what tasks have been completed, and what tasks remain?

- Task Completed:

- Procurement of matterial. ✓

- 3D CAD Design. ✓

- Plasma cutting of Enclosure cabinet parts. ✓

- Burner system Assembly.✓

- Painting of Enclosure cabinate.✓

- Assembly of encloser cabinet and ashtray.✓

- 3D design of control panel handle.✓

- ATtiny 1614 PCB board design, fabrication and testing.✓

- Incinerator Arduino Program.✓

- Control panel wire routing.✓

- tasks remain:

- 3D printing of control panel handles.

- Copper pipeline fitting for LPG supply.

- Electronic components mounting and wiring on machines.

What's working? what's not?

- The 1.K-type thermocouple is not showing appropriate reading.It might be because I have used around 5 meters of wires to transmit a signal from the Incinerator to the control panel.

- Some of the Ignition Circuits got damaged. During testing.

- My last final board MOSFET IRF546 switching circuit was not working So I have to made a new board with another ATtiny 1614 .this time I use another N-CHANNEL MOSFET 50N06 SMD .which was running perfectly I test my Electronic integration code on it .All working perfectely until I connect it with an External power supply from fablam .which damage the Ic.Then I make 3 final board using 3216 which has almost similar characteristic as ATtiny 1614.

what questions need to be resolved?

My K-type thermocouple is not working. Is it because I use a long wire(4 core pvc wire 5 meter) to carry signals.It works on Spi communication.and Its work perfectely when I connect to direct bord without long distance cable.

what will happen when?

Just one week remains for the final project presentation. A bundle of work with me. To make my project presentable work. I have to manage my work in a very sincere and focused way.- Plane of action for this week:

- Day1:Design and fabricate ATtiny 3216 board and test with all components keeping K-Type thermocouple on hold. also on the other hand supporting the 3D printing job running simultaneously.

- .Day2:Start Making copper Pipeline assembly for LPG gas flow with help of Purnesh and assemble also dose simentensly control panel wire routing with the help of Shanker.

- Day3:leakage testing of pipeline assembly and installing it on the machine. Mounting the Gas flow controlling Automation system involving solenoid valve servo motor with variable flow adjuster.

- Day4: Mounting all electronics including the Ignition circuit and Control panel.

- Day5:Taking trials of the incinerator, recording videos for presentation and making presentation slights.

- Day6:one day for extra if something misses I will cover it simultaneously video preparing for the presentation.

- Day7:Presentation day.

what have you learned?

During this 6 month of course and this hard working time of the final project.I learn so many soft skills as well as technical abilities.

- I learn how to manage a team and project work.

- I improved my last version code and also solved somany hardware issues and troubleshooting the electronics.

- Did friendship with rapid prototyping tools including 3D printer ,SRM20,LASER cutter.

- Learn how to learn new things.without knowing any thing.

- Try to implement a Design thinking process .

- .Learn how to do work smartely.

- .learn workshop fabrication processes. And many more… With the help of modern technology like rapid protiping tools anything can be made in fablab.

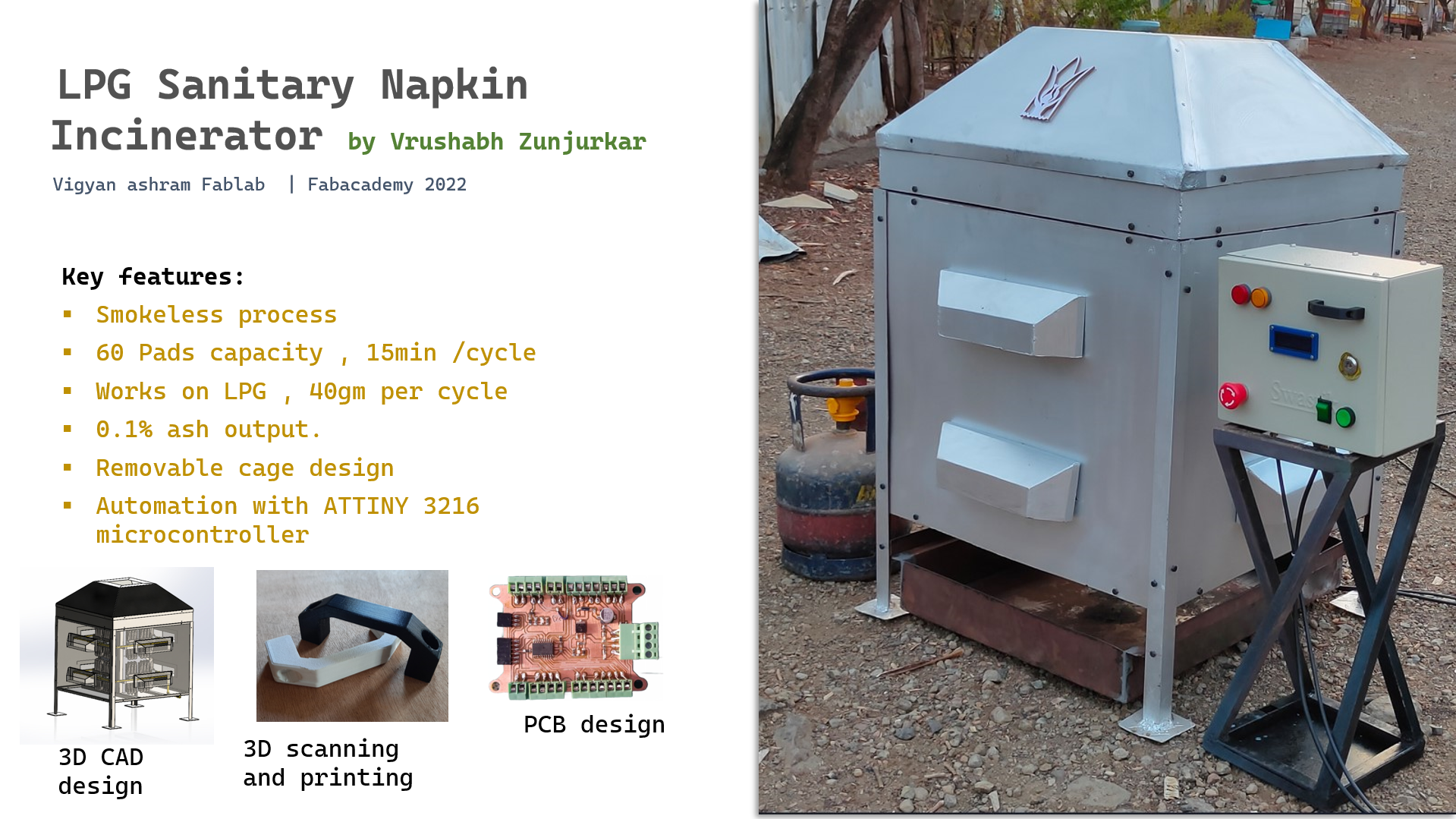

Presentation Slide:

project presentation Slide.

Presentation Video:

I Prepare above drafts of project summary slide and video clip and put them in my root directory.