Group Assignment – 3D Scanning and Printing - Puebla

General objective (group assignment):

- Test the design rules for your 3D printer(s)

- Document your work and explain what are the limits of your printer(s) (in a group or individually)

- Document your work to the group work page and reflect on your individual page what you learned

uPrint SE Plus

Technical characteristics:

- Work area: 203x203x152 mm

- Type of technology: FDM

- Max and min resolution: 250 - 330 microns

- Power, if any necessary: 100–127 VAC 50/60 Hz

- Model: uPrint SE Plus

- Mark: Stratasys

- Software: GrabCAD Print

DP 200 Sindoh

Technical characteristics:

- Work area. 210 × 200 × 195 mm

- Type of technology. FDM

- Max and min resolution. 50 – 400 microns

- Power: 110-220V 50-60Hz AC

- Model. DP 200 3DWOX

- Software: 3DWOX DESKTOP x64

- Mark. Sindoh

Development

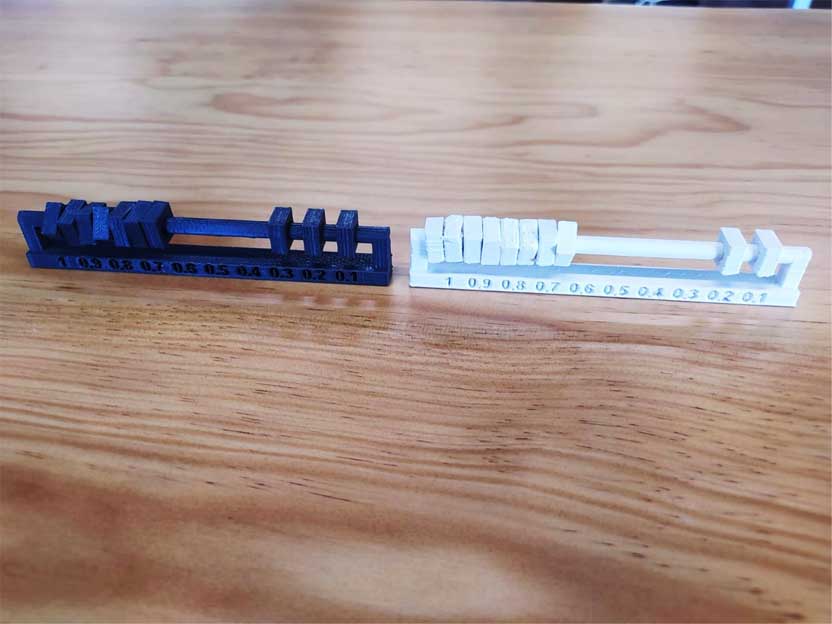

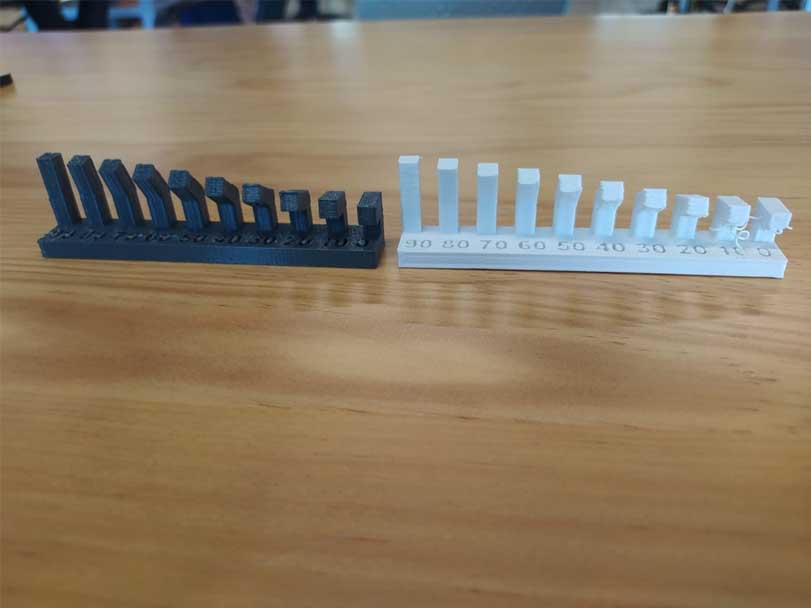

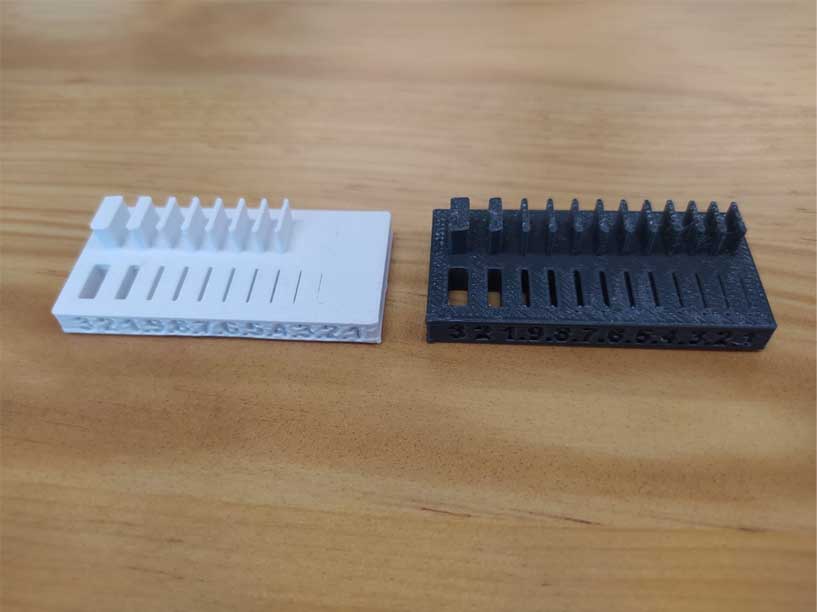

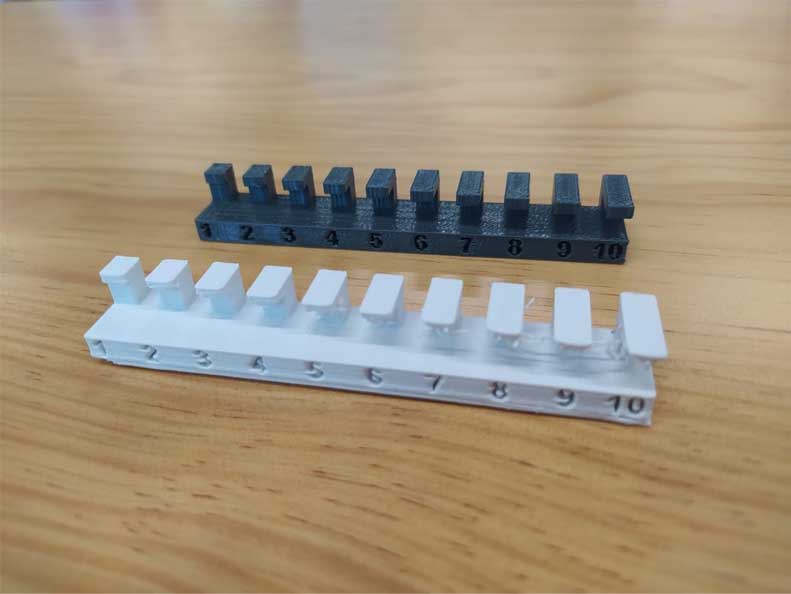

1. The first thing I did this week was to print the models that Neil shared with us, to experiment with the printing rules, I did these tests with the two printers available at the Fab Lab Anáhuac Puebla. (uPrint SE Plus and DP 200 Sindoh)

2. You can find the models here academy.cba.mit.edu/classes/scanning_printing/index.html

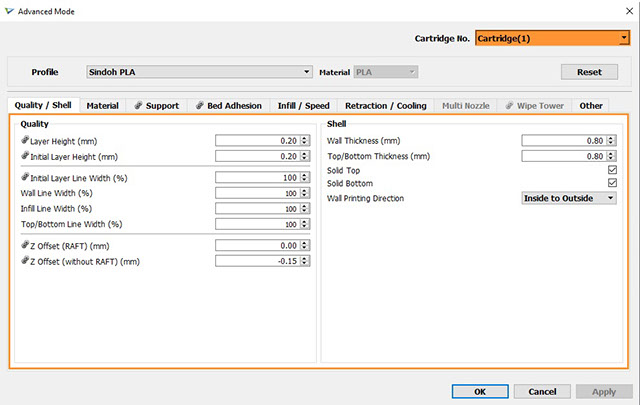

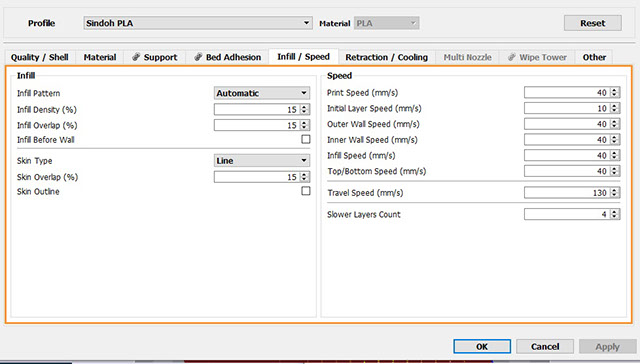

3. For the DP200 use the standard quality print parameters, this is a balance between quality and time optimization:

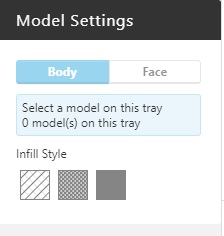

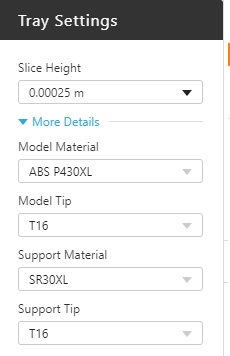

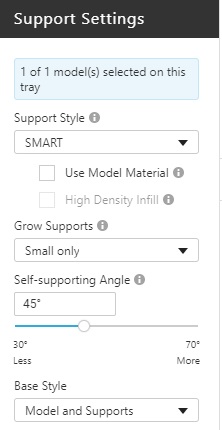

For uprint SE use parameters that also give us a balanced result between quality and printing time:

4. The clearance varies between the two tests, in the Uprint from 0.3mm the material expands and prevents the movement of the pieces. In the 3DWOX this same effect is presented from 0.2mm

5. The Angle test shows something very interesting, the 3DWOX is capable of making parts with angles of 10 and 20 degrees, but the quality of the surface is a bit low. The UPRINT made support by Default from 30°

6. The wall thickness test showed us what we already suspected, the Uprint can build GAPS and walls up to .1mm although it modifies the final dimensions a bit, the 3DWOX surprised us because it can manufacture up to .5mm

7. The surface test gave us very similar results in both devices, but in the hemisphere the 3DWOX seems to have a little more quality, although the color of the material also modifies the perception of the finish.

Results

Parameters optimized of machine.

- 3D WOX DP 200

- Layer Height (mm) 0.15

- Wall Thickness (mm) 0.80

- Infill Density (%) 15

- Print Speed (mm/s) 30

Uprint SE PLUS

- Slice Height: 0.00025

- Wall Thickness (mm) 0.60

- Infill Style: Mod A

- Support Style: SMART

- Grow Supports: Smart only