First

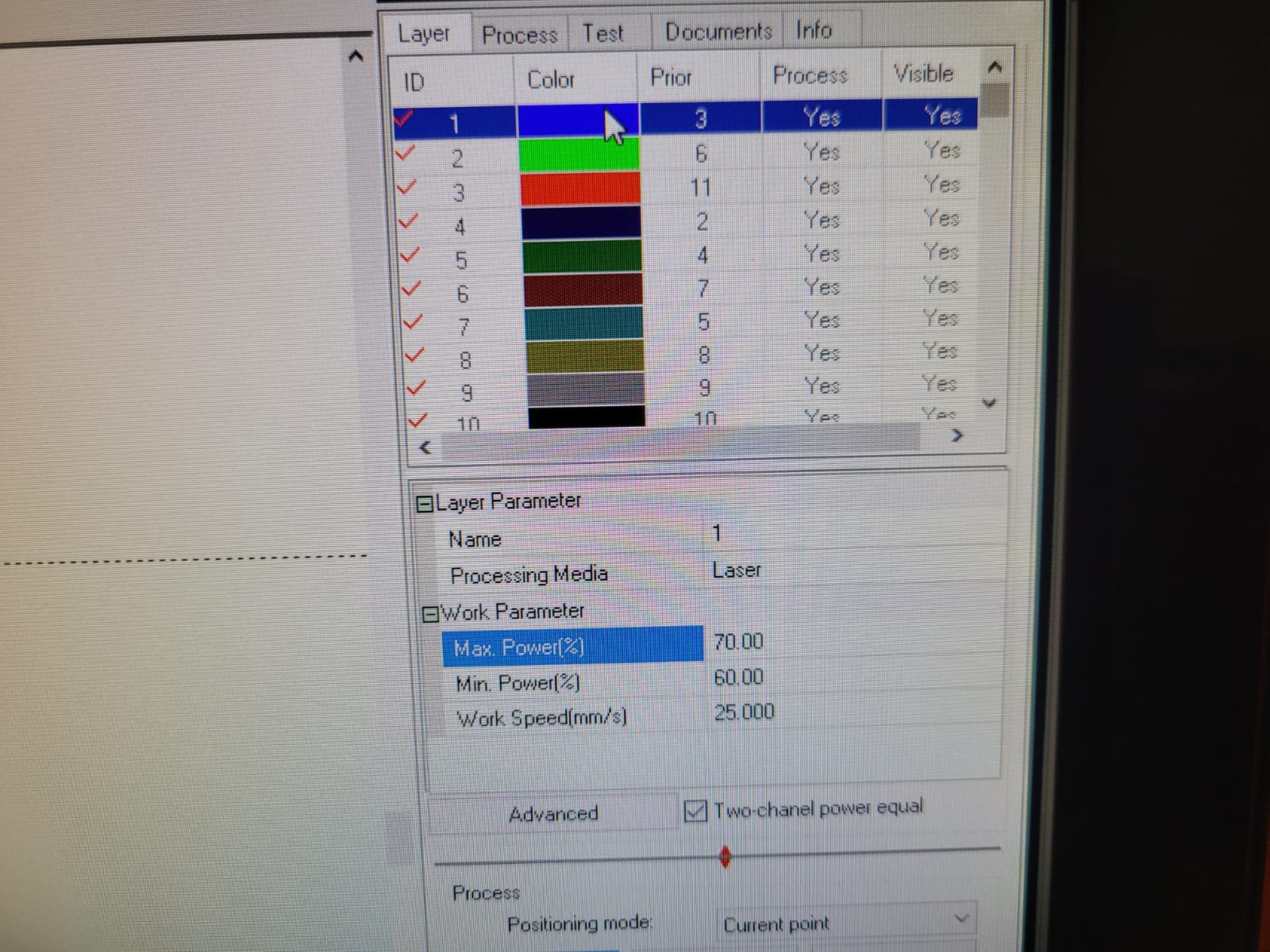

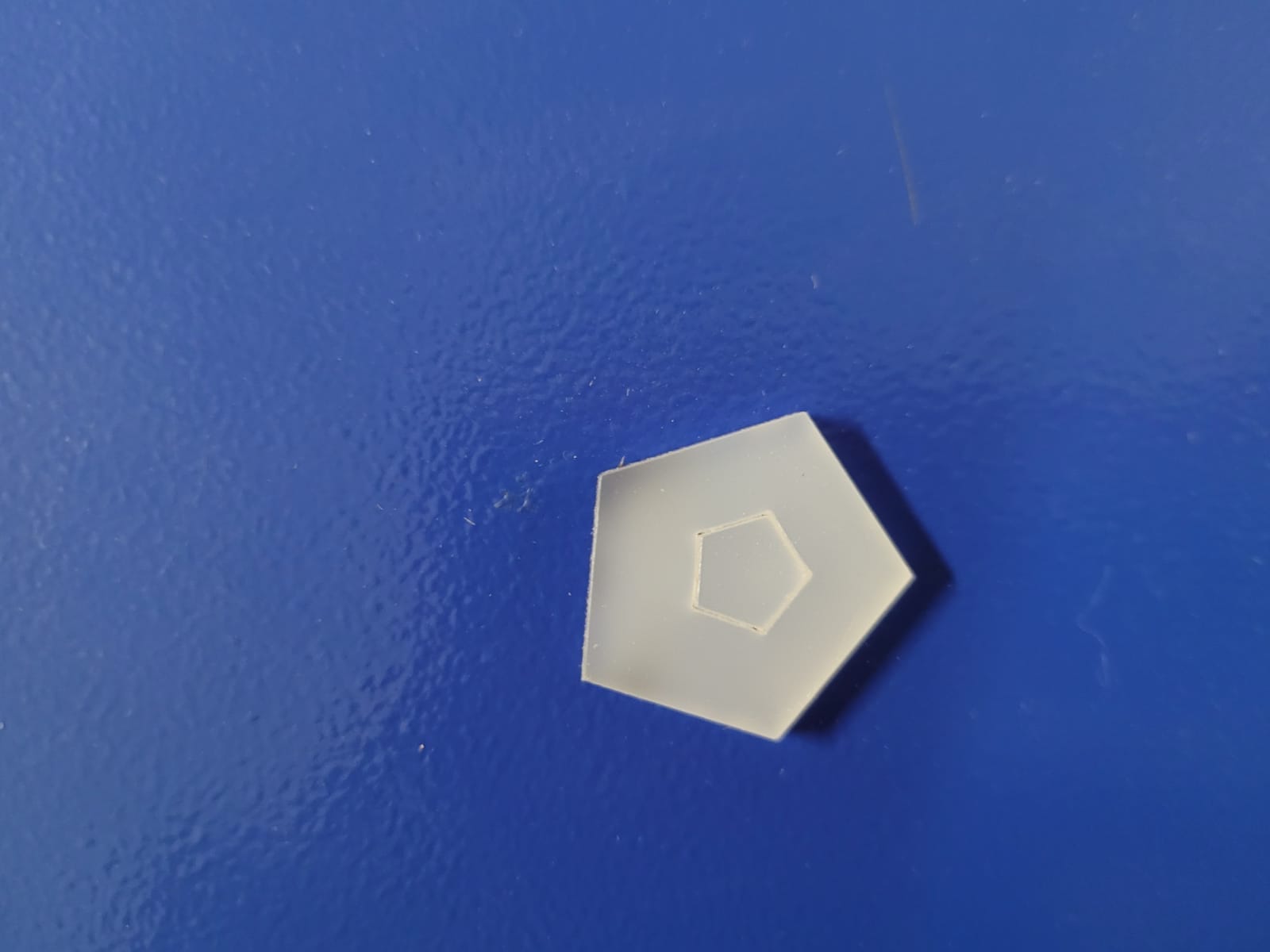

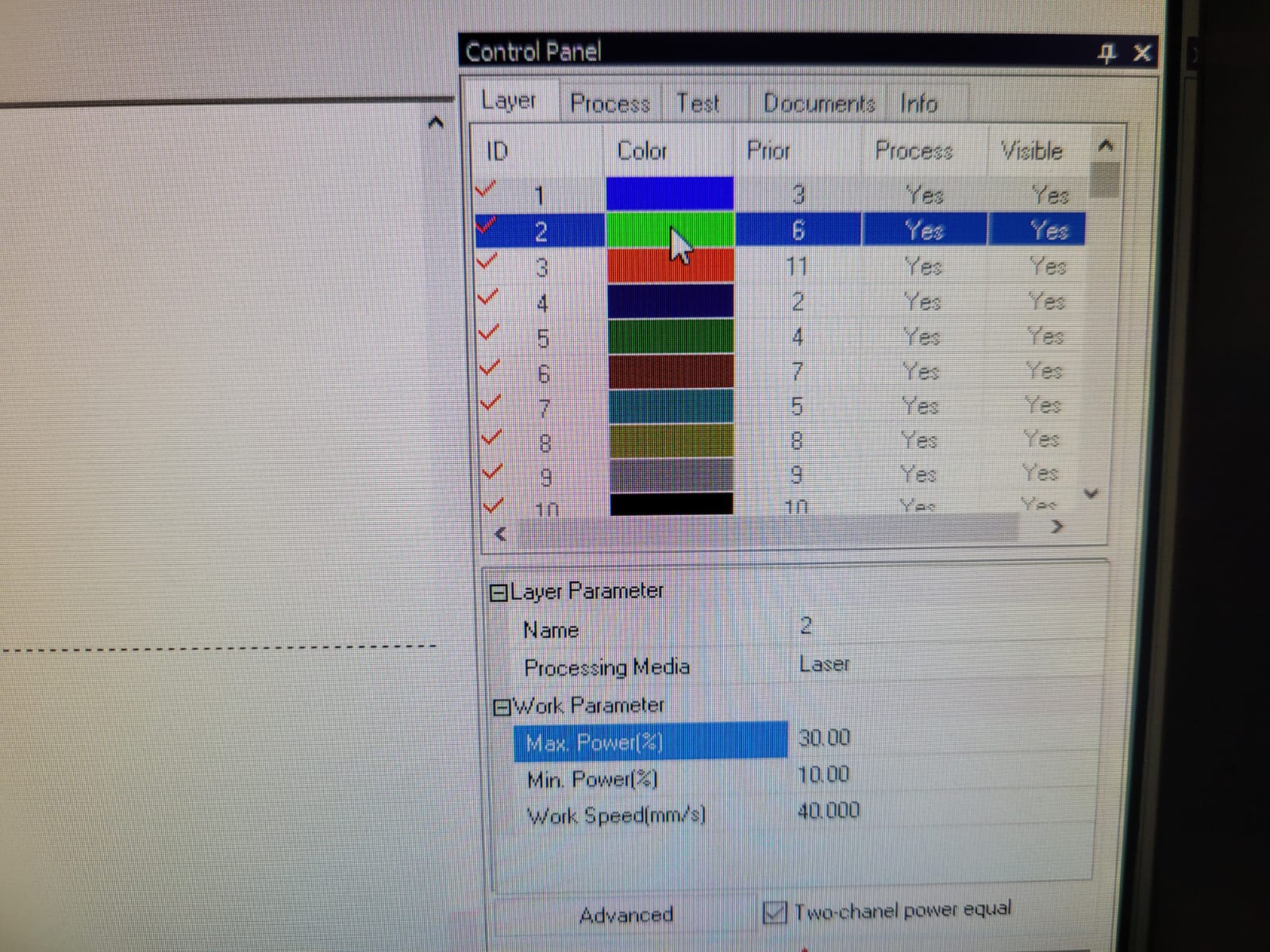

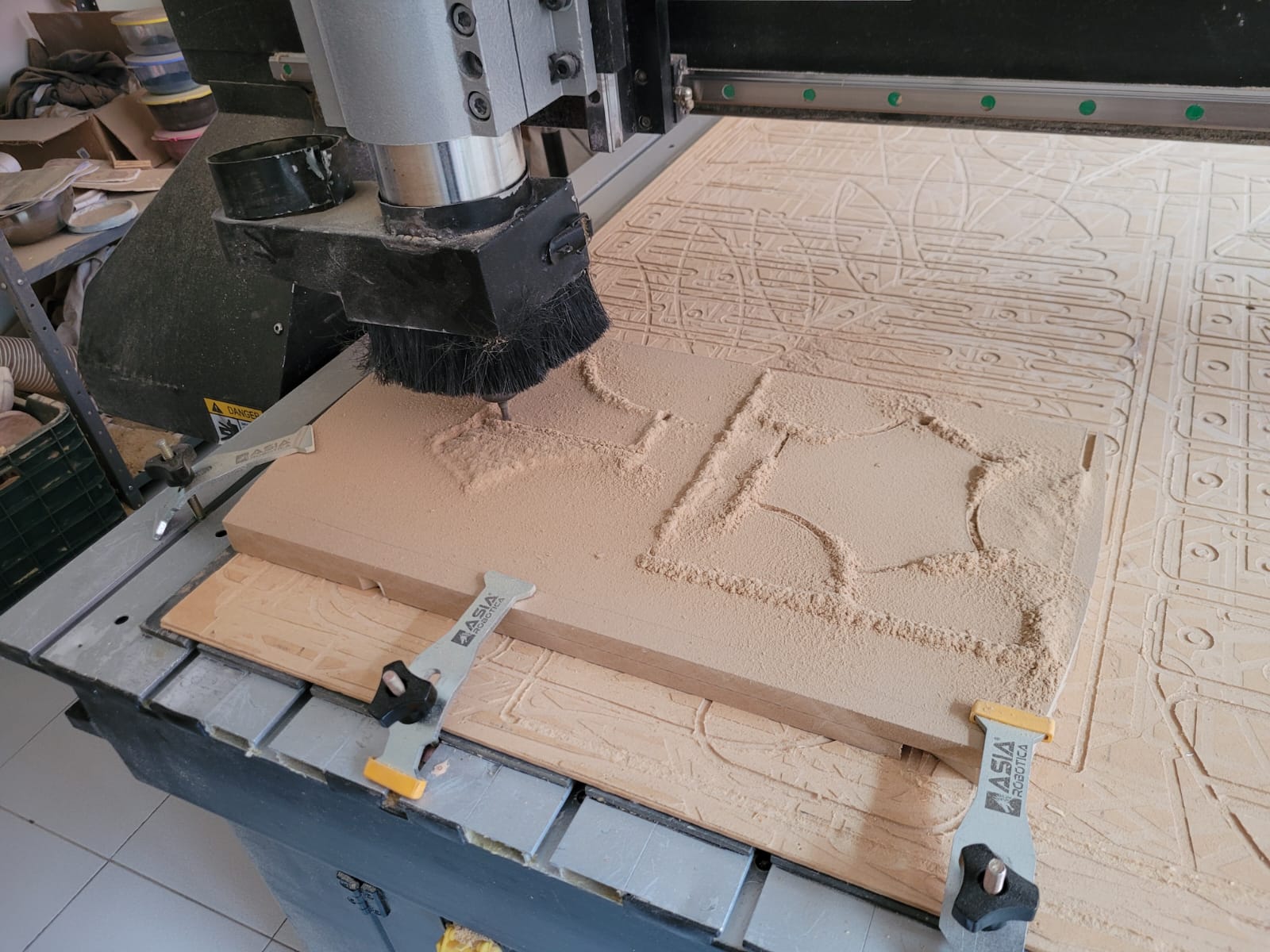

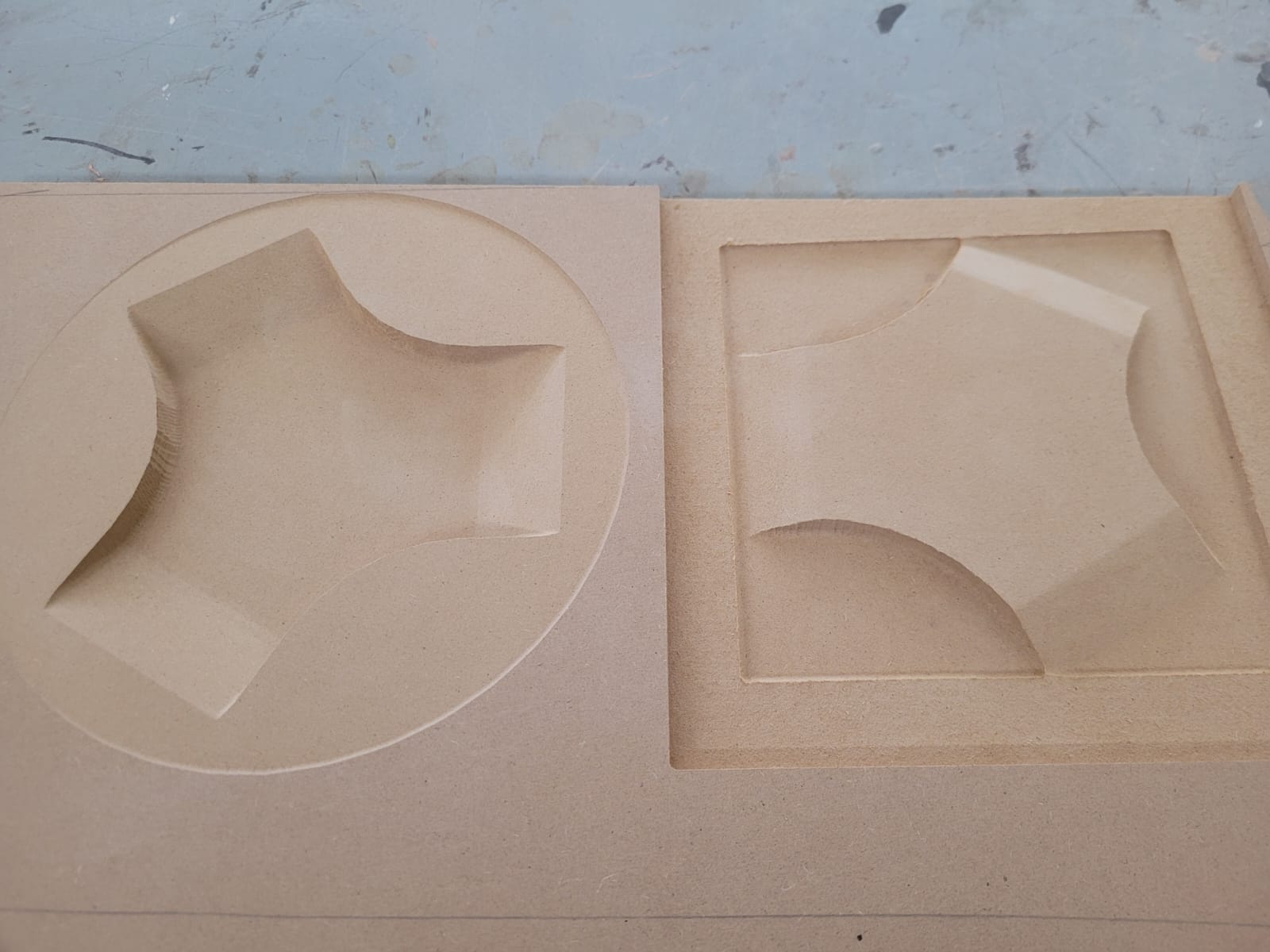

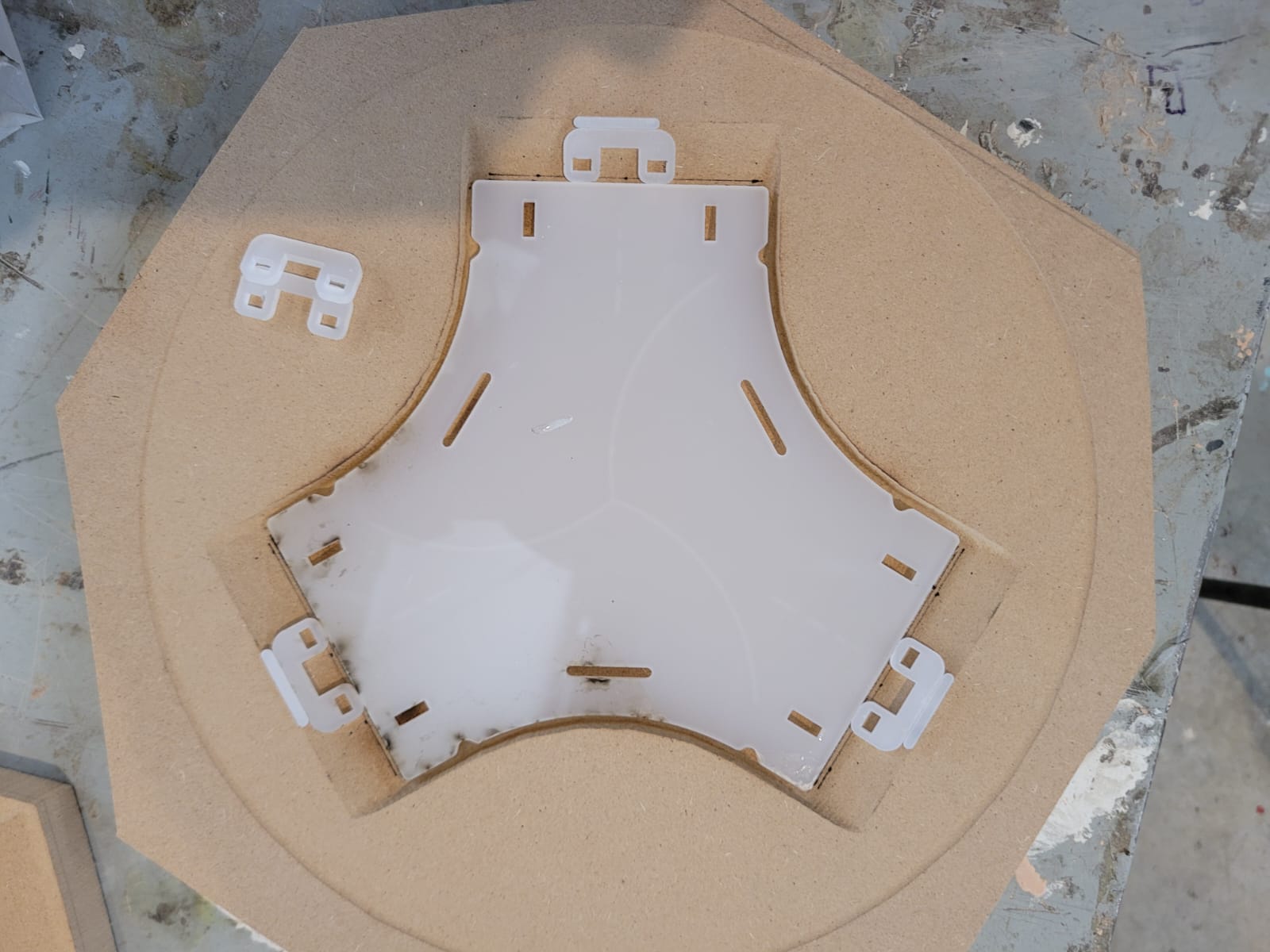

Throughout the weeks of the FabAcademy I was carrying out several projects related to digital manufacturing, these exercises could lead to the development of our final project. In my case, I directed most of my exercises, but it was in week 15 (Wildcaed week), when I began to manufacture my structure.

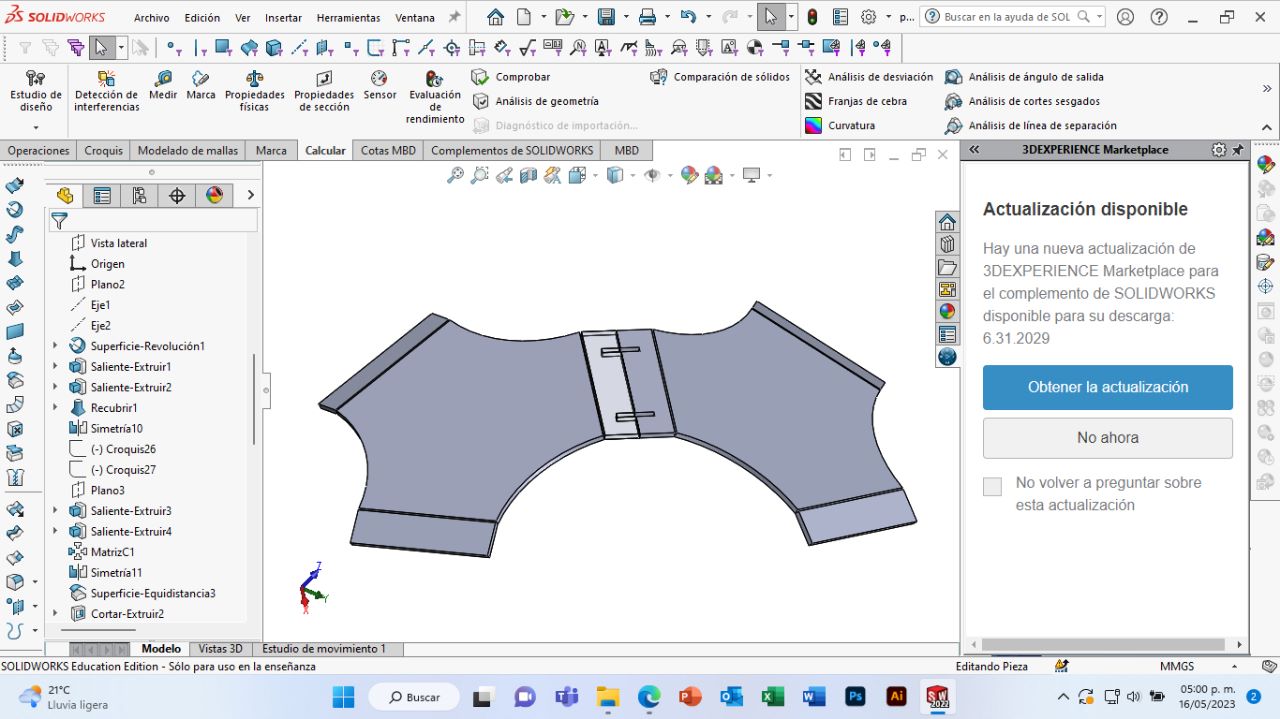

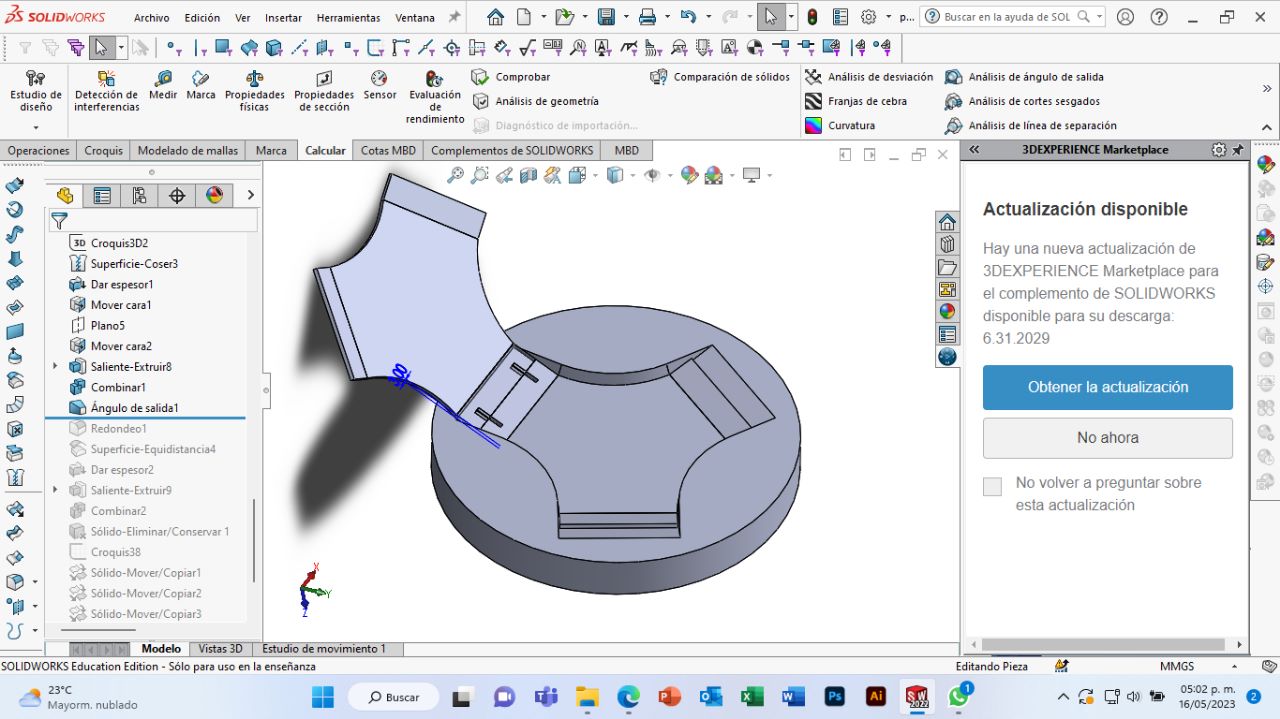

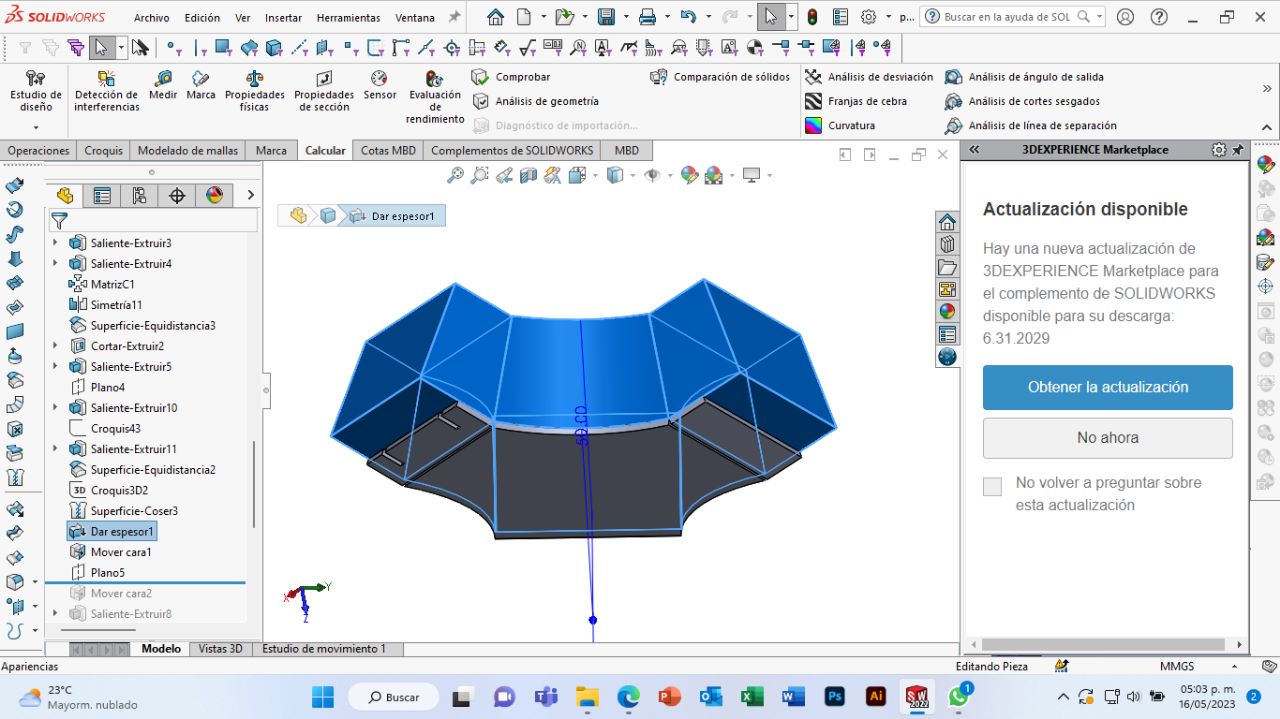

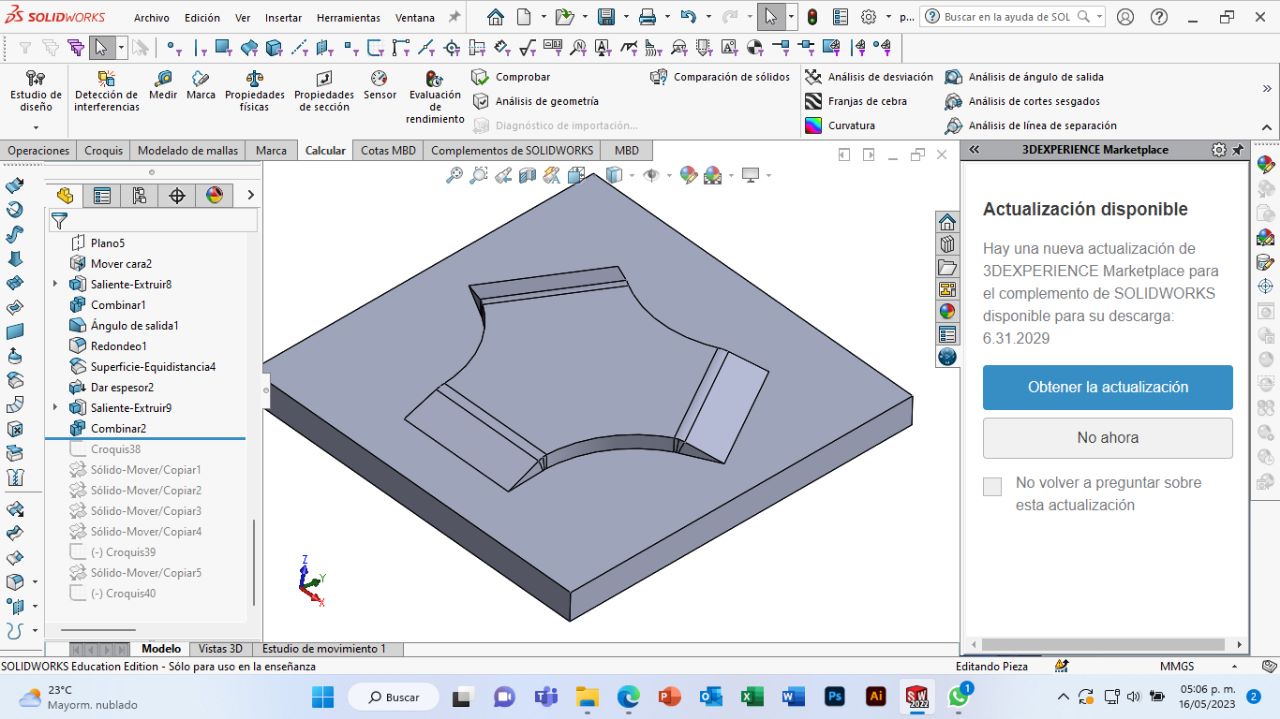

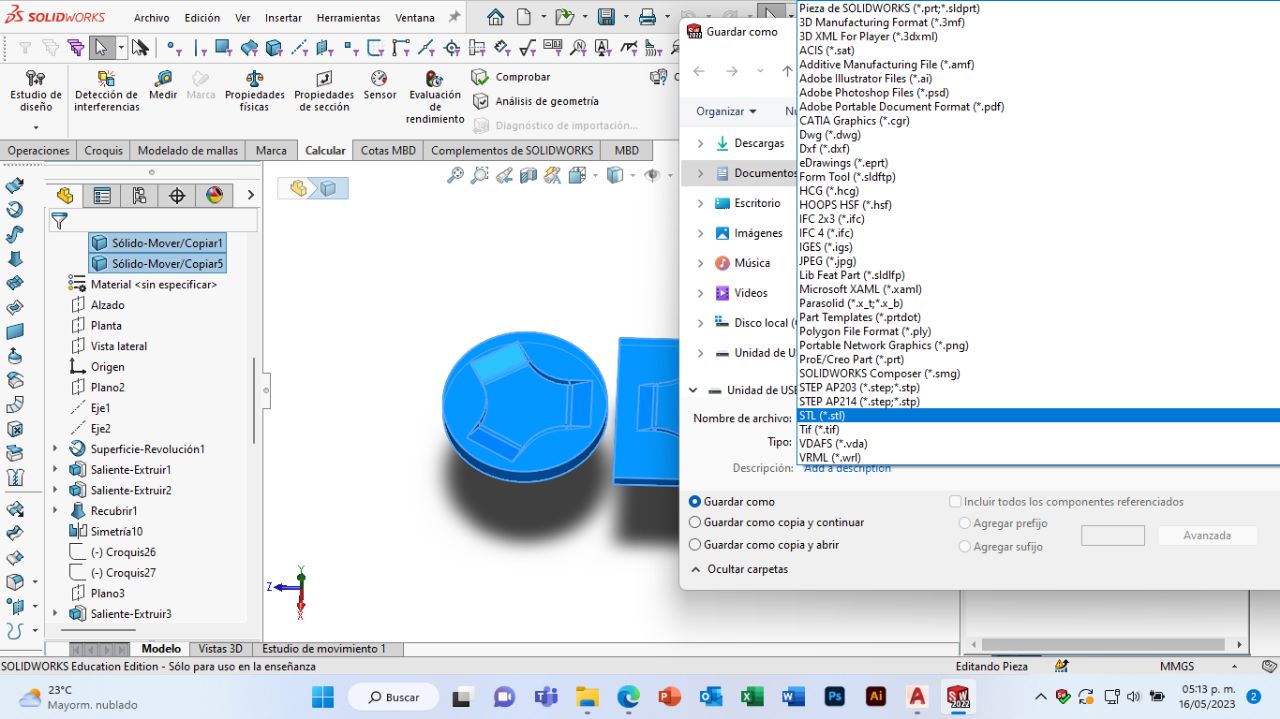

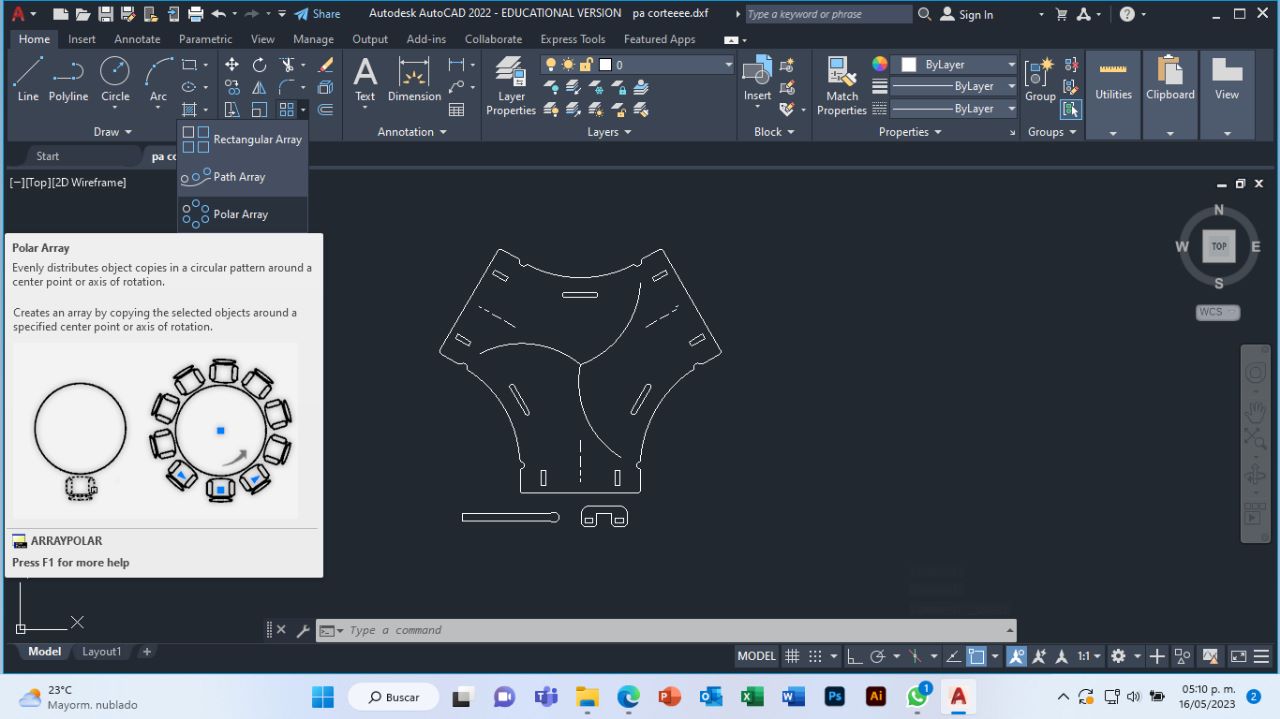

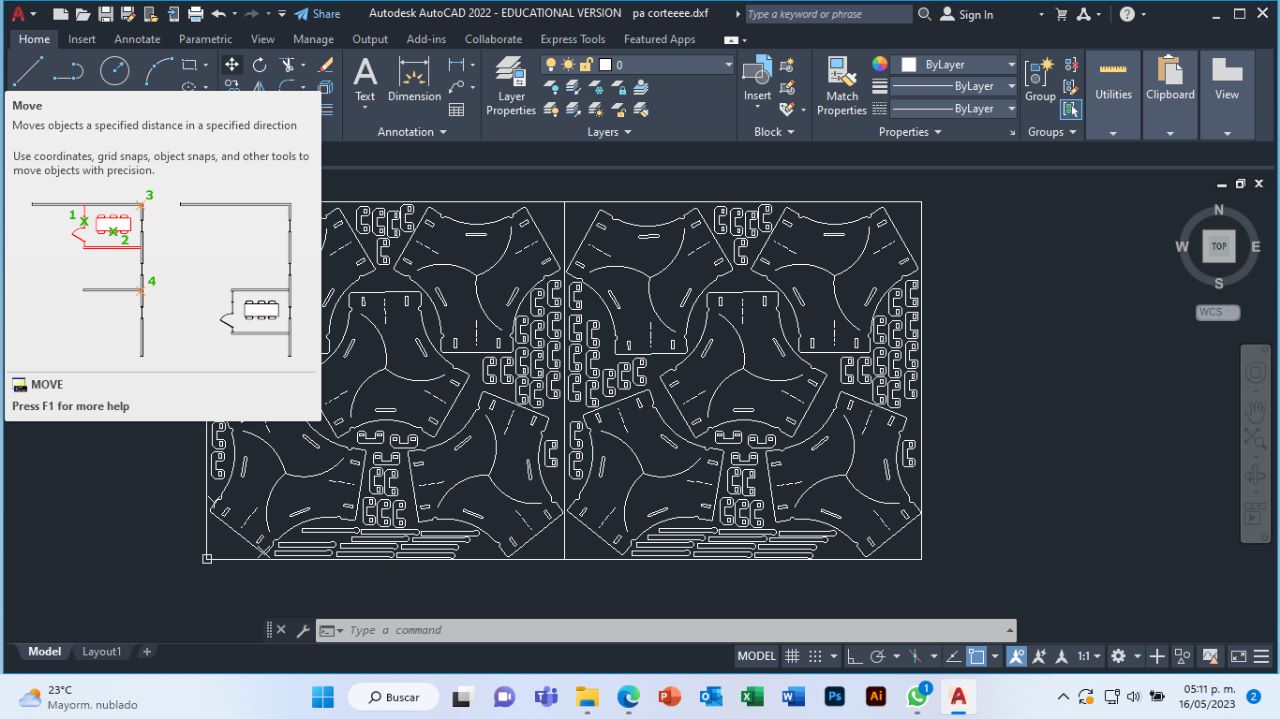

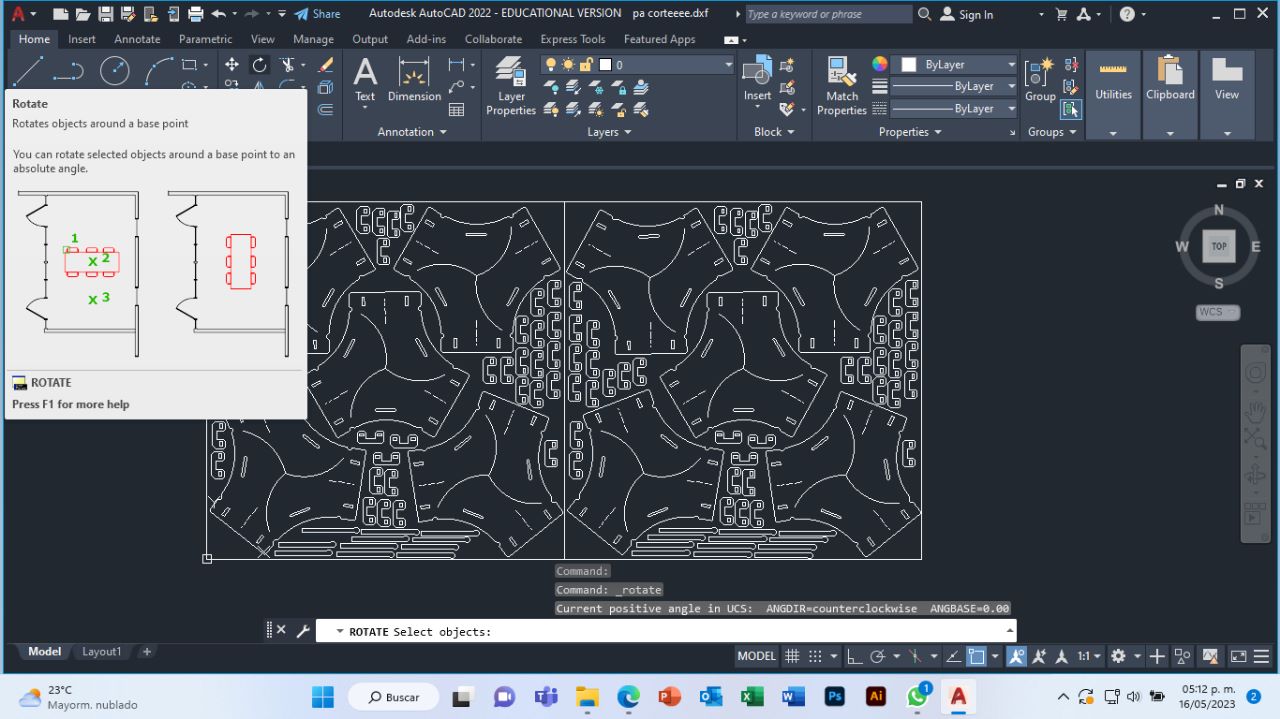

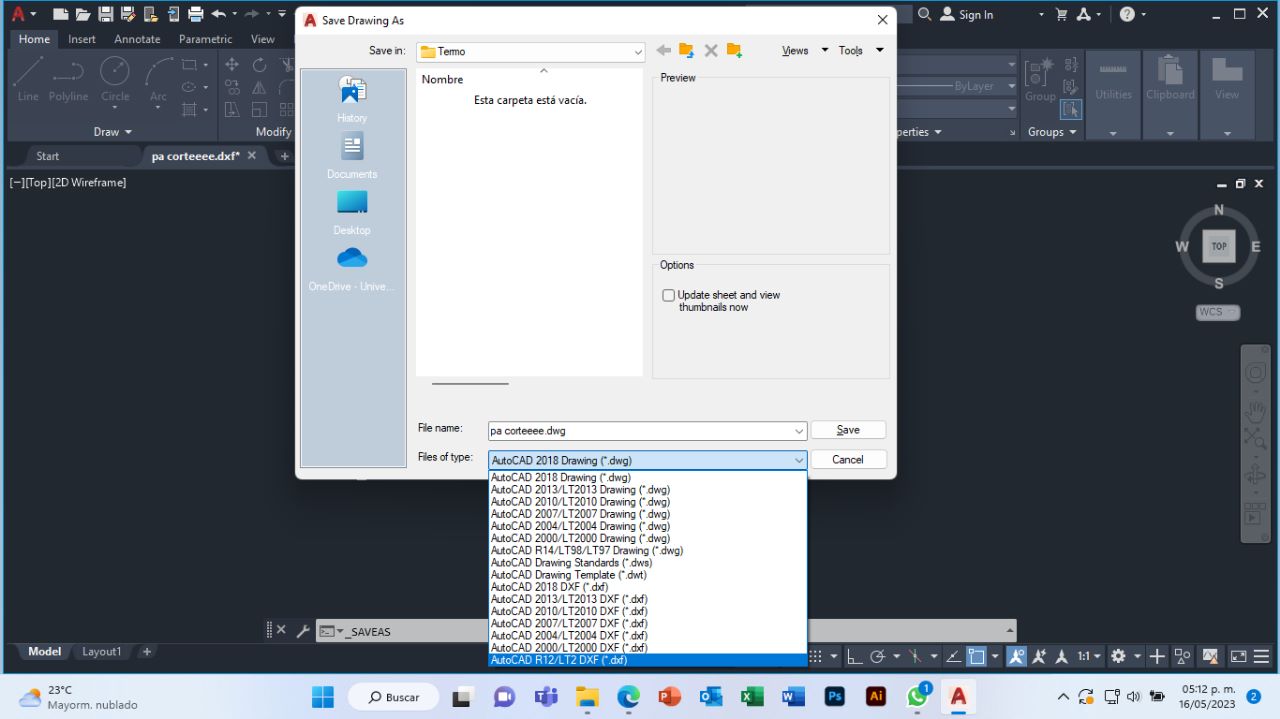

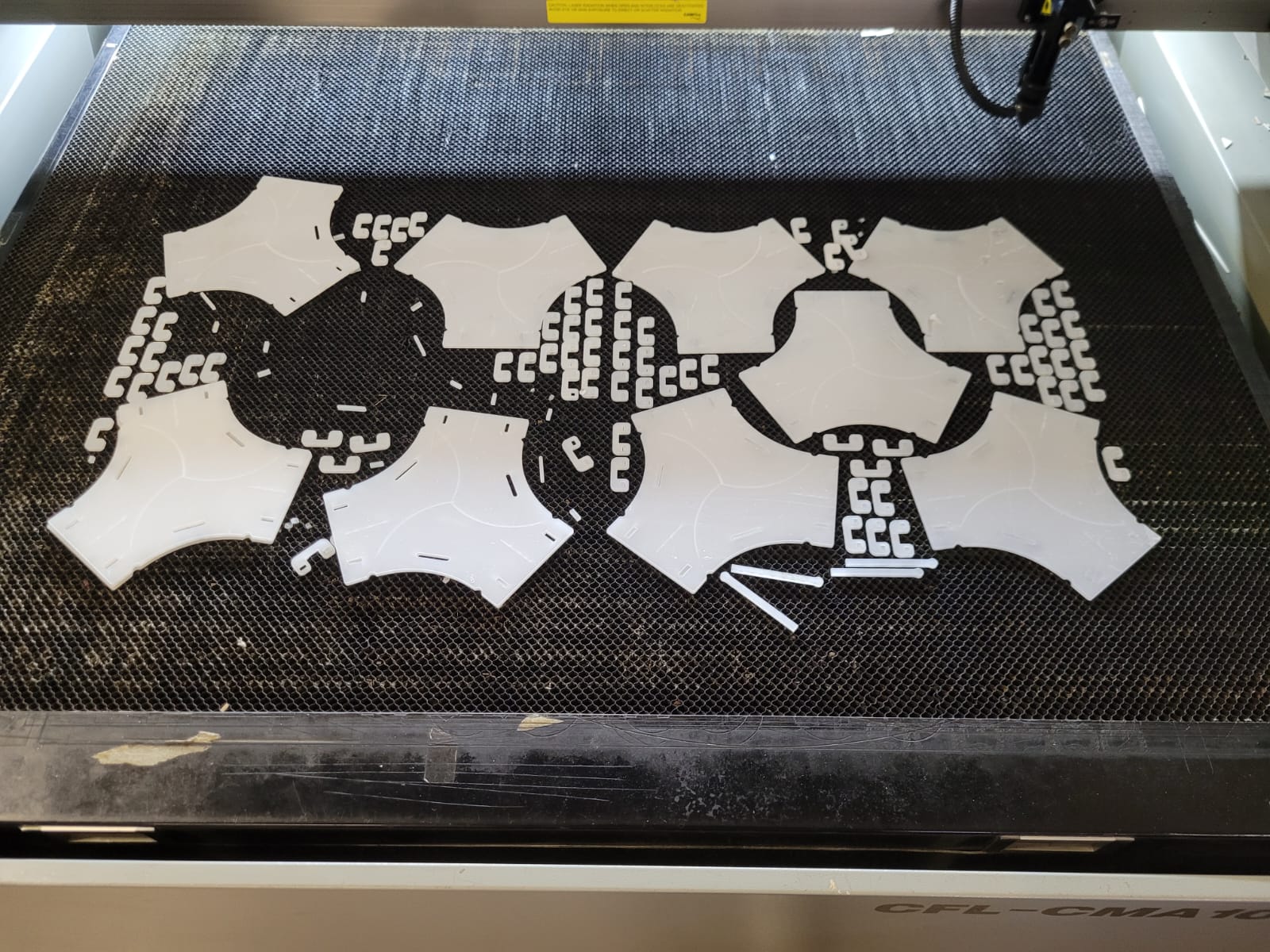

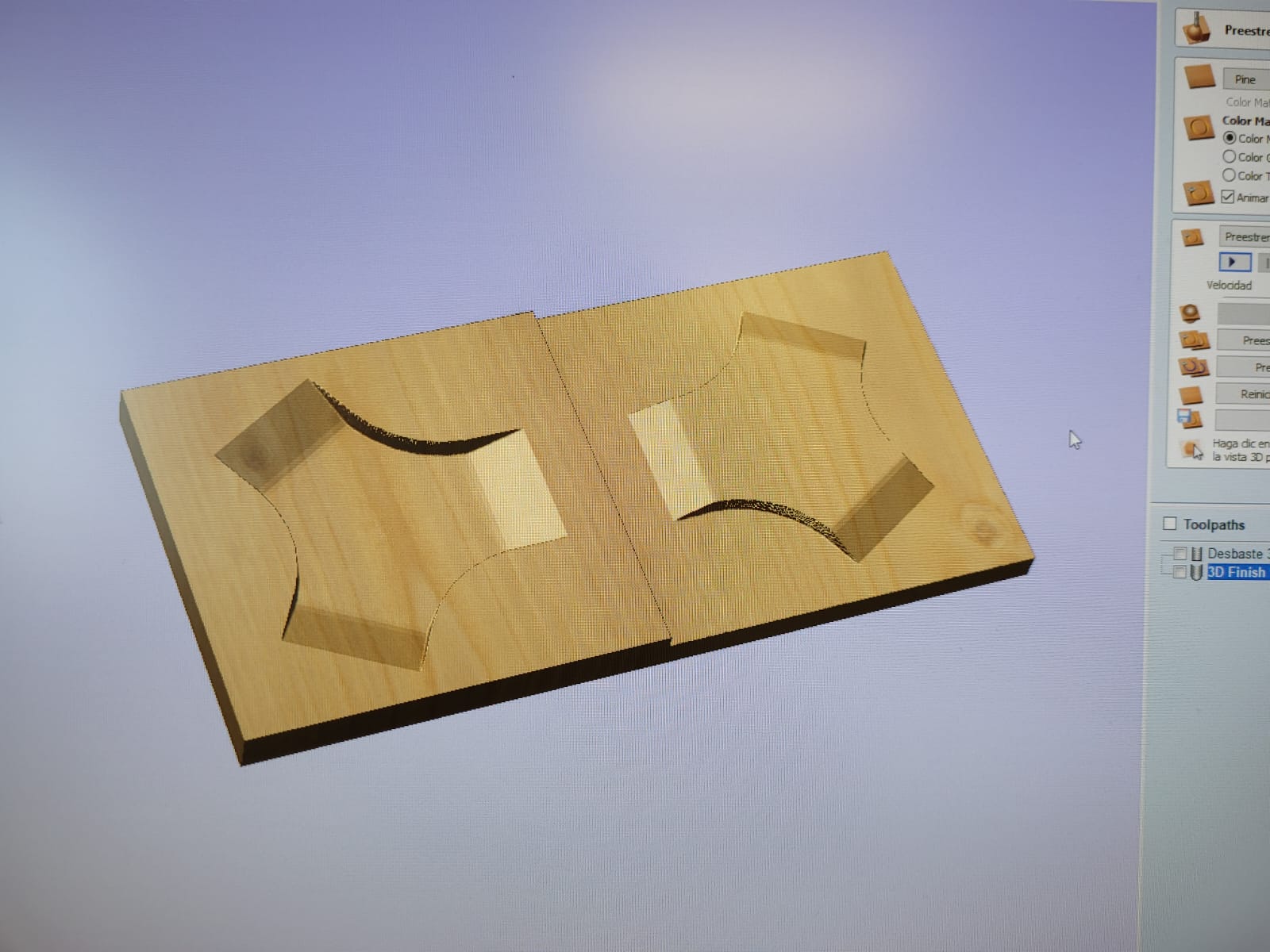

First I designed my file in solid works to make a flat piece with the help of my project that I did in week 3 "Computer controlled cutting".