Molding and casting

Group Assignment

Here is the link to groupe assignement Click here

WHAT ARE MOLDS & WHAT ARE THEY USED FOR?

Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The hollow forms of the mold get filled with water (the casting material) to produce ice cubes. The cubes are released from the mold and voila! Finished cast pieces.

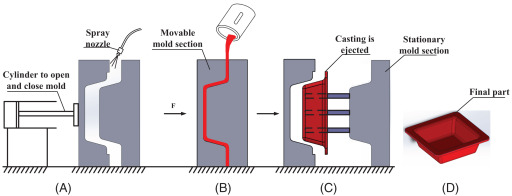

Many industries use mold making as a way of producing their wares. Commercial ceramic factories use plaster molds and slip (liquid clay) to produce bowls, cups, candlesticks, figurines, and more. Plastic factories use metal molds and different processes like injection molding, rotational molding, and blow molding to produce plastic parts. The glass industry blows molten silica into metal or graphite molds to produce drinking glasses, bowls, vases, etc. Most parts of any car's body and engine are made in molds.

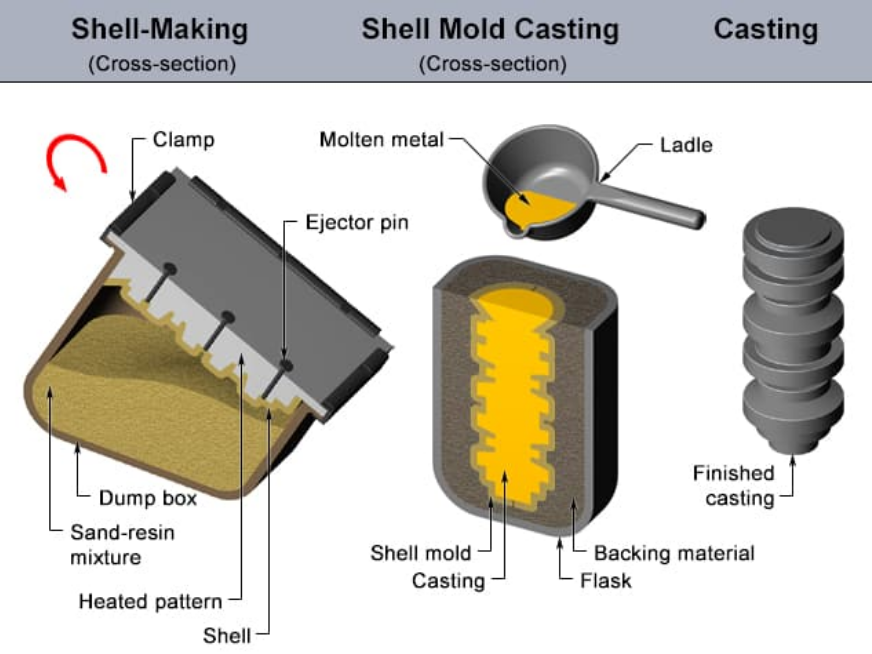

THERE ARE 3 BASIC TYPES OF MOLDS:

1.One part

2.Two part

3.Multi-part (advanced)

CASTING

Casting is a manufacturing process in which a molten material is introduced into a solid mold and allowed to solidify. The solid material takes the shape of the mold. The term usually refers to metals but can also apply to the same process for other materials.

Molding and Casting Molding

Molding or moulding:

is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object.

A mold or mould:

is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material.The liquid hardens or sets inside the mold, adopting its shape. A mold is the counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated moulds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs.Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larger and more valuable objects

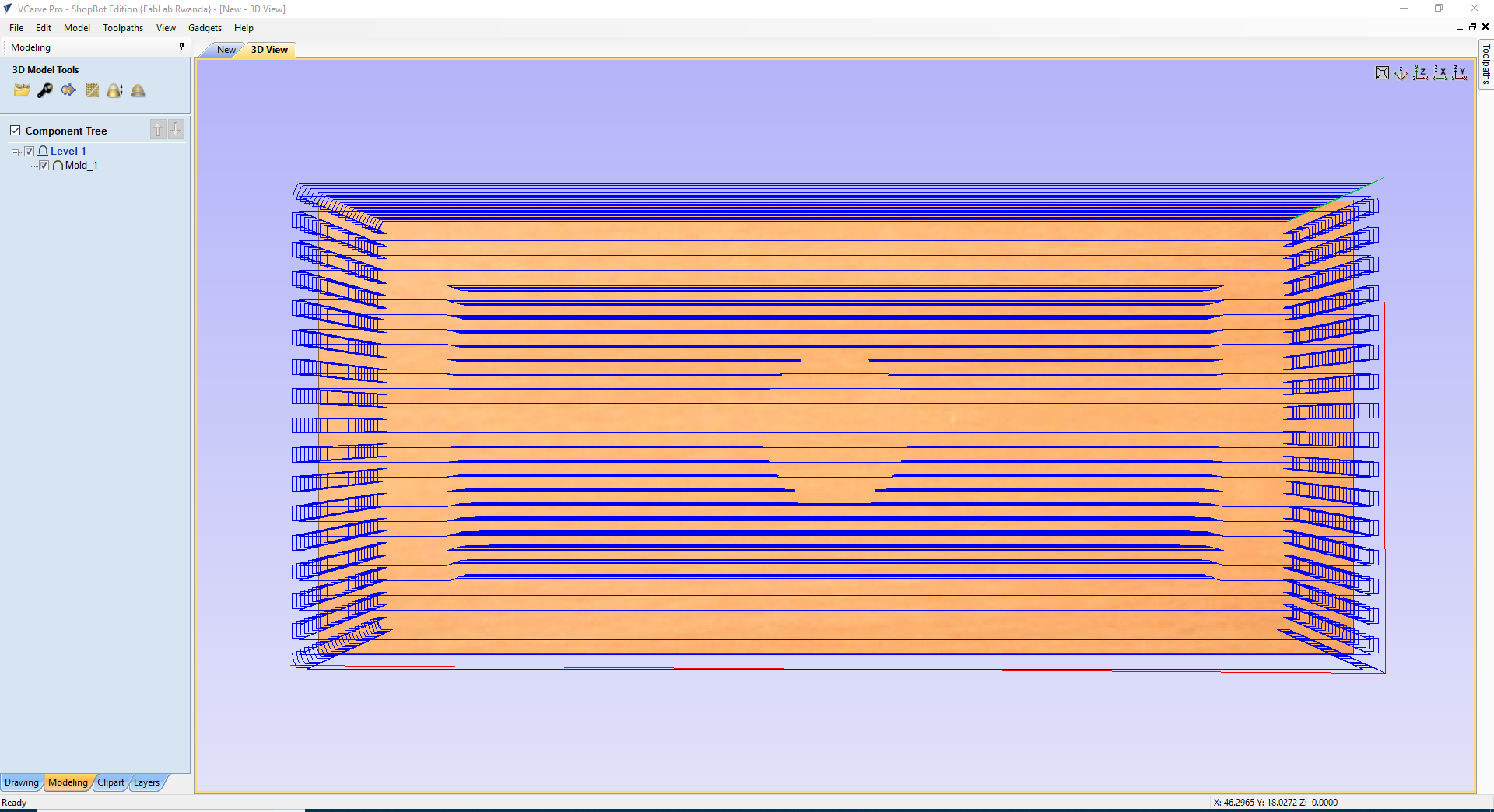

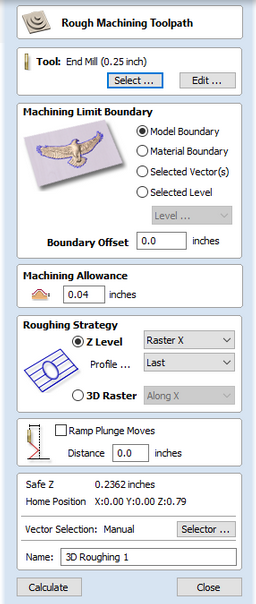

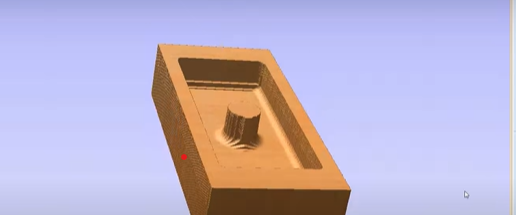

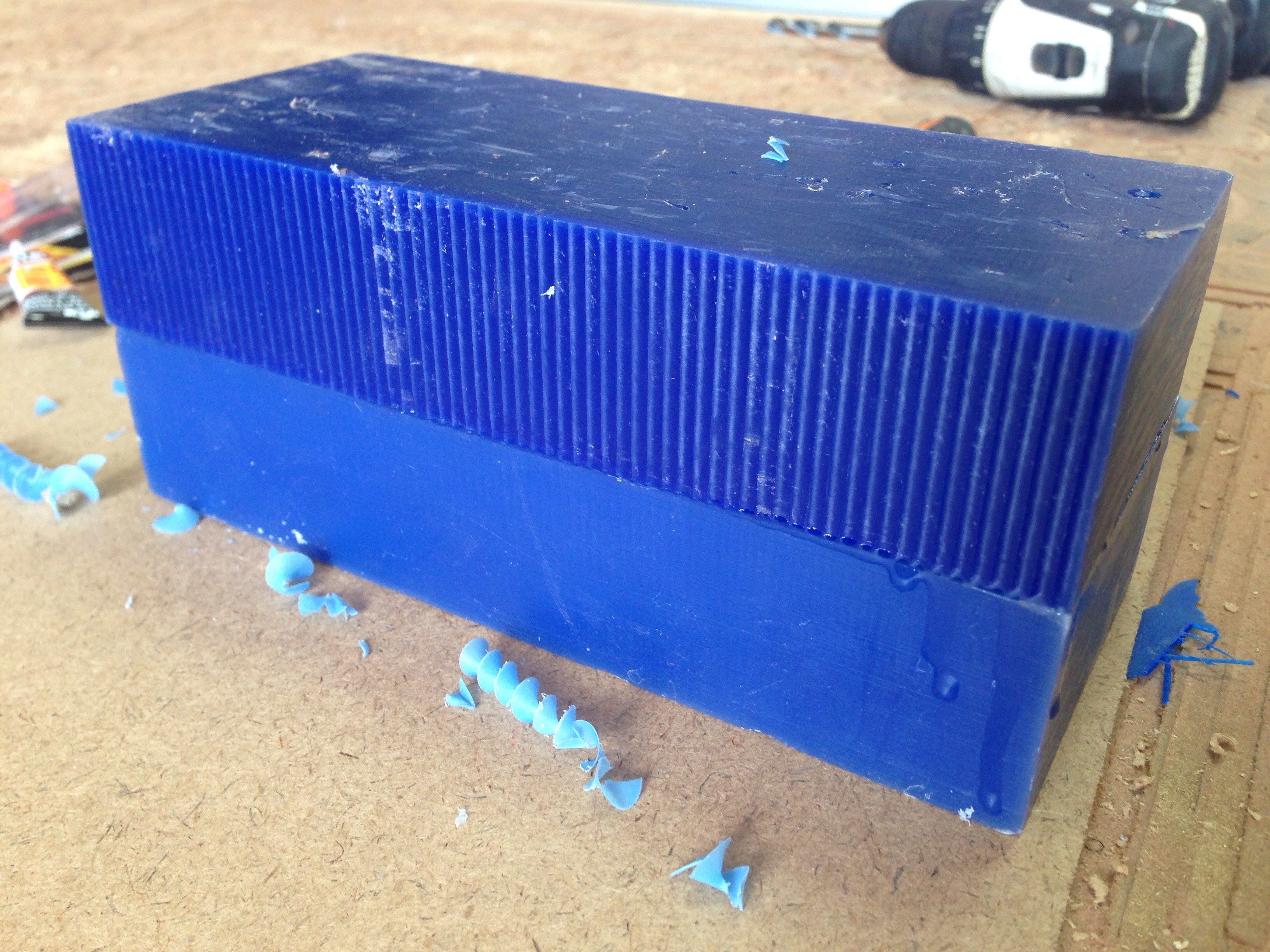

3D Roughing

Rough Machining is used when carving 3D parts to clear away excess material when the part is too deep for the finishing tool to cut in a single pass. these images below will show the all steps i pass. when i was using Vcarve in to generate shopbot file.

The image below shows where the toolpath will pass in Vcarve software

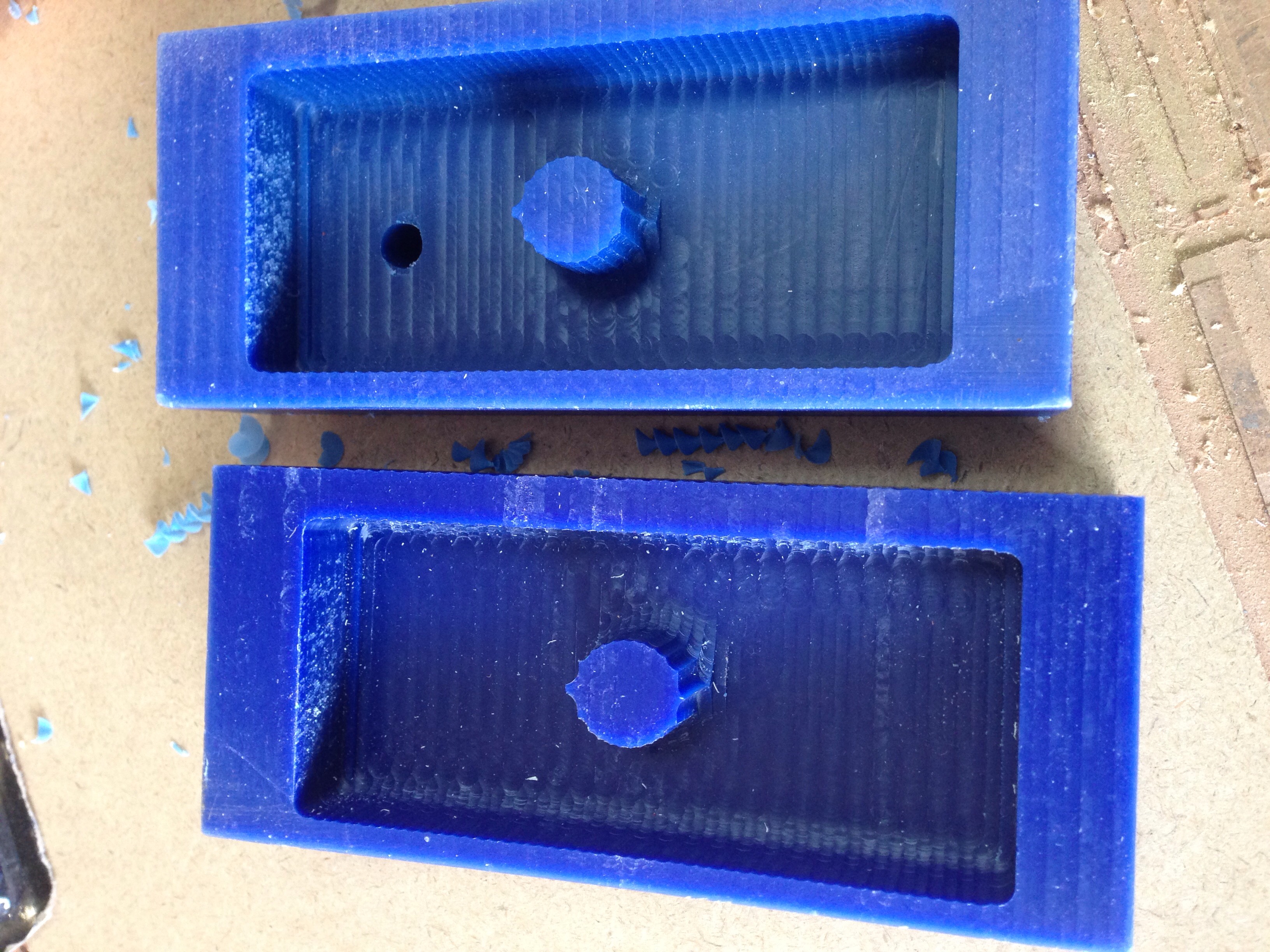

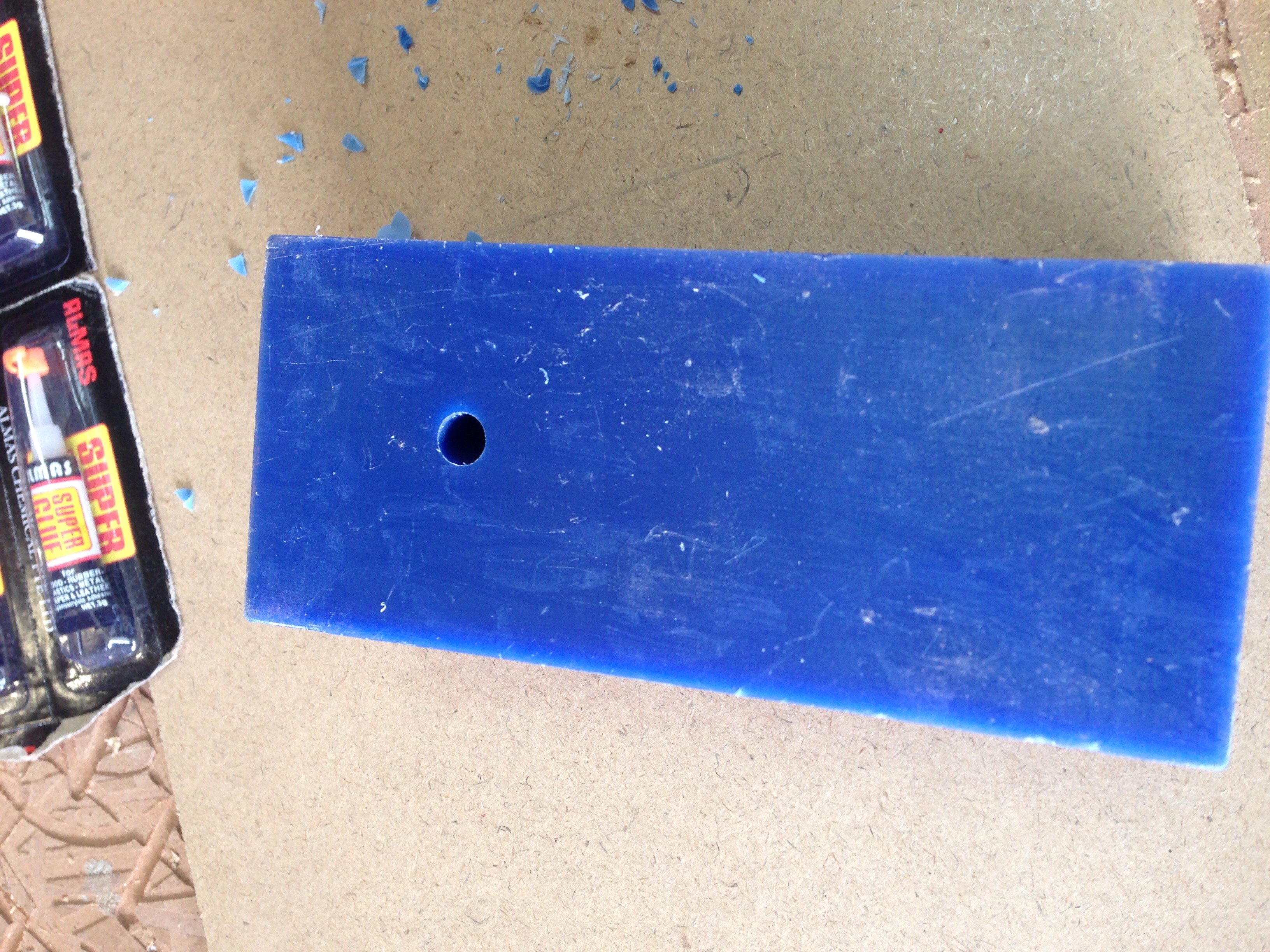

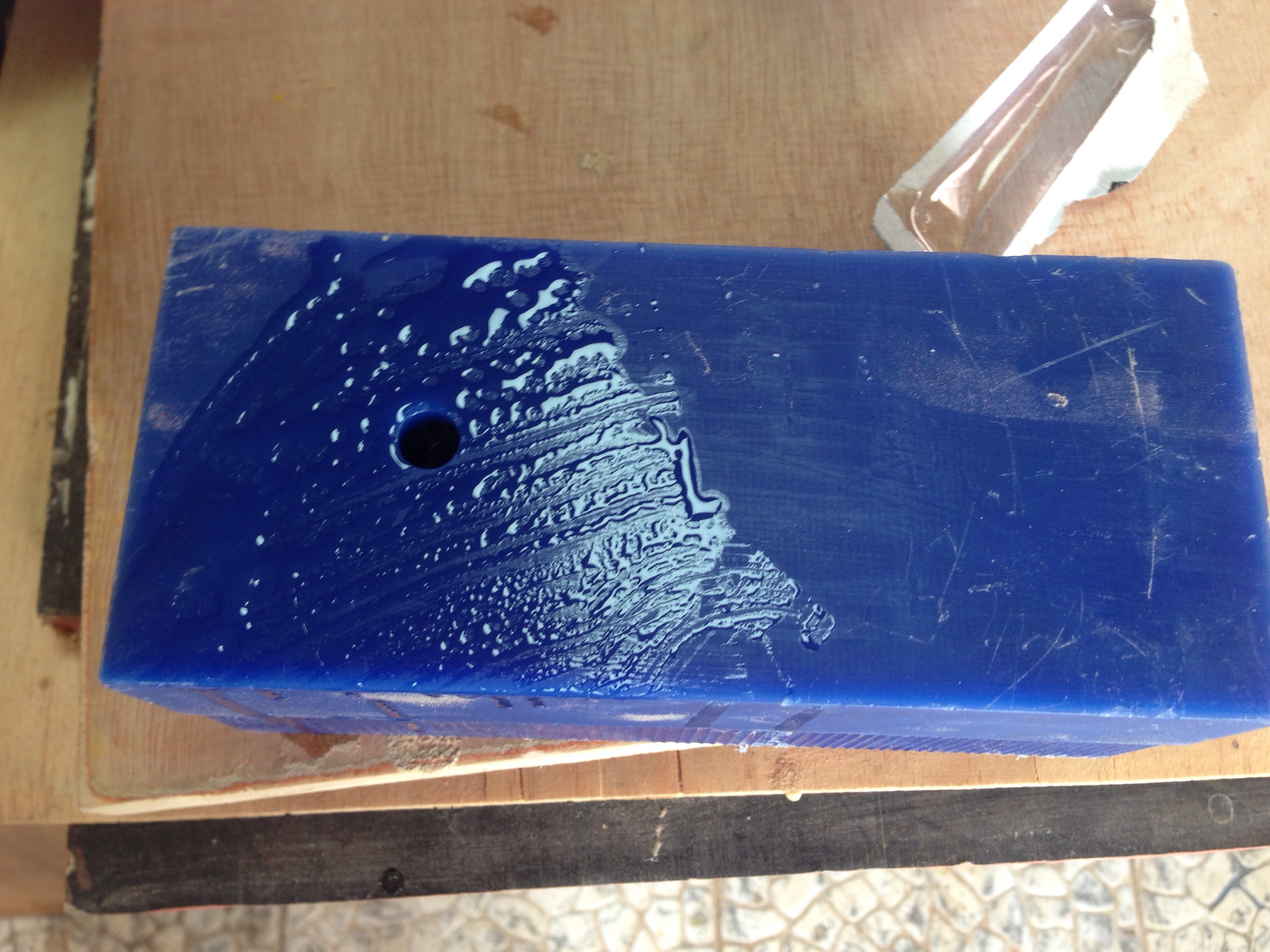

After finishing designing and 3D roughing i try combine two part,i rough by using glue in order to make full molding. And also i need to make a hole in my part in order to see where the casting material it will pass in easy way.

After all of this i putting a glue on the part in to combine my all part.

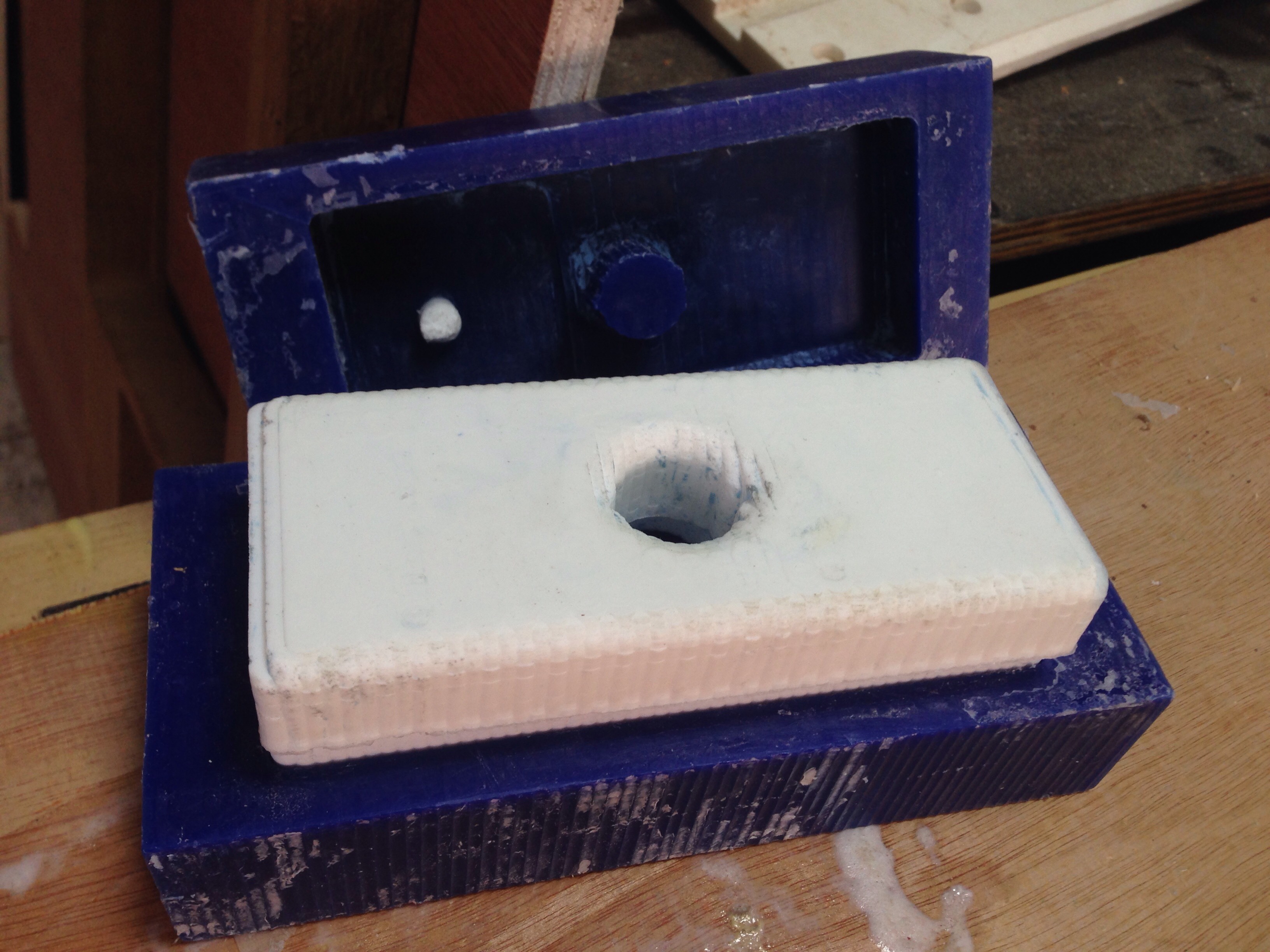

And then i combine them together

After that i use my horder to make it stable and it is ready for casting as shown below

Casting

Casting:

is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various cold setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

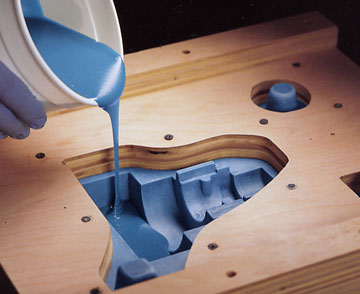

Here Before i start i take that molding staff i made. and then i putting inside in the hole the component A&B for casting after while i waitting to dry and then remove my solidy.Actually casting it done First you need to mix this component A and B 50 by 50 of volume and then mix it both A and B in one container.

After mixing it both compont A abd B you need to put the things you have mix in your mold, you have made in order to fill the all empty space along on your mold design.

the following as shown in the image below.

After that i have to wait like one to two hours to get dry

After one hour my waiting for results it final get dry

After dry you need to breakyour mold in order to remove the things you have made.

here is the image of how it looks

Down below is my orginal filles