5. Electronics production

Group assignment:

- Characterize the design rules for your in-house PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

- Document your work to the group work page and reflect on your individual page what you learned

Individual assignment:

- Make and test the development board that you designed to interact and communicate with an embedded microcontroller

Group Assignment

The group assignment is documented here.

Individual assignment

After week6 deisgning my xiao expansion borad, this week we move to producion. And I did find some problems which I didn't realize before.

Here are the functions I want my board on.

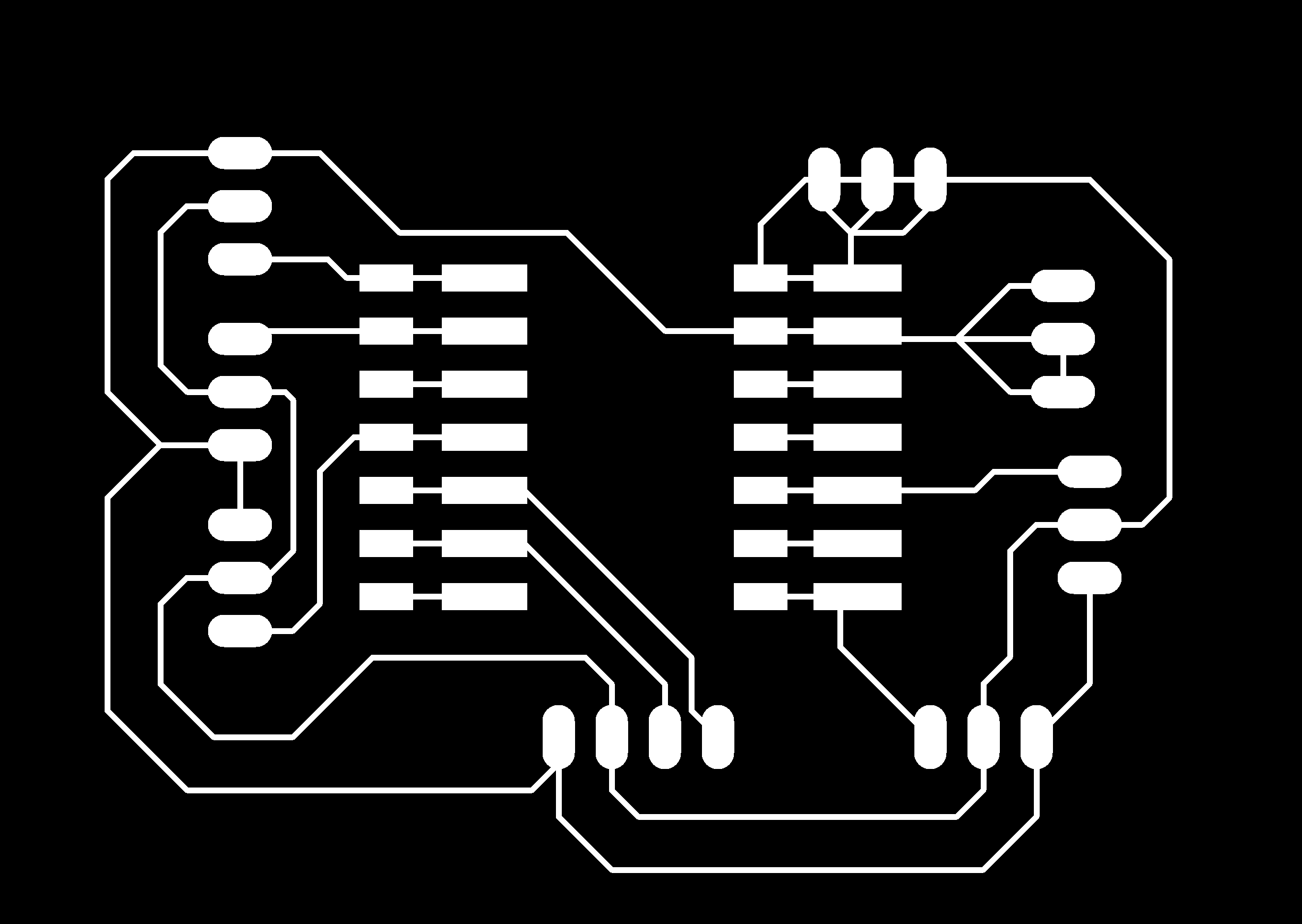

Version ONE

Firstly after the group assignment we make sure the design rule for out machine is ok,and did the test.

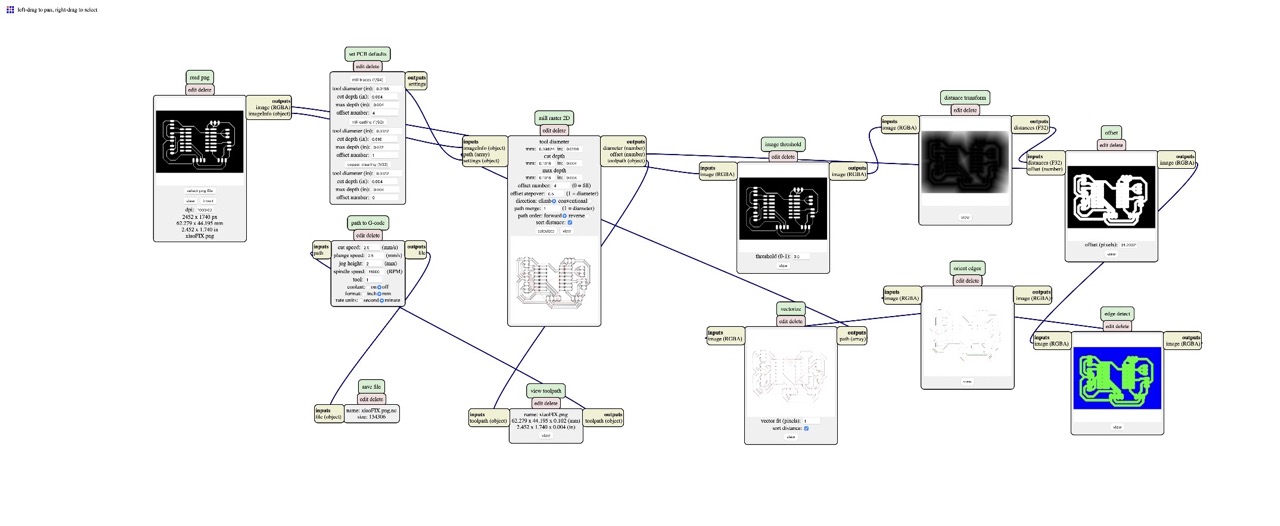

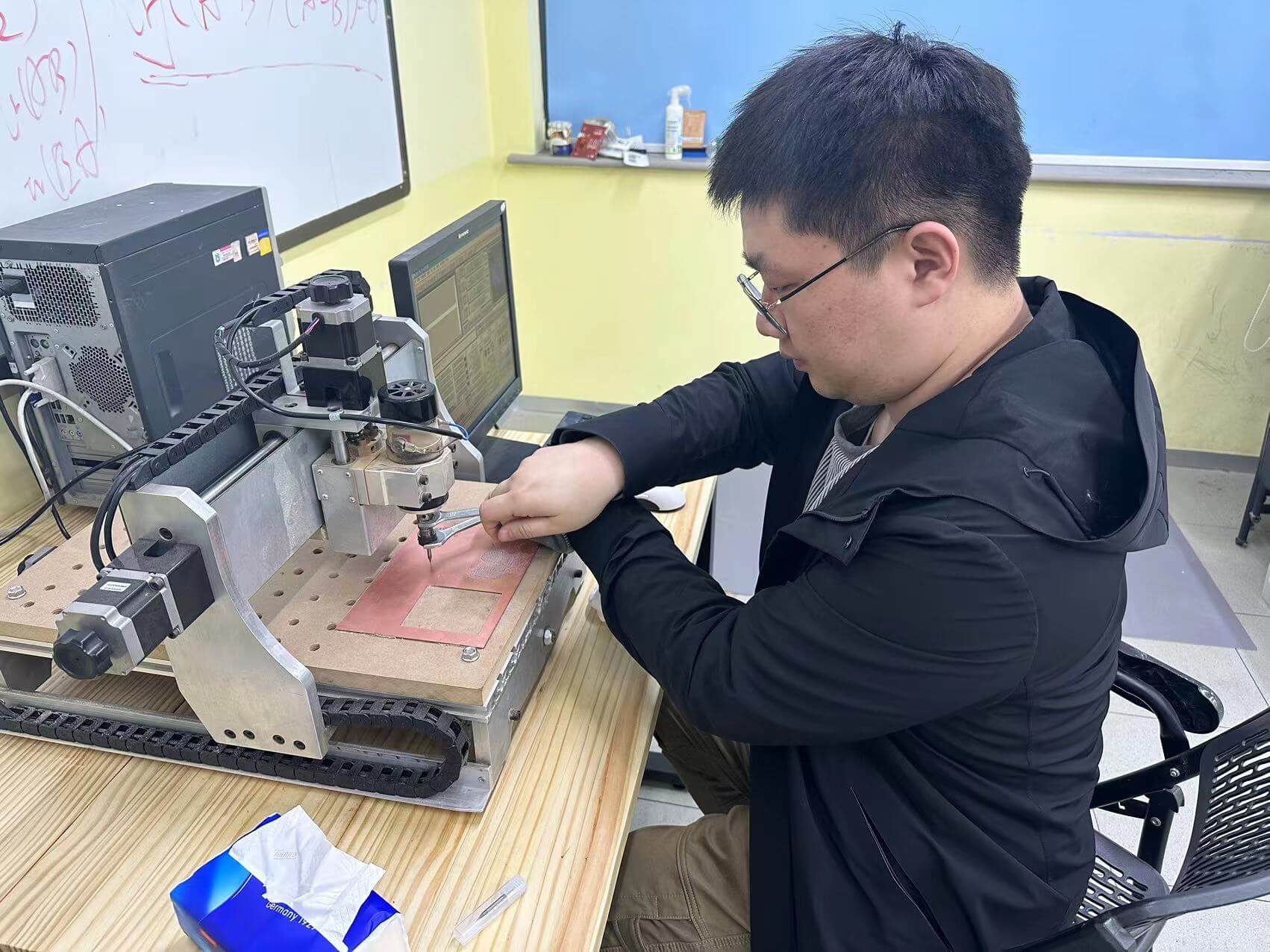

We use mods to genarate tool path.

We change the presetting cut depth and max depth (in) 0.004 to 0.005 for taces. For outline we change 0.010 to 0.011 to make sure it's well done.

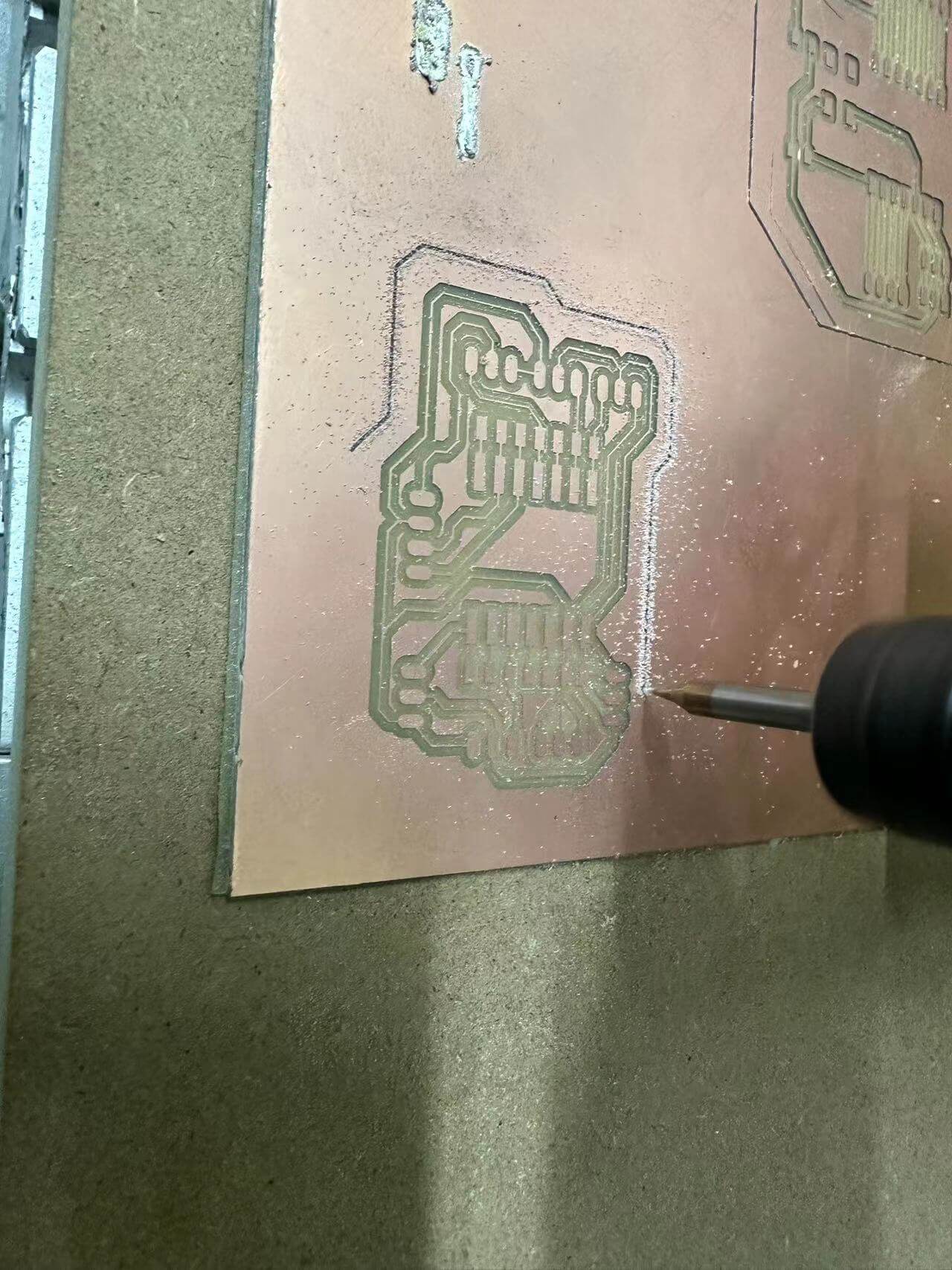

Load the end mill and set the home point, the detail will be in group assignment.

Change the 0.4 end mill to 0.8 end mill to cut the outline.

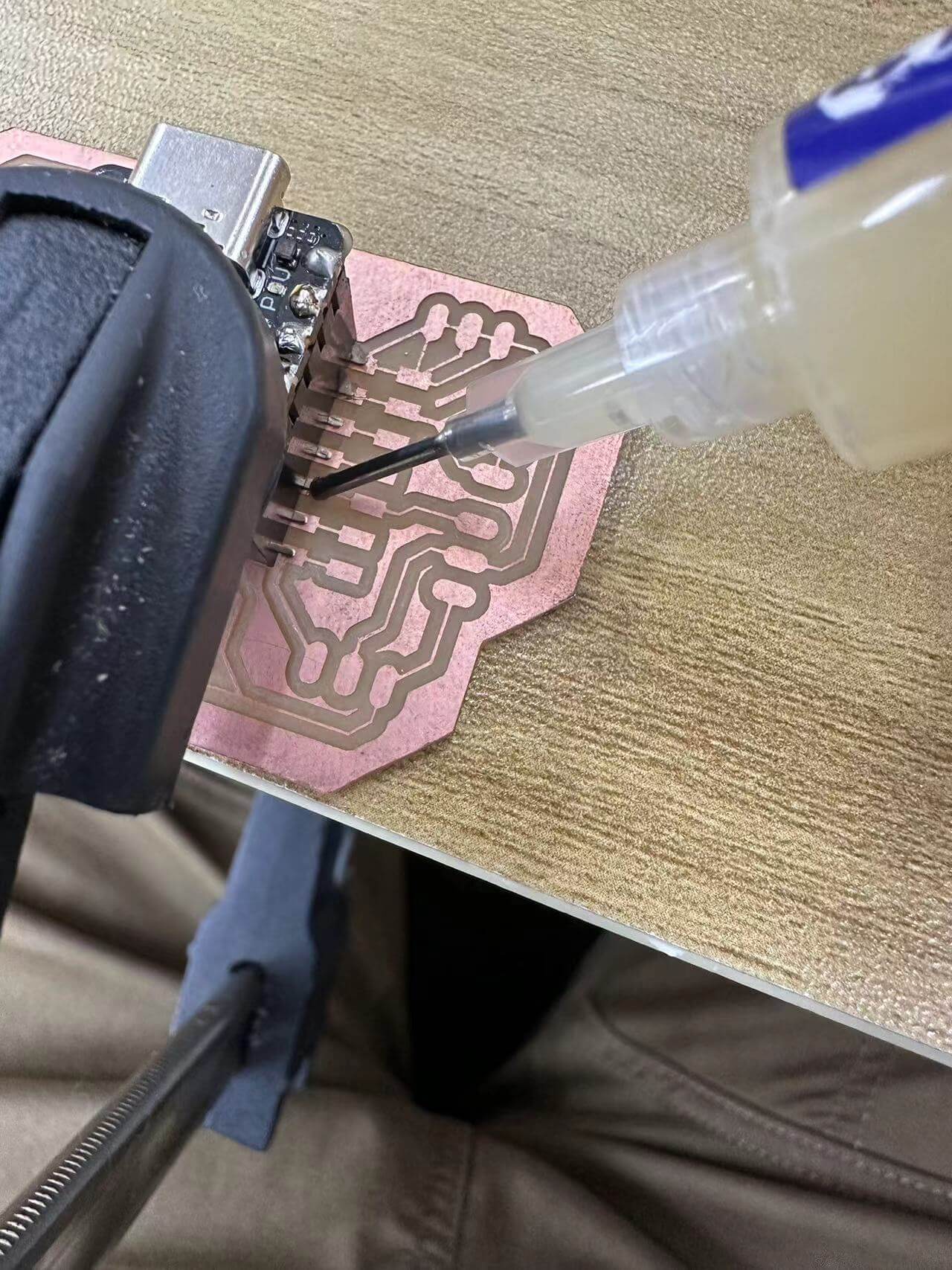

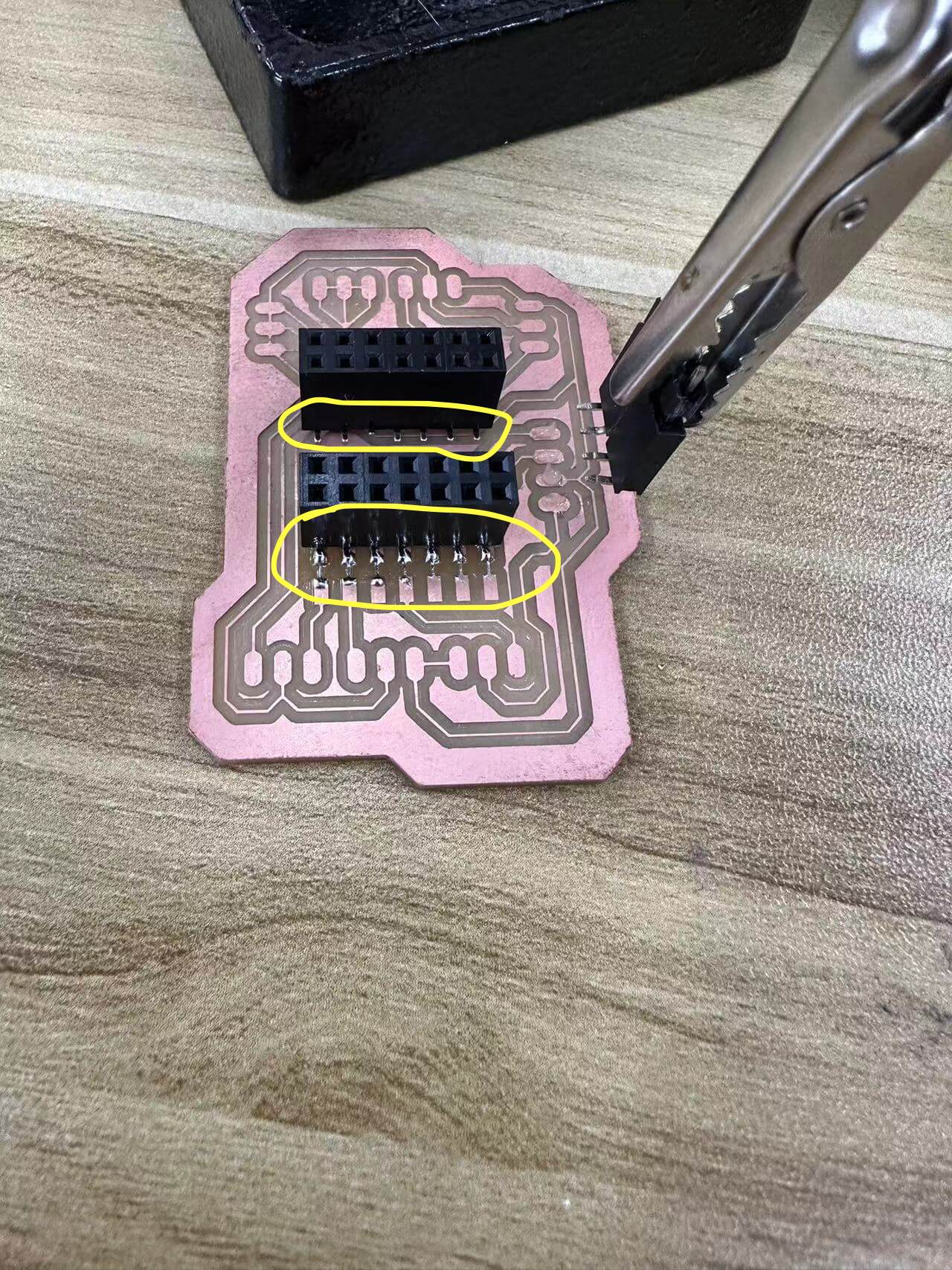

To solder them, I use the bar clamp from the wood workshop .

Highly recommend.

Highly recommend.

After the pcb and female header is stable, I start inject flux.

I found I miss calculate the sapce, I should use this smd female header library in Eagle.

I wanted to use 2x7 famle headers, because I want to copy all the pins in case my expension pins not fitting some 4pin sensors or acuator like stppers.

But now because of the sapcing, I can not copy all the pins. I can only use one side.

It's actually working. But I start to correct the spacing to make my Version 2.

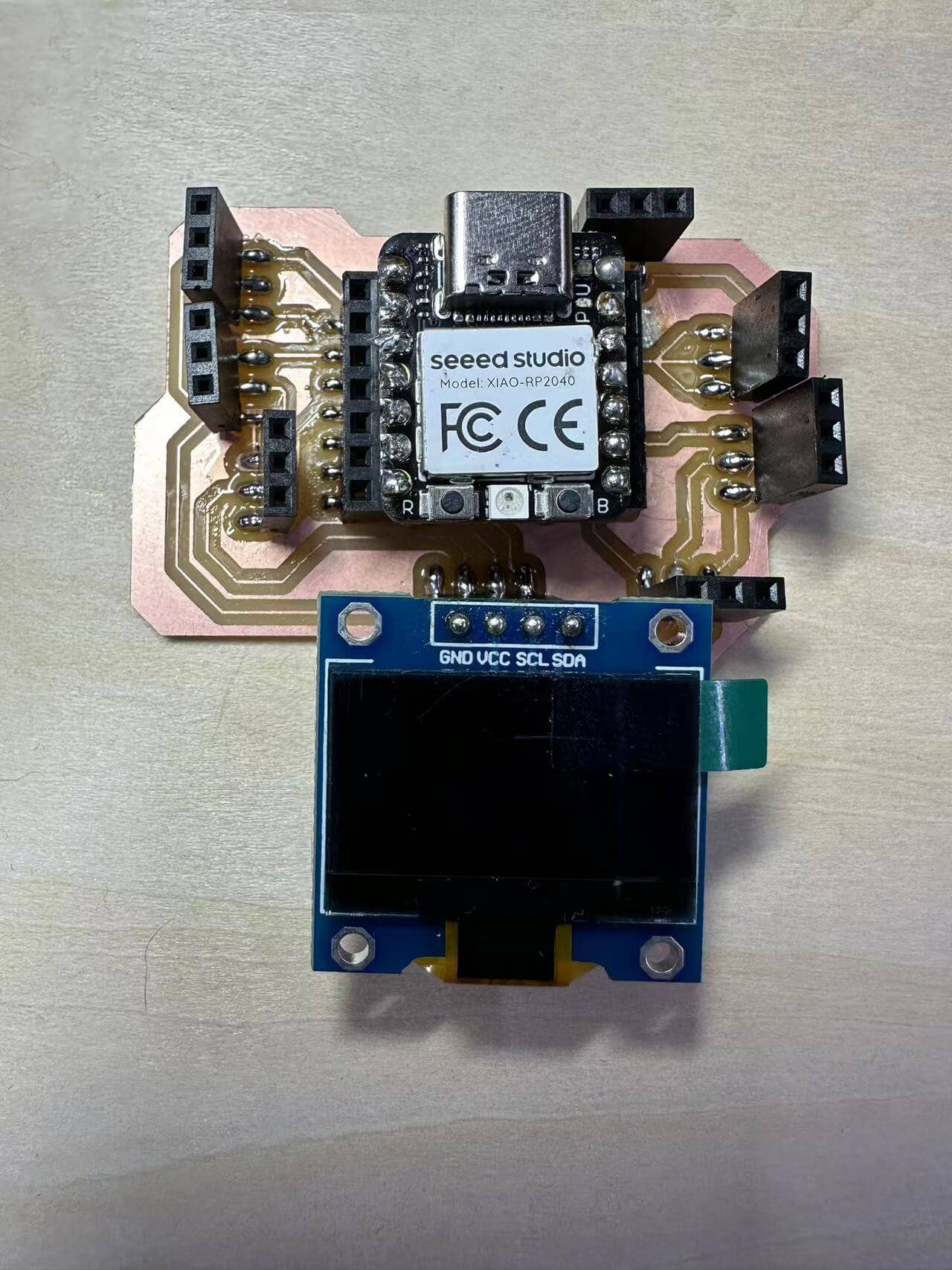

Version TWO

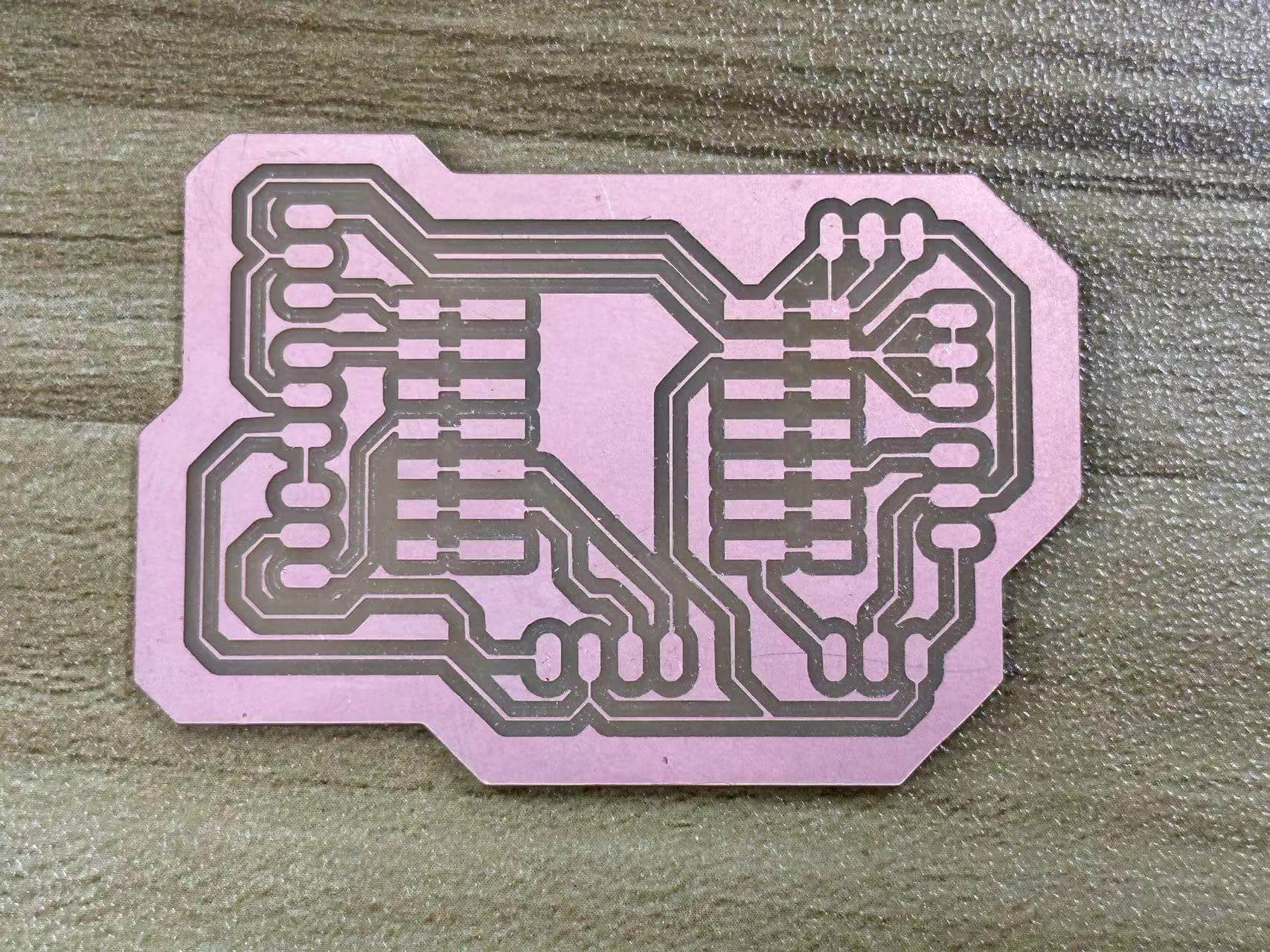

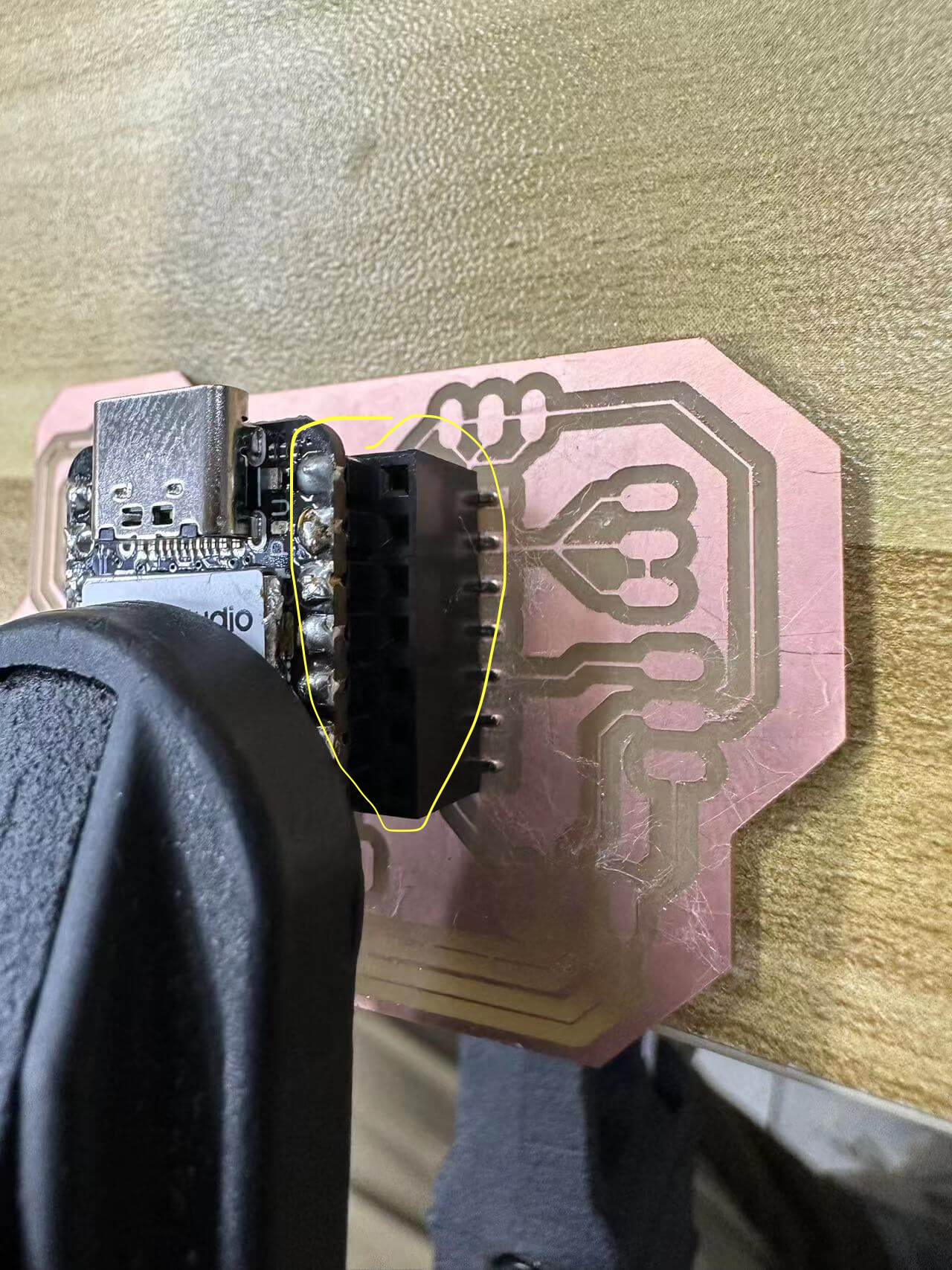

With fixing the sapce, I made the second one.

Mill

Changing end mill

Prepare sodering

Now I can copy all the pins.

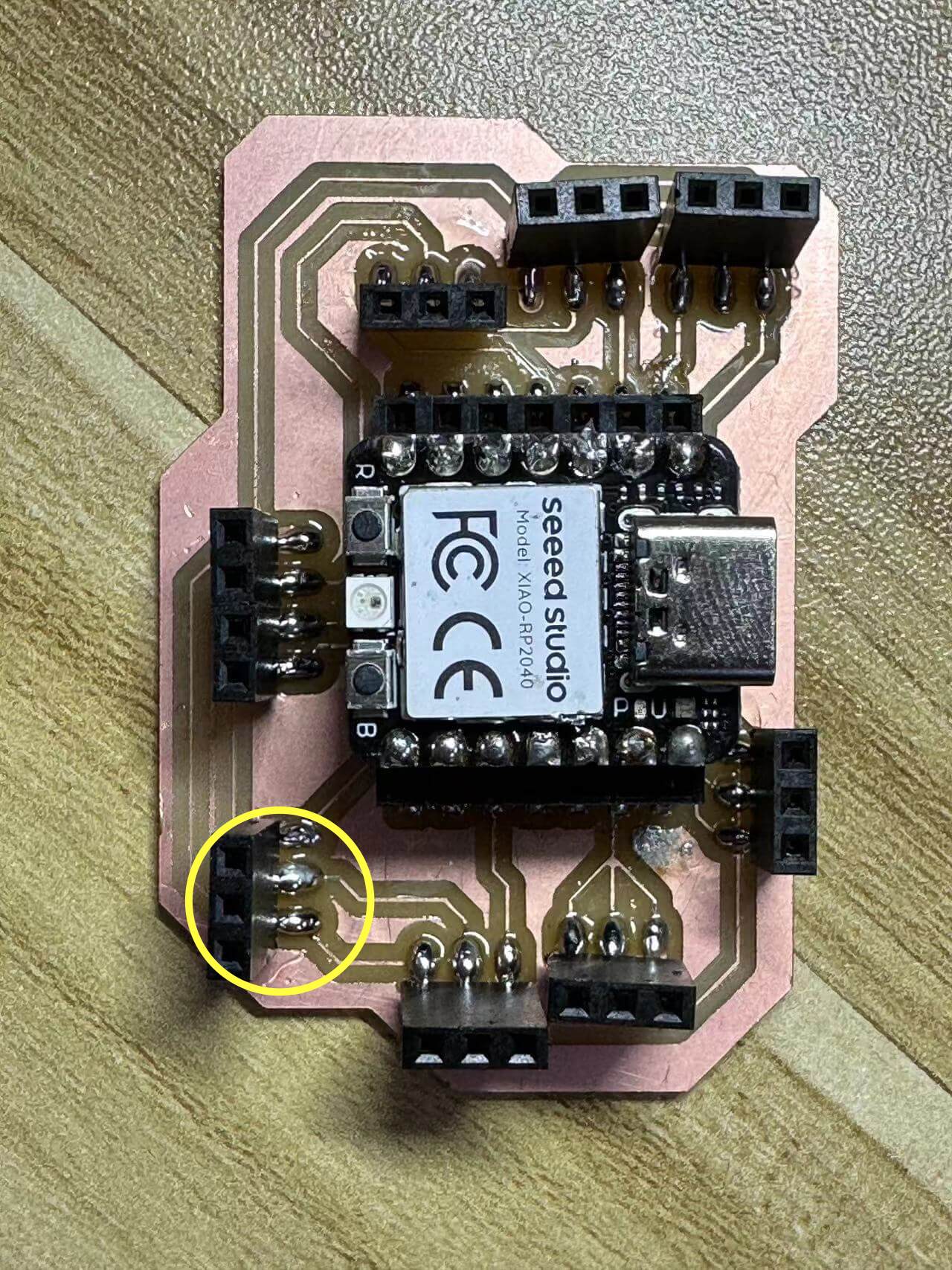

I test the traces first. They were all ok.

I made the joint pretty strong.

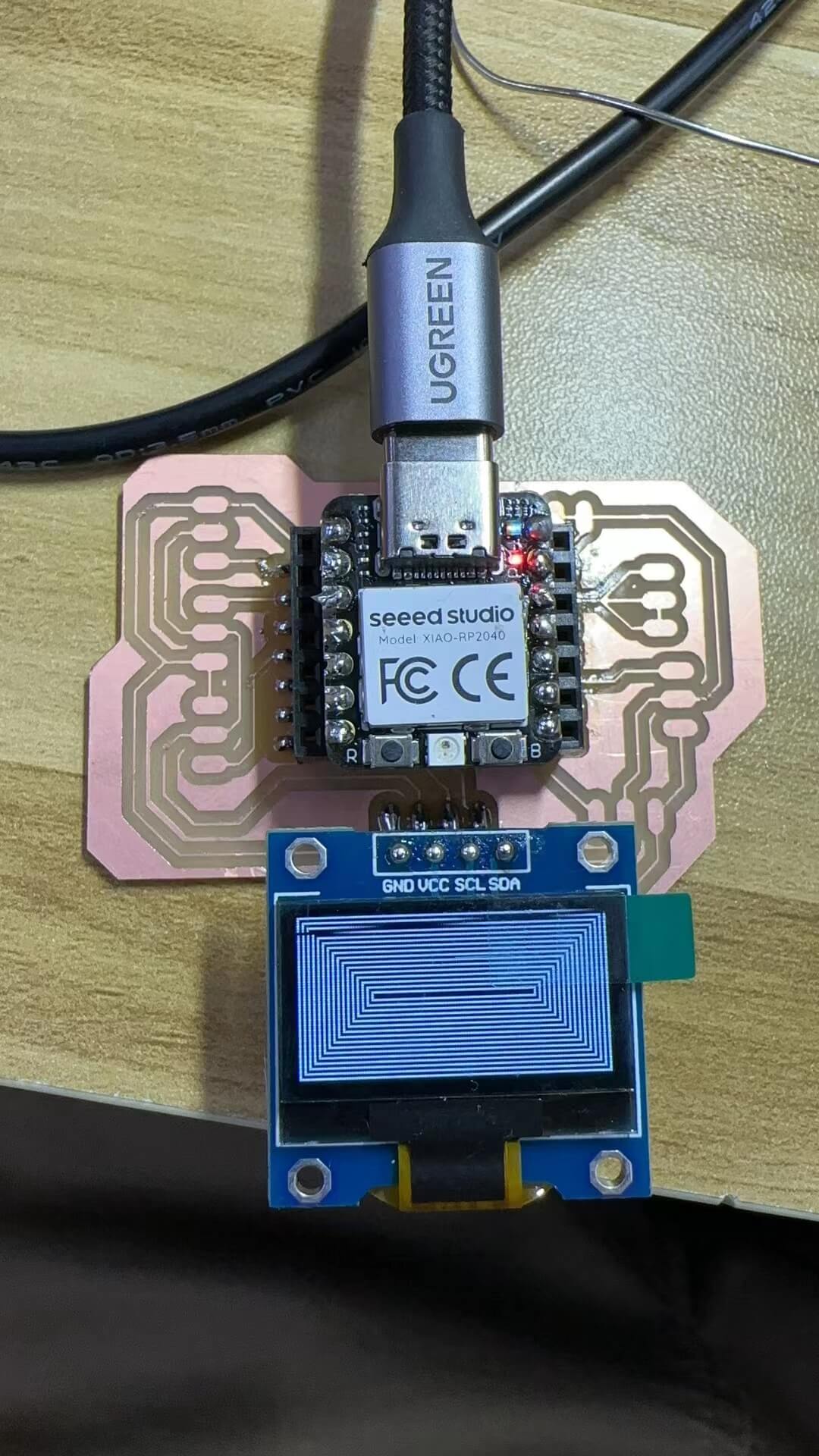

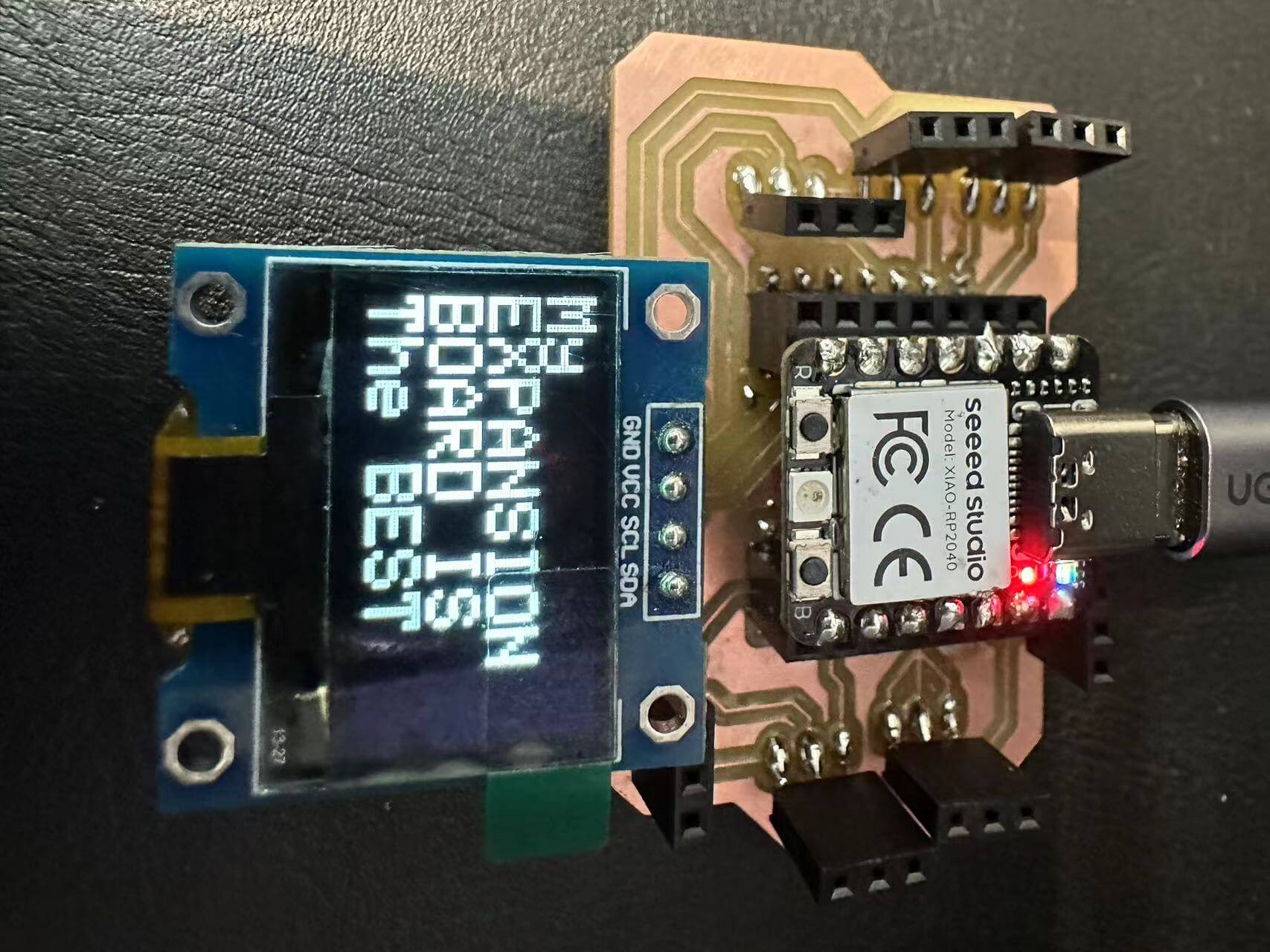

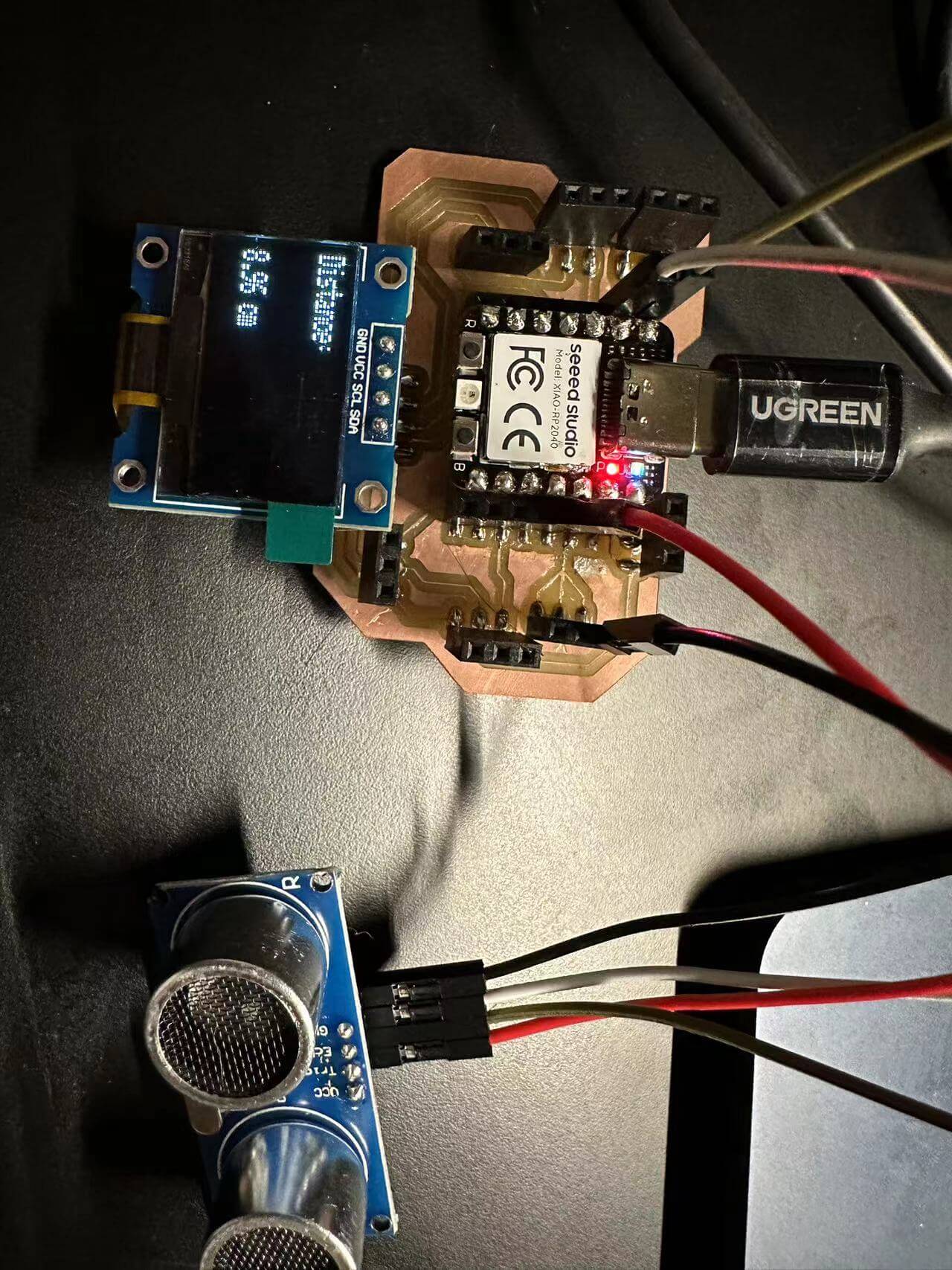

I use the screen quite often, it's a key fiture on my board..

After all hearders sordered, it's still all working.

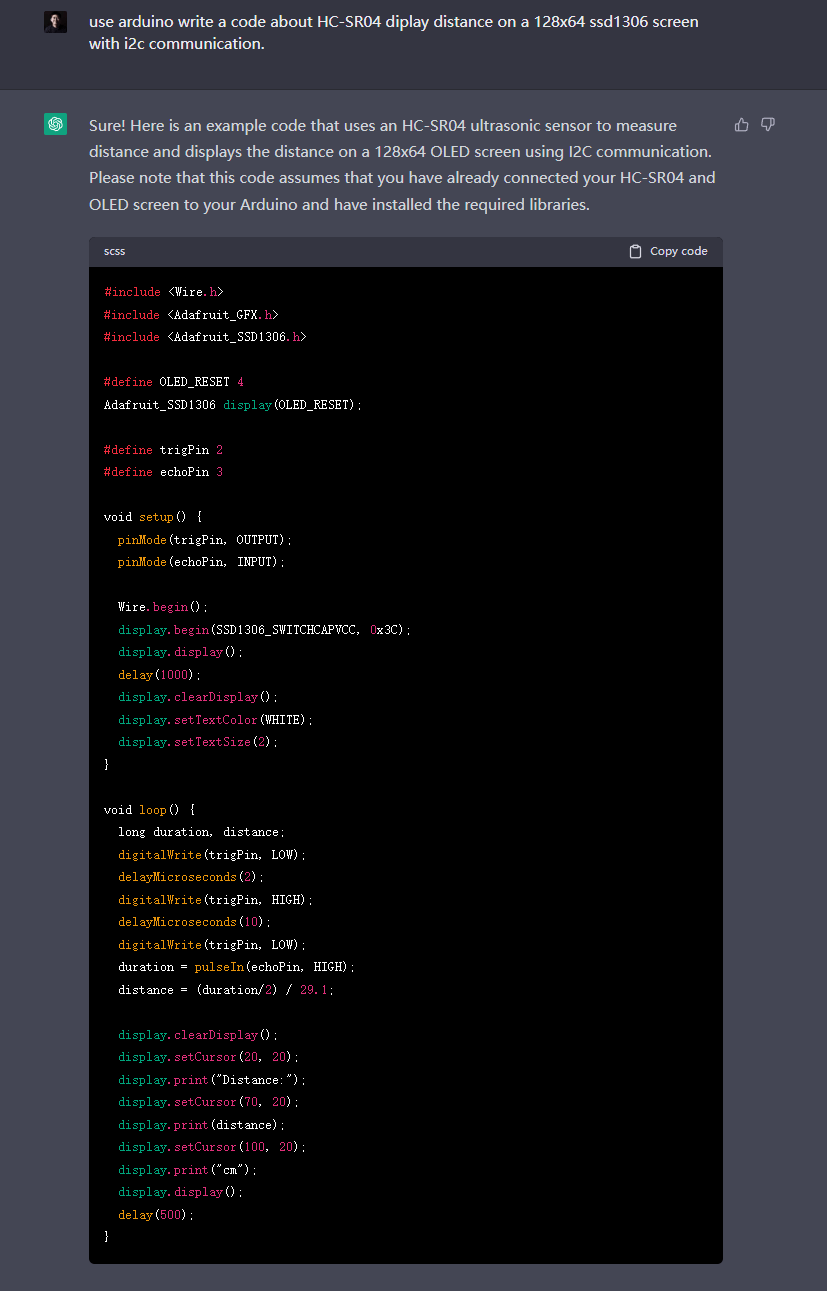

I asked chatgpt to write a code for hc-sr04 to make a distance sensor. It's precislly correct.

I tested all pins.

When I want to use 3.3V or some other 4 pins sensor like ultrasonic sensor, I can still use the copied pins, which make it very easy to use. and It's quite compact.