Week5- 3D scanning and printing

Introduction

Currently I am attending both fab-academy and fabzero. Since Bhutan is under lockdown, I had to work in containment zone along with Fran, Sibu and the SFL team in superFablab to set up the lab. So luckily for me, I had access to all the machines (Lots and lots of machines).

In this week, we are first testing the design rules for 3D printer where we will work in groups and then we have to design and print an object (using a 3D printer) that could not be done subtractively, that is from laser cuter or milling machine. This task allows us to use and work with 3D printer that is a machine most oftenly used in the fablab. The second part of the assignment is to scan a 3D object and if possible print it.

Group assignment

Group members:

- Zina choden yonten

- Kencho Wangdi

- Anith Ghalley

- Sangay penjor

- Sonam Paldon Dorji (myself)

Different 3D printing processes have different capabilities and different design restrictions.Anything can be "drawn" in 3D on a digital canvas, but not everything can be 3D printed as in the digital design environment, there are no laws of physics to adhere to, such as gravity.

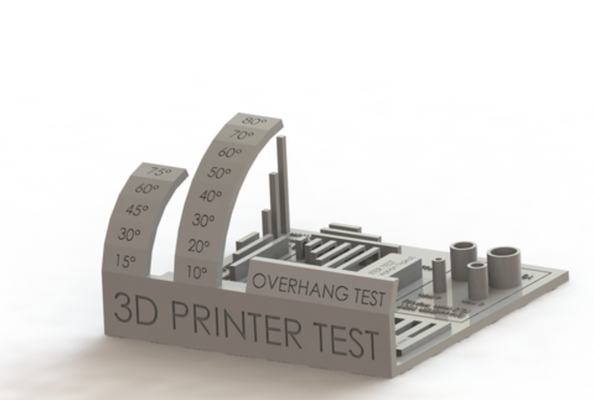

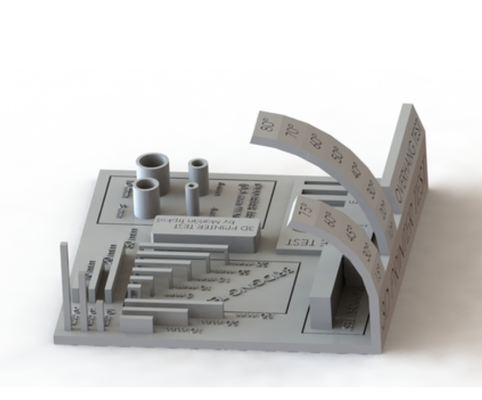

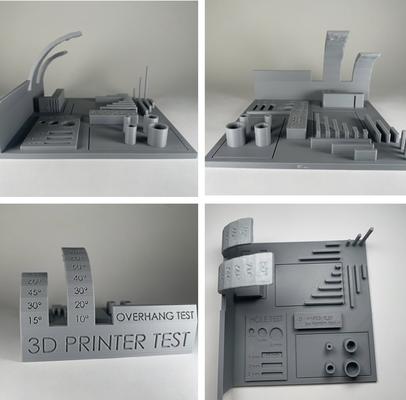

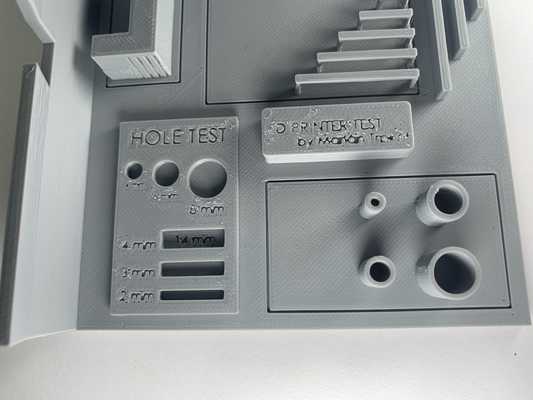

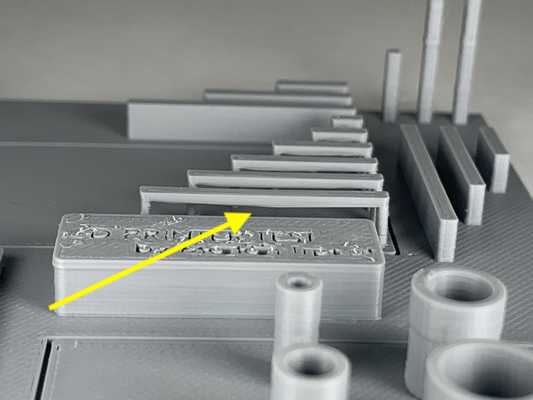

For the group assignment, we had to test the design rules for your 3D printers. So we chose a design where there are overhangs at different angles, bridging test, hole test, etc

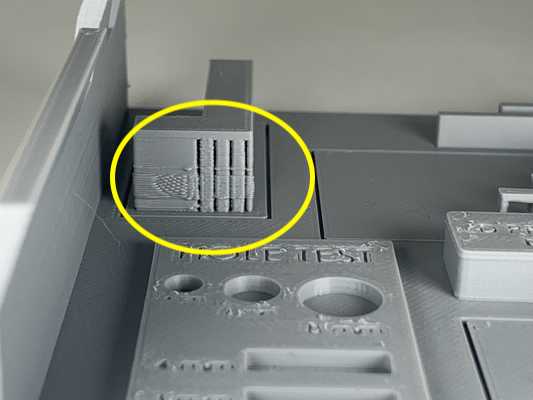

The result:

Comments:

-

The overhangs after 60 degrees has strings of filament hanging

-

The finer details were not printed well

-

The bridges were hanging

- Even when we used 0.15mm layering height, the layering were not so good.