For a long time ago I was already interested in plastics and this caught my attention PET (Polyethylene terephthalate) is a plastic polymer that is made from a polymerization process of terephthalic acid and monoethylene glycol. This material is manufactured in different formats and can be transformed through different extrusion, injection and even thermoforming processes.

Currently, the PET acrylic material has become one of the most rigid and resistant thermoplastics on the market, with transparency and crystallinity being one of its most precious characteristics.

The properties of polyethylene terephthalate are endless, among which the following stand out:

• A material of great hardness and rigidity, which can be used in contact with food due to its non-toxic characteristics.

• Great transparency, although it also admits different loads of dyes

• This type of plastic or acrylic material acquires a very good chemical resistance. Therefore, it can come into contact with different solvents and oils without damaging it.

• In addition, it obtains a wide resistance to wear, impacts and breakage

• It becomes a fireproof product, that is, it rejects combustion and protects itself against fire.

• It is, thanks to its composition, a fully recyclable and environmentally friendly plastic.

MOST OUTSTANDING APPS

There are different things made of polyethylene terephthalate or PET. Below, we highlight some objects and materials made from this recyclable thermoplastic:

Recyclable plastic containers and bottles

Said thermoplastic is widely used in the production of containers or beverages, such as soft drinks and water bottles. Thus, it becomes a material for daily use in the industrial sector, thanks to its rigidity and hardness. Although, also, the fact of being able to be recycled in its entirety influences, a fact that helps to manufacture many other custom-made plastic bottles and containers.

Textiles of all kinds

PET It is a type of plastic that is used in the textile industry for the manufacture of different clothing items. In fact, it becomes an excellent substitute for linen and even cotton.

Film or film photographs

This plastic polymer is also used for the creation of different photographic films. Although, it is also very useful for creating basic X-ray printing paper.

machinery manufacturing

Currently, polyethylene terephthalate is used for the manufacture of various vending and recreational machines.

lighting items

For the manufacture of different design lamps. In fact, PET turns out to be one of the most attractive materials in lighting design, both exterior and interior.

Other advertising elements

As, for example, displays or signs for visual communication. Likewise, it is also often used as an ideal material for the creation of exhibitors in shops and all kinds of fairs or events.

Knowing that there is a PET thread to be able to make objects through 3D printing and that it was more versatile than printing ABS made me look for information and compare anyway with what I already knew about PET.

3D printing takes advantage of the resistance, toughness and transparency of PET, and its properties that can be used the most are the following:

• Temperature: 210°C – 255°C

• Platform temperature: 55° C

• Polymerization method: By steps or condensation

• Degree of crystallinity: From amorphous to 30% crystallinity

• Density: 1.34 – 1.39 g/cm

• Modulus of elasticity: 2300 Mpa

• Tensile strength: 59- 72 MPa

• Elongation: 200%

• Hardness: Rockwell M94 M101

• Thermal expansion: 15.2 -24

• Machining quality: excellent.

Although the PET for 3D printers is not pure it is mixed with glycol, (being known as PETG, PET-G or PET G) to be able to melt at temperatures from 210°C to 255°C because pure PET has temperature values around 300 °C to be able to melt it.

The G at the end stands for Glycol-modified, and refers to a change in the chemical structure of the polymer that makes it more transparent, less brittle, and easier to process than ordinary PET. With these improvements and its ease of printing, PETG has become one of the most used materials in 3D printing.

PETG has very good mechanical properties. We are going to compare its properties with the other two most popular plastics, ABS and PLA.

• Rigidity. We call rigidity the difficulty of a material to be deformed (for example, bent or stretched). PETG is a less rigid (more elastic) material than PLA: it is easier to bend and less brittle than PLA. It is also less rigid than ABS, but in this case the difference is much smaller.

• Resistance. In general, PETG is more resistant to blows, stresses and "it is more difficult to break" both than PLA and ABS. In addition to having better properties on paper than ABS (often considered a strong plastic in 3D printing), the greater adhesion of the layers makes PETG parts even more resistant in practice.

• Resistance to temperature. PETG is slightly more temperature resistant than PLA, but less so than ABS. PETG begins to soften at 80ºC, more than PLA (70ºC) but less than ABS (105ºC). Also, as we have been able to verify through the experience of our clients with PETG, this material can also resist low temperatures for long periods of time.

PETG has its own ideal characteristics for certain jobs.

• Approval for food use. PETG is approved by the FDA (the US agency that regulates food, drugs and cosmetics) for food use. This is a feature to be wary of for PETG-printed parts, which are printed or stored in an uncontrolled environment, can come into contact with contaminants, and have cavities and grooves that are difficult to sterilize.

• Chemical resistance. PETG is very stable and chemically resistant to attack by acids and bases.

• Transparency. PETG in its natural state (without dyes) allows around 90% of light to pass through, making it suitable for printing transparent or translucent parts. It also means that you can buy PETG filament in translucent colors, which leave a shiny finish on the pieces and hide the grooves of the layers very well.

• No smell when printing. Unlike ABS and similarly to PLA (which has an odor when printed, but not a strong or unpleasant odor) PETG does not produce an odor when printed.

• Recyclable. Being the material used in bottles and food containers, we already have an infrastructure to recycle PETG! This infrastructure in Spain is the one that begins in the yellow container. You can throw away your failed prints and used parts along with the containers and bottles to be recycled.

We have already seen some characteristics of PETG, now we will see what we require to print this type of plastic.

The first thing we did is look for information and we came to adjust certain parameters that we already had when printing PLA in assignment 06 print and scan.

Of all the tests I did, the profile for the Cura laminator for PETG helped me.

No. Settings Values No. Settings Values

1 Nozzle temperature 235 °C 7 Styling: “Not into the skin” or “Into the filler”.

2 Bed temperature 70 °C 8 Cooling fan speed 50%.

3 Printing speed 40-50 mm/s 9 Initial layer cooling speed 0%.

4 Initial Layer Print Speed 20mm/s 10 Build Plate Adhesion Edge

5 Retraction speed 40-45 mm/s 11 Edge width 5-6 mm

6 Retract distance

- For Bowden configurations. 6mm

- for direct drive configurations 2-3mm

And to check, some tests were done on an ender 3 V2 and we have some recommendations.

- When testing a new filament, it's an excellent idea to print a temperature tower.

- If the pieces are curved or deformed, lower the printing temperature.

- IF the layers do not stay together, decrease the fan speed or increase the printing temperature.

- PETG is quite prone to stringing and oozing and excessive cooling can cause layers to laminate.

- Usually for PETG, glue stick or hairspray is applied to the print surfaces to help the parts adhere to the bed or some material that has some roughness to help the object adhere well.

- If the print layers begin to separate or crack, reduce the fan speed. In our ender we did not have good cooling so we took the opportunity to test the PETG printing and see how it printed, it turned out excellent.

- PETG retains its shape at much higher temperatures than PLA, so overhangs and complex shapes will still be sharp.

We also made some pieces for wristwatch insurance that is lasting to date.

These models are found on Thingiverse. (https://www.thingiverse.com/), they helped us to calibrate the machine and be able to work with PETG.

ONE PIECE ORDER:

What a coincidence that we were just asked to create a cover for the roof of a truck and since it would be environmentally friendly, we suggested to our friend that it be made of PETG, which I accept.

First: we take the photos of the left model and sizes to guide us and create the object for the right side.

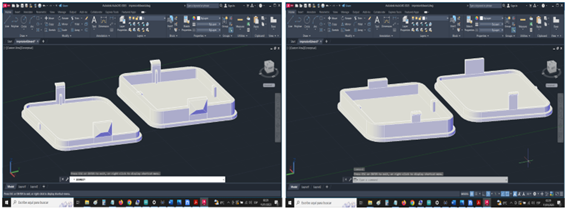

Second: we designed the model this time in AutoCAD. We present two models to test the best grip.

Tercero lo enviamos a el laminador CURA para configurar la impresión.

Fourth: The object could be reproduced, it was painted and installed in the truck.

It was possible to learn more about PETG plastics and provide a solution to a friend's problem.

created with

Free WYSIWYG HTML Editor .