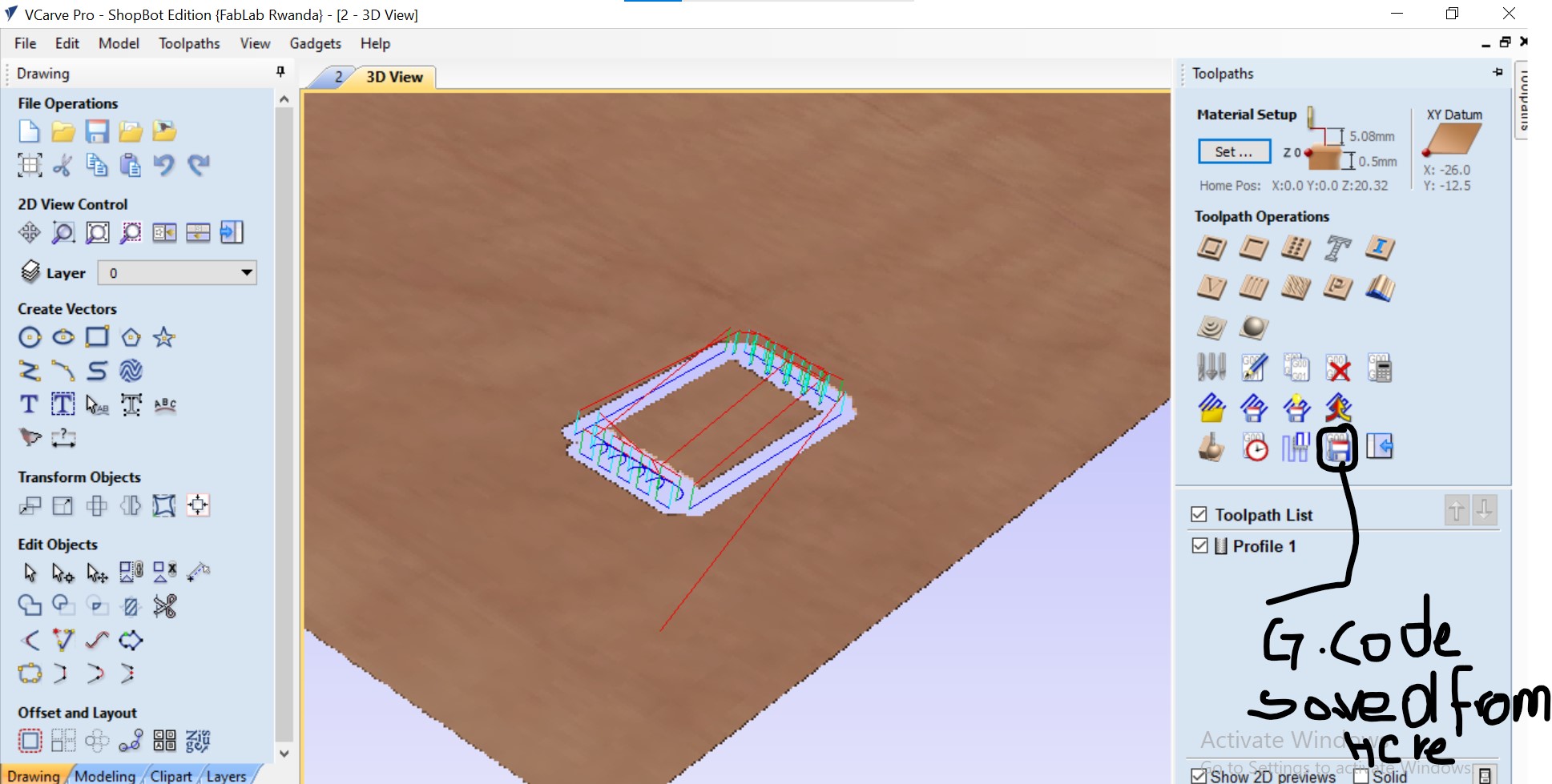

The manufacturing process for a my hive designed in SolidWorks and cut using a Shopbot CNC machine with a V-Curve involves several steps. First, the CAD model is created in SolidWorks and exported as an xdf file. Next, tool paths are generated using CAM software, taking into account the V-shaped cutting tool. The material is then prepared by cutting it to the appropriate size and shape. The CNC machine is set up by configuring it to match the material and tool specifications, and the program is run. During the cutting process, the machine follows the tool paths, cutting the part from the material using the end milling cuter. This results in a high-quality, precise part that can be used in a wide range of applications.

demonstration of work done on cnc in the video

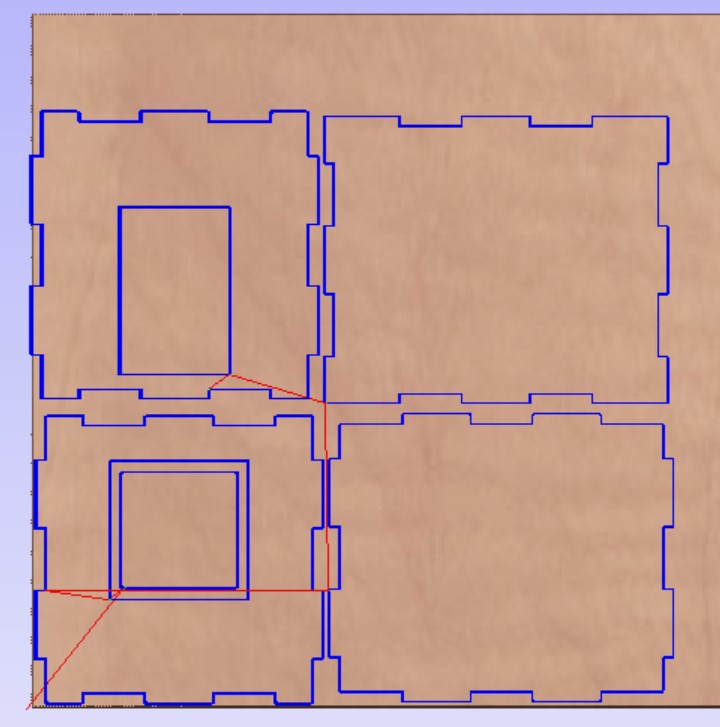

Dogbone fillets are a creative method used in engineering and manufacturing to provide a precise fit between two components in an assembly. Dogbone cuts or fillets are intentionally used to overcut into a corner when constructing a part that needs to fit tightly with another. To deal with any dimensional tolerances or changes in the production process, these fillets are often rounded or curved pieces. A smoother transition is made possible and any potential interference or misalignment problems are avoided when the pieces are put together thanks to the introduction of dogbone fillets, which essentially eliminate the material at the corners. This rigorous method guarantees a tight fit between parts, fostering maximum functionality and maximizing the assembly's overall performance.

After addresing the problem of dog bone all components fited to gether easly during assembly of my final project.

FInd the file hire.