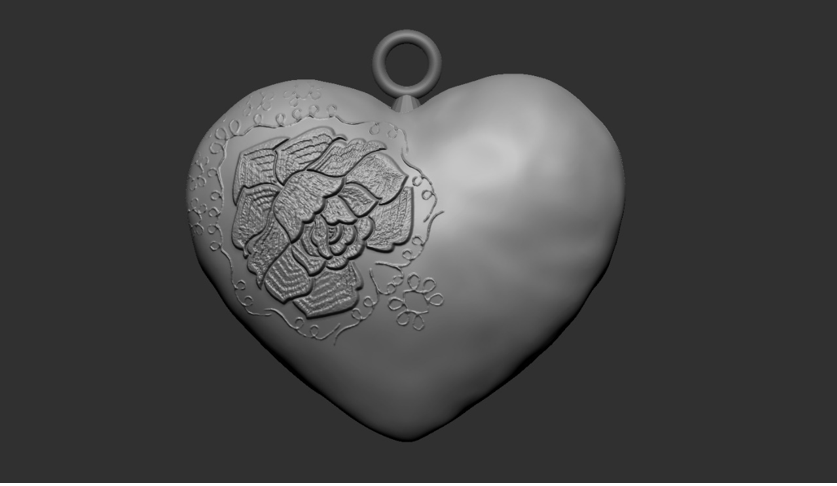

Inspiration

In this practice, we developed a model for the heart that is going to contain the board which will allow us to recognize and play Zapotec language. Because this object has to look like Zapotec we made a design o a heart with this pattern imprinted.

Molding

Molding

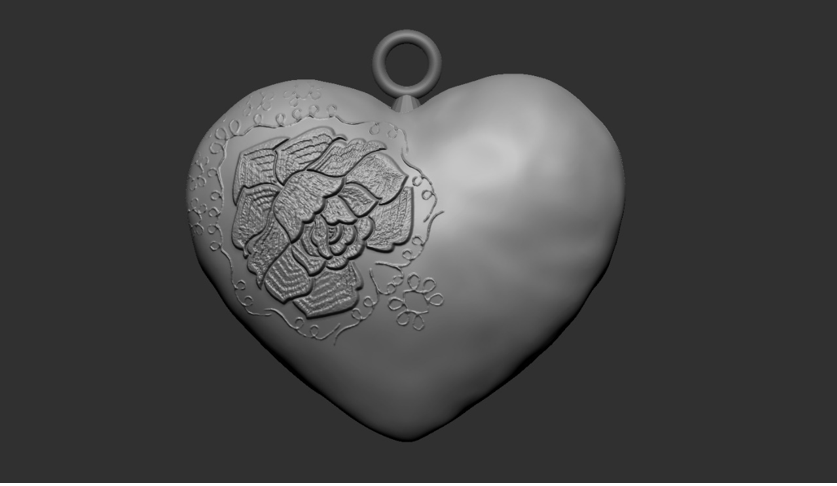

The object was designed with the software Zbrush from Pixologic. This is a program for #d scripting, primarily for organic sculpture. The original model was geometrical, and then an Alpha was applied to make the pattern of the flower, a brush to make specific figures and provide a shape on top of the forms sculpted in the object’s geometry. Then the object was polished.

Then a Dynamesh process was applied was plied to give integration to the form of the mesh. The object was duplicated and then taken to an STL file. Then the object files were charged on the Photon mono 4K of Anycubic. Afterward, the slicer was applied after some supports were put. Here, we experimented with a primary failure since the supports were not well settled and, consequently, one of the hearts exploded. We believe this happened because there were no holes to remove the resin. The heart was too heavy, and the lack of support provoked the failure.

The resin was painted with a pigment for polyester resins. It worked well and did not affect the process catalysis with UV. The supports were removed when the process was finished, and the object was cleaned with isopropyl alcohol.

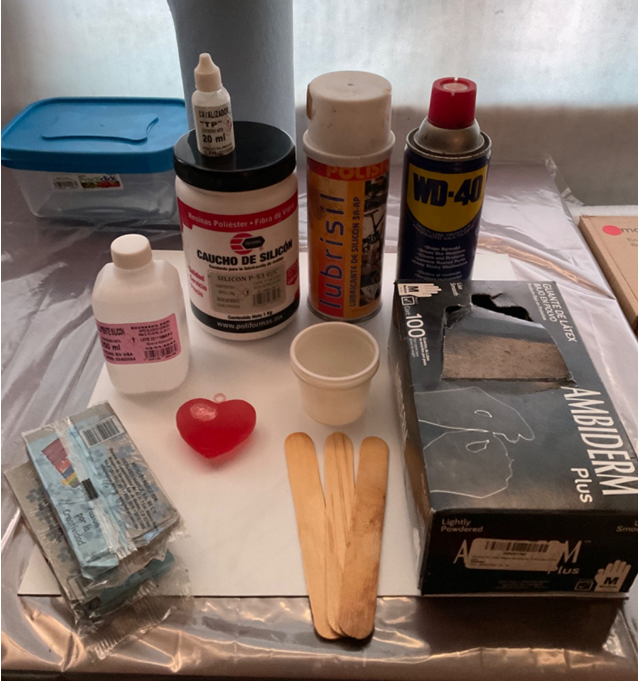

When the object was very clean, we proceeded to make the mold. To do that, we placed the object on a table where it was easy to manipulate. Then we did the walls to contain the object and its different sections. This was made with plasticine. This was convenient because the mold was for silicone and did not stick.

Once the box was ready, we poured the silicon into it, following the product’s instructions and using a catalyzer to make it hard. You have to make it fast to avoid bubbles when pouring the silicone. When the object gets hard enough, you tour it upside down to make the other part. First, you have to use a product to take off the silicone. In this case, we used baseline, and you repeat the process. Finally, you get a mold having a mold in negative. Afterward, you can start the casting.