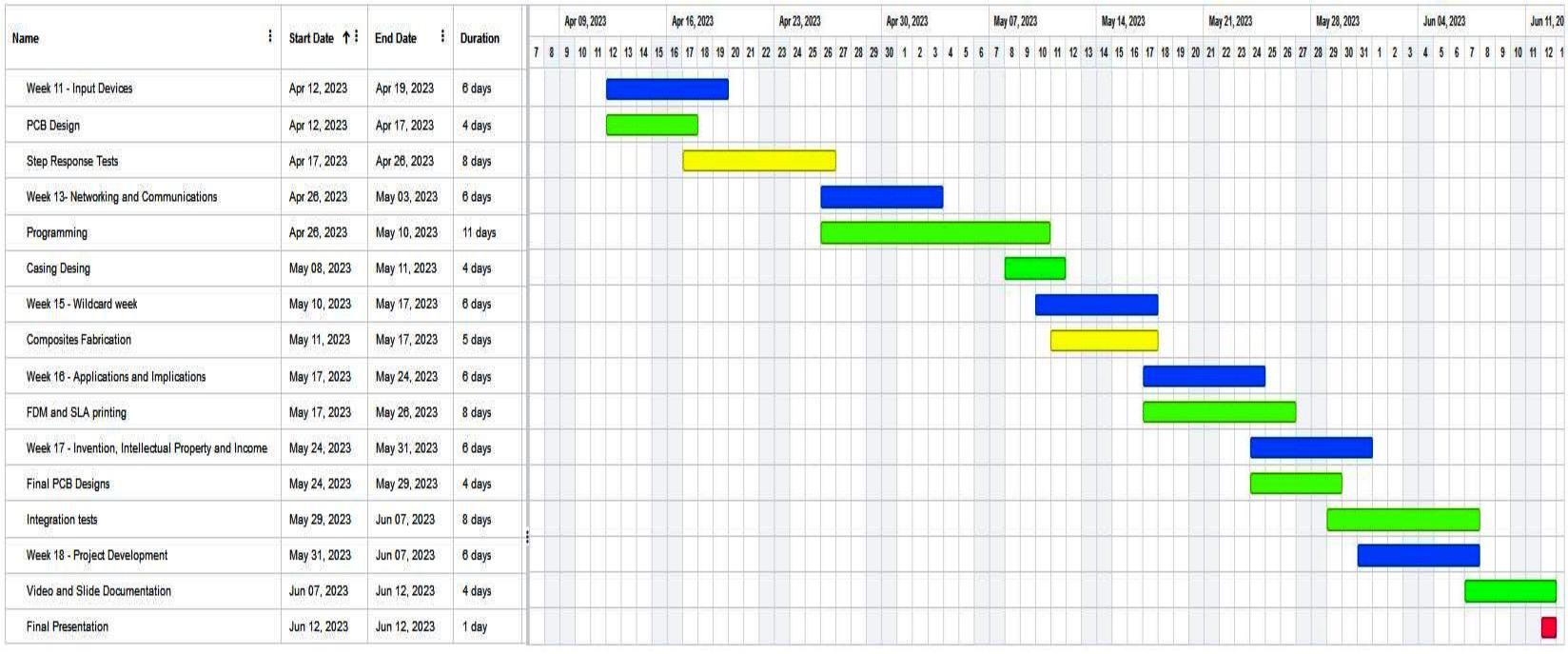

Completed Tasks:

Remaining Tasks:

The project will be exhibited on June 12, after this presentation the remaining documentation will be worked on until the closing of the diploma course.

There are many skills that I have been able to learn developing this final project, the one that surprised me the most was composites since I was able to convert cardboard that can be brittle into a completely solid structure, I have also been able to improve my knowledge in 3D printing, especially in the use of resin that allows us to create objects of better resolution. Regarding electronics, the use of step response seemed quite versatile for different applications in the case of this project to evaluate the weight of the object on the electrodes.

Figure N°1