About me

Hi! I am Ana Pilar Valerga, Anapi for my friends and coleagues!

I am the coordinator of the Degree in Industrial Design and Product Development Engineering and one of the people in charge of FabLab Cadiz. Therefore, I am going to learn as much as I can from the Fab Academy and more!

If you want to learn more about me or connect this is my LinkedIn or follow me in Instagram.

Previous work

I am a mechanical engineer. I graduated from the University of Cadiz in 2014. I then decided to continue my studies with a Master's degree in manufacturing engineering. Finally, I obtained my PhD in 2018 in the PhD programme in manufacturing, materials and environmental engineering at the same university.

I am a lecturer at the School of Engineering of the University of Cadiz, where I teach technical drawing and computer-aided design, although my research is mainly focused on additive manufacturing.

Each year I direct several Bachelor's and Master's final projects, as well as carrying out more specific research in design for additive manufacturing outside of teaching. Also, I studied some reverse engineering techniques, as 3D scan or photogrammetry, to redesign things.

The following are examples of some of the work that has been carried out.

ANDALUSIAN INDUSTRIAL DESIGN

I am part of the organisation of an Andalusian (soon to be national) competition of Andalusian Industrial Design, where undergraduate and graduate students can present their work. It is a very nice annual competition that encourages students' interest in their careers.

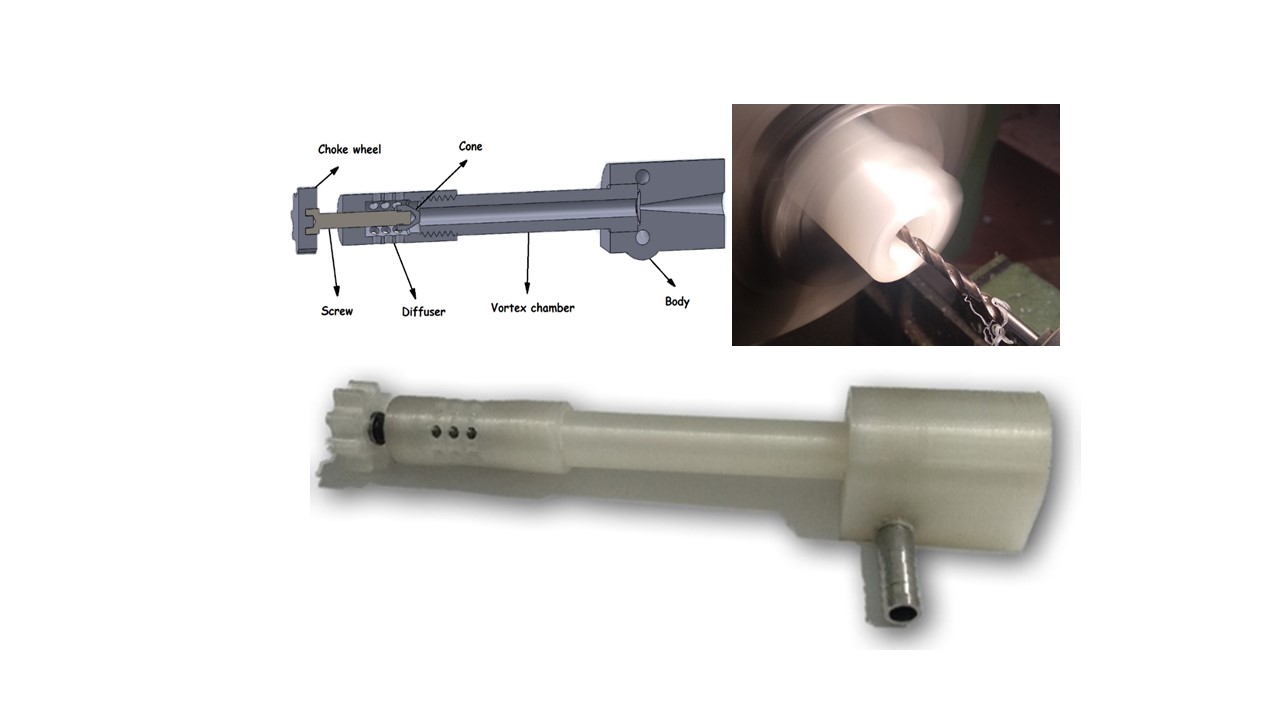

LOW-COST VORTEX TUBE DESIGN

The most commonly used cooling systems in machining processes are dry lubrication, lubricants/coolants such as MQL (Minimum Quantity Lubrication), emulsions, cutting oils, cryogenics and air. Among these, we can highlight cryogenics and air as being the most environmentally friendly. For this reason, we have developed a vortex tube made of a biodegradable material as an efficient and environmentally friendly device for cooling in machining processes. The most innovative or relevant aspect of this study is the application of low-cost and environmentally friendly cooling technology made of PLA (Polylactic Acid), and its customised application to the drilling process.

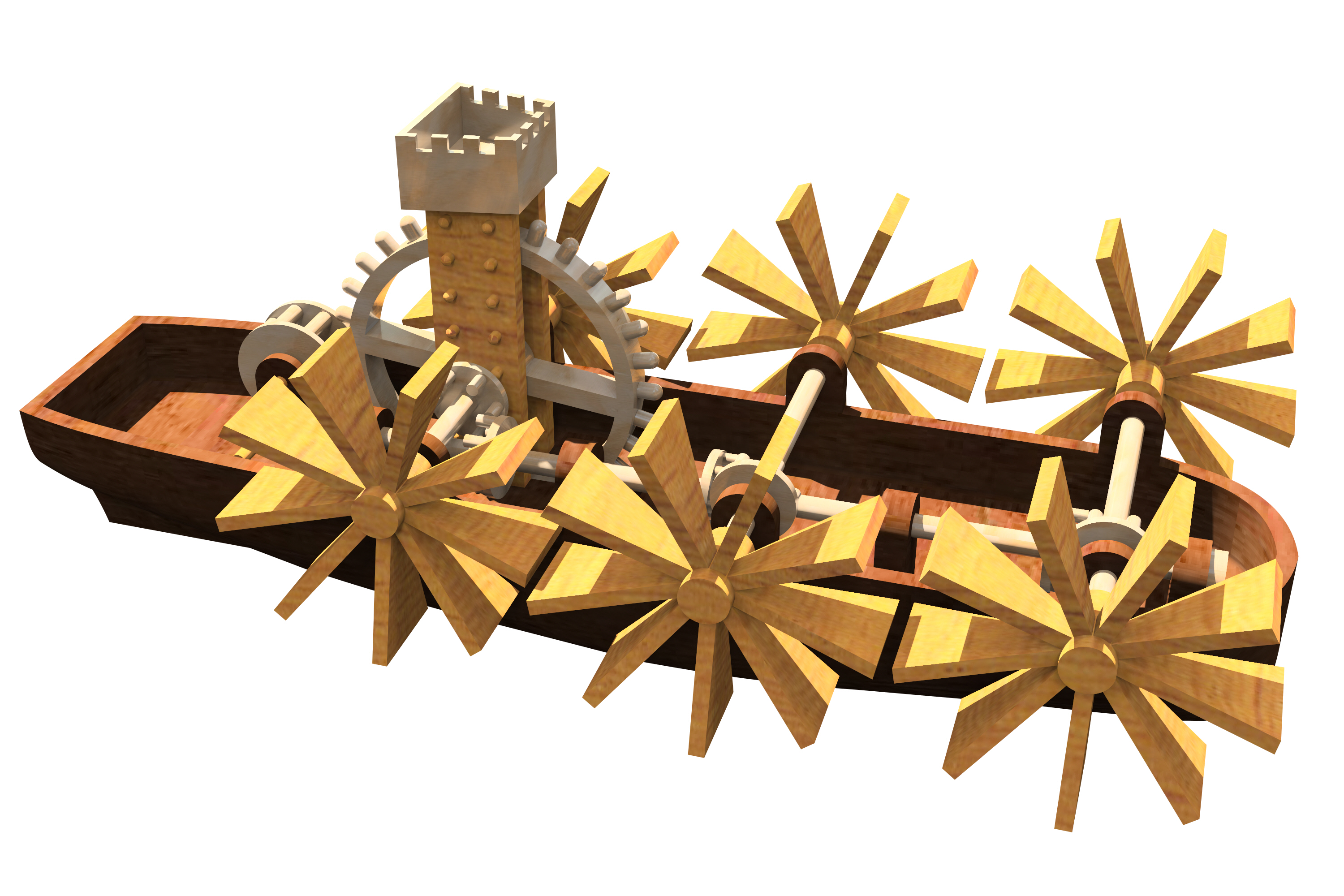

APPLICATION OF COMPUTER AIDED DESIGN AND ADDITIVE MANUFACTURING TO THE RECOVERY OF THE PADDLE BOAT BY FRANCESCO DI GIORGIO

The application of Computer Aided Design and Engineering tools (CAD / CAE) in the study of the History of Machines and Mechanisms for their recovery and analysis, allows the modelling and graphic reconstruction for their simulation and virtual recovery. These technologies make it easier to design and modify structures. In addition, it can serve as a starting point for its technological analysis through the mechanical design modules and its reproduction by rapid prototyping. This means that, from undefined plans, an interpretation can be made for the recovery of a proposed old mechanism that never materialized. In this work the interpretation, analysis, virtual reconstruction and scale manufacturing of a prototype is carried out by Fused Deposition Modelling (FDM) of the paddle boat of Francesco Di Giorgio.

A simplification of the model calculated and designed in CAD is shown in the image below.