3D Scanning and Printing

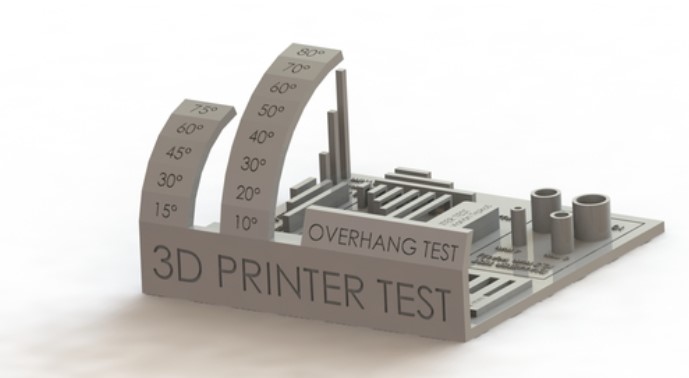

Test the design rules for your 3D printer(s).

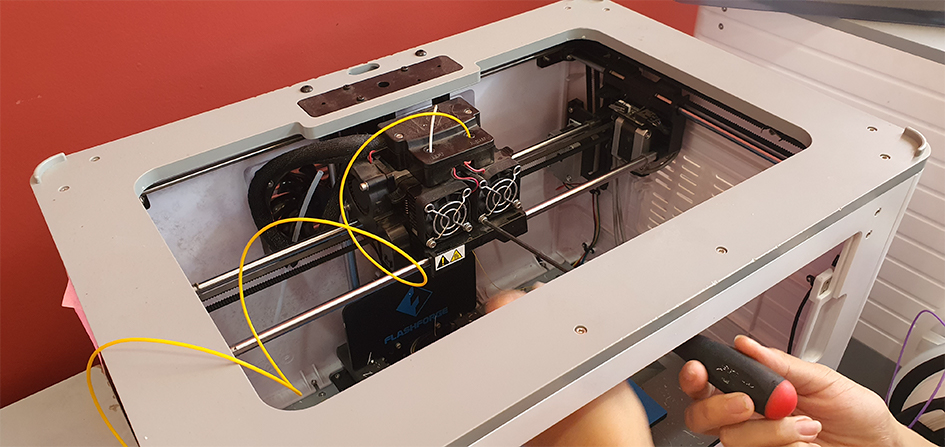

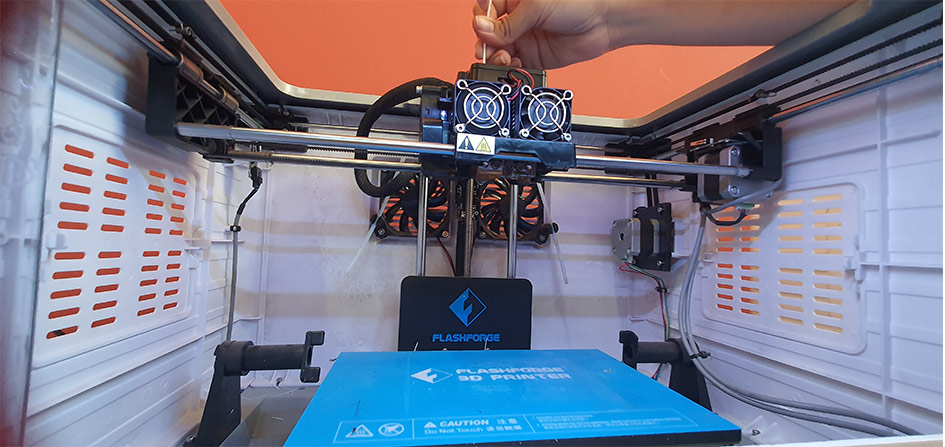

3D printer: Flashforge Dreamer

Specifications:

Testing 3D printing rules

- Download a 3d printing test from thingiverse: All In One 3D printer test

- Open the stl file with flashprint

- We used this parameters:

- Extruder: left

- Material: PVA (Equals to PLA+)

- Layer height: 0.18

- Minimum speed: 60mm/s

- Extruder temperature: 210°C

- Platform temp.: 50°C

- Infill: 25%

- Raft: No

- Supports: No

- Save file as gx in a SD card

- Leveling Z: We used a paper to define the right offset for the extruder point. Placed a paper over the platform, press the “level” button on the dreamer screen. when the extruders move, test the friction between the extruder point and the paper, It should be tight but allow paper’s movement. Do this 3 times in each part of the platform.

- Plug the SD in

- Press print and wait

Learning from our experience:

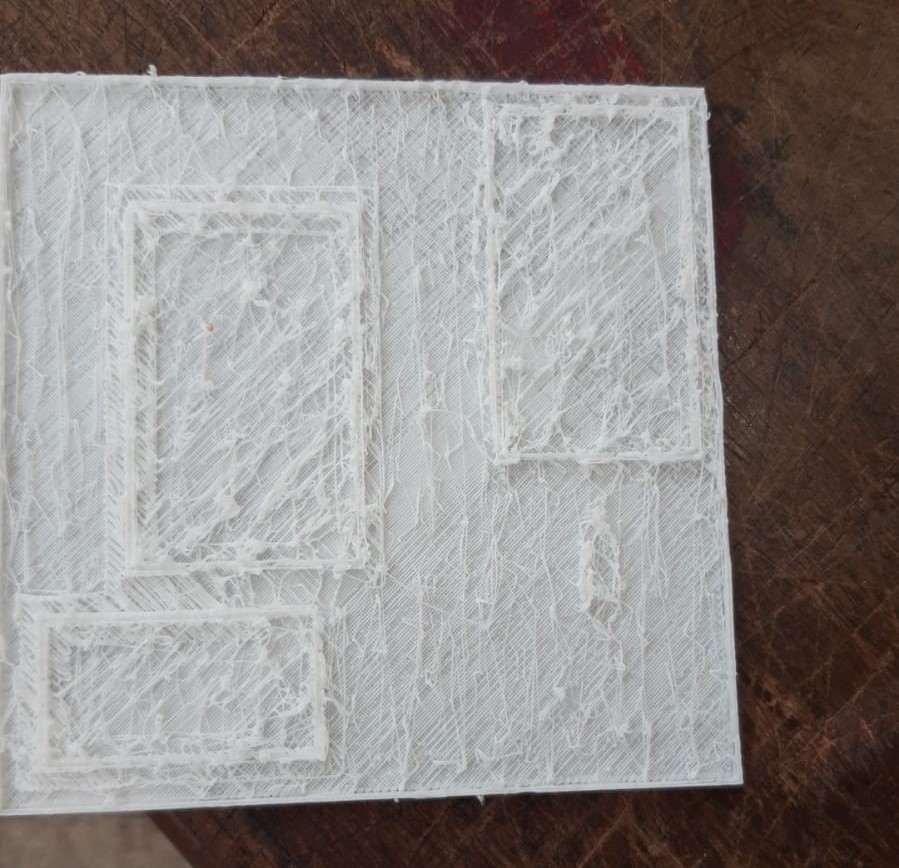

Few minutes after start printing this happened:

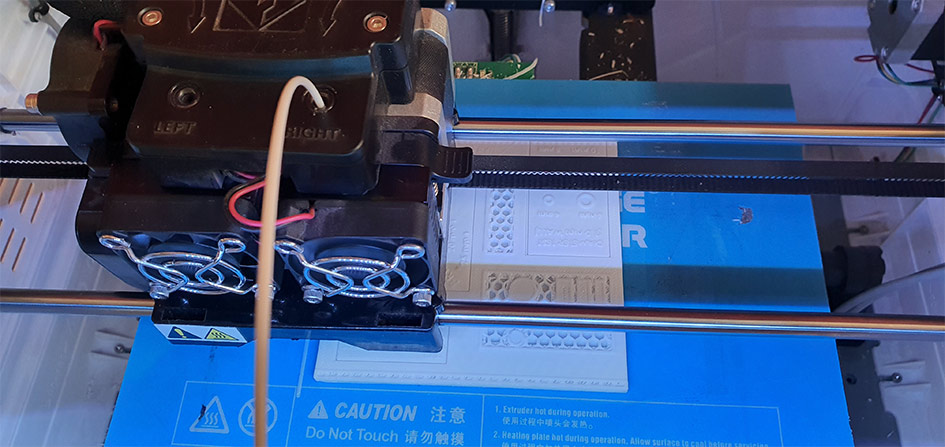

This happened because our extruder was blocked. So we learned how to clean the extruders. We tried again and changed the extruder to the right one and it worked:

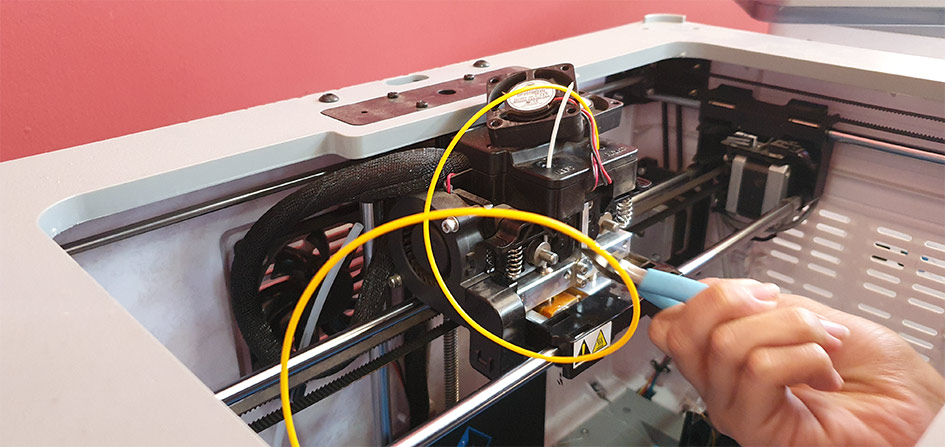

- Open the extruder’s box:

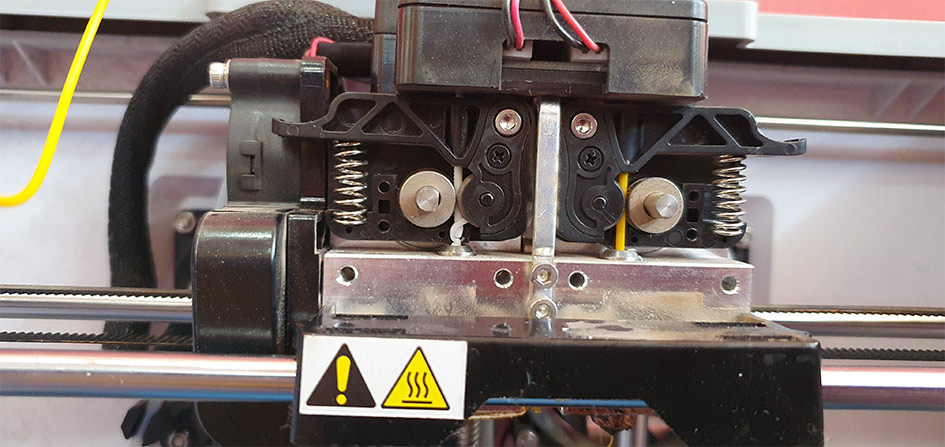

- This is how a blocked extruder looks like:

- Unblocking the extruder:

- Loading filament:

- Working again:

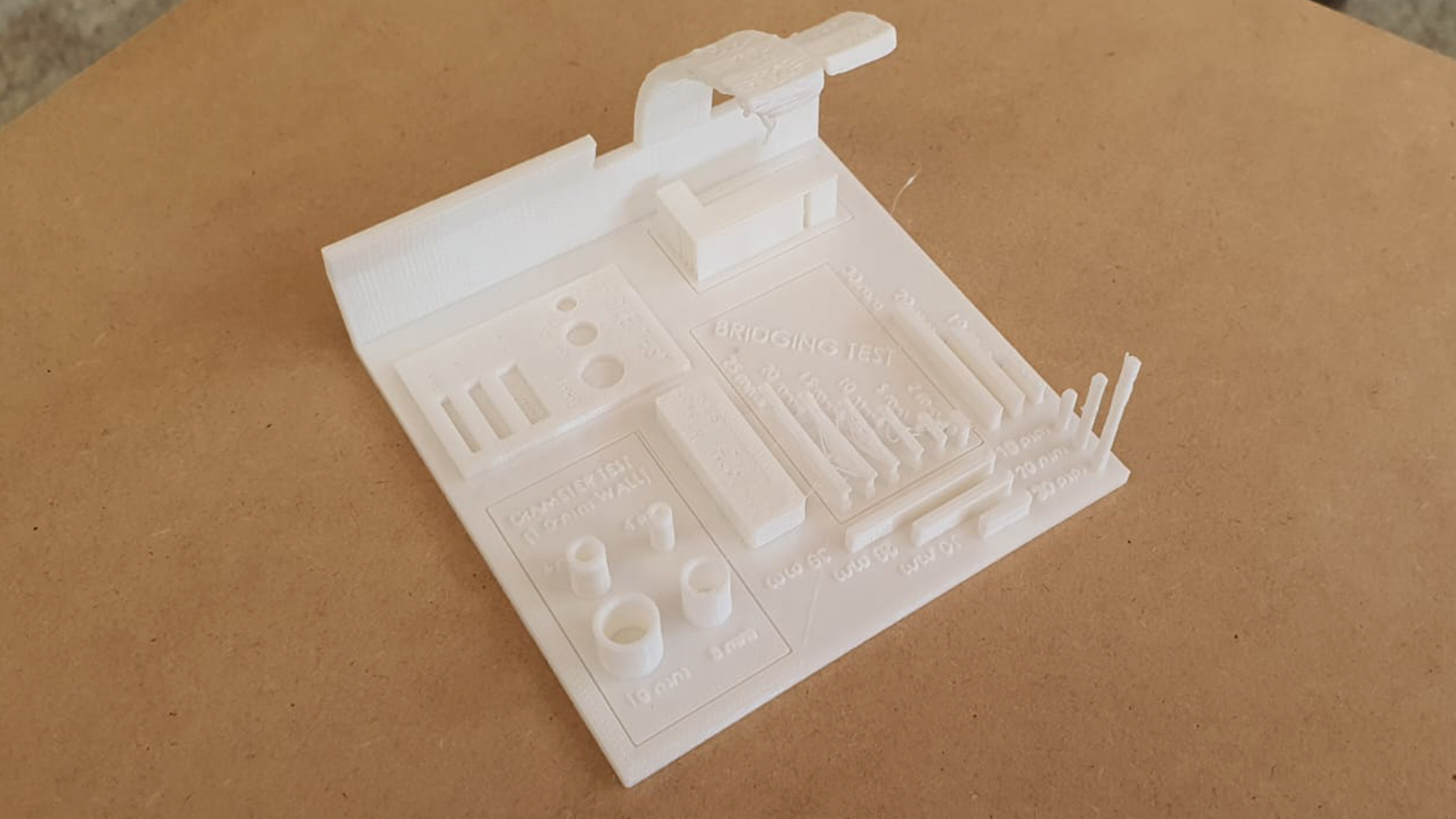

Results

- Overhang test: Works well until 50%

- Bridge test: work well until 10mm

- Hole test: 100% test worked well

- Diam test: 100% worked well

- Column test: 100% worked well

- Support test: 100% worked well