4. Computer - Controlled Cutting

Assignments:

Group assignment:

⚡ Characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types.

⚡ Document your work on the group work page and reflect what you learned on your individual page

Individual assignment:

⚡ Cut something on the vinylcutter design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways and for extra credit include elements that aren't flat

During week #4 we been experimenting 2D cutting with the Laser Cut and the Vinyl cut, the machines used are descripted below. I already had the opportunity to learn of Laser cut with other machines so this one was new for me. For more information CLICK here

JQ Laser JQ-1390

Interesting facts..

- The Laser type is a Sealed CO2 laser tube and th cutting area is 1300 x 900mm. To use it you have to be sure of actuate the extractors ( I forgot once and the odors aren't good haha)

- The Software that we used was PowerCut and used it charging the cut parameters of Power and Speed related to the material that we choose cut.

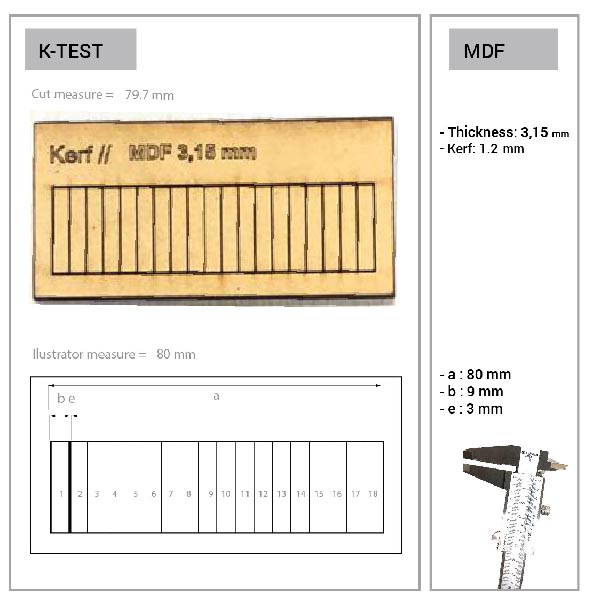

- To test the joints fitting we did a KERF TEST.

The kerf is the difference between the known size and the actual size of the rectangles, I mean .. Kerf = width of rectangle - width of square (measured with the caliper)

Press kit

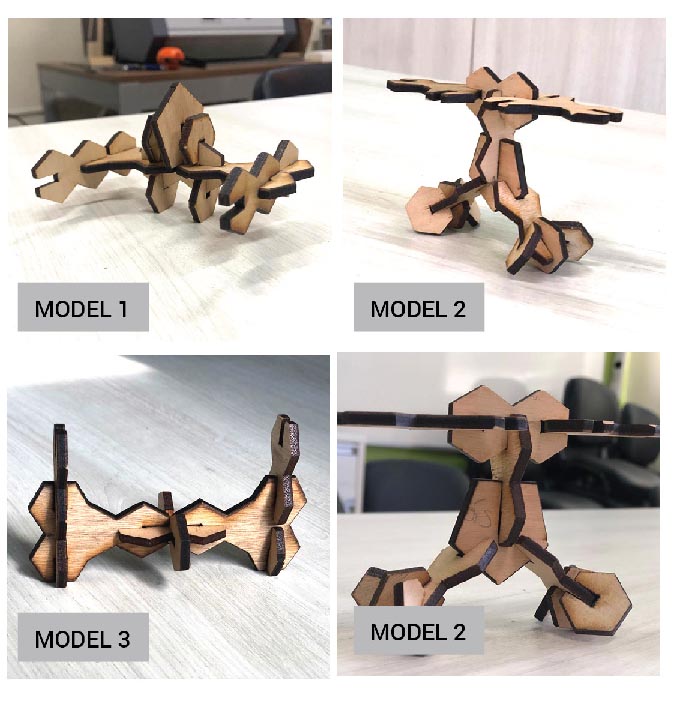

Using this information I did a Press kit which can be assembled in multiple ways, the shapes where polygonal ones with diferent sizes

The kerf founded in this materials below were this

Parametric shapes:

The shapes were designed from hexagons whose sizes are changing in order to create different possible combinations. Once the value of Kerf (3. 28) was obtained, subtractions were established that function as a recess.

- The Laser type is a Sealed CO2 laser tube and th cutting area is 1300 x 900mm. To use it you have to be sure of actuate the extractors ( I forgot once and the odors aren't good haha)

- The Software that we used was PowerCut and used it charging the cut parameters of Power and Speed related to the material that we choose cut.

- To test the joints fitting we did a KERF TEST.

The kerf is the difference between the known size and the actual size of the rectangles, I mean ..

Kerf = width of rectangle - width of square (measured with the caliper)

GCC Puma IV 60 LX

I already knew how desktop vinyl cutters work, but some issues vary, for example some shortcuts that the software required to be specific. For example, the cutting power, which should vary depending on the material used.

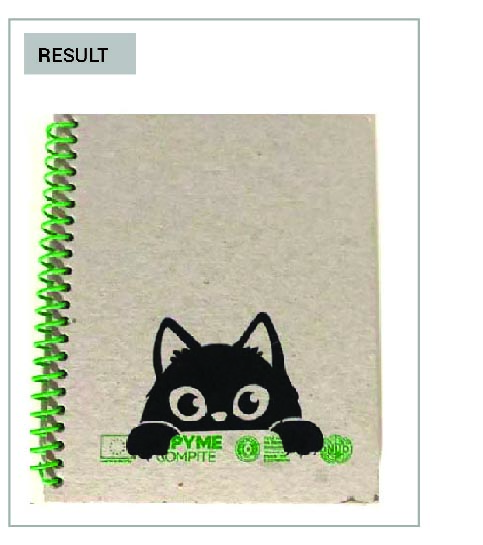

The work developed with the machine was related to the customization of my notebook. I started with a vectorized design in Ilustrator (part of the tests done in the Controlled Aided Design module)

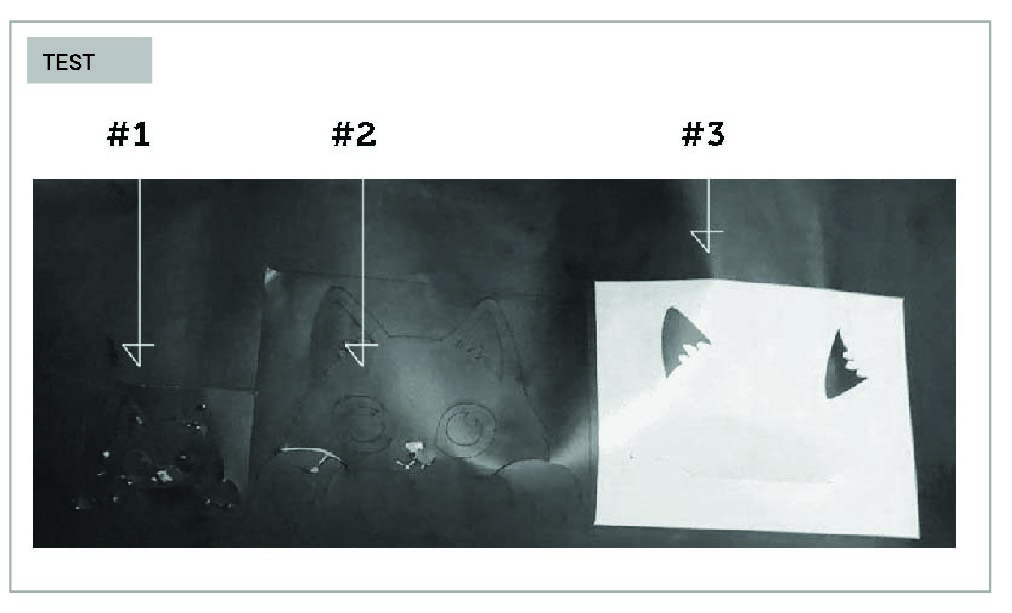

In the pictures you can see this cutting process of the machine, where test 1 was cut with a high power and this caused wrinkle

The values were: for cutting speed 30cm/s and cutting pressure 50 grams of pressure.

In test 2: the power with which the blade descended to the material and the speed of the passage were already reduced. But it had a lot of effect on the cut because the figure did not come off the sheet.

In test 3 there was already a good balance of these parameters and the design could be taken off and placed on the notebook mentioned above.

The values were: for cutting speed 10cm/s and cutting pressure 30 grams of pressure.

Comments

Problems:The operation of a laser machine and a vinyl cutter are similar, but some parameters are specific to each machine model. Once the cuts are made, the entire verification process for turning on extractors and other things is done automatically (yes, I forgot about that sometimes and the smell spread throughout the place haha).

Solutions: Trying till the end