PROJECT FINAL

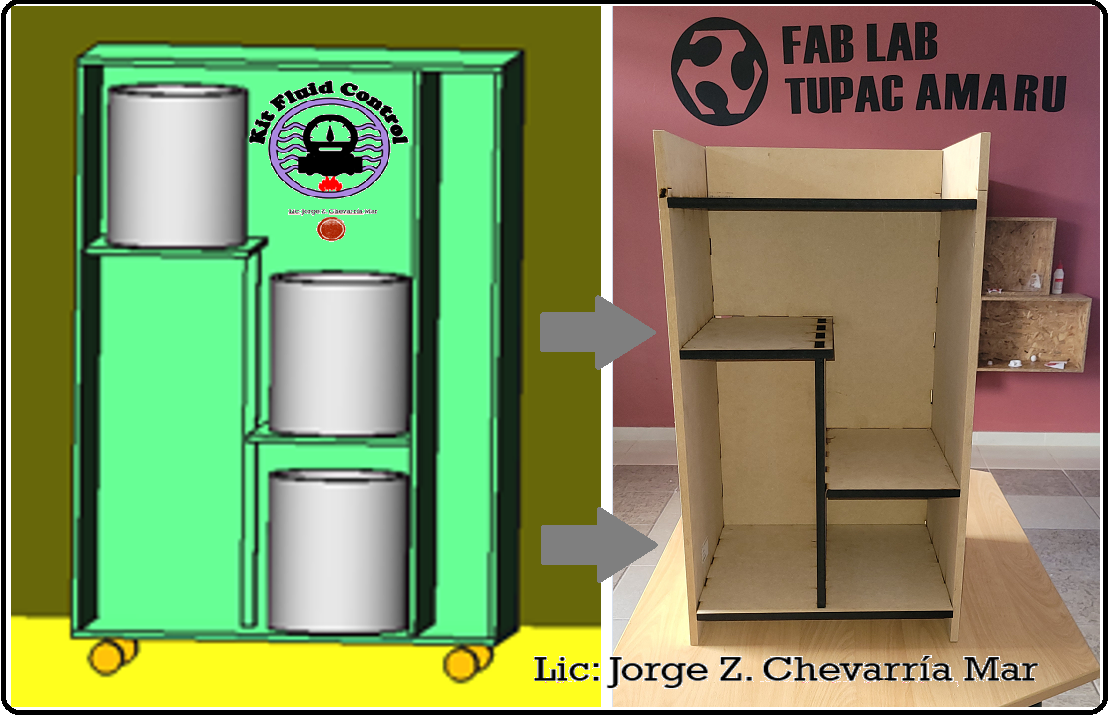

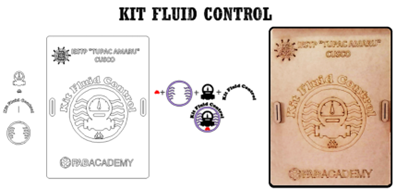

WE PRESENT THE “FLUID CONTROL KIT”

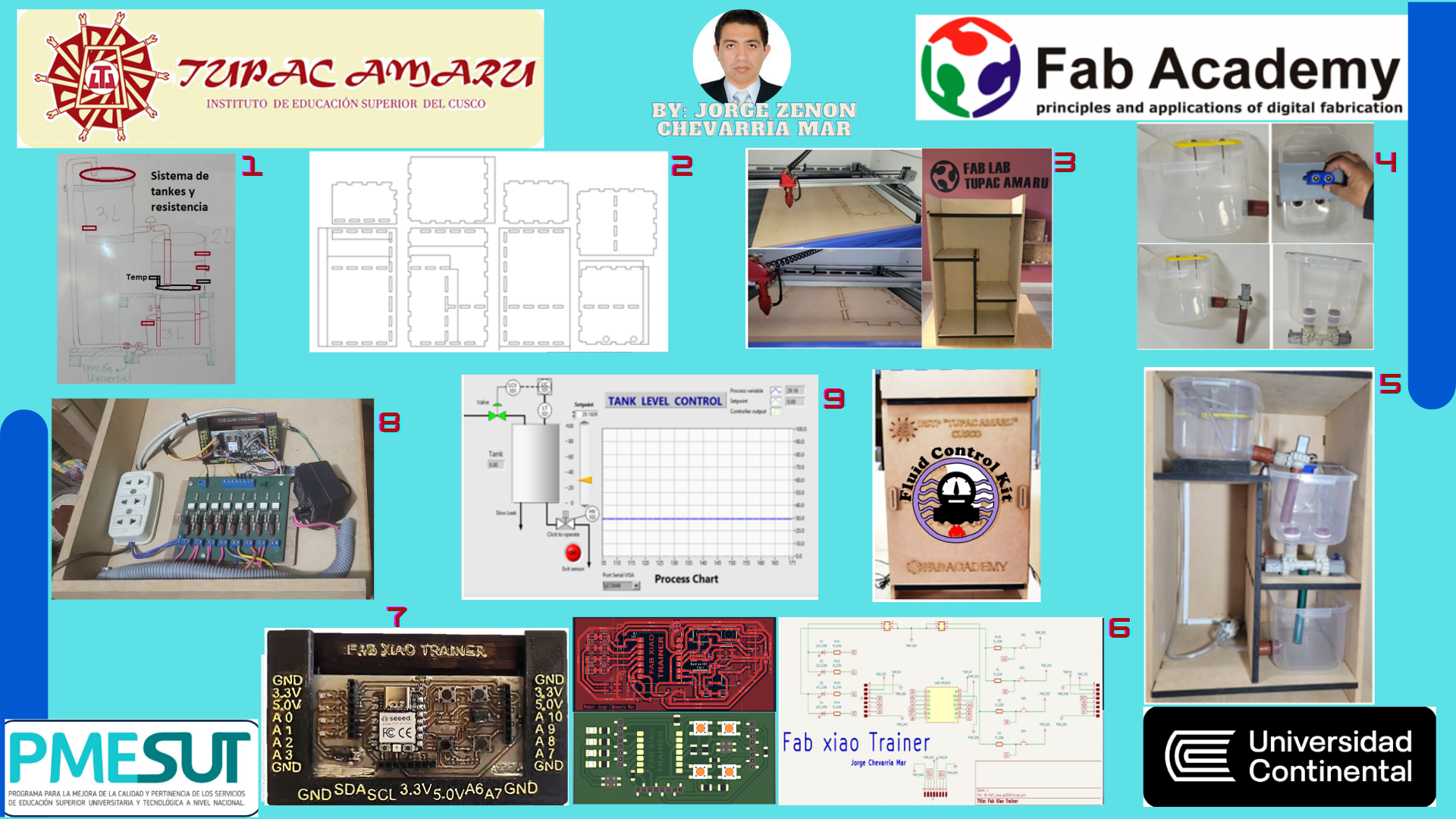

The module presented helps us to teach process control theories to students, regulating the liquid level in a tank built with cheap but resistant material to be able to teach learning sessions that allow us to know the elements, types, control actions and everything related to the control of industrial processes, whether working with a microcontroller, PLC, digital circuits, FPGA, etc.

Several individuals propose their modules, but many times they do not use known materials or use tools that are not available to most, there are also companies that sell modules of this type, but they are very expensive both for the hardware used and the software used. For this reason it was decided to create this module, I consider it easy to build since our FABLABs are becoming more widespread internationally and are increasingly reaching the general population.

This is the proposal of the module when starting the Fab Academy sessions.

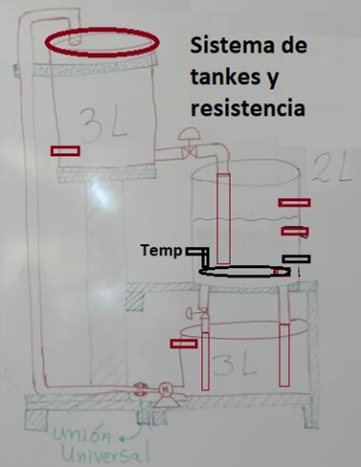

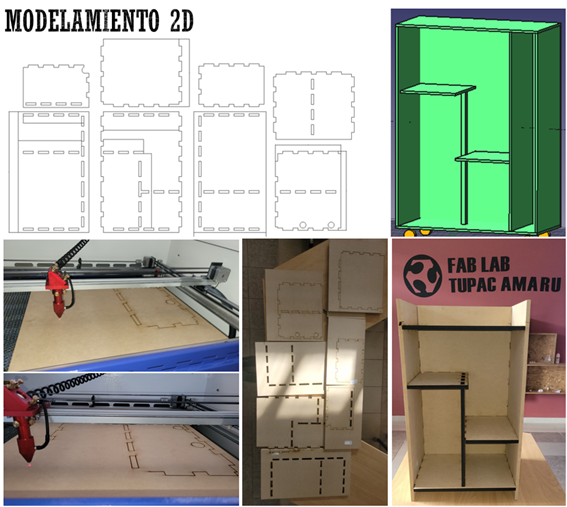

To meet our goal, we began by designing the structure of our module in a 2D plotter (AutoCAD) for a thickness of 12 mm in MDF, we simulated its assembly by generating a 3D model before cutting, generating the exploded view in FreeCAD so as not to make mistakes in the cut with laser machine.

Considering the holes where the pipes and wiring of the equipment will be installed.

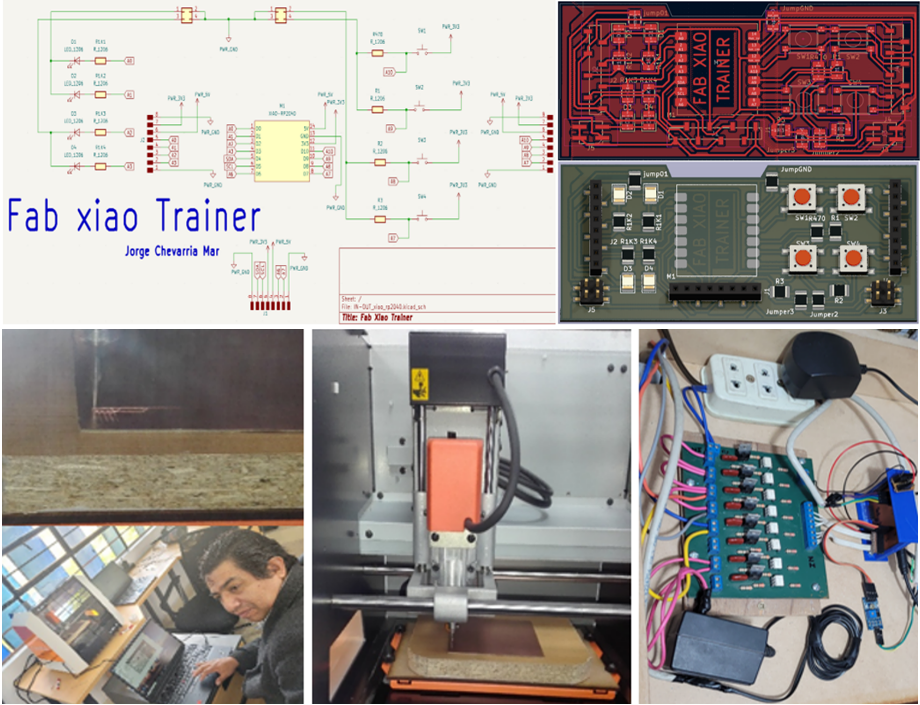

ELECTRONIC PANELS IN KICAD

At the same time, the electronic boards were designed in KICAD, using the milling machine, the tracks for the electronic cards of the control system and/or the command card were created, while continuing to use some commercial boards necessary for the project. The necessary voltage for the solenoid valves is 220V that works with an optocoupled triac strip to control the opening and closing of the solenoid valves.

In turn, we adapt the humidity sensors and distance meter in personalized 3D supports, encapsulating them in models printed in PLA to improve their performance in measuring the liquid level in water tanks, these adaptations are printed in PLA.

In addition, the logo of our module "KIT FLUID CONTROL" was designed with the inkscape program to be able to recreate it on the door of our module.

It remains to be noted that we required a water pump for our project, it had ½-inch PVC water, solenoid valves, water sealant, connection cables, gutters, electrical terminals and an energy source for the control and power part.

The actuators, in this case the valves work at 220Vac and we recovered them from a washing machine that was already in use because the motor was damaged and they preferred to buy another one, we adapted them and they were made as indicated on his channel "El Angelito" that I modify the solenoid valve so that it works without water pressure. https://www.youtube.com/watch?v=523j6paSa0s.

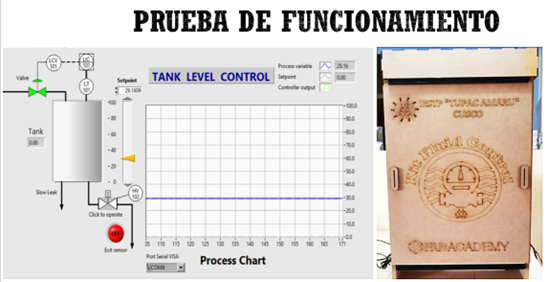

MODULE TEST:

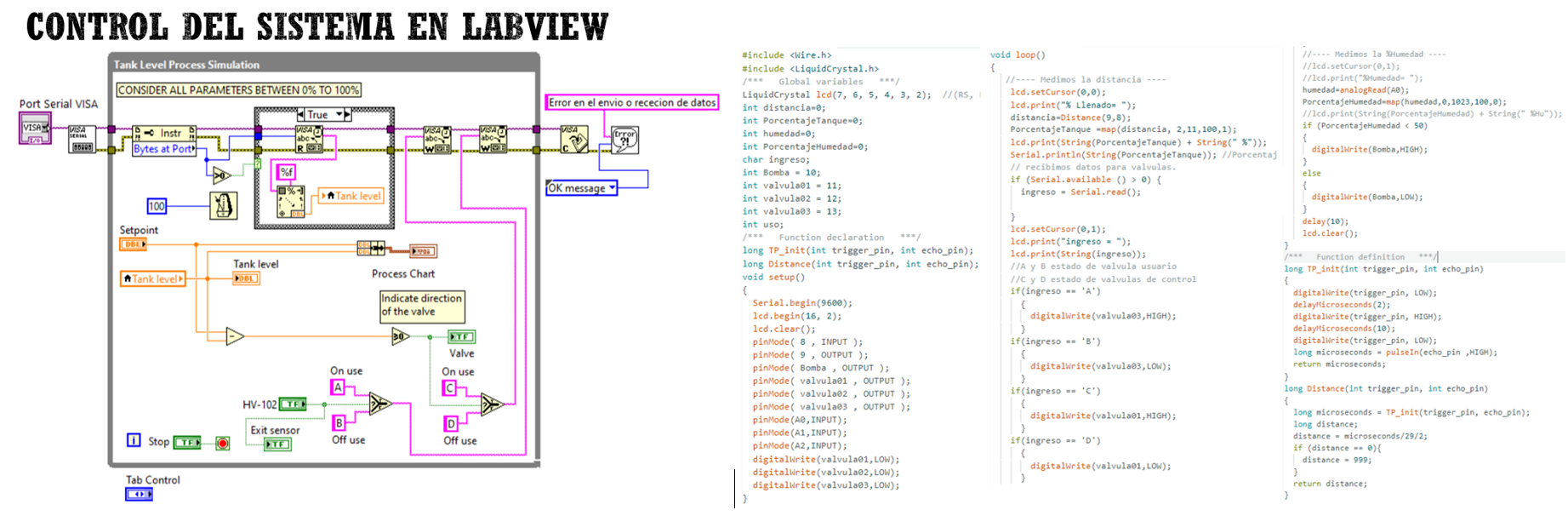

We prepared a control system in LabView and for our control card to test our project.

To improve this project, it is desired that students be able to interact with the module remotely, be able to program and test it from home, since the module can be used in the laboratory or in a specific application.

All the test came out successful as seen in the following video.

Slice for Fluidcontrol Kit:

https://www.canva.com/design/DAF5zS3-sGQ/W9Y5hgSfwvHvYHxflyHABA/view?utm_content=DAF5zS3-sGQ&utm_campaign=designshare&utm_medium=link&utm_source=editor

created with

HTML Designer .