Final Project

| Week | |

|---|---|

| Assessment Guide | http://fabacademy.org/2023/nueval/project_requirements.html |

| Lecture Notes | |

| Progress Estimate | 8% |

Centricaf

Intro

Coffee. It’s great. It’s effective for waking you up and is chemically stimulating. It gives you something to do with your hands. It’s also an excellent excuse to avoid having to say something on zoom, by taking a well-timed sip.

I’m a coffee snob, but in a less than pretentious way. I don’t care what you want to drink, or what your preferred coffee is, that’s your business. But I expect a lot from my cup of coffee, in terms of both flavor and caffeine. Because of this and my frequent travel, I’ve gotten into a lot of niche, manual ways of making coffee like the aeropress, pipamoka, and classics like french press and pourover. The problem with all these methods is they require a certain amount of effort and brainpower that’s usually lacking before having a coffee. And on the flip side, most of the more automatic machines don’t deliver consistent quality in a cup. Cue inspiration:

https://youtu.be/j8J_0OTmXQg

https://youtu.be/j8J_0OTmXQg

James Hoffmann, the Internet’s favorite Coffee Connoisseur and advocate for science in the field, decided to run coffee through a centrifuge. And got… a surprising result. The coffee didn’t taste that bad. The roots of an idea started to grow for me after watching this - but first, a detour.

Coffee as we know it is actually two things: a plant, including the “cherries” that become roast beans and eventually grounds, and a beverage that’s basically (parts of) that plant dissolved into water, usually hot. All brewing is mostly an attempt to dissolve enough of that plant into water that the resulting solution tastes good, but not so much that it tastes bad again. There’s fancy terminology to describe this, like over-extraction and under-extraction, Total Disolved Solids, and more, but the basic thing to remember is that there’s a sweet spot you’re trying to land in. Since you’re basically making a solution, controlling variables for consistency is generally the best way to achieve a positive result.

Enter Centricaf, a single-serving “centrifugal” coffee brewer that delivers consistent quality cups of coffee without making your head spin.

Simple Summary

The basic premise for my final project is a coffee maker that rotates a filter basket submerged in water at various speeds to make a cup of cold brew. By initially spinning the filter basket at medium-ish speeds to agitate the grounds you can get a fairly consistent extraction. Then lift the amphora that’s restricting the liquid around the filter and spin again at higher speeds to dry out the grounds and halt extraction, letting that sweet sweet coffee flow down a channel into your cup. With the right speed settings this should result in a consistent brew in that sweet spot of of just enough plant dissolved into your water. The basic mechanics of this are similar to a magnetic stirrer in the first phase, and a salad spinner in the second.

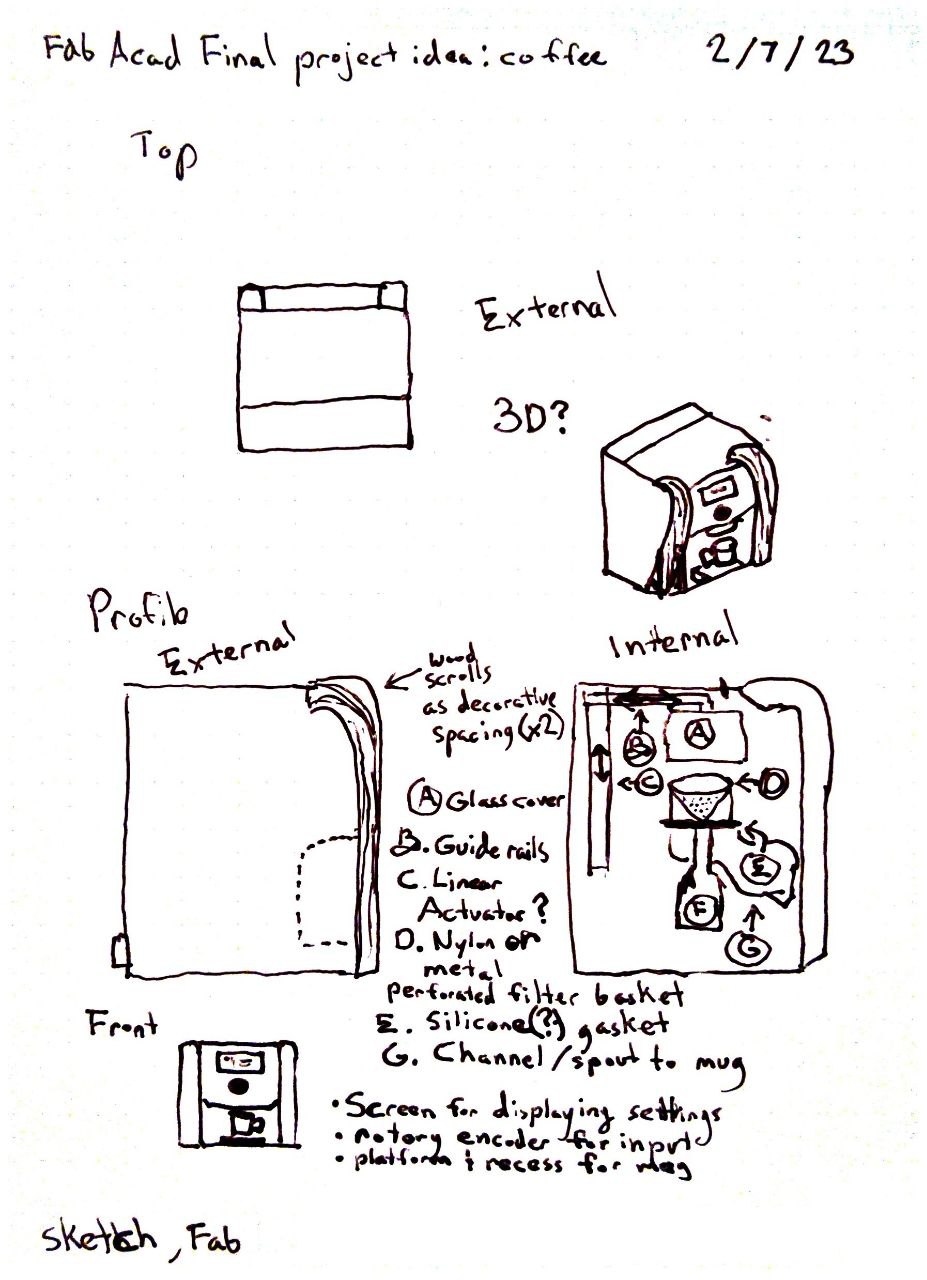

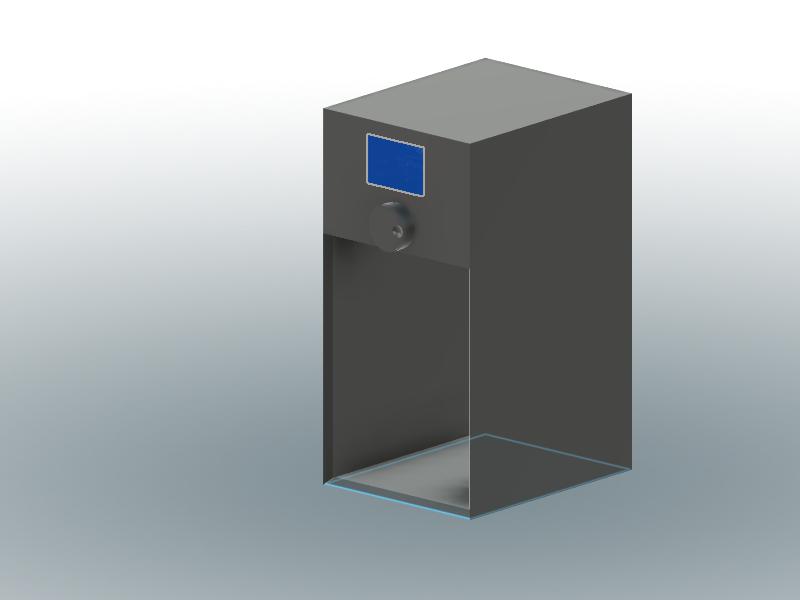

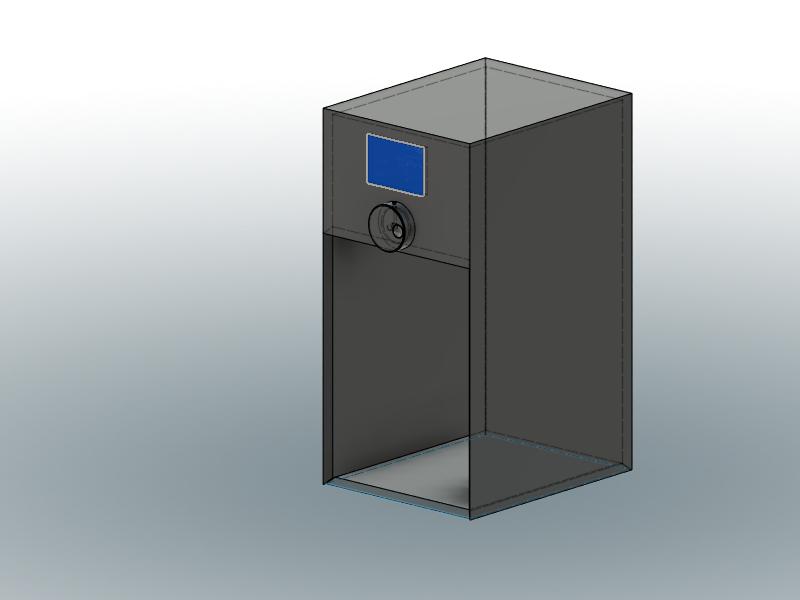

Design

The outer construction would consist of a fabricated outer shell, with an embedded OLED or eInk display and control knob (likely rotary encoder) on the front face for user interaction, a hinged lid for accessing internals, and a recessed lower area for distributing beverage into your mug. The internals would be a filter for collecting grounds, a motor of some sort for producing controlled spin, a likely glass amphora with gasket for a foodsafe way of keeping the basket in water, and possibly some sort of mechanical petcock for controlling the release of beverage. Electronics would most likely be an rp2040 XIAO for translating user input, output to display, storing settings, and control of motors. Powering would be an important consideration as well. These would need to be made watersafe.

Later spirals could include adding a heating element to make additional styles of coffee, redesigning form factor for portability or more contemporary aesthetics, increased filtration, and alteration for production at scale.

Who Wants This?

I am my own most enthusiastic user base, however given sufficient development time I could see this product being commercialized at a niche scale, and am designing with limited production run in mind. There are challenges in larger scale production that likely preclude me from wanting to pursue this at industrial scale, including navigating the legal side of things and securing manufacturing. Hobbyist or Connoisseur markets are likely more viable, including up to Kickstarter size, with proportionally increasing challenges. For now though, I just want coffee I can enjoy without having to think about.

Notes In Progress:

Parallel Designs

Fusion 360 Tutorial, with Nate B, and The Henrys (And Drew, Too!), 2/08

While giving me a Fusion 360 tutorial of modeling a traditional coffee maker, Nate, Drew and the Henrys suggested I look into cyclonic separators and cyclone traps for more information on the spiny coffee concept.

- possible lid hinge mechanism for drop lid

💡Stopcock valve for water control

Glass Making Consult, 3/01

On March 3rd I met with the coordinator of our Kiln Zone for a discussion on glass making, to assess the feasibility of fabricating simple glass components for my project during Wildcard Week. Wildcard Week is still a ways away, but I’d rather plan now so I can change direction if need be. Given that Jody, our coordinator, is also in charge of the Welding Shop, this meeting put me in a good position to pivot in that direction if need be. Altogether a good start.

A Highlight Reel of My Glass Learnings:

You can get sharper knife out of glass than metal. Glass often works like metal, where you can add ingredients to adjust the properties like you would for alloys - Jody

Heated glass melts. This Snapple bottle display is just formed from gravity and heat. These on the left are slump (after the untouched bottle)

The order of phases is Slump→Tack→Fuse→Cast. Those stages are further broken down into “Fast” and “Slow” subsets, with slow being more time in the kiln, more melting.

- Slumping doesn't connect

- Tacking lightly connects but keeps the details

- Fusing starts to lose details and merge together, but can maintain general shape

- Cast just straight up melts

Glass gets cloudier / goes through “vitrification" the longer it’s heated.

“COE" = Coefficient of Expansion, rating of approximate expansion/contraction behavior in heat and cooling . Generally want similar ratings in the glass materials you’re working with, or else you risk shattering and other issues as the adhered glass pieces contract at dissimilar rates.

COE 90 & 96 are likely most common among hobbyist glass firing.

No matter where they are in the process, same COE value materials still have the same basic properties.

One of the big things to avoid is crazing.

- Crazing: tons of little cracks that make like a spiderweb of cracks

- There are artistic exceptions, and some use it as a stylistic selling point distinguishing handmade glass from factory glass which avoids such imperfections.

Other Notes and references

Rotary encoders in arduino

Pen to Paper