17. Applications and Implications

assignment Propose a final project masterpiece that integrates the range of units covered, answering: What will it do? Who's done what beforehand? What will you design? What materials and components will be used? Where will come from? How much will they cost? What parts and systems will be made? What processes will be used? What questions need to be answered? How will it be evaluated? Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, system integration and packaging Where possible, you should make rather than buy the parts of your project Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable What will it do? I will construct a motorized xy-table as my final project for the FabAcademy. This table will move a diamond with a NV-centre, which can be used for a quantum sensor (see https://fabacademy.org/2023/labs/bottrop/students/michael-bennemann/final-project.html). The table will move the diamond to all possible positions of the xy-table and the intensity of the fluorescence of the diamond will be measured. Following, the xy-table will move the diamond to the position of the highest florescent intensity. Who's done what beforehand? There is a publication about quantum sensors build out of cubes: Modular low-cost 3D printed setup for experiments with NV centers in diamond: https://iopscience.iop.org/article/10.1088/1361-6404/acbe7c and a kit to build optics out of similar cubes: https://github.com/openUC2/UC2-GIT What will you design? A reliant mechanism with attached stepper motors and a sensor to measure the intensity of the fluorescency of the diamond. What materials and components will be used? The 3D printed reliant mechanism (see week 2. Computer Aided design and week 5. 3D Scanning and printing) lasercutted cubes (see week 3. Computer controlled cutting) stepper motor (see week 9. Output devices) a photosensor (see week 12. Input devices) maybe the signal of the photosensor will be send via wifi (see week 14. Networking and communications), so that you can see the intensity of the fluorescence on your smartphone. Where will come from and how much will they cost? Stepper motors (9.41€ for 10 motors): https://de.aliexpress.com/item/1005003181912785.html?spm=a2g0o.order_list.order_list_main.16.6f4e5c5fQbVthD&gatewayAdapt=glo2deu gear rack(5.58€ for 10 gear racks): https://de.aliexpress.com/item/32719713951.html?spm=a2g0o.order_list.order_list_main.395.6f4e5c5fQbVthD&gatewayAdapt=glo2deu sensor (5.31€ for 3 sensors): https://de.aliexpress.com/item/32972107781.html?spm=a2g0o.order_list.order_list_main.66.6f4e5c5fQbVthD&gatewayAdapt=glo2deu What parts and systems will be made? - the xy-table - the sensor unit - a PCB to control the stepper motors - the cubes What processes will be used? - 3D printing - lasercutting - electronic design and production - embedded microcontroller interfacing and programming What questions need to be answered? I have to evaluate the best stepper motor for the xy-table and to adjust the design of the reliant mechanism of the xy-table. Further, inserts for the cubes have to be designed. How will it be evaluated? By 3D printing the xy-table, mounting the xy-table and evaluating the performance of the stepper motors.

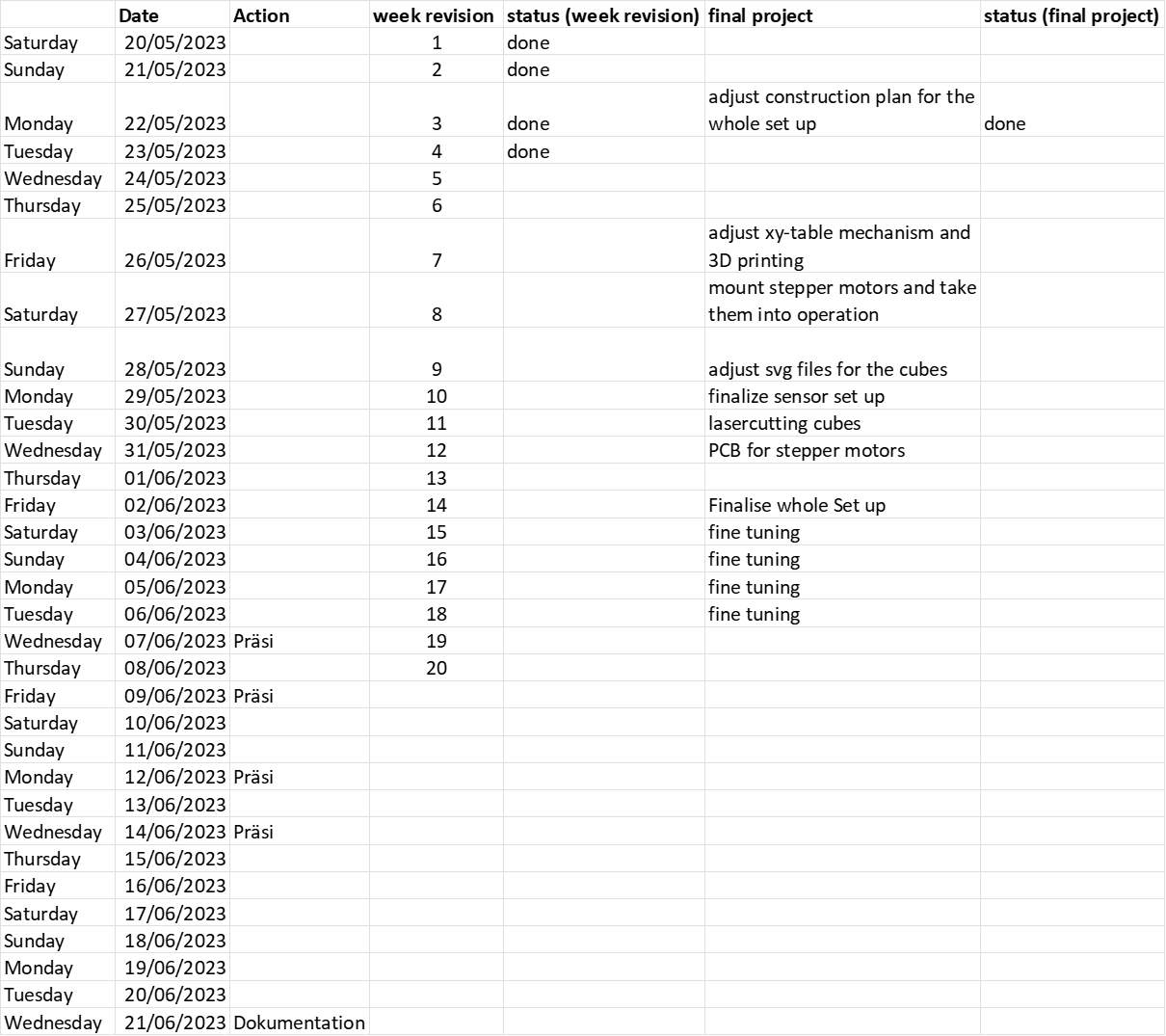

Here my shedule for the comming weeks:

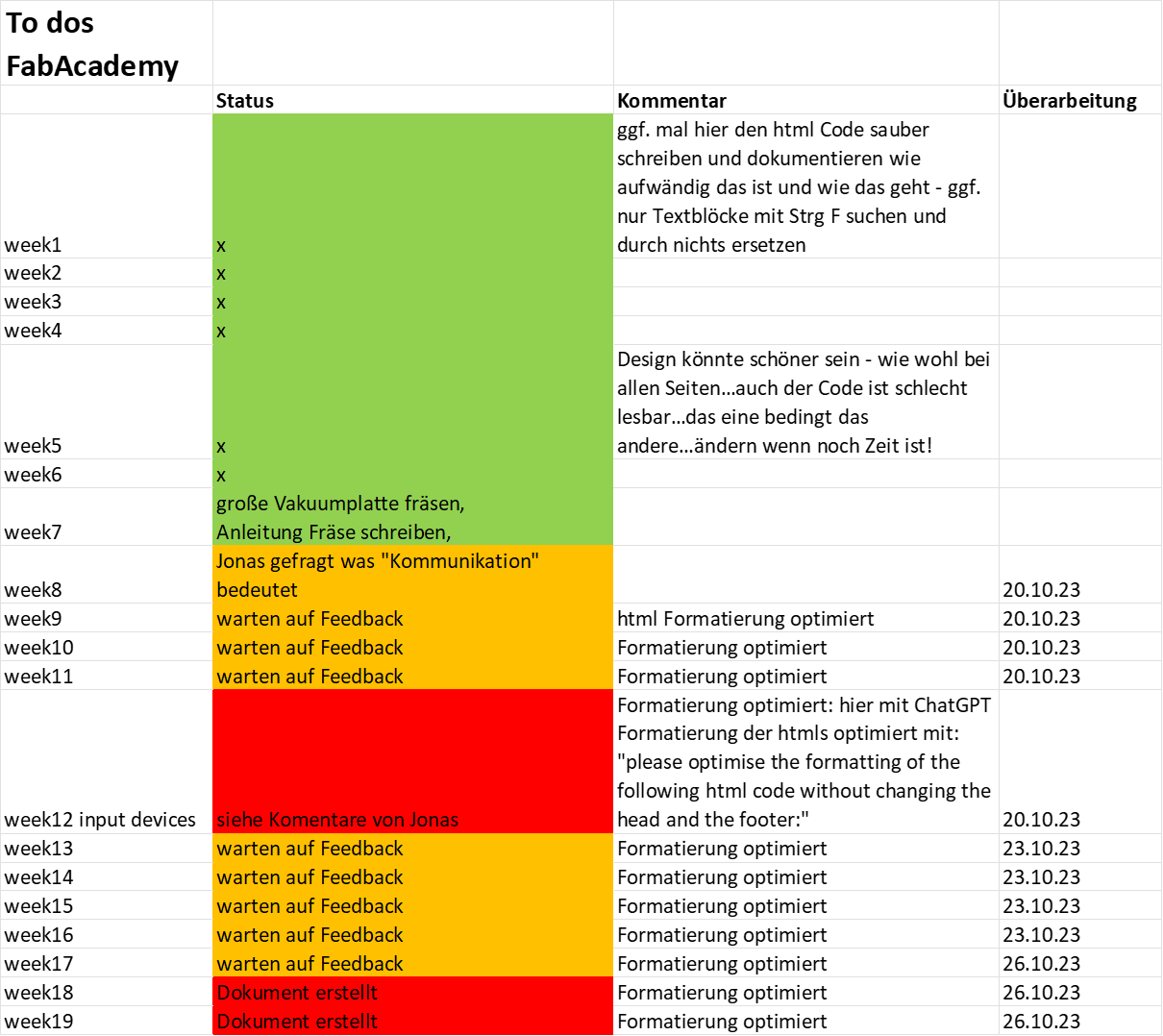

Due to serious back problems I could not continue the FabAcademy from week 17 on. Here is an updated overview of my plan to complete my FabAcademy documentation by the end of October 2023: