Group Assignment Computer Controlled Machining

FablLab Kamp-Lintfort Jan Bewersdorff

Assignment

- Do you lab's safety training

- Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

Safety Training

I wrote everything on what our CNC in the lab is and how to operate it safefly and also what the whole procedure of using looks like in my Individual Asssignment for this week, which can be found here.

Runout

To test the runout, I simply measured a hole after a drill operation. Since the tool is 6mm in diameter, the hole should also be 6mm, which it was on the dot. This means that the runout could only be in the thousands of a single milimeter. This is also supported by the fact that M6 screws worked like a charme with the 6mm drill holes.

Alignment

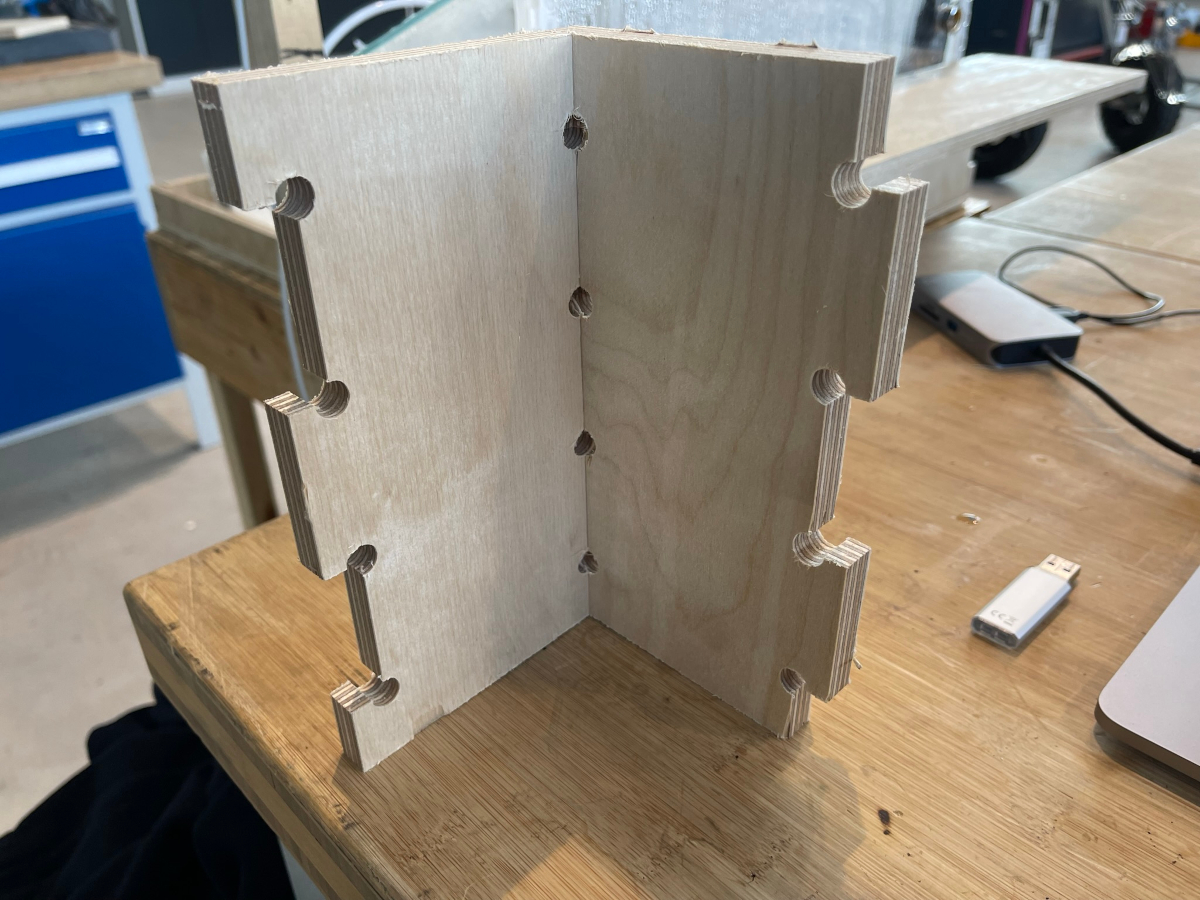

As you can see with both of the Images below, the alignment of the X and Y axis is pretty much perfect. The slots fit perfectly and the both parts combined sit flush on the table. So X and Y are perfectly in a right angle to one another.

Fixturing

For fixturing we can use two main "Systems". The first one is integrated into the CNC, which is its Vacuum Bed. The stock is getting pulled to the Bed by the Vacuum Pup, even through the sacrificial layer! For the most part this works pretty good, the problem lies within warped stock. With warped stock, this works semi okay, so to help the vacuum bed and have the stock as straight as possible on the front of the machine, where all the cutting is going on most of the time, we also have the possibility to use a very large variety of clamps available to us. Here the User just hzas to very carefully plcase them outside of the toolpath of the machine or bake them into the toolpath like its possible in Fusion360 for example.

Speeds

Since the machine is at the Lab quite a long time now, a safe machining speed has been established which is great for all of the wood stock we have at the Lab. For tthe most part we used the following established settings:

- Spindle Speed: 20000rpm

- Ramp Spindle Speed: 18000rpm

When Feeds and Speeds are not already established for the machine one is using, this here is a great tutorial on how to get the perfect feed and speed settings for the machine you are using!

Feeds

The same that goes for speed also goes for the feedrate. The machine already has established great working feedrates we tested:

- Cutting Feedrate: 2000 mm/minute

- Lead-In Feedrate: 1800 mm/minute

- Lead-Out Feedrate: 1800 mm/minute

- Ramp Feedrate: 1800 mm/minute

- Plunge Feedrate: 800 mm/minute

Again: when Feeds and Speeds are not already established for the machine one is using, this here is a great tutorial on how to get the perfect feed and speed settings for the machine you are using!

Materials

For the most part the CNC is used for Wood, which we have plenty of at the Lab in many different thicknesses and types. We have Plywood, Coated Plywood, MDF and much more in varying thicknesses from about 10mm up to about 25mm. We got told that the machine is also capable of machining aluminum. Of course not with the same settings as shown above, but rather much slower, but it could theoretically machine aluminum just fine!

Toolpaths

To control the machine, we learned how to use Fusion360s CAM processor. If you're interested in what I did personally with this way of CAM processing, you can read up more about it on my Individual Assignment Page here. The other way we quickly went over in our introduction into the machine, was the machines own CAM processor, running on the control PC of the mill. It is a really simple CAM processor that can do Outside and Iside Cuts, Pockets and let the Tool follow a specific line. Instead of using 3D-Models, this tool works by using DXF files, which should in the best case be prepared in a way, that they are layered depending on the operation that should take place with each line. A program that does so, is for example Rhino. With this dxf file the User can then select individual layers and start operations on them, setting tool, tooldiameter, speeds, feeds and stuff like briding. The user has to pay extra attention, as this CAM processor does not have a collision detection or something else along those lines, so double and triple checking everything is a given with such a CAM processor.

Test Piece