Weekly Practices

Reasearch

For this week’s research, I found this video very helpful. I will summarize this week’s topic here:

Take Away from the session, difference and importance of molding vs 3d printing.

- Surface finish: The 3d printing has surface finish limitation, example layer height.

- Low cost : plastic vs wood/wax cost

- Short run production: time and cost of material.

- Range of materials : 3d printers have limited materials.

Flexible vs rigid :Rigid (positive) to flexible (negative) then back to rigid (cast final product)

Importance of using flexible material as negative:

- Flexible to ease the process of removing

- Flexible to ease the process of correcting any errors

- Recasting is flexible to enhance the rigid mold life and recast it for more production.

Relevant terms:

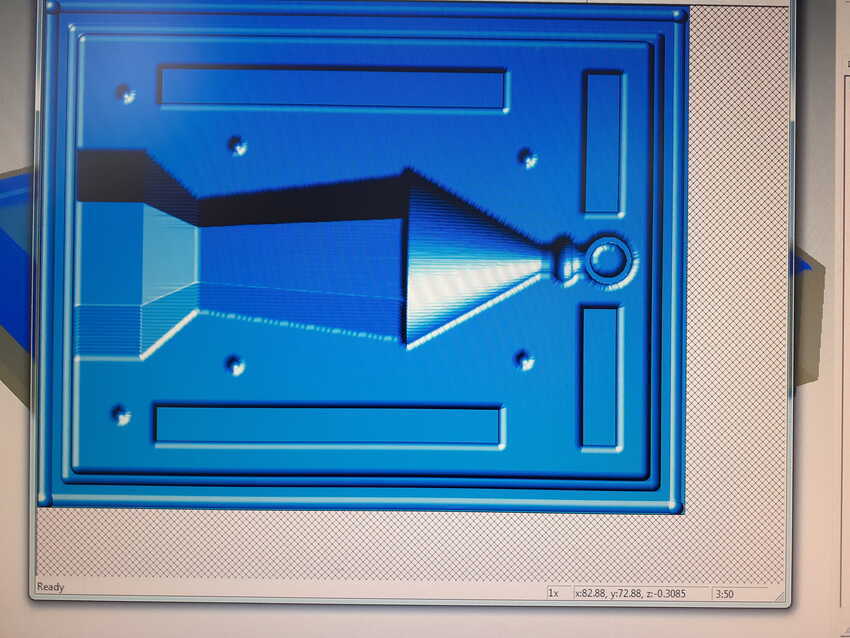

Pour spouts: basically a delivery system for casting medium, importance: makes it easier, efficient, saving the material and keeping the working environment clean while casting.

Types: direct casting and in direct casting.

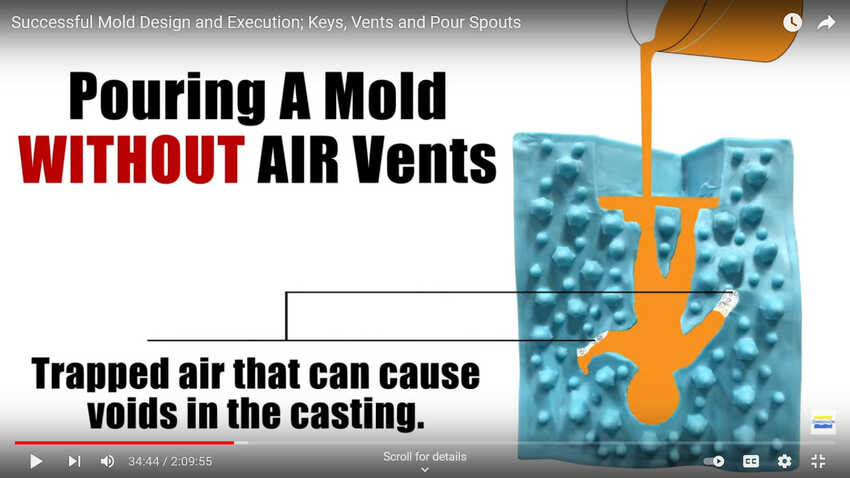

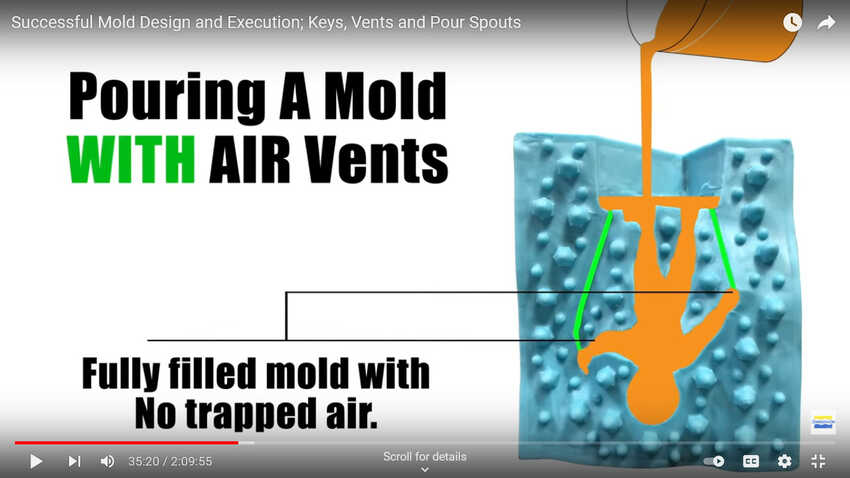

Vents: to let the air out while casting and avoiding any bubbles which damages the casting process.

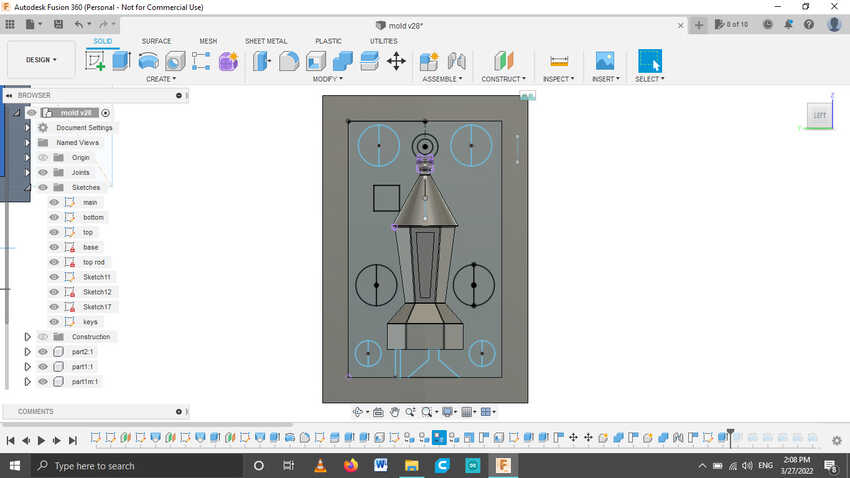

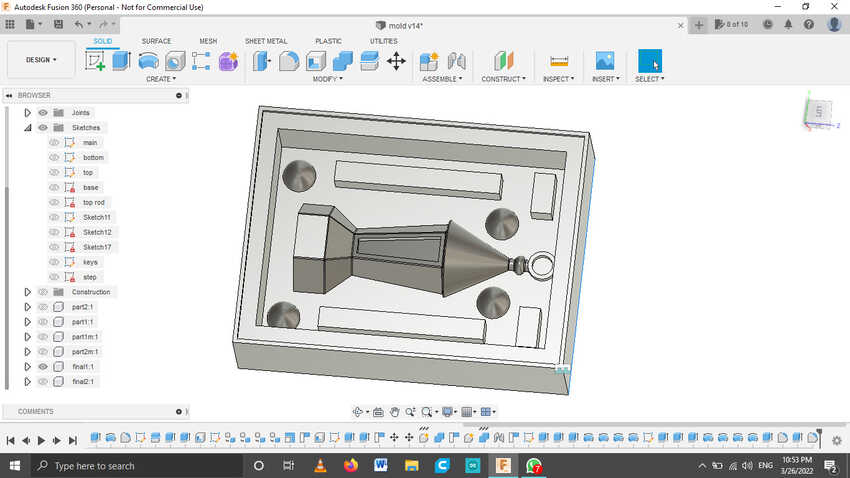

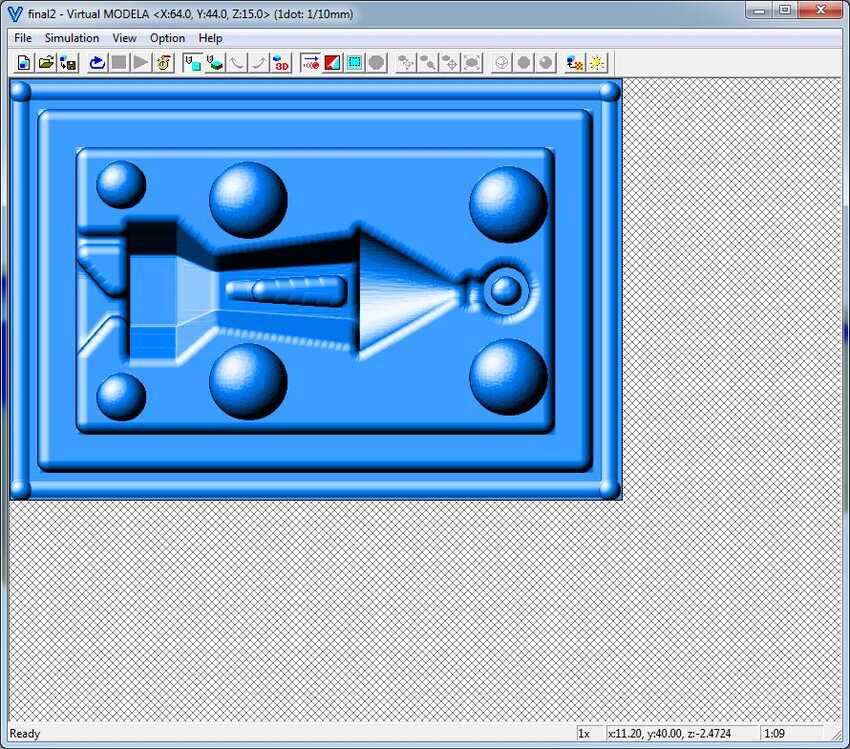

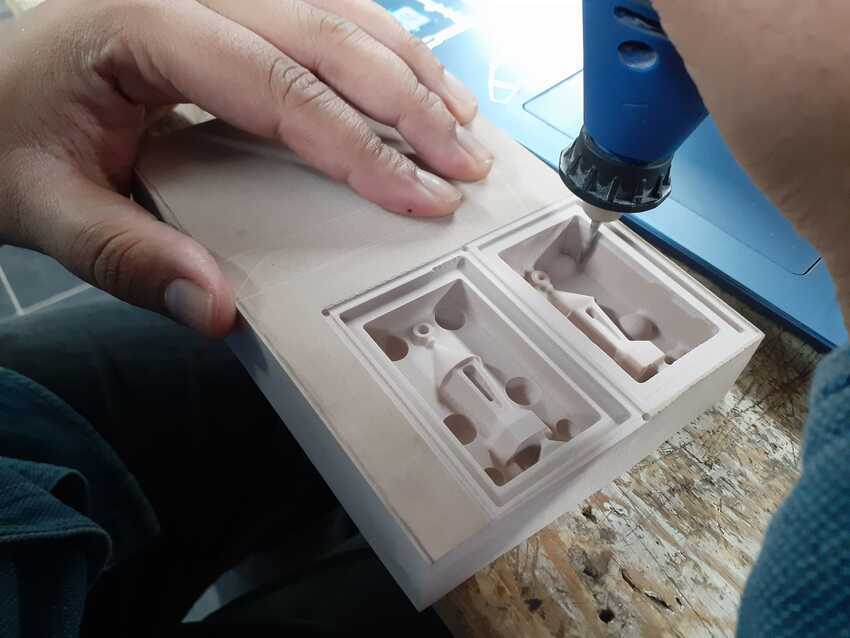

Keys: register 2 part molds - to make one part connect to the other, importance: enables better casting, minimizes post processing and eliminates any flashing in casting.

Types of keys: plugged keys, orientation keys and step keys.

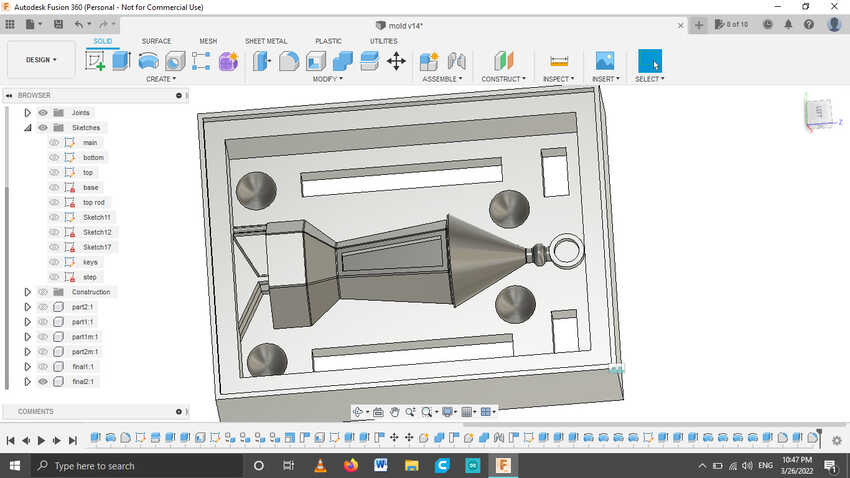

Parting Line --This is the line that will define where the two halves of the molds separate. Usually, you'll want to make sure this generates the minimal number of undercuts. Also, to make sure the two halves of the mold align nicely.

Undercut: In manufacturing, an undercut is a special type of recessed surface that is inaccessible using a straight tool. In turning, it refers to a recess in a diameter generally on the inside diameter of the part. In milling, it refers to a feature which is not visible when the part is viewed from the spindle. In molding, it refers to a feature that cannot be molded using only a single pull mold. In printed circuit board construction, it refers to the portion of the copper that is etched away under the photoresist.

Tips:

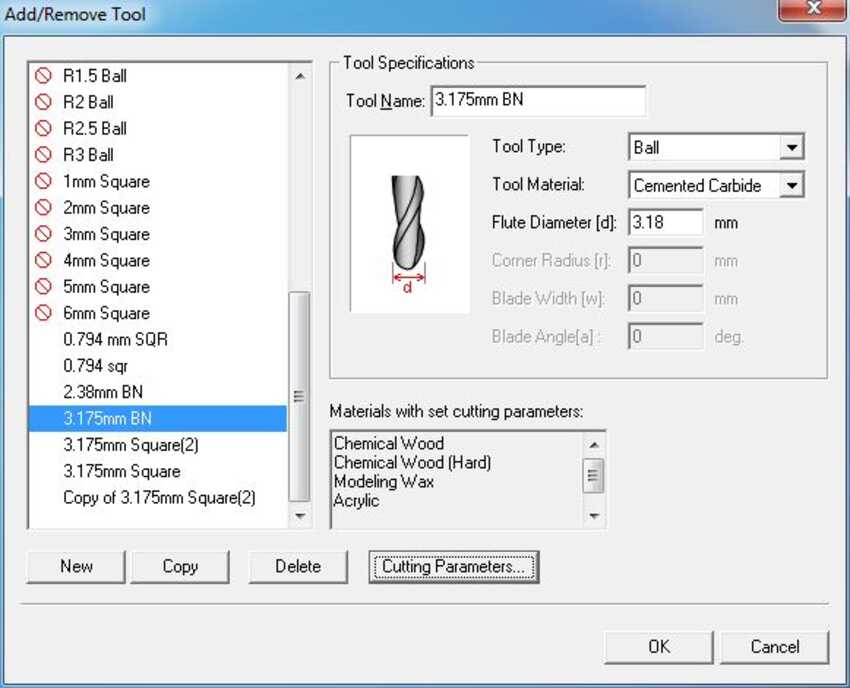

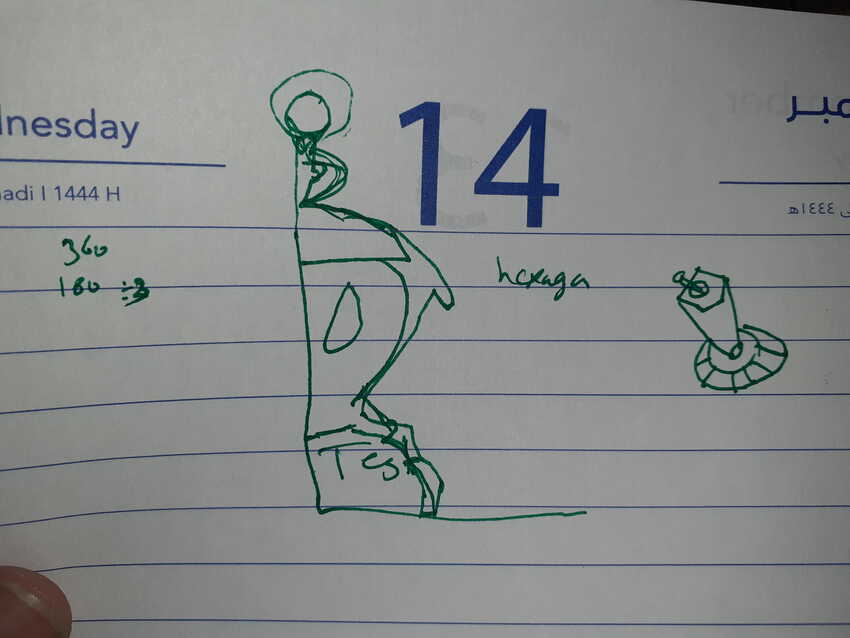

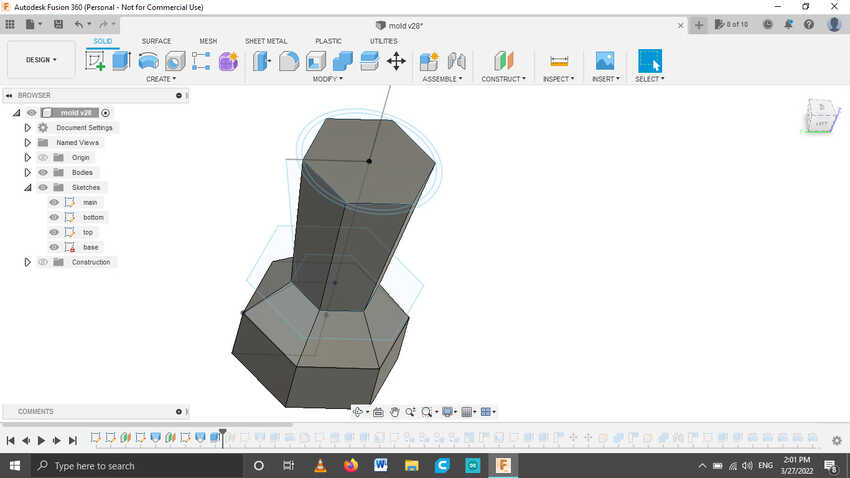

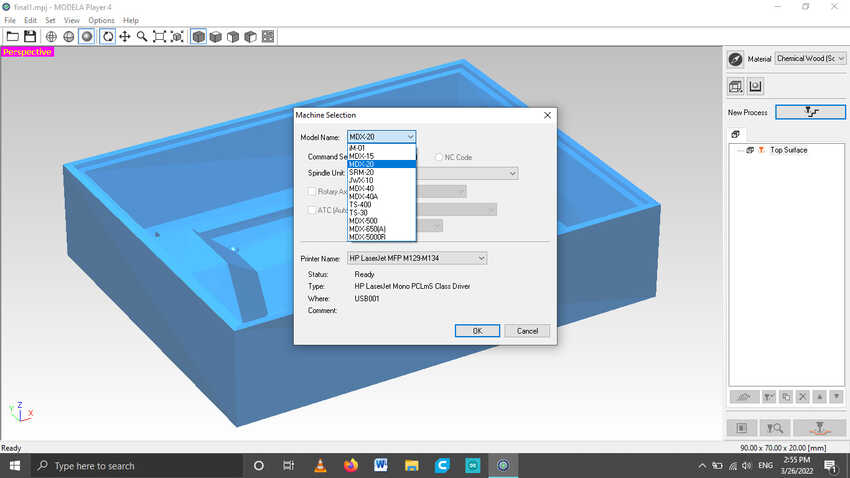

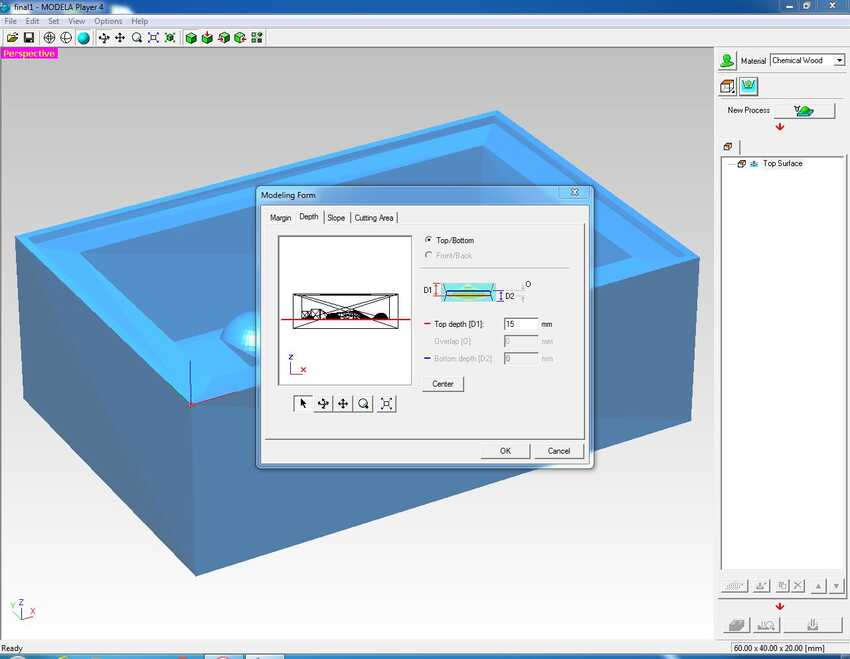

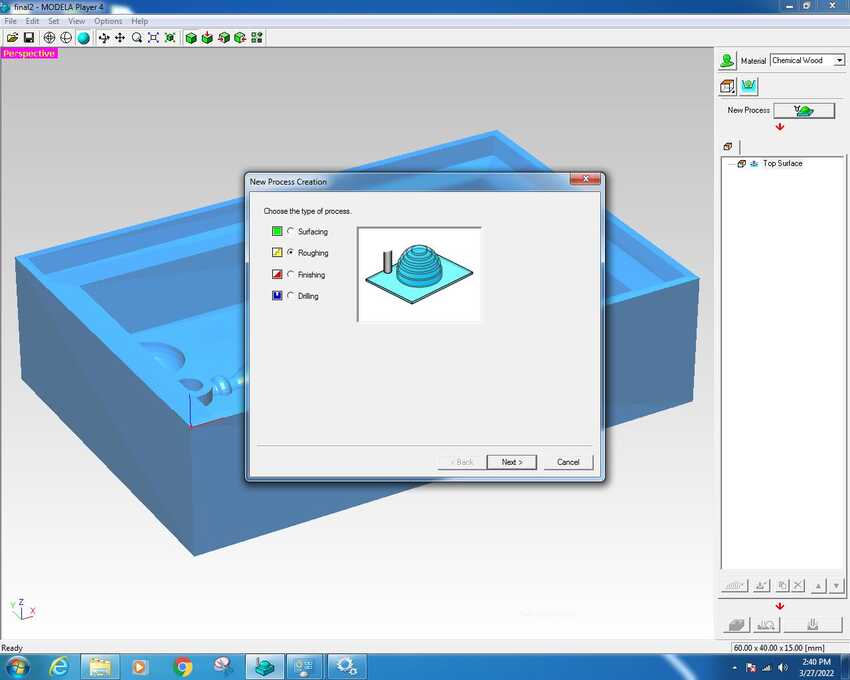

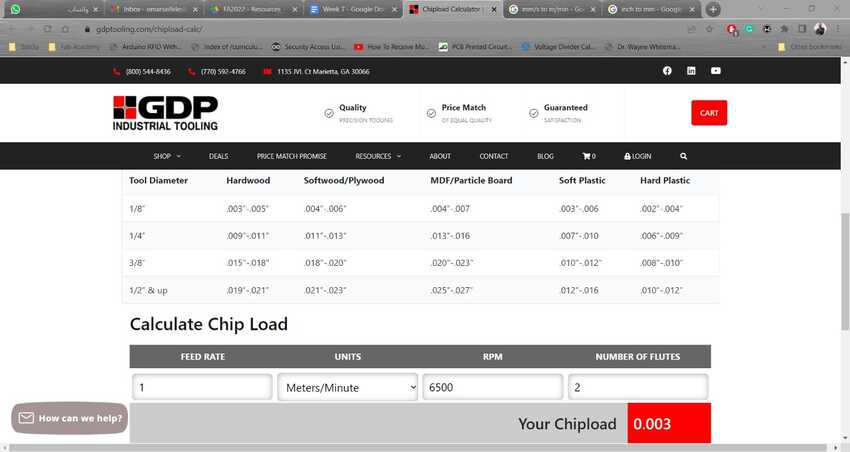

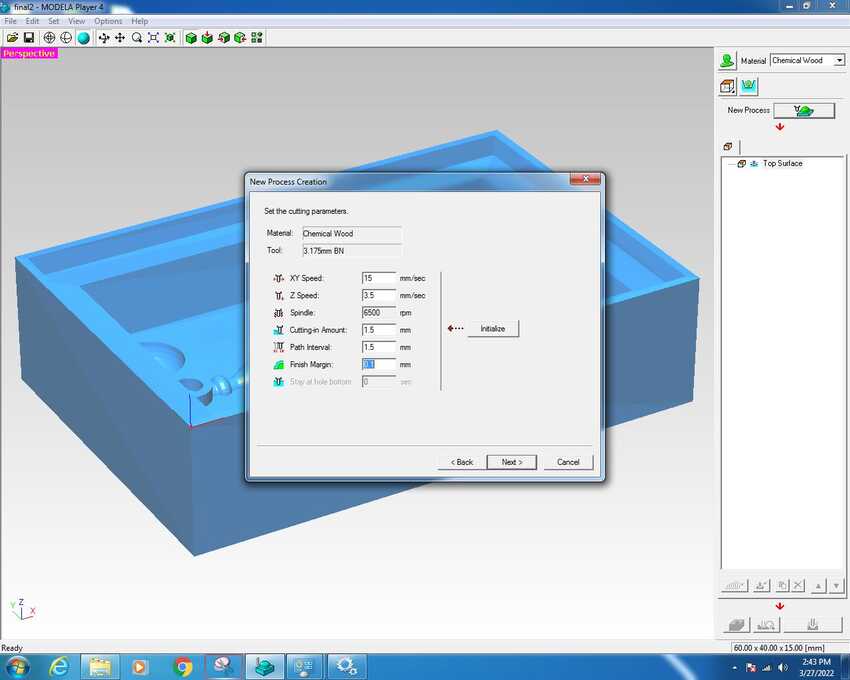

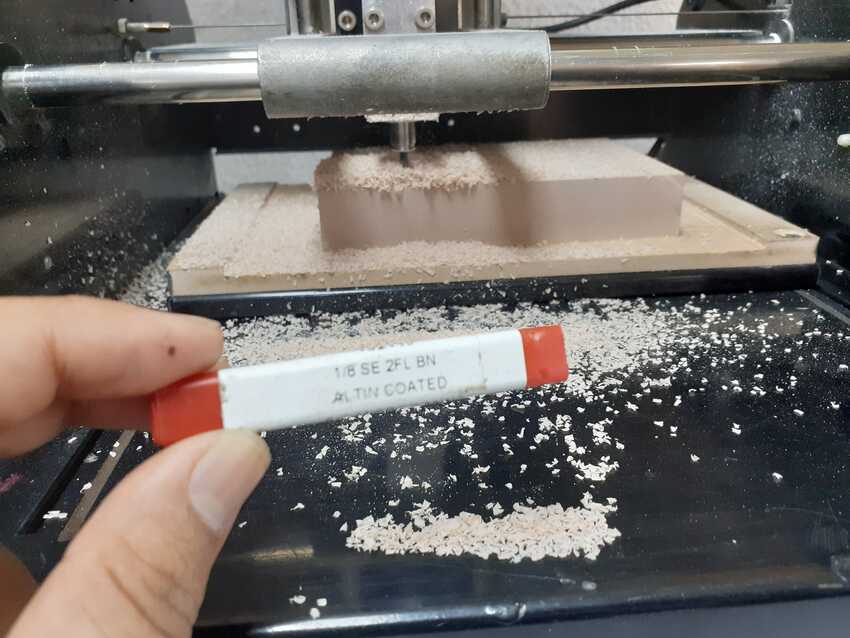

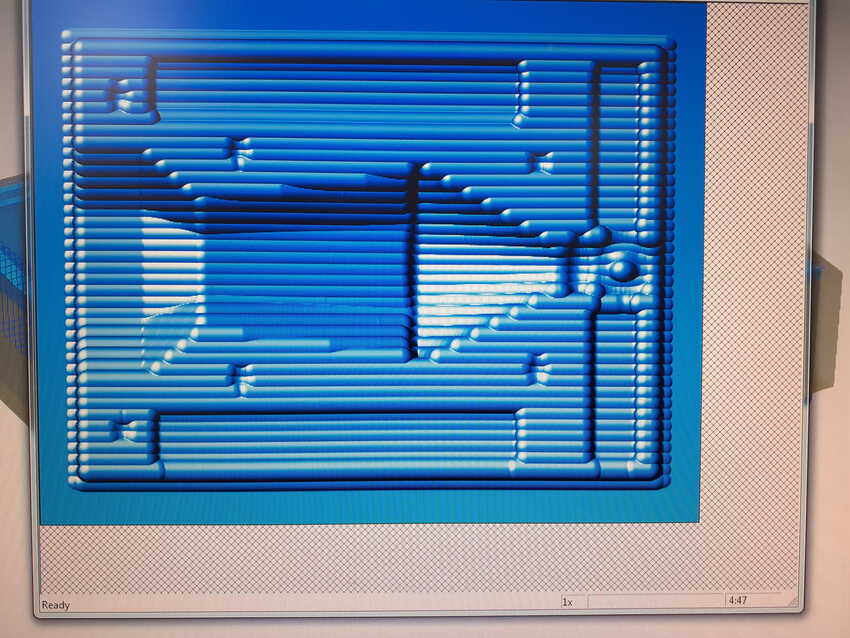

Before designing: mold stock measurements plus tool diameter - check cut depth to avoid colliding the tool or its holder to the part

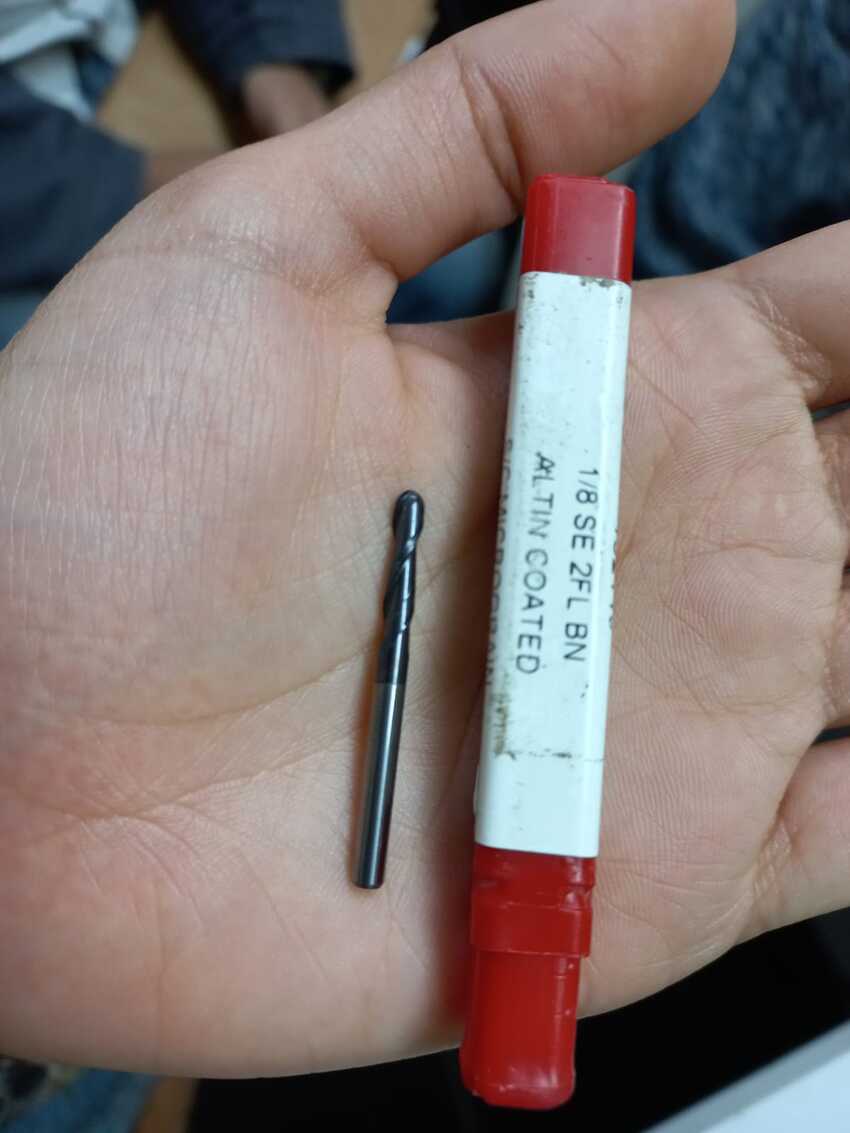

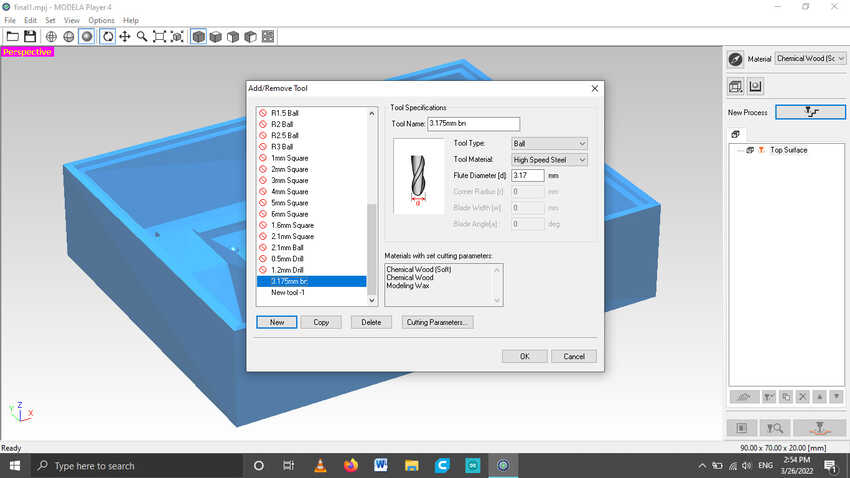

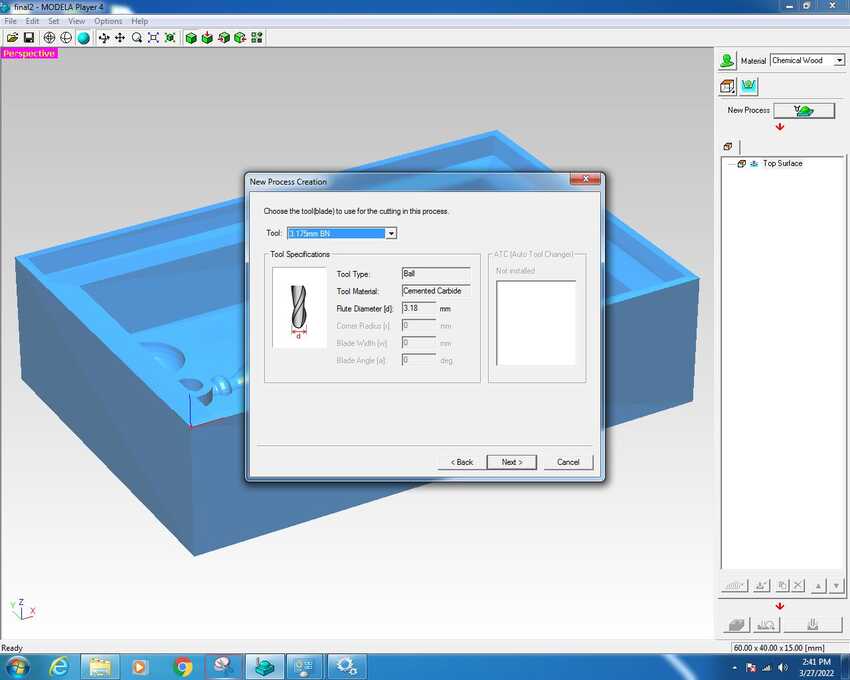

Also: Smaller diameter bits have shorter cutting depths. (for a finer cut)

Larger diameter bits (1/8") - standard size used in the fab modules - has a longer shank and can reach deeper into the wax. (for a rougher cut)

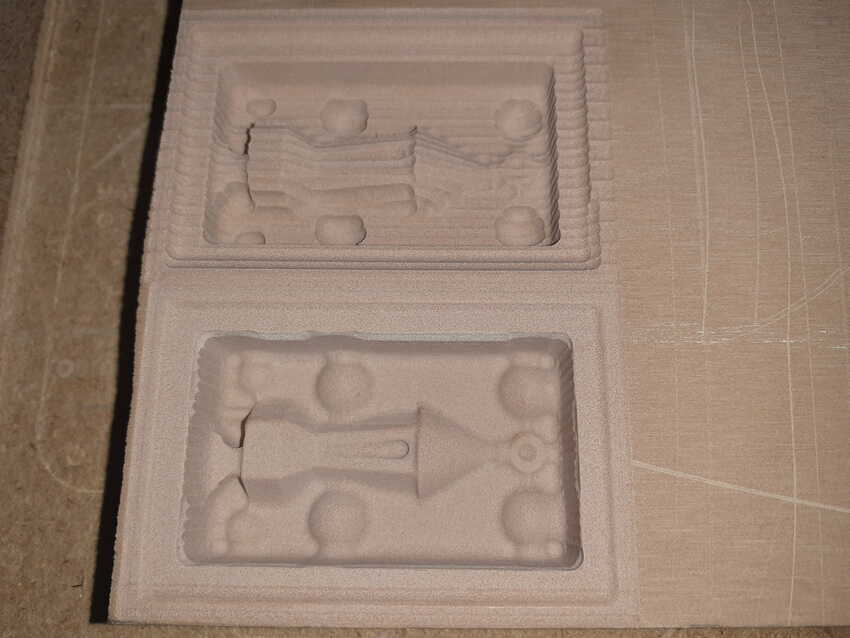

For curvy models - use ball nose bits

For mostly flat parts / straight angles - use end mill bits

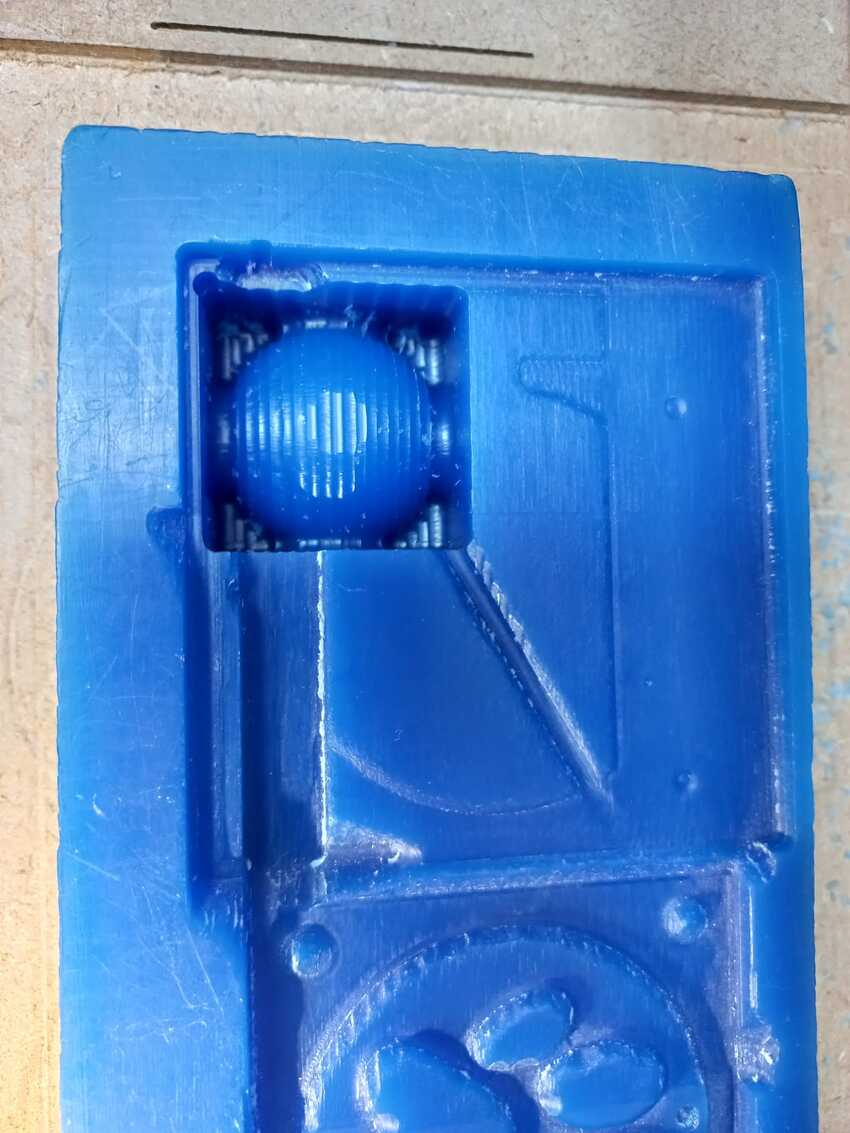

Golden rule: the cleaner the molding the cleaner the casting.

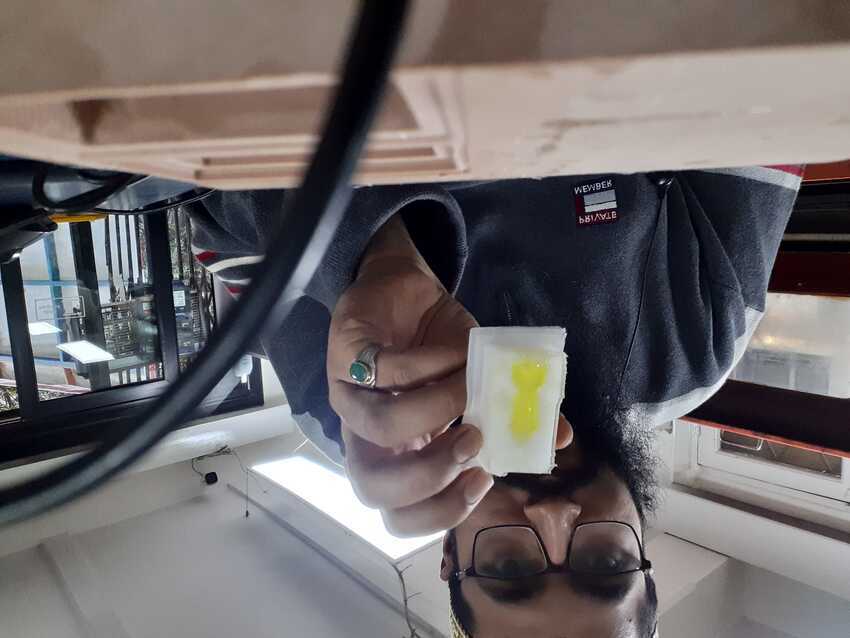

Practical tips: mixing technique while stirring scrape from bottom and sides.

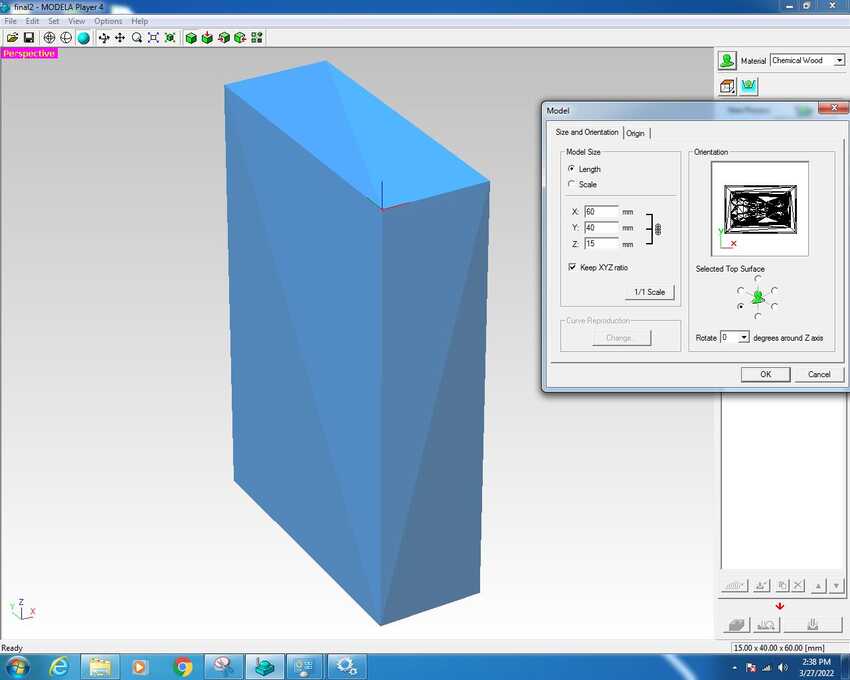

Designing the wall should be higher than the design

Make thick walls if using a two sided mold.

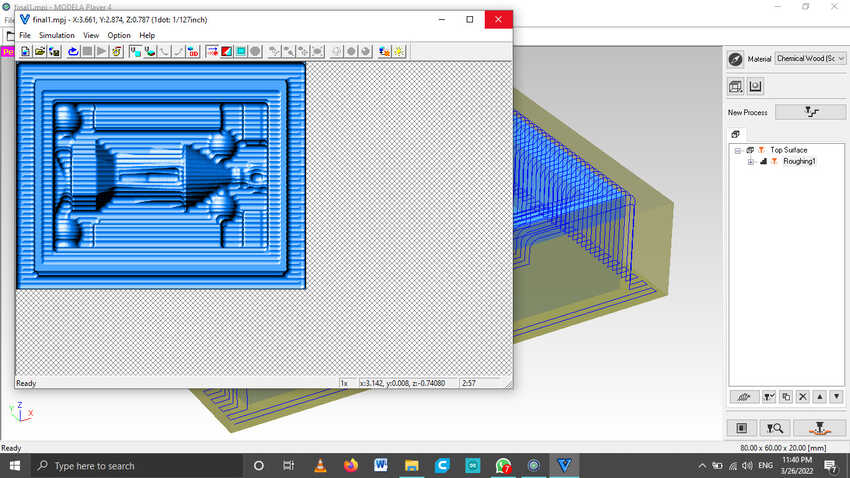

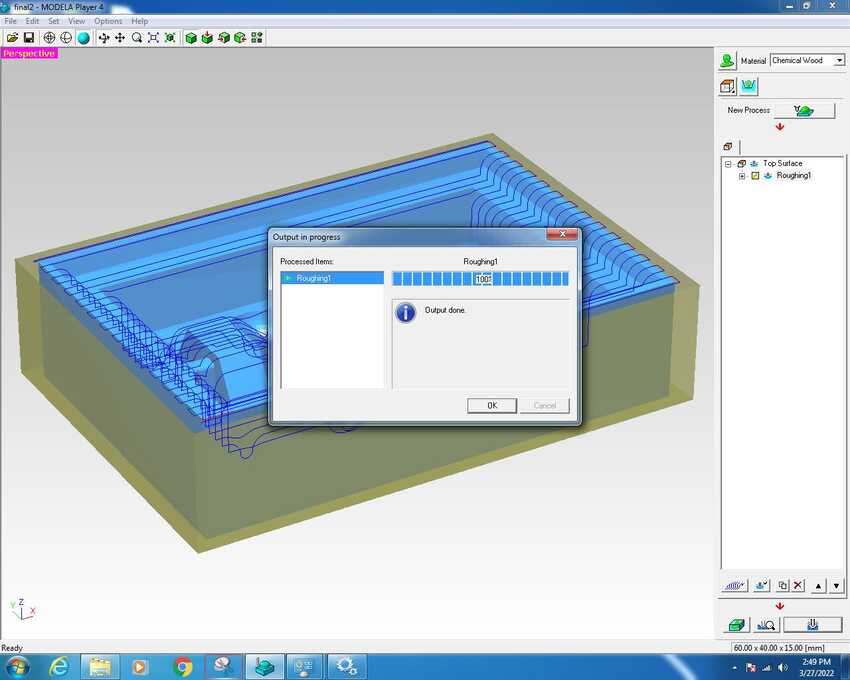

Don't forget that complex geometry will generate complex tool paths. Complex tool paths can take a very long time.

Be aware! It seems that bubbles form at right angles. Keep this in mind during design. Also, lots of 'local minimum' (aka lots of different dips and valleys) probably lend themselves to bubbles.

Machining: Zero out your Z axis to the top of the wax. Stop when a few shavings of wax come up. Starting at zero will begin milling your model at the very top of the wax, where you zeroed the Z axis.

Leave epoxy for 14 hr at least

While pouring from height, small amounts slowly , and steady.

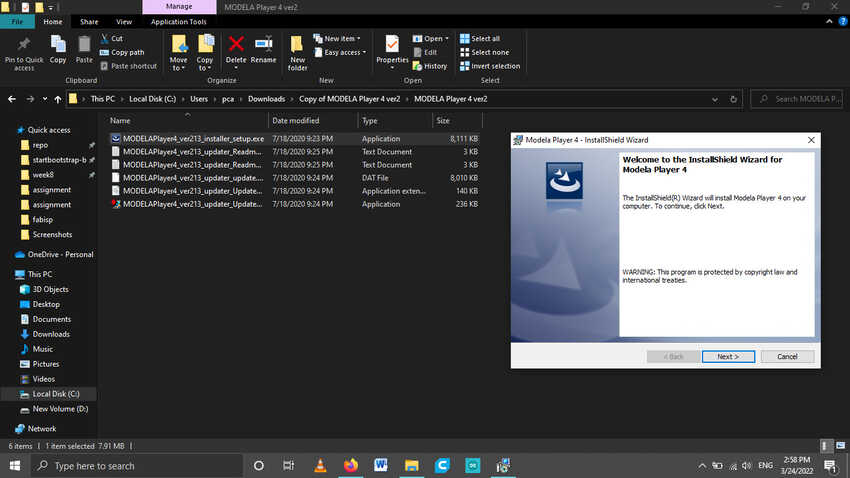

for workflow information click here .

Safety:

- Gloves to protect the hands

- The work area must be well ventilated.

- Protective gloves and safety glasses must be used

- If anything got spilled on hands, it must be washed very well

- If it reached the eyes, it must be immediately washed, and a doctor must be consulted

- It's a bad idea to smoke or eat while handling these materials

- The package should be stored in a temperature less than 35°C

- Plastic sheet on the working surface to protect the surface.