Project Idea Conception

One of the task given to us for the first week of the Fab Academy was to select an idea for our final project and to make a basic sketch of the project Initailly when we discussed the ideas for our final project, I had couple of ideas that I wanted to work on. However, I finalized to work on the idea to build an electric kiln

Why this Project idea?

There were many reasons for choosing this idea as my final project but my personal interest in pottery was the main factor in pushing me to select this idea. Some of the reasons that pushed me to select this ideas are;

First Project Sketch

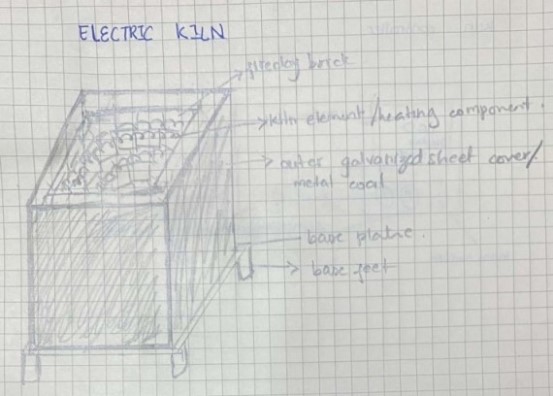

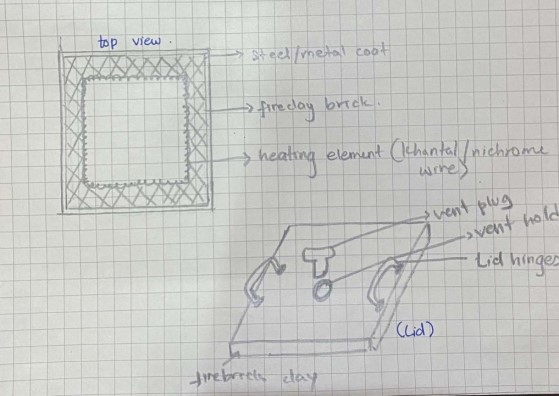

The idea for my final project is to build an electric kiln that is safe, portable, functional and semi-automated. The idea is to include temperature sensors to regulate the temperature inside the kiln and a timer to automatically turn the kiln off as per the set timer

Outer body Components;

The project has multiple components most of which is to be fabricated during the fab academy session

Kiln Controller

Components of a kiln controller

The kiln controller is the main commanding component of the electric kiln. The controller includes components such as timer, display screen, temperature regulator and exhaust/vent regulator

While searching for kiln controller connections, I found this picture on the left. I plam to make my kiln controller in a similar manner with an additional timer and vent regulator options. The components to be used for a the kiln controller are as follows;

CAD Design2D design

The 2D design of my final project was made using the Inkscape software. The design can be seen below;

The deatioals on how to make the design can be found in my week2 assignment page.

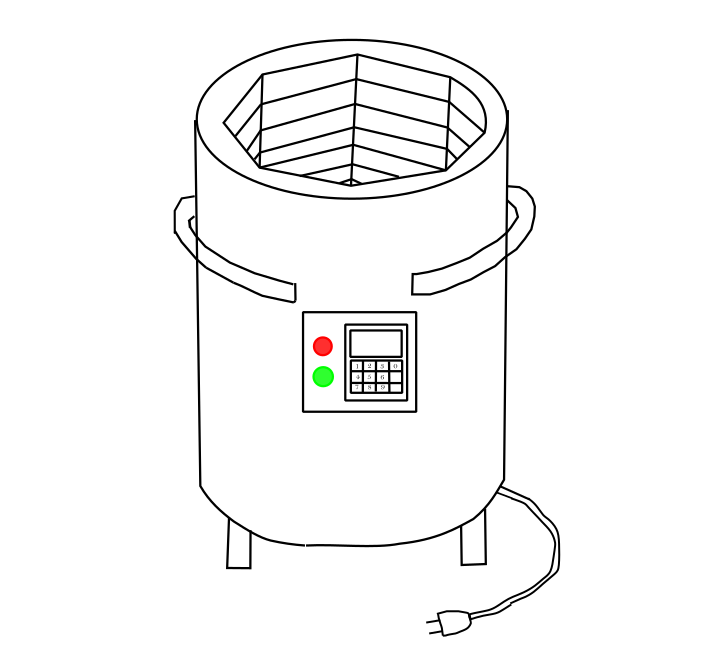

I created the 3D design of my project using the fusion 360 software. The 3D model is as shown below;

The details about the design process can be found on my week2 assignment page.