Molding and Casting

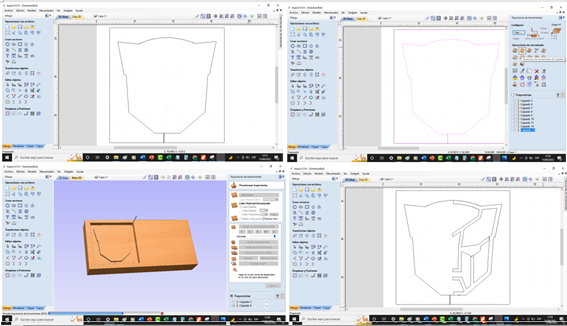

For this assignment I will consider betting on the nostalgia of our first versions of the autobots, developing a mold of the insignia.Searching the internet, I found this image at https://www.pinterest.ch/pin/858076535224054252/ that we will design to be able to machine it and then remove the mold.First, I will draw them, for this I will help myself with the vectorization of Inkscape images and we will give it its touches.

Since vectorization didn't work out very well for us, we ended up redrawing it.

Now we generate a contour and then we take it to FreeCAD to have a 3D image, we present it in a base shape for machining.

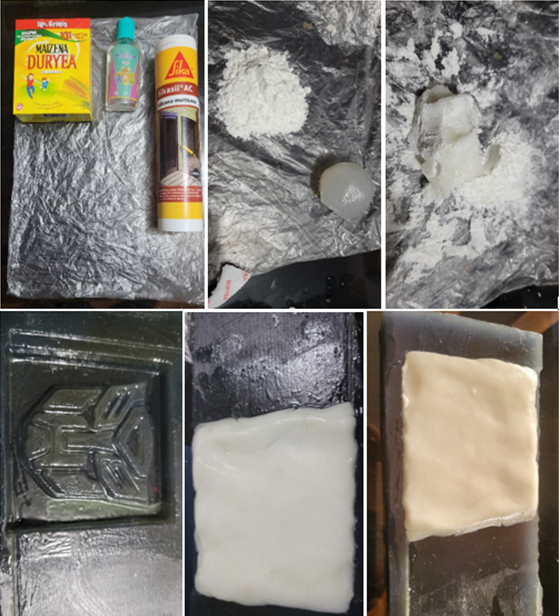

Once the model is finished, we now prepare our paraffin to machine it. We collect candles and dissolve them in an old pan that I found over low heat, after removing the wick, we empty it into a mold that I prepared with scraps of hard plastic.

At the end of the unmoulding, the edges are equalized trying to give it a rectangular shape.

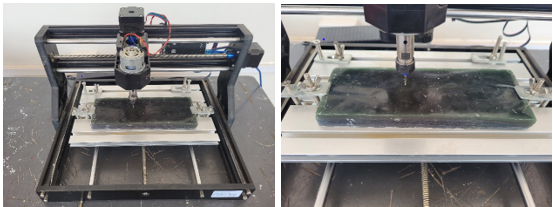

The next step was to mount it on the router machine to machine it, I was able to get a well-known router on the internet that is the Cnc Router 3018 Pro model created on the basis of Aluminum and Bakelite.

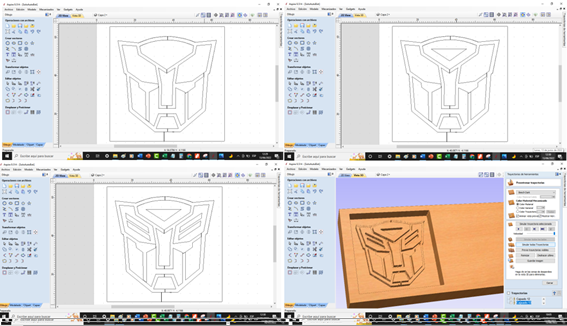

Putting the paraffin on the machine we prepare the Gcode, for this practice I want to use a new software, the ASPIRE, to fulfill this objective I went to visit my friend Fernando who works for a company that develops wooden articles for gardens and schools.

Now, let's get to work, we open the program and import our model, first we will make a rectangle that will serve as a container and limit of the mold. We give the parameters to the right side as required and we accept by clicking on "CALCULATE", we go to the 3D tab and simulate it. In this way for each profile in the following order.

Now that we have the Gcode we can send it to the machine, it will work in the same order that we prepare our machining process.

After the machining we clean and grease it to be able to generate a mold but we do not find the materials suggested in class to be able to generate our mold, searching the internet we find another more homemade and economical way to obtain molds as suggested by this web page:

https://www. .youtube.com/watch?v=ErZ405eqSAQ, the first thing we get our materials.

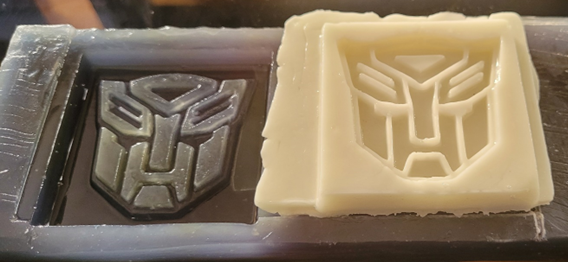

After a week of drying as suggested in the video we see the results.

Now we take a reproduction in dark resin and put a base at the end to be able to paint it.

created with

Website Builder .