Group Assignment – Computer-Controlled Machining - CDMX

General objective (group assignment):

- Complete your lab’s safety training

- Test runout, alignment, speeds, feeds, and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

Machine used

AXYZ CNC ROUTER

Technical characteristics

- Work area. 1220x2440mm

- Power: 220V, 5Hp

- Mark. AXYZ

- Model: 4008

Development

We read and apply the safety rules to considering when in the lab and when using the machines, we fabricate and test the CNC router with 3 different materials

Parameters optimized of machine.

For Aluminum:

- Tool ¼” straight 1 flute

- Passes: 6 passes , 1.2mm per pass

- Rpm 10000rpm

- Speed 10mm/seg

For OSB15mm:

- Tool ¼” straight 1 flute

- Passes: 3 , 3.8mm per pass and 3mm for the last pas

- RPM: 11000rpm

- Speed: 58mm/seg

For Plywood 18mm

- Tool ¼” straight 1 flute

- Passes: 5 . 3.8mm per pass and 3mm for the last pas

- RPM: 11000rpm

- Speed: 58mm/seg

Model of the CNC router we used

.jpg?crc=3792789442)

The CNC router milling the aluminum pieces

One of the finished pieces of aluminum

-crop-u14589.jpg?crc=10006293)

Cutting the OSB board

.jpg?crc=296222467)

Sample of the top cover and pieces of the drawer

A detail of the assemble of the legs support

-crop-u14619.jpg?crc=4090288526)

Cutting some different joints to test the runnout

-crop-u14629.jpg?crc=3832185983)

-crop-u14906.jpg?crc=4162106160)

-crop-u14639.jpg?crc=179132864)

The runout of the tool is 0.16

-crop-u14930.jpg?crc=108979412)

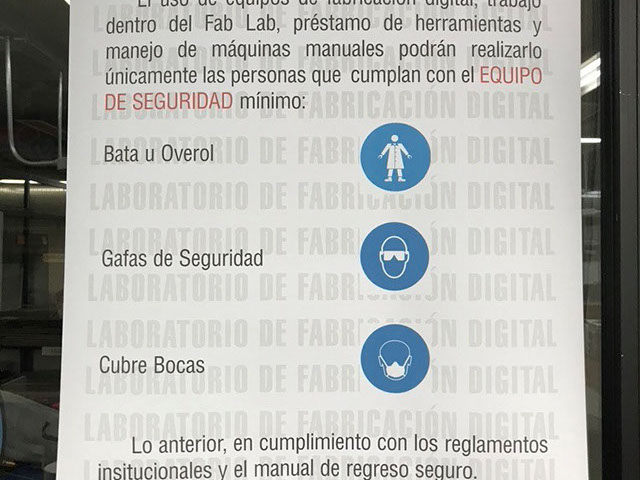

Safety Rules for our Lab.

Wear Overol, gogles and face mask as basic equipment , also, each machine has it´s own safety rules and protection guidance.

More details in this link: