WILDCARD

In this week i try to find a simple thing to do till i design a small object but useful here are steps i used:

Here in this week i decided to make my composite by using formbot and epoxy. Actually i design dish plate in solidWorks. After i cut it by using shopbot

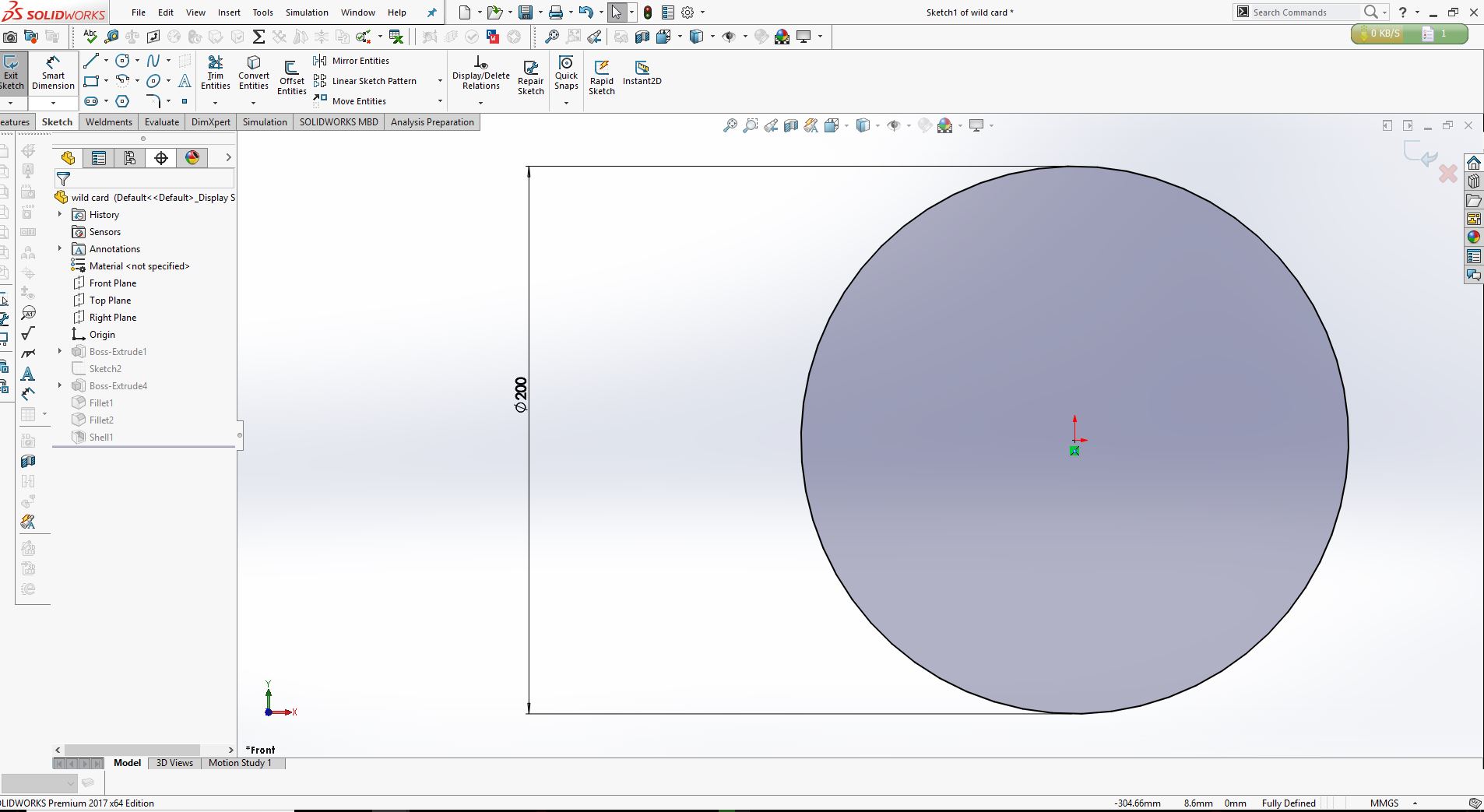

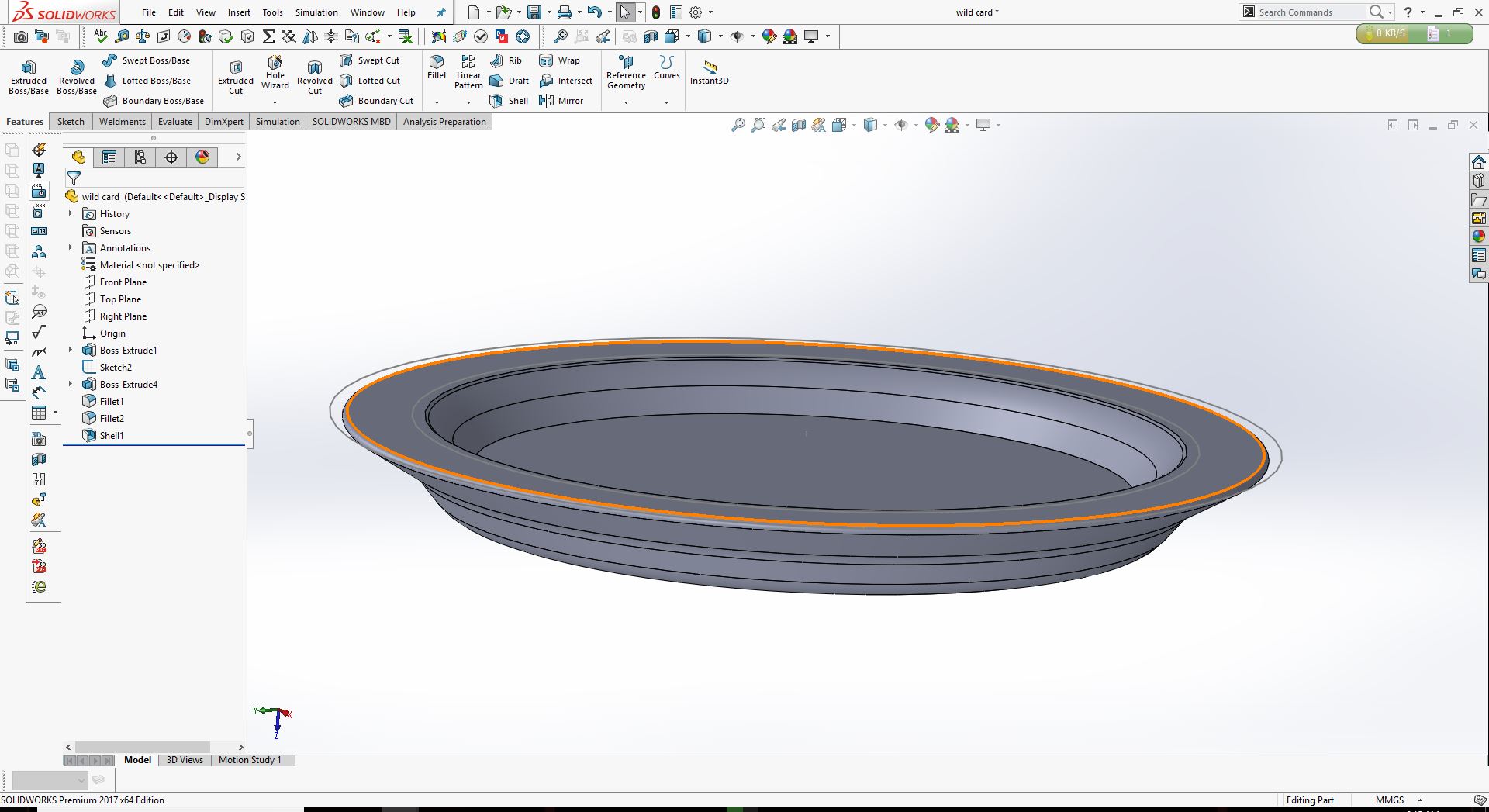

Step 1: SolidWorks Design

After doing my design i save my work in STL fille so that i will use VCarve very eazy for me

Step 2: ShopBot Machine and Vcalve software

Vcalve software: Is a software i use to give our cnc command to do

Cutting Process

Here is my frame on same size with my dish plate i desgn it looklike this.

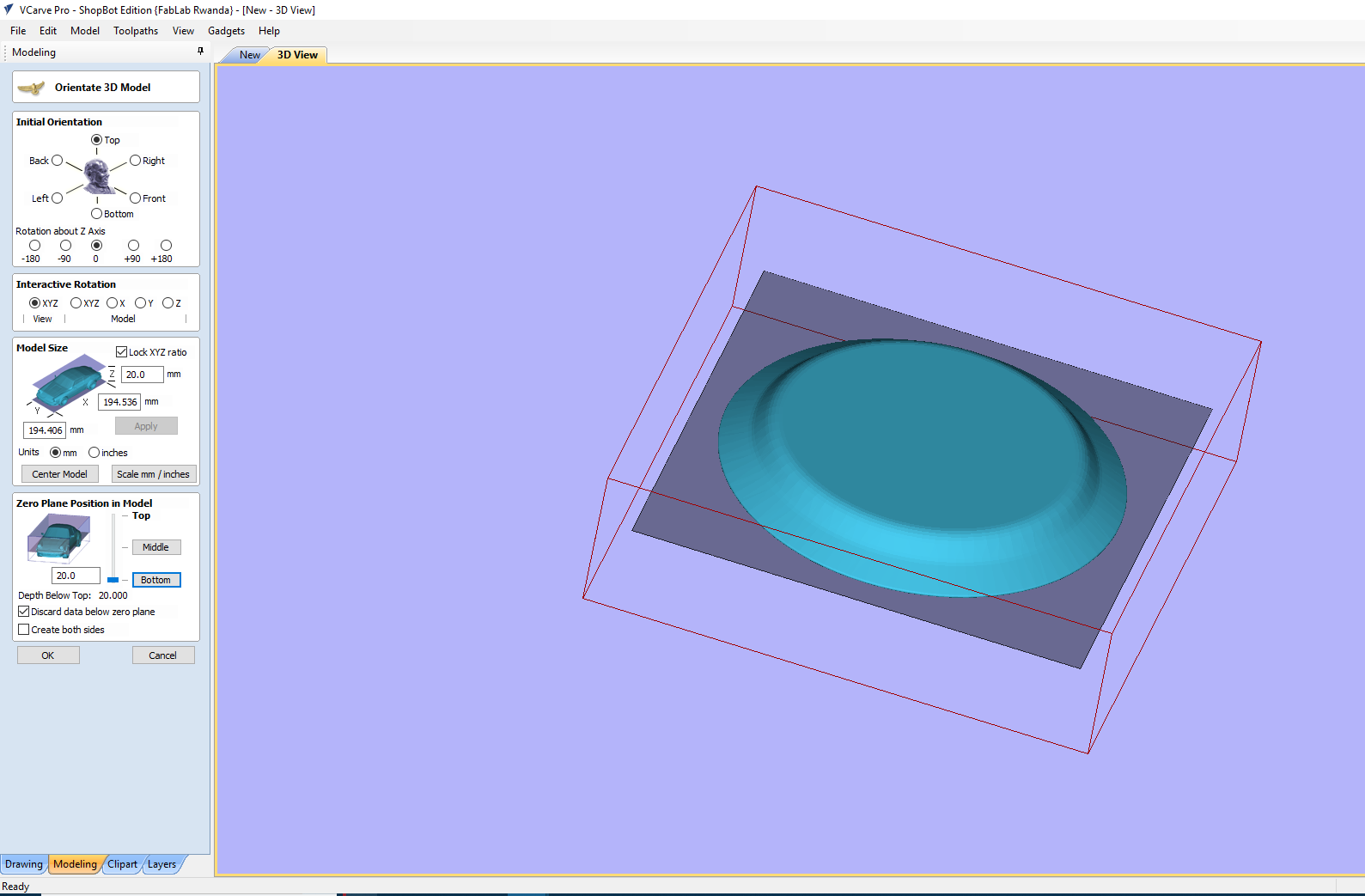

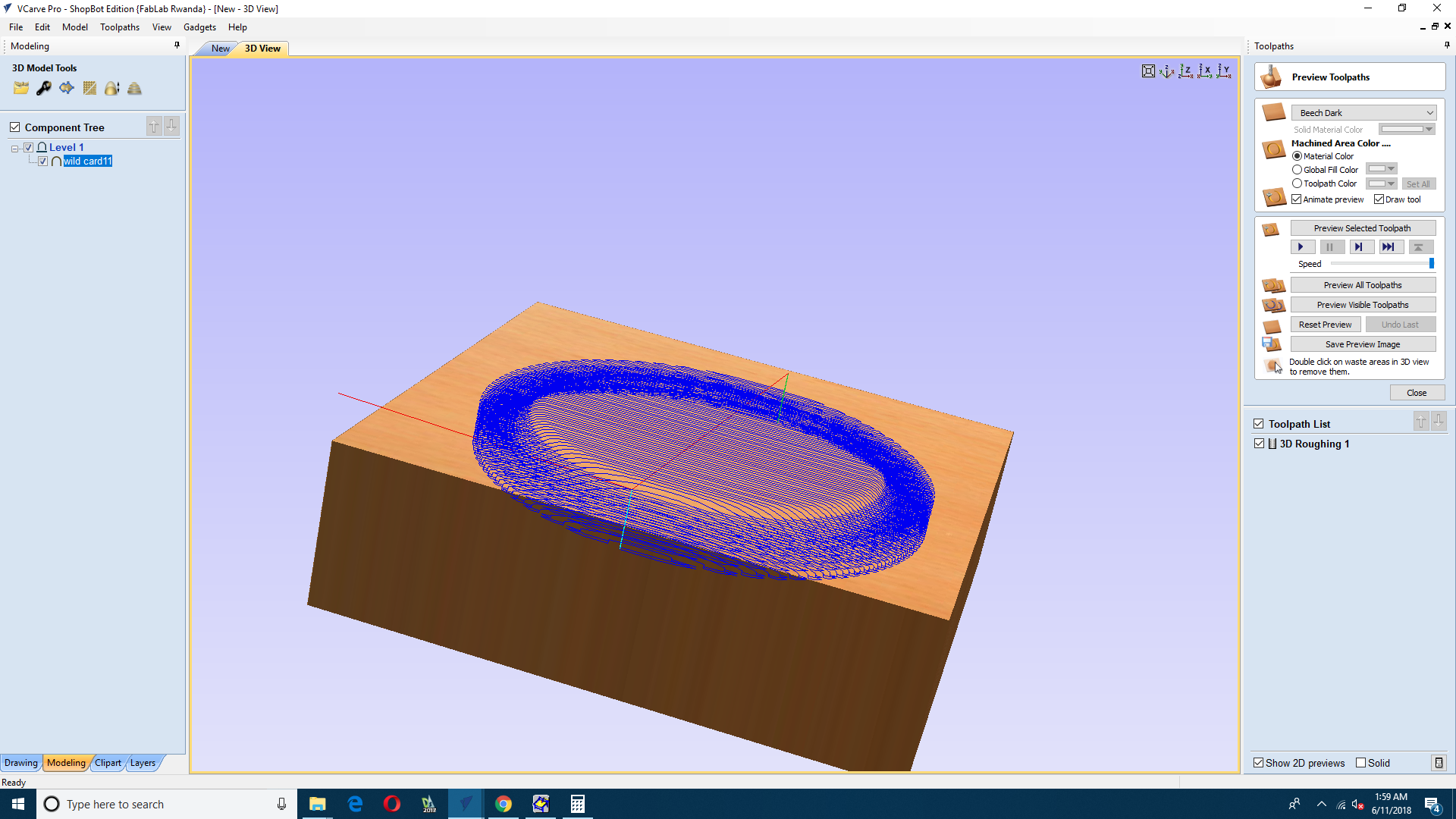

After cutting that frame i try to insert That STL file i was generate in Vcalve in order to make 3D roughing cut.

View of my work

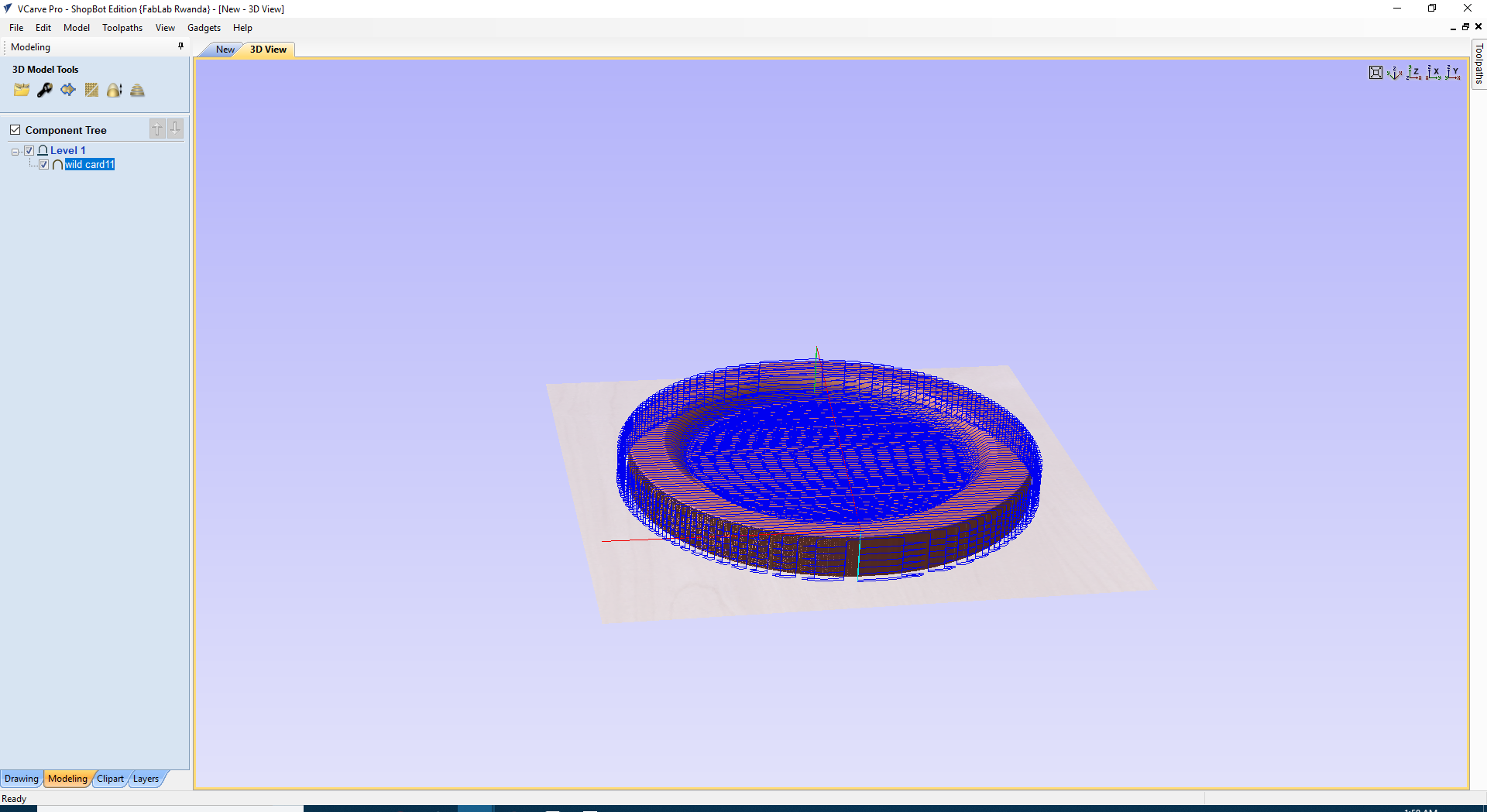

This top view of dish plate on vcarve before starting cutting

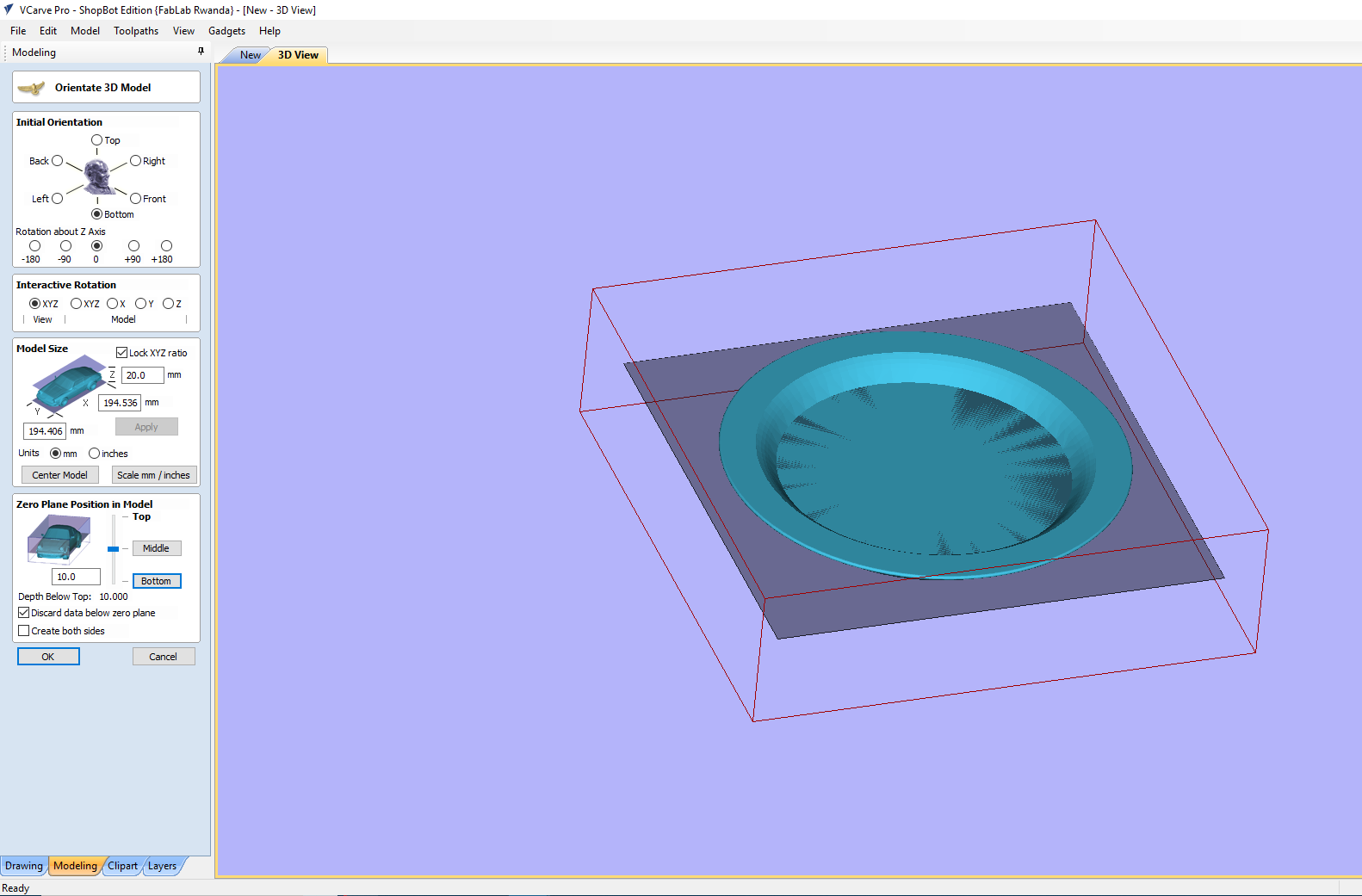

This bottom view of dish plate on vcarve after fliping

This image below shos the toolpath of each layer on top view of my dish plate

This image below it show the toolpath of each layer on bottom view of my dish plate

Cutting

Now it start to make 3D roughing. This how it look like in this image.

Now after making 3D roughing on top view. i am going to flip my plate and then make 3D roughing on bottom view.

After making 3D roughing i try to mix both component A and B of epoxy.In order to make full assignment(composite).

For mixing i take 100g of component A mix with 30g of component B in order to make balance.

As you see this plate it does not attached very well.

Here i try to solve problem i was show above by putting another material on the edges.and staff for fixing layers.

After fixing i waiting like one hour for dry and then i remove that stuff for fixing. This is how it look like.

After same time of finishing my assignment i put something like cake on my dish plate.