15. Wildcard week

Biomaterials

Def1: A biomaterial is a substance that has been engineered to interact with biological systems for a medical purpose, either a therapeutic or a diagnostic one.

Def2: A material derived from, or produced by, biological organisms like plants, animals, bacteria, fungi and other life forms. These are also called biologically derived materials.

Well, this past week was a really interesting one, because we create our own materials from a recipe....like mad scientists, muahahahaha (crazy laugh).

We took as a reference the recipes of our own mad scientist, instructor and great designer... Silvia Lugo.

Also, some recipes from Materiom.

With all the information we need, and the ingredients....the magic began.

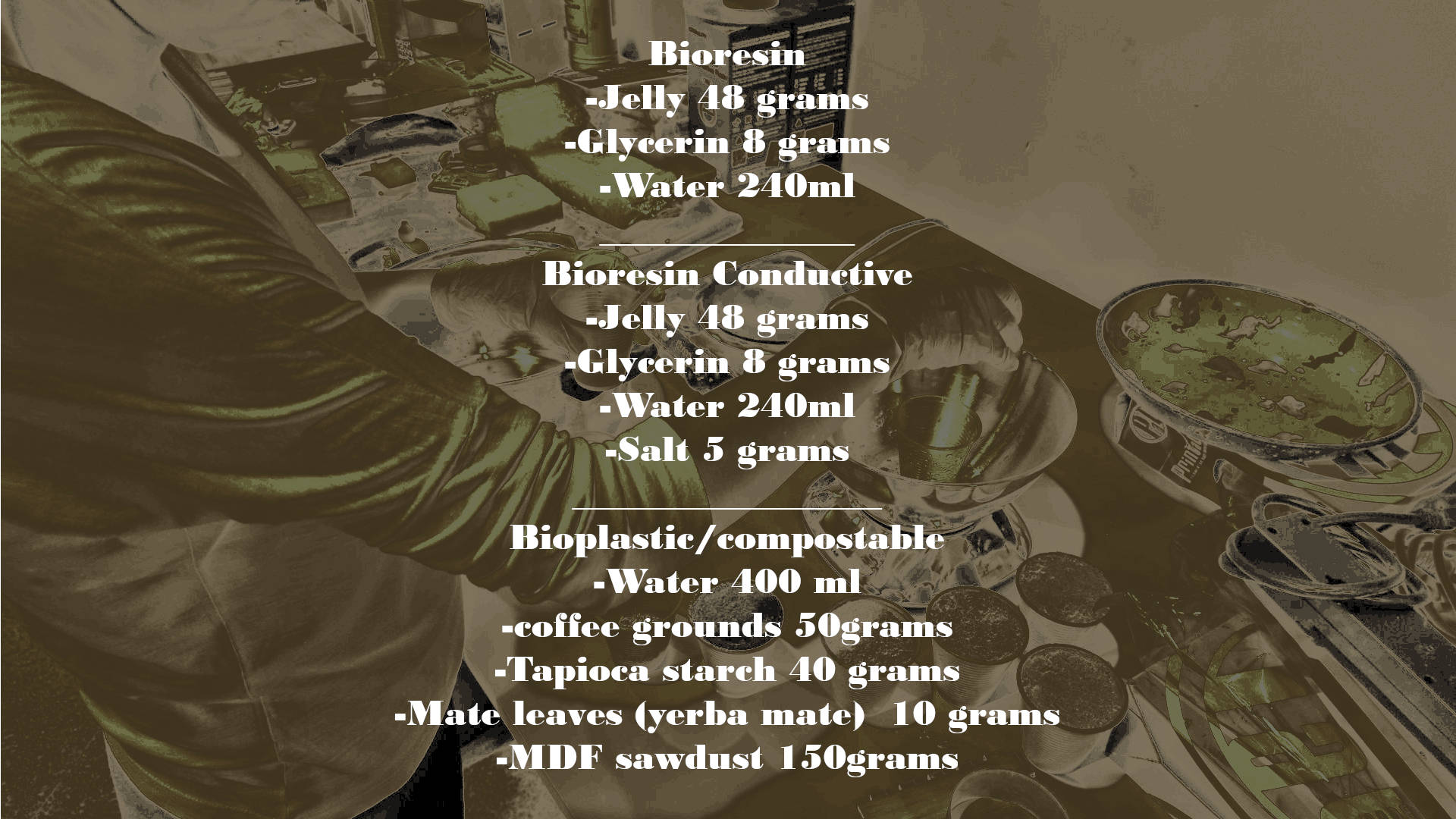

Recipes

Bioresin

Let's start cooking....literally

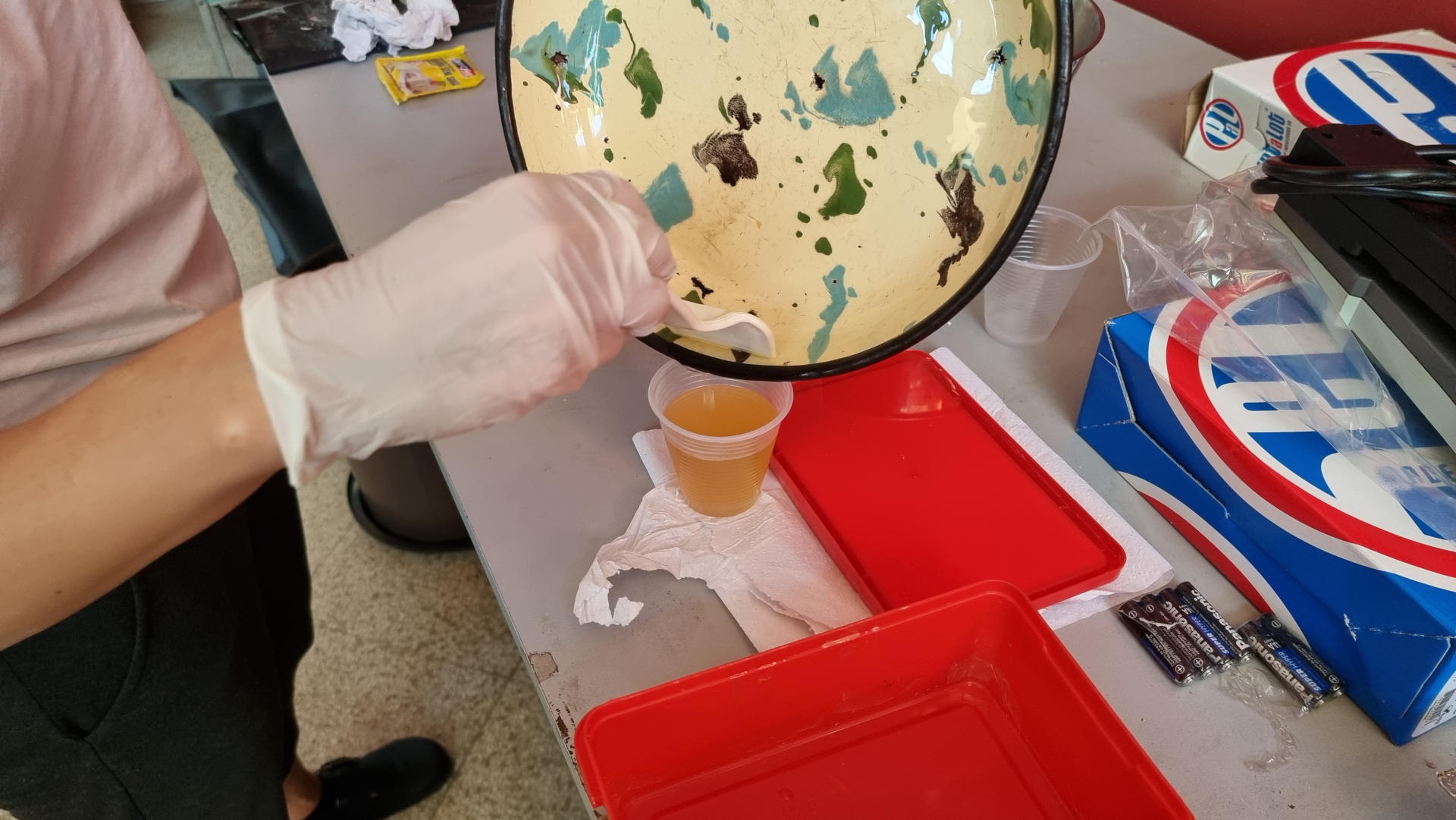

1-Pour water and glycerin, and turn on the cooker.

2-Sprinkle the Jelly and stir gently.

3-When water start to boil, and the mix is homegeneized, turn off the heat, pour in the moulds and let them cool for 24hs

After a few minutes, the thiner layers started to catalize.

We also made another experiment, because none of the recipes told anything....some moulds, we put them in the refrigerator, to accelerate the process...and it worked great.

Bioresin conductive

Same recipe to resin, but we add some salt to the mix...we read that to make a bioresin conductive we could add activated charcoal...or salt...we had salt, so we used it.

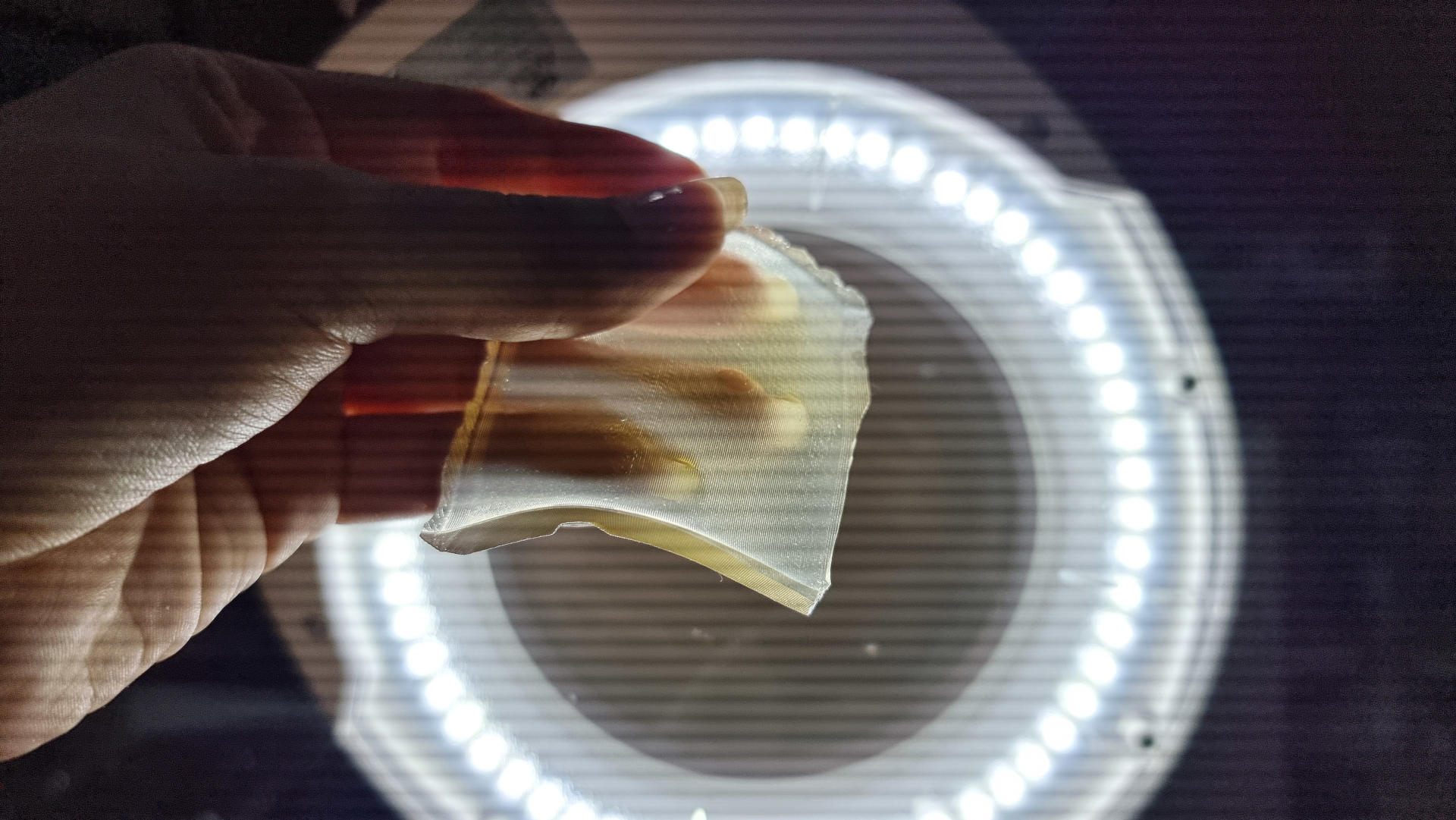

The result waas amazing, resin was crystal clear and copy every detail from the mould.

Ok, let´s test it.

First we put the multimeter to see if the material was conductive...and then, directly to connect to the variable voltage source...and it worked.

We got confident, and put our flexible circuit with 6 leds to the test....with 4 volts through the jelly...and increasing the voltage gradually to 12 volts

It worked great....so, we test some strips of the jelly...and worked astonishingly.

We added 5 grams of salt...but seeing the results, we think we should add more salt in the future, to increase the ratio and make it more conductive and less resistant.

Bioplastic compostable

This time the recipe went different.

We used the recipe from Materiom.org, and added some turns

1-Mixed the water and the vinegar, and boiled

2-Add the tapioca starch, the coffee and the mate leaves, and stirred.

3-While it was boiling, we added the saw dust, and made a thick mixture.

Took out of the heat and put in the moulds, to let them cool 24hrs...and let them dry also.

Digital Fabrication

We had some thin layers of resin ready and we tested with our laser cutter machine.

We set some parameters to see how the material react to the heat of the laser...and was amazing.

After a few tryies, we found that: 600mm/s speed and a 40% power was perfect to engrave the material.

what we learnt

The most important thing, biomaterials are awesome...studying them could bring a lot of alternatives to classic materials.

Second, with digital fabrication we can easily work them and do amazing things.

Third, with basic elements and ingredients, we can achieve a lot of substitute materials and keep caring our planet.

Link to group assignment