Appearance

Computer Aid Design - 2D & 3D

In this week, I have tried AutoCAD for 2D design drawing, Fusion 360 & OpensCAD for 3D modelling.

2D Design with AutoCAD

AutoCAD is a commercial computer-aided design (CAD) and drafting software application. Developed and marketed by Autodesk, AutoCAD was first released in December 1982 as a desktop app running on microcomputers with internal graphics controllers.Before AutoCAD was introduced, most commercial CAD programs ran on mainframe computers or minicomputers, with each CAD operator (user) working at a separate graphics terminal. AutoCAD is also available as mobile and web apps. AutoCAD is primarily used for 2 Dimensional drawings, and even though 3D modeling is available in AutoCAD other computer-aided design software like Fusion 360, Inventor and SolidWorks are preferred in 3D modeling. Wiki

The Autodesk CAD user interface is shown as below.

I drew a square using 'rectangle' command.

Then I used 'offset' command to create concentric square.

Then I used 'pattern' command to copy the concentric squares.

I saved the drawing as .dxf file which can be read by most of the cutting machines. This drawing will be further ued to test the clearance of our laser cutter.

3D Design with Autodesk Fusion360

Fusion - is a powerful, cloud-based CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering) tool. It's designed to help us create, analyze, and manage my designs from start to finish.

This section I have tried Fusion360 for 3D design. I have designed a dog feeder box which can be further used in my mechanical design & machine making project dog-feed-machine (https://fabacademy.org/2023/labs/ningbo/students/yaorun-zhang/assignments/week11/).

2D sketch

The 3D design start from 2D drawings, therefore a 2D sketch was built.

3D extrusion

Then 2D drawings were extruded to 3D.

The thickness of the extrusion can be defined to creat a 3D sheet.

Parametric design

The parametric design can be achieved using 'change parameter' function.

I have defined a line length as 'thickness' and applied it to lines that is equal to this length.

The thickness of the extrusion can also be set to a parametric value.

Assemble of different parts

Then the designed parts can be assembled using joint command.

First select one surface of the part you want to assemble then select one point on that surface.

Then select a surface of the other part that you want to assemble then select one point on surface.

Adjusting the direction by click the flip button, then you will have two parts assembled.

Export .dxf file

The drawings can directly save to .dxf file using export command as follow.

It should be noted that if you want to export a specific part then other parts need to be hided.

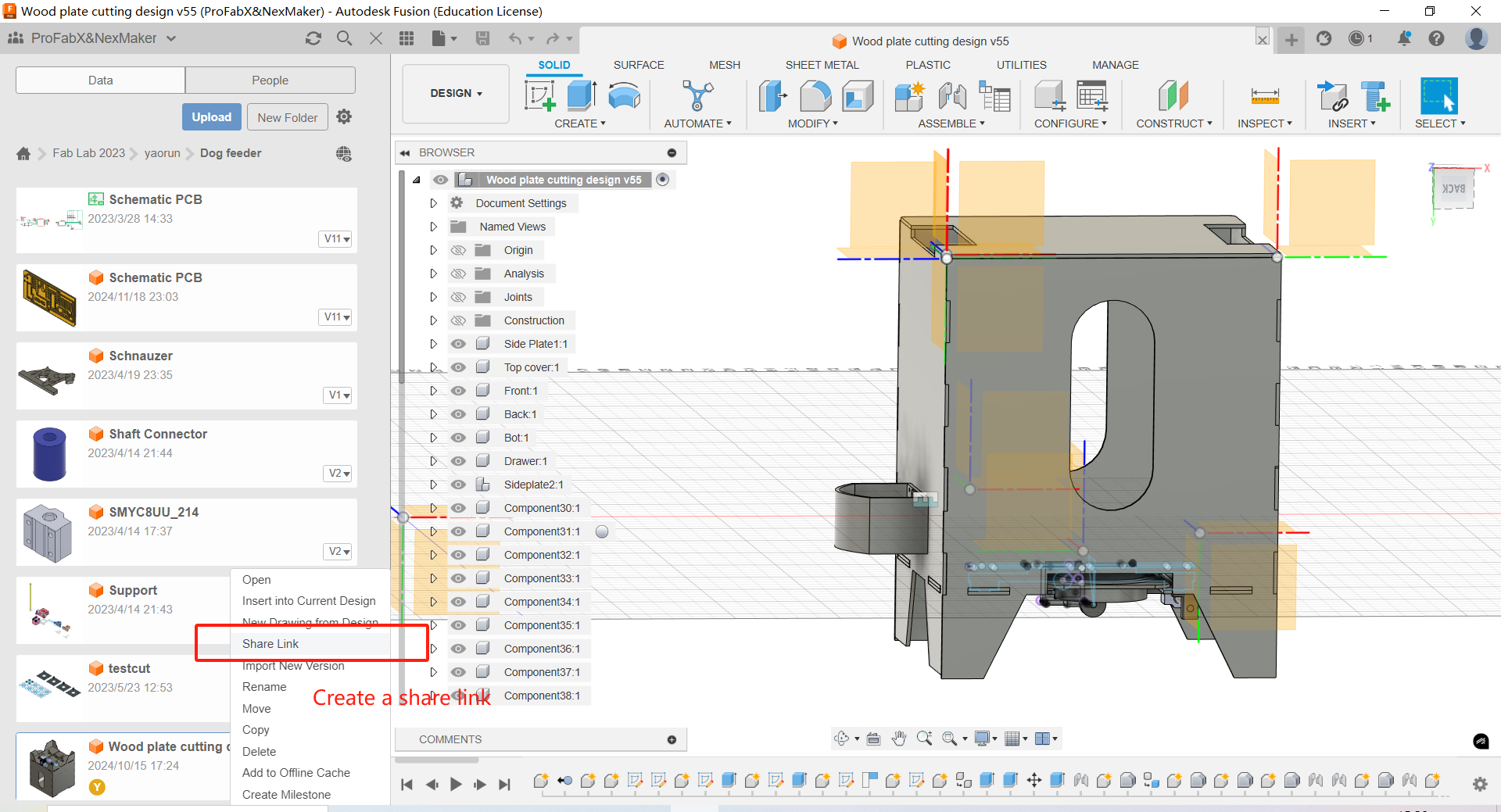

Create a 3D design share link

Generate a share link with Fusion 360.

Here you can choose the access method of the design you want to share.

3D Design with OpensCAD

OpenSCAD is a free and open-source software for creating solid 3D CAD objects with program scripts. It's particularly popular among programmers and those who prefer a script-based approach to 3D modeling.

// Define parameters for bowl dimensions

bowl_radius = 50; // Radius of the outer bowl

bowl_height = 20; // Height of the bowl

wall_thickness = 5; // Thickness of the outer walls

divider_thickness = 3; // Thickness of the divider in the center

// Hollow out the inside by subtracting the inner cylinder

difference() {

// Combined outer shape

union() {

// Outer cylinder (main bowl shape)

cylinder(h = bowl_height, r = bowl_radius, $fn = 100);

// Outer cylinder (Add up the outer frame)

translate([0, 0, bowl_height - wall_thickness])

cylinder(h = wall_thickness, r = bowl_radius + wall_thickness, $fn = 100);

}

// Inner cylinder (hollow out the inside)

translate([0, 0, wall_thickness])

cylinder(h = bowl_height + wall_thickness, r = bowl_radius - wall_thickness, $fn = 100);

}

// Create the center divider

translate([0, 0, 15]) {

cube([divider_thickness, 2 * bowl_radius, bowl_height+10], center = true);

}The final result is shown as below.

The same result can be get using Fusion.

The export process is also quite simple.

Comparison between 3D design tools

Key differences between the tools used:

- AutoCAD is primarily used for 2D drafting and documentation, making it ideal for architects and engineers who need precise technical drawings.

- Fusion 360 offers a comprehensive suite of tools for 3D modeling, simulation, CAM, and CAE, making it suitable for a wide range of industries including manufacturing and product design.

- OpenSCAD is a script-based 3D modeling tool, which is great for those who prefer coding and scripting to create complex models. It's free and open-source but has a steeper learning curve.

| Feature | AutoCAD | Autodesk Fusion 360 | OpenSCAD |

|---|---|---|---|

| Primary Use | 2D drafting and documentation | Comprehensive 3D modeling, CAM, CAE | Script-based 3D modeling |

| Platform | Windows, Mac, Web | Windows, Mac, Linux, Web | Windows, Mac, Linux |

| Pricing | Subscription-based | Subscription-based ($495/year) | Free |

| Ease of Use | Moderate | Moderate to High | Steep learning curve |

| Collaboration | Limited | Extensive | Limited |

| Simulation | Basic | Advanced | None |

| CAM Capabilities | Basic | Advanced | None |

| 3D Printing Support | Basic | Advanced | Basic |

| Electrical Design | Basic | Advanced | None |

| Community & Support | Extensive | Extensive | Limited |

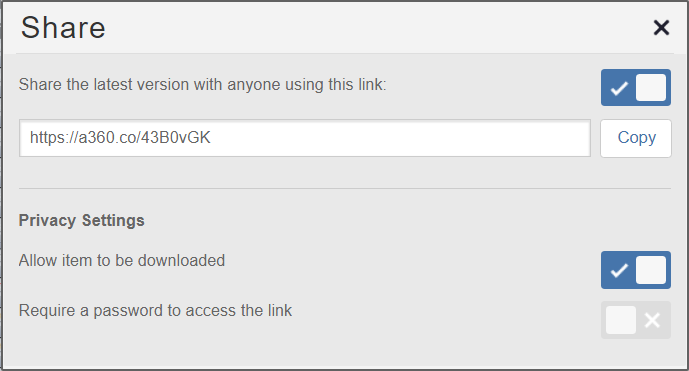

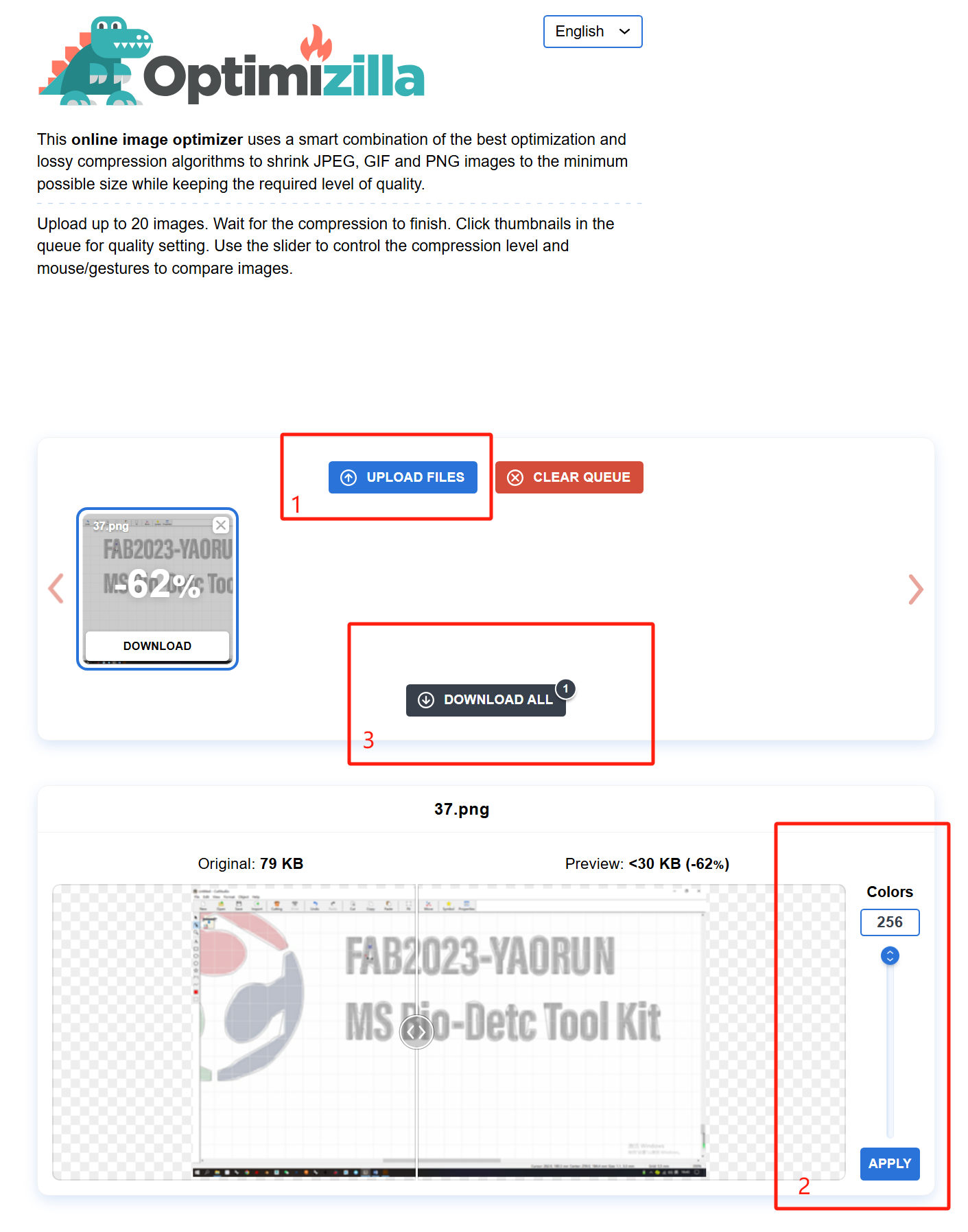

Picture and Video Compression Tool

Picture Compression

For picture compression, I have used the webpage link here: https://imagecompressor.com/. AS you can see in below picture, first you can upload the original picture, then you can choose how much you would like to compress it with color bar. Finally, you can download the compressed result. The original pic I have upload is 79KB and it is shrink to 30KB.

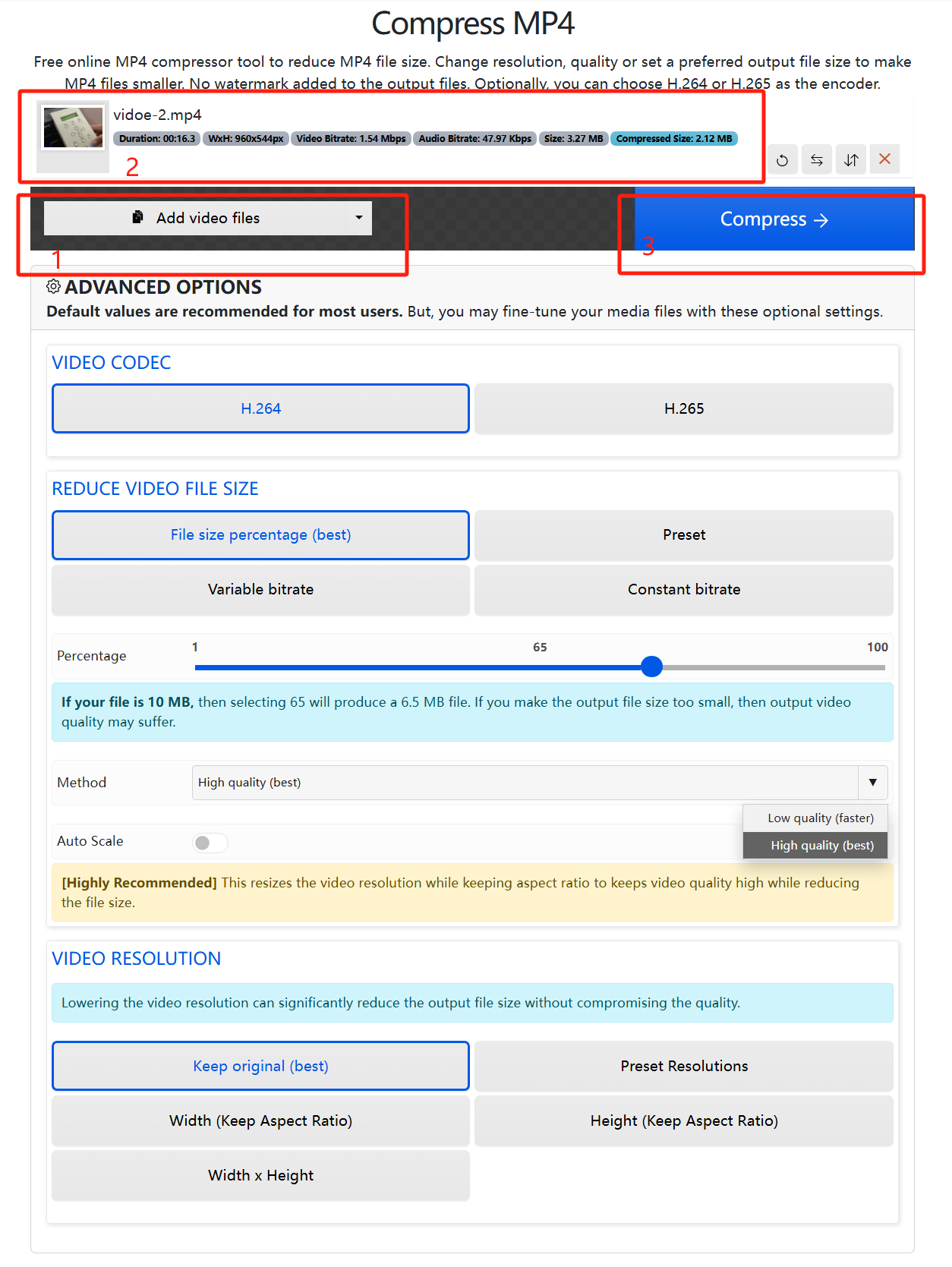

Video Compression

For video compression, I have used the webpage link here: https://www.xconvert.com/compress-mp4. AS you can see in below picture, first you can upload the original video and you can choose the way you want to compress it (video codec, percentage of reduction and video resolution). Then you can see the simulated compression result, where in my case the video was compressed from 3.27MB to 2.12MB. Finally click the 'compress' button for it to compress the video.

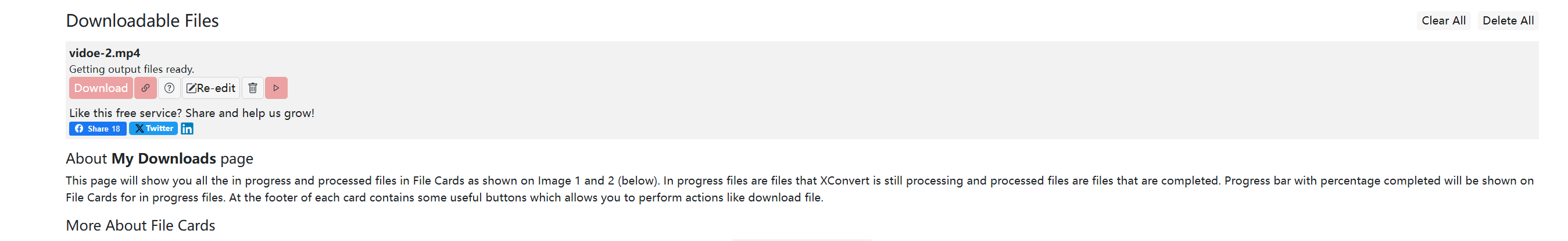

After click the compress button, you can download the compressed file when it is ready or re-edit it if you want.

Reference:

The reference and design files are listed below:

- The original AutoCAD .dxf files can be found at my repo (https://gitlab.fabcloud.org/academany/fabacademy/2023/labs/ningbo/students/yaorun-zhang/-/tree/main/docs/assignments/week2/design-files).

- The 3D Design can be downloaded in the Fusion 360 link here (https://a360.co/43B0vGK) and the .step/.f3d file can be found in my repo (https://gitlab.fabcloud.org/academany/fabacademy/2023/labs/ningbo/students/yaorun-zhang/-/tree/main/docs/assignments/week2/design-files).

- The OpenCAD software can be download by link here (https://openscad.org/) and the bow.stl file can be found in my repo (https://gitlab.fabcloud.org/academany/fabacademy/2023/labs/ningbo/students/yaorun-zhang/-/tree/main/docs/assignments/week2/design-files).