I was looking forward to this week before, it's a week that allows us to do something new of our choosing, that's why I chose to learn Soft Robotics.

Learning:

- Individual Assignment

- Design the Mold

- Fabrication with 3D Printing technology

- Creating the Silicone Mold

- Blowing air into the mold

Individual Assignment

Design the Mold

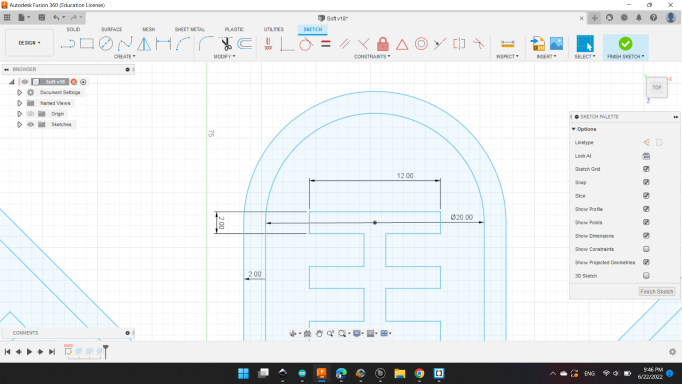

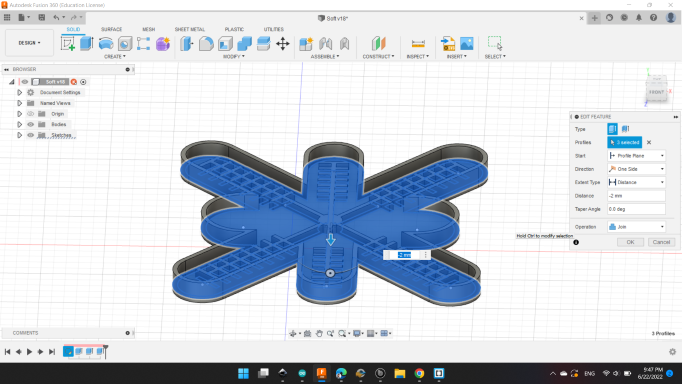

I started with my friend Fusion 360.

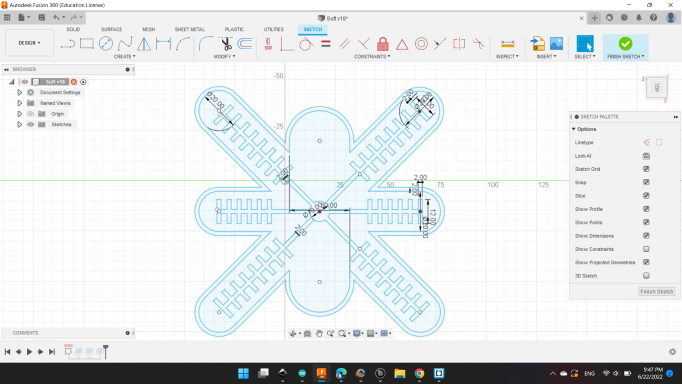

I wanted to design a soft robotic a little bit different from the traditional one. Looks close to my HEXI Robot. So, 6 parts as legs and the front & back sides.

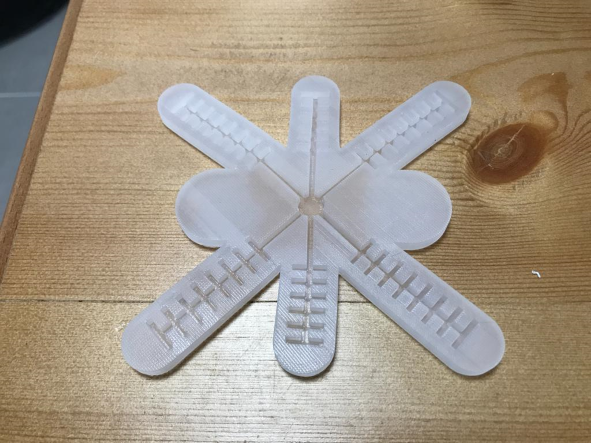

I started with design the chambers, each ont is 12mm tall and 2 mm in width.

Then I design the 6 legs.

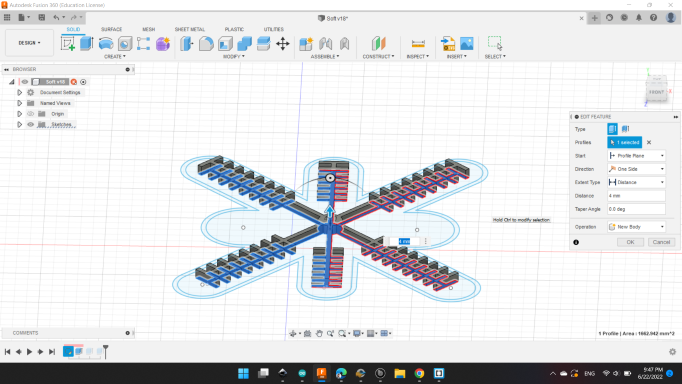

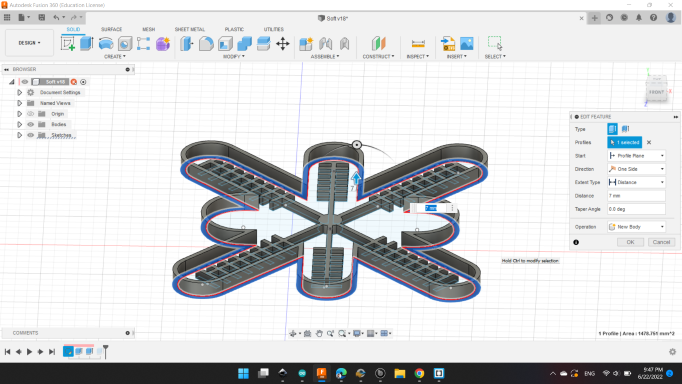

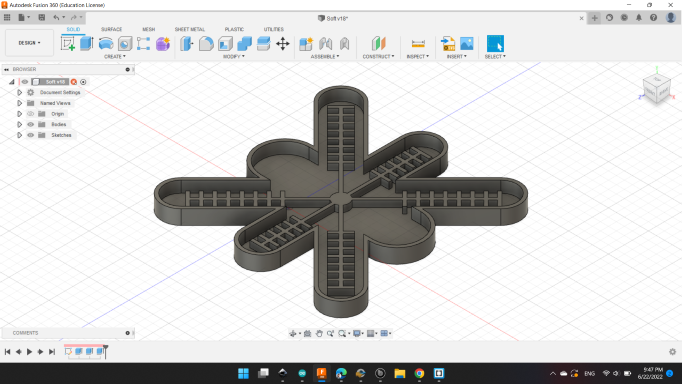

I extruded the chambers with 4 mm high.

And the frame with 7 mm.

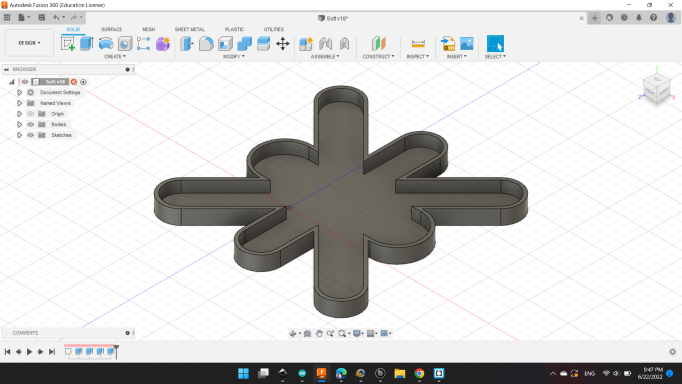

Finally extruded the base to be one body at the end.

Here's my mold 😁.

Also, I made another mold to be used as the bottom side of the silicon, I will explain later.

Fabrication with 3D Printing technology

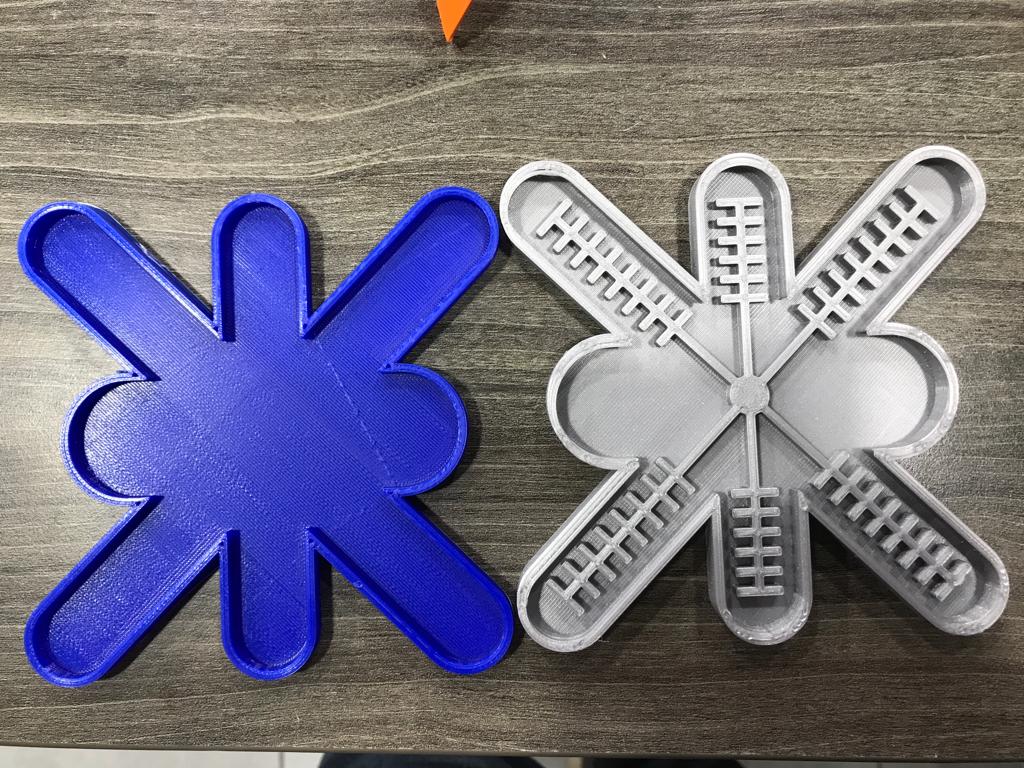

After 7 hrs and a little bit, The two molds were ready.

Creating the Silicone Mold

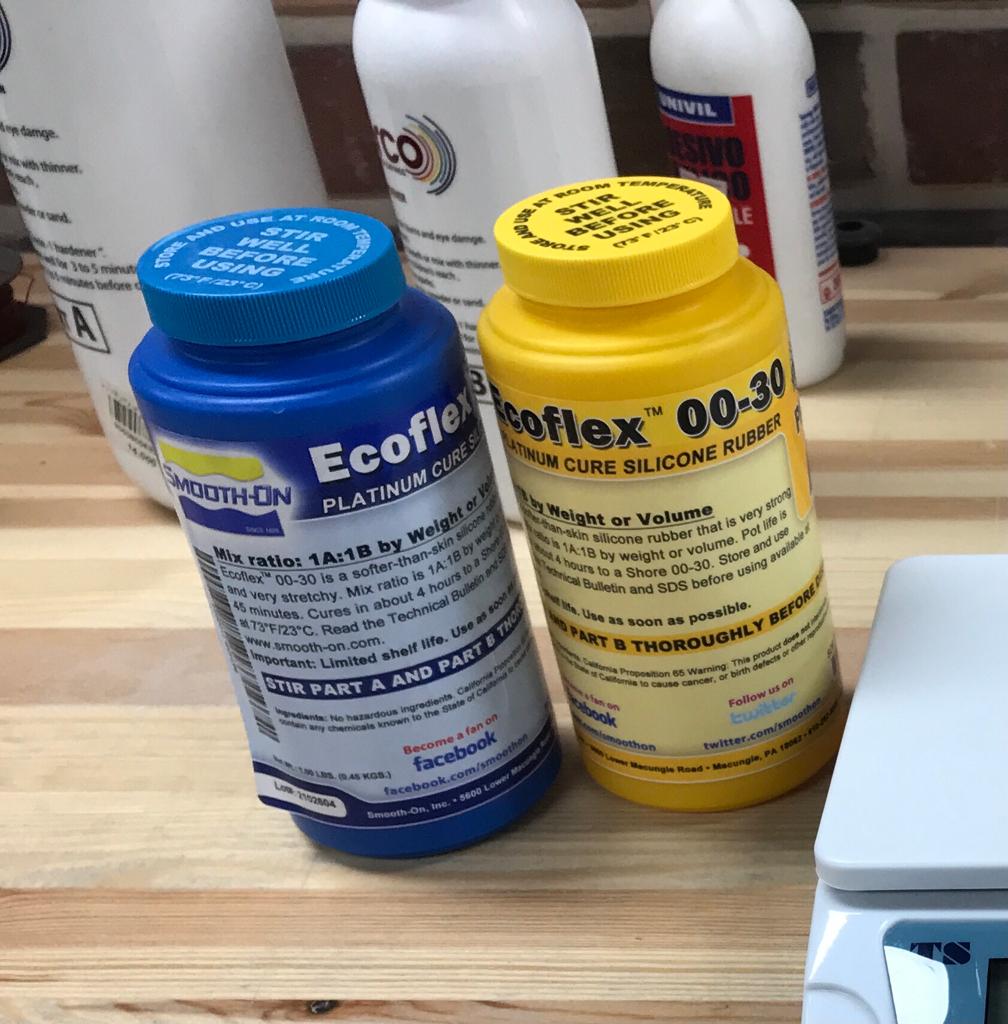

I used Ecoflex™ 00-30 as the silicon for my robot.

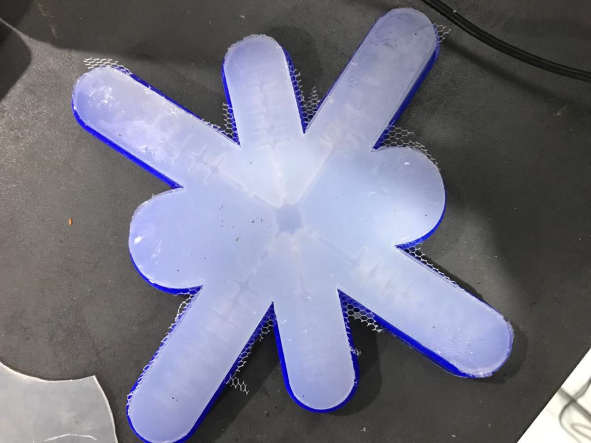

And after carefully pouring, here is the view of the first mold with silicone. The other mold, I will pouring after the first one be ready.

After few hours, the first robot became ready 🙂

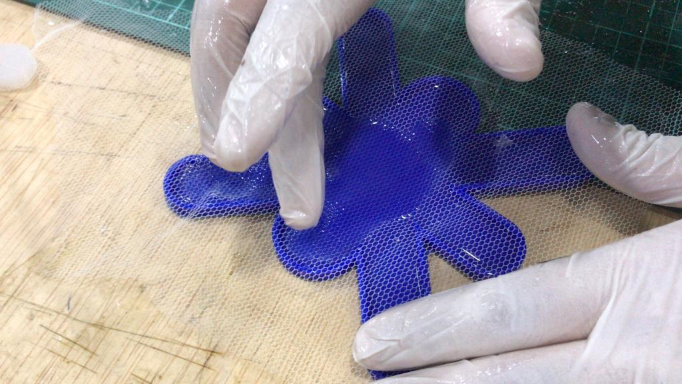

Next, I poured a simple layer of silicone into the second mold.

Then I added a piece of fabric to bend the robot in one direction and not the other.

After that, I put the silicone from the first mold on top of the fabric so that they fuse together.

After few hours also, my HEXI Sofot Robot became ready 🙂

Blowing air into the mold

I used Hand Rubber Pump to blow the air into the robot.

I had some air leakage, so I sealed the holes with the same material (Eco Flex), and the results good 🙂

You can download my files here: