Weekly practice

Research

- Workflow.

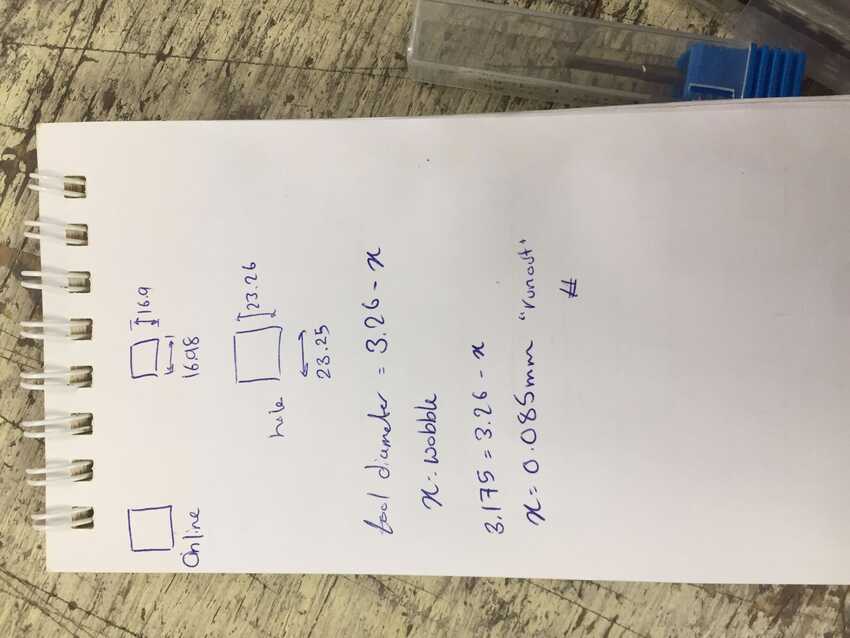

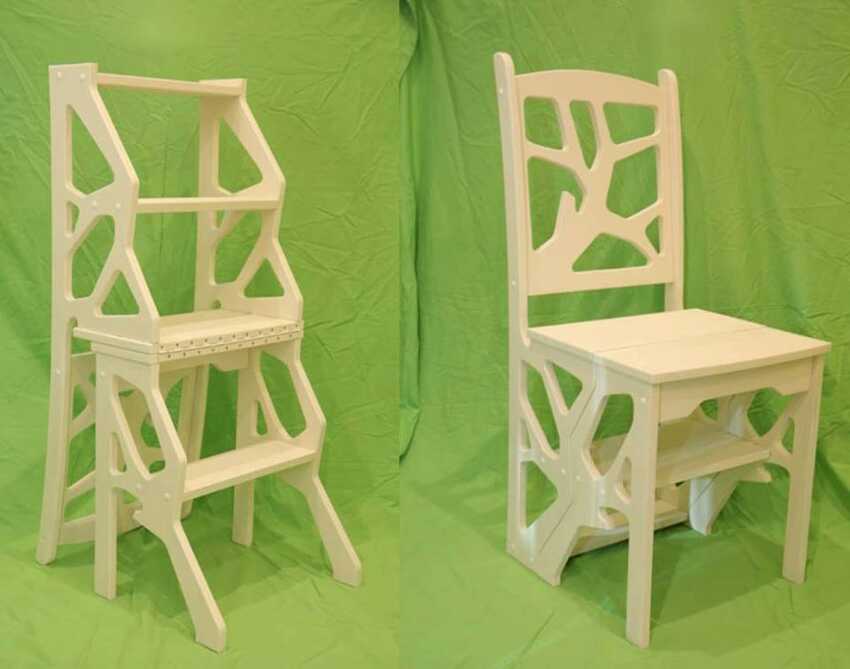

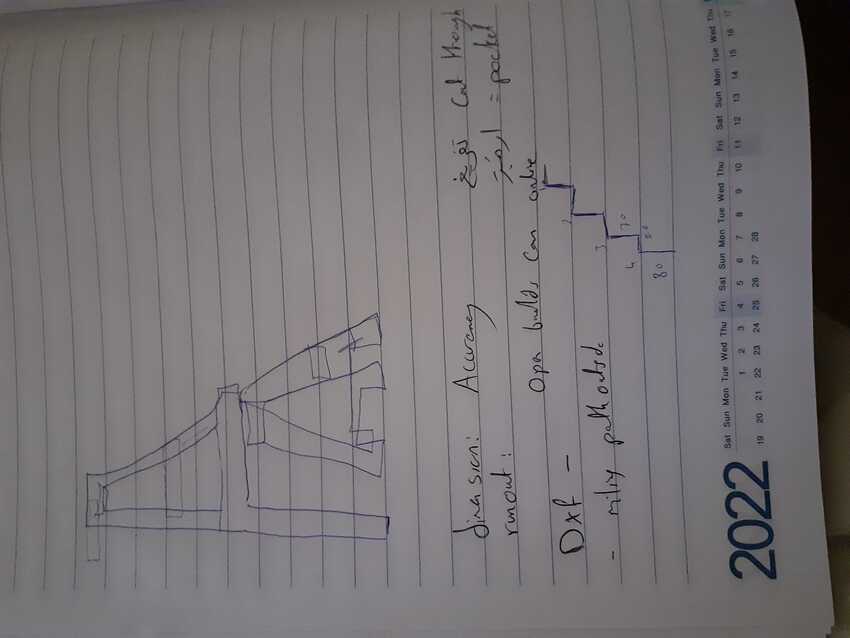

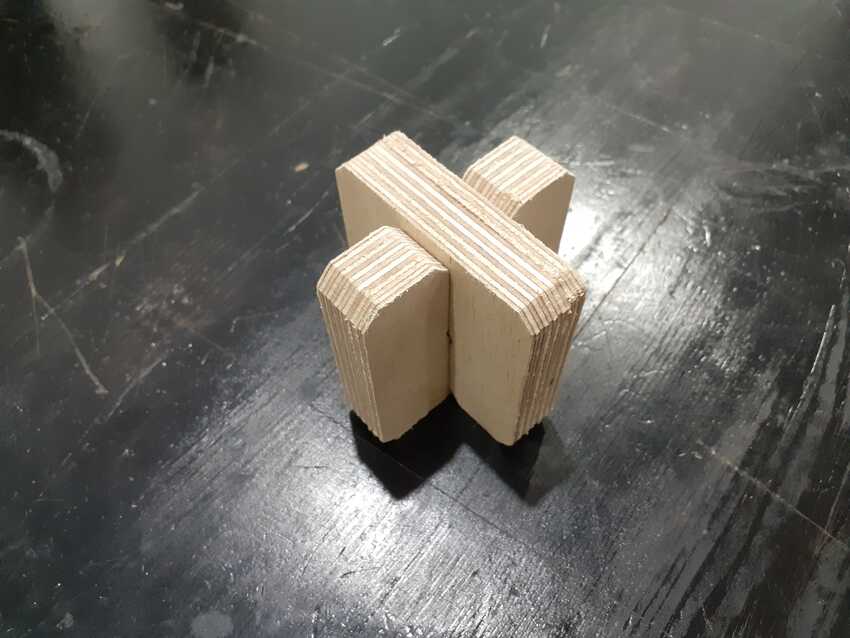

1) You should have an idea of what you want to make and it is recommended to make a solid draft using pencil and paper.

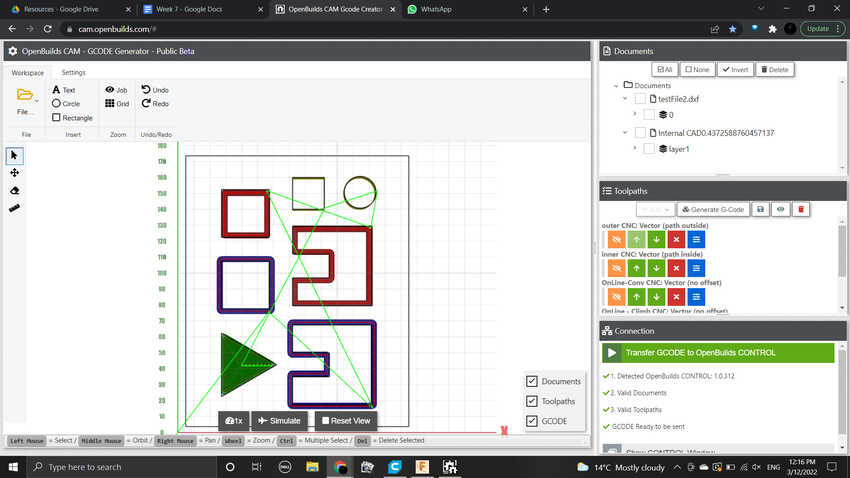

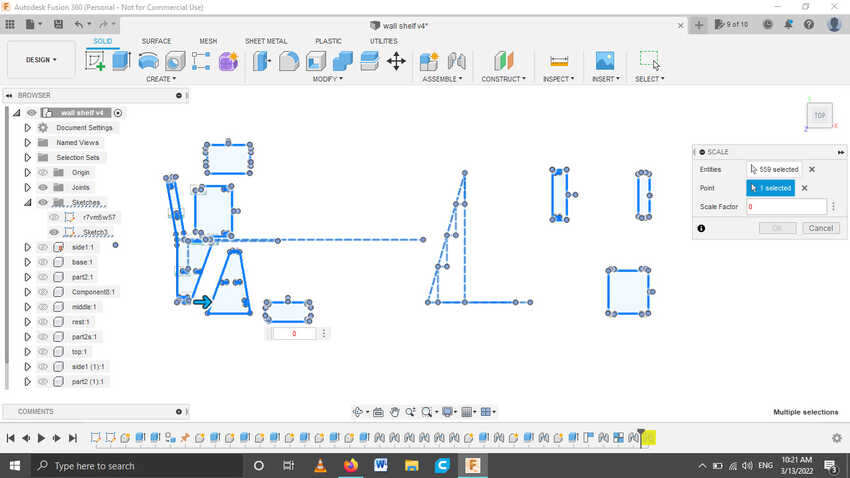

2) Either 2D or 3D dessign, you have to design on a cad software like Fusion 360, FreeCAD, SolidWorks, ...etc. and have the digital file in a supported format.

3) The most important Choose the suitable material for the design and the machining type.

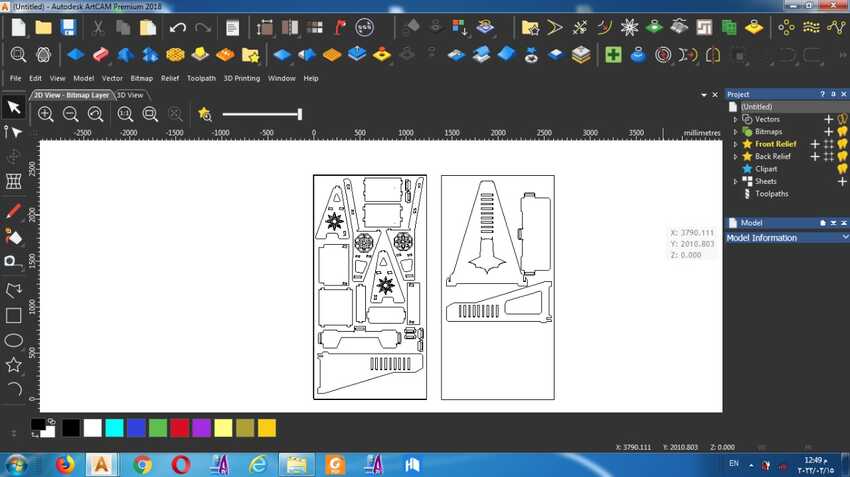

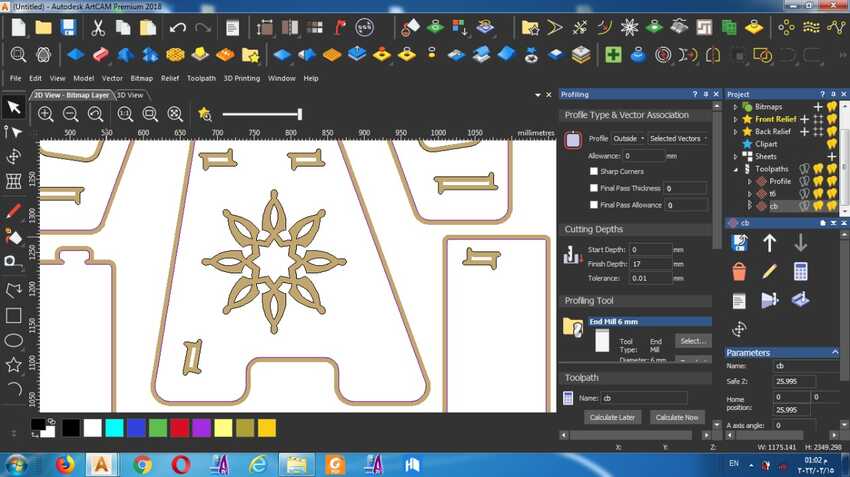

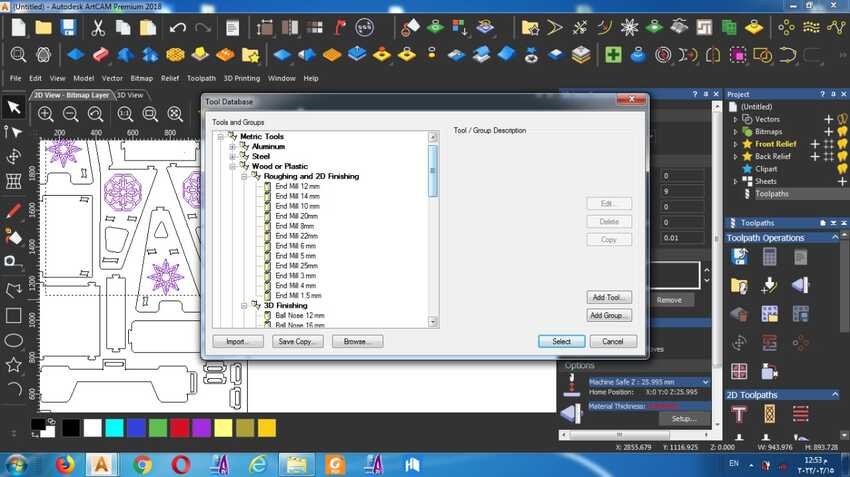

4) As for the CAM software also known as toolpath, here you select the appropriate cutting tool and set its cutting parameters, select the toolpath type either 2d or 3d, select the toolpath operation, setup the material and its orientation, simulate the program and export the supported code for the machine.

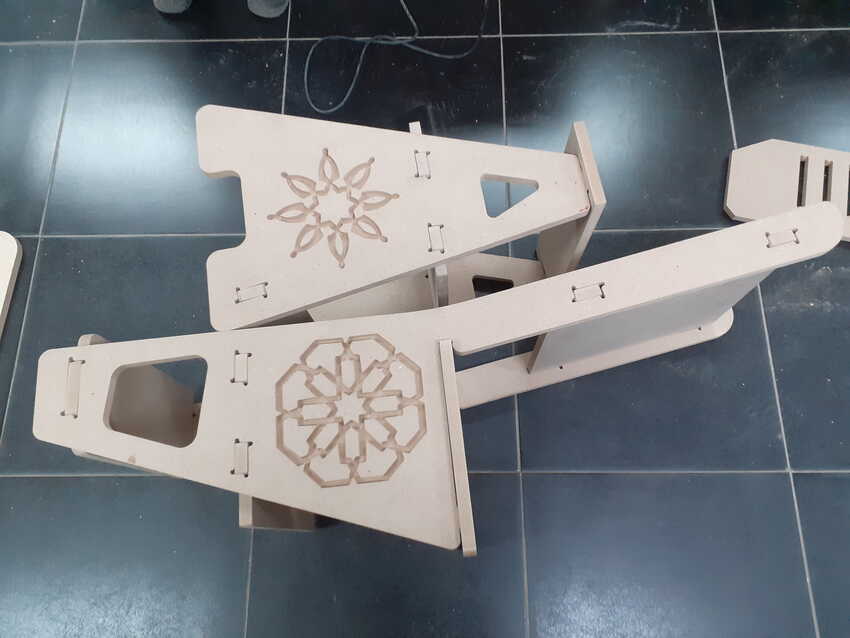

5) The easy part, Load the codes into the operating software, fasten the material on the machine bed, fix the tool in the spindle, set the origin points for the axes, dry run then actual run.

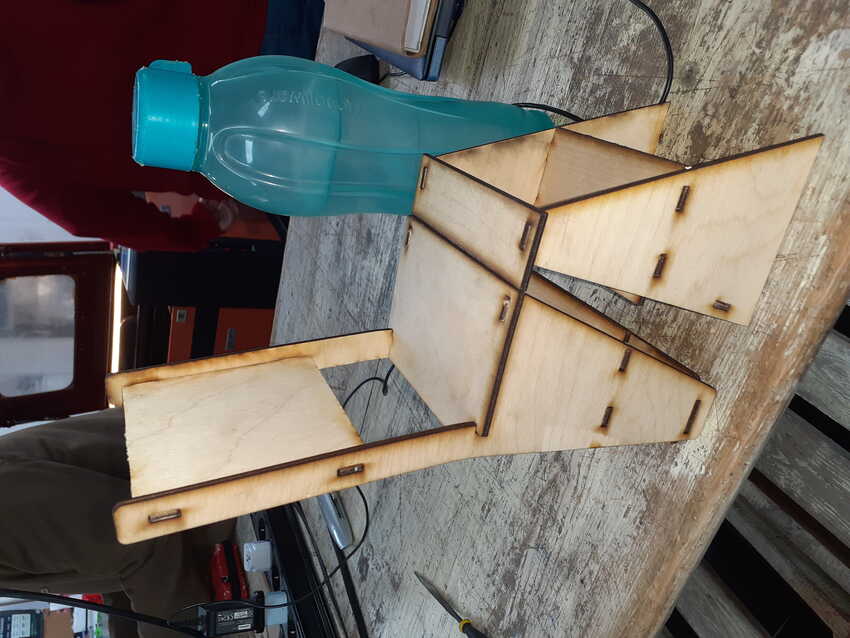

6) Post processing like sanding, painting, or any required post processing operations.

Need to know this week, this documentation really helped to understand the basics.

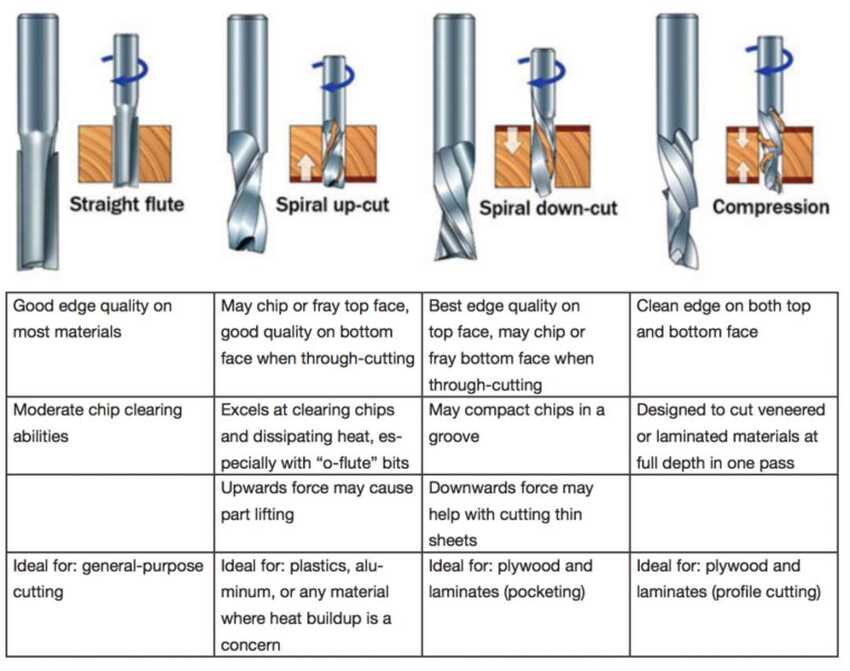

- Bits, Feeds, Speeds.

The challenge of getting a good CNC cut is in selecting the best tool for the job (Bit), the optimal cutting speed (feed rate) and router/spindle RPM (speed of rotation) for your material.

- Flutes.

The end tool or Bit closely resembles a drill: it consists of a round shaft with several blades (flutes) wrapped around it in a spiral fashion. The difference is these flutes have a sharp, exposed edge running along their entire length. This is because the bulk of their work is meant to be done by moving sideways,

- Chipload.

Chip load is the size of the chips produced during cutting. This is dependent on the Bit you are using and the cutting speed. The goal is to get the maximum chip load possible to increase productivity, reduce heat, and prevent the tool dulling.

When the chip are too small (or you are producing sawdust) the Bit can overheat and dull quicker. When chip load is too high, the tool can deflect creating a bad surface finish and, in extreme cases, even break the Bit. I used the Fablab Speed and Feeds Calculator to determine the chip load for plywood.

- Safety Tips with the CNC Router.

1) Never leave the room while the machine is routing.

2) Do not put any part of your body closer than 6 inches to the cutting tool when it is moving.

3) Always use eye and hearing protection When the machine is working.

4) If the bit is acting up or breaks, shut down the machine straight away.

5) Do not force material into the router.

6) Make sure that all workpieces are securely clamped down.

7) Always make sure you have inserted the correct bit for the job you are doing.

8) Do not operate a CNC router in a damp or moist environment.

9) Clean the machine and the floor around it after every use.

.jpg)

.jpg)