Group Assignment – Computer controlled cutting - Puebla

This week we have two assignments, one group and one individual.

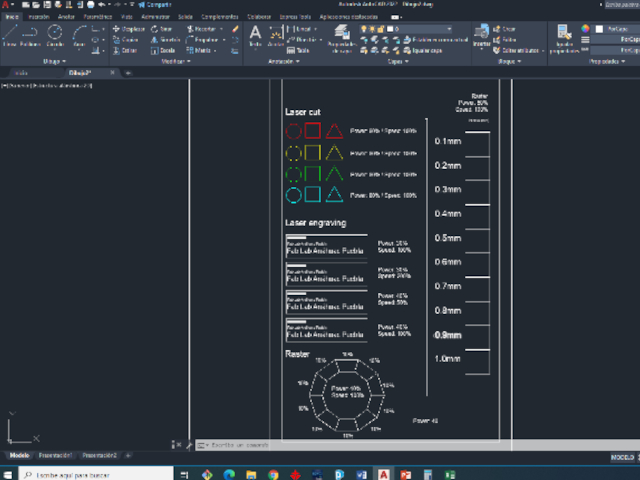

To start with the group assignment I will design my templates, I will include geometries to test the engraving, rasterizing and cutting, each process will have different parameters to discover the best of them.

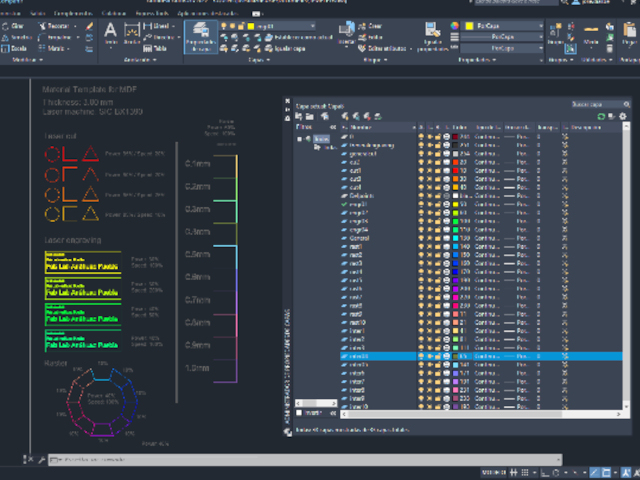

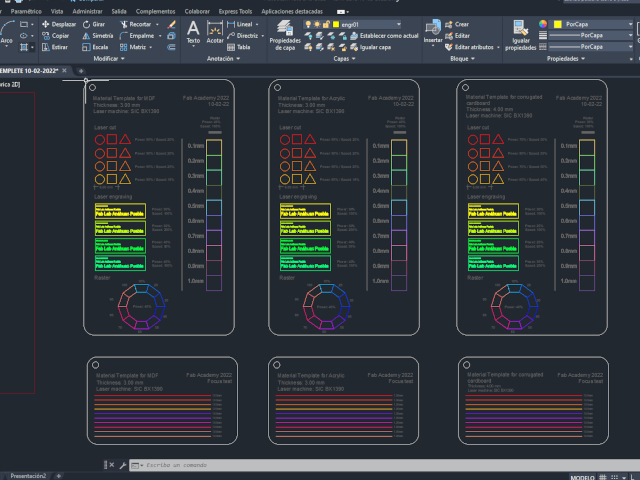

I use AutoCAD for the design of the template, the very useful layer properties management to assign the different processes.

I chose a template in metric system to work in millimeters, since the control software of the laser machine works with these units.

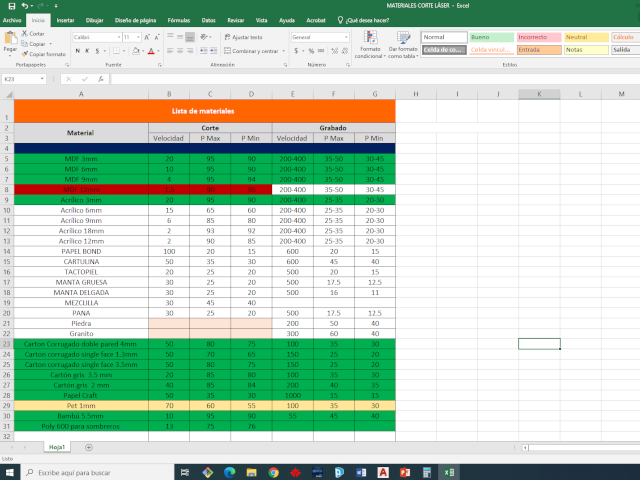

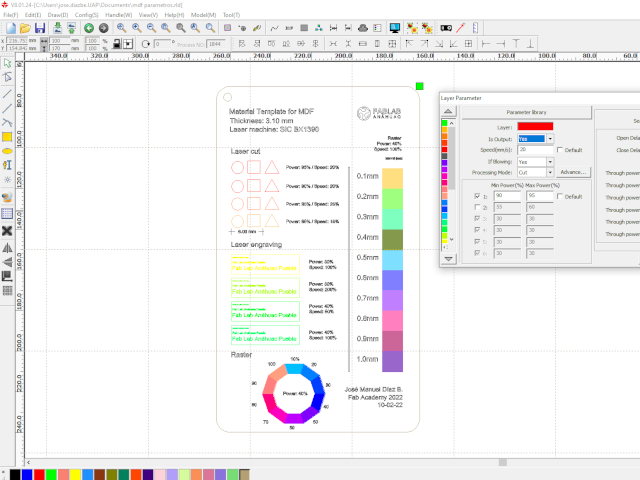

In the Fab Lab we have a database with values that have been generated according to the recommendations of the equipment supplier and the user experience.

I will use these parameters as a reference and make some variations to see if I can optimize them according to the results.

Template desing

Layer management.

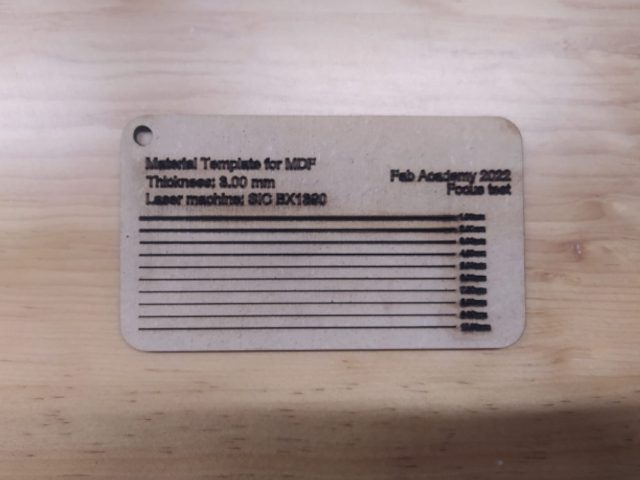

Finally, I made the template for the focus test, I hope to get interesting results, the supplier of the machine recommends a focus separation of 6mm from the material to the nozzle.

The NEXT STEP is to import the DXF template into the RD Works program.

Here I assigned each of the template values. A bit of a slow process but the result will be worth it.

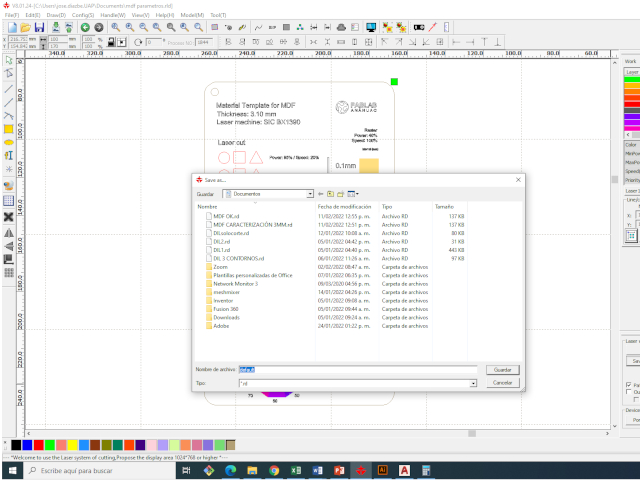

I exported the file by clicking Save to File, it's time to give it a name, save it on the USB and go to the laser cutter.

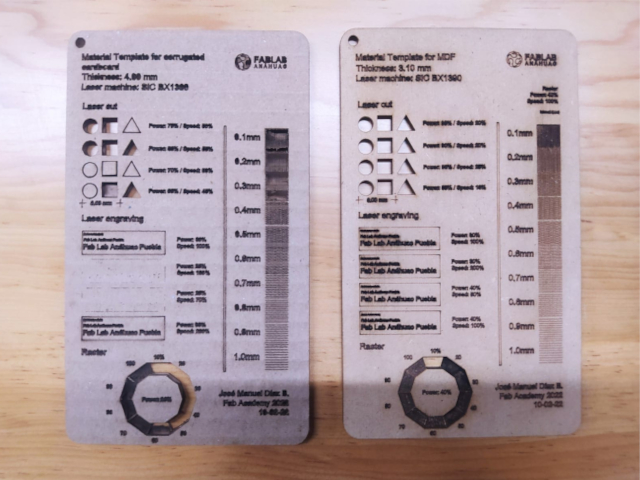

Below are the results of the experimentation with the laser machine

After the focus test, I came to the conclusion that the best distance is between 6mm and 8mm from the head.

The test of pressure assemblies that will serve for the individual assignment

The test of pressure assemblies that will serve for the individual assignment

The material has a loss of 0.175 millimeters per cutting side. In this case, having two cutting lines, the loss was 0.35 millimeters.

Results

The material has a loss of 0.175 millimeters per cutting side. In this case, having two cutting lines, the loss was 0.35 millimeters.

MDF

- Thickness. 3.00 mm

- Engraving. Power 40% Speed 100m/s

- Raster. Power 40% Speed 80m/s Interval 0.2-0.3mm

- Laser cut. Power 95% Speed 25m/s

- Kerf. 0.175mm

- Focus. 7.00mm

Corrugated cardboard

- Thickness. 4.00 mm

- Engraving. Power 35% Speed 200m/s

- Raster. Power 28% Speed 100m/s Interval 0.4-0.7mm

- Laser cut. Power 80% Speed 55m/s

- Kerf. 0.175mm

- Focus. 7.00mm