Computer-Controlled Cutting

Group assignment:

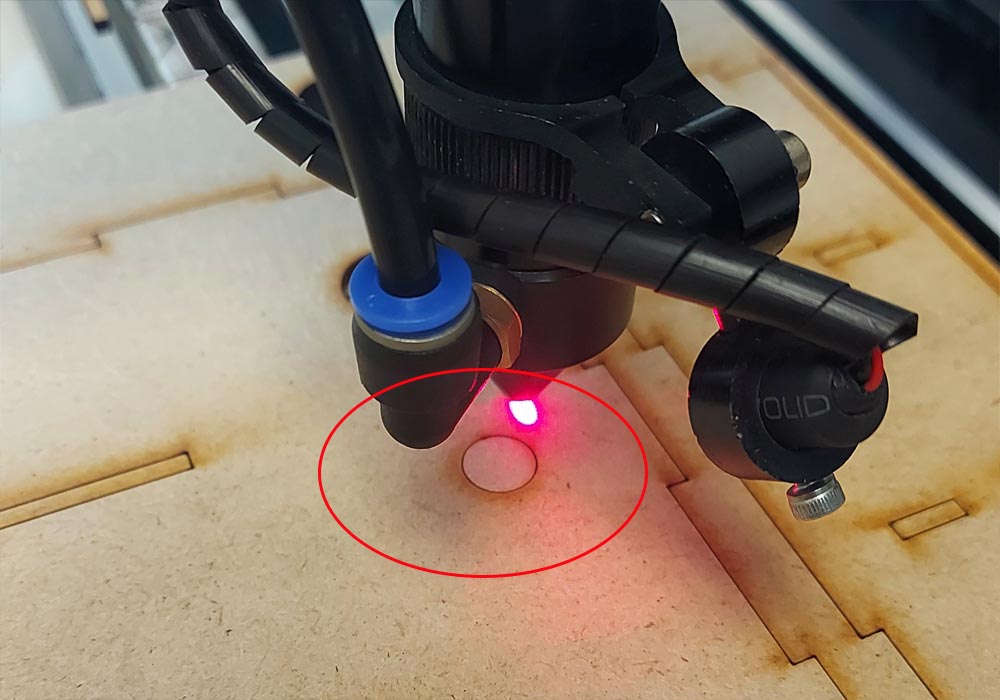

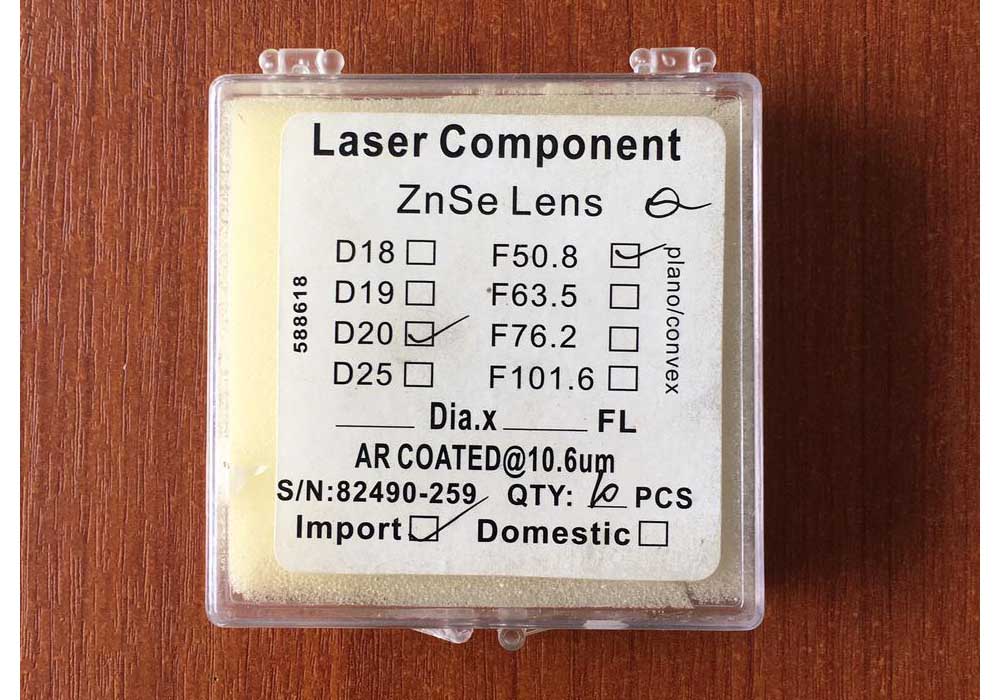

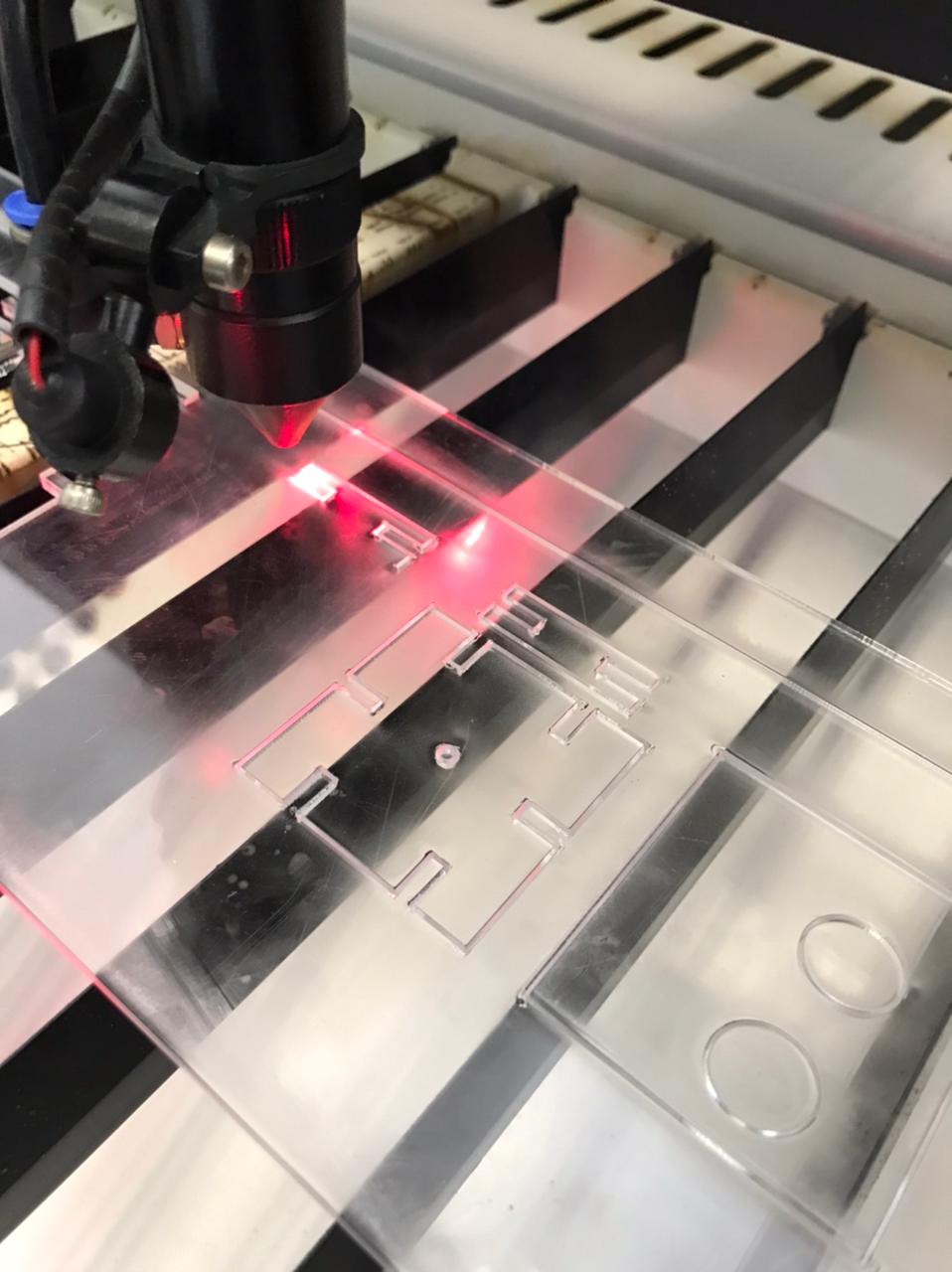

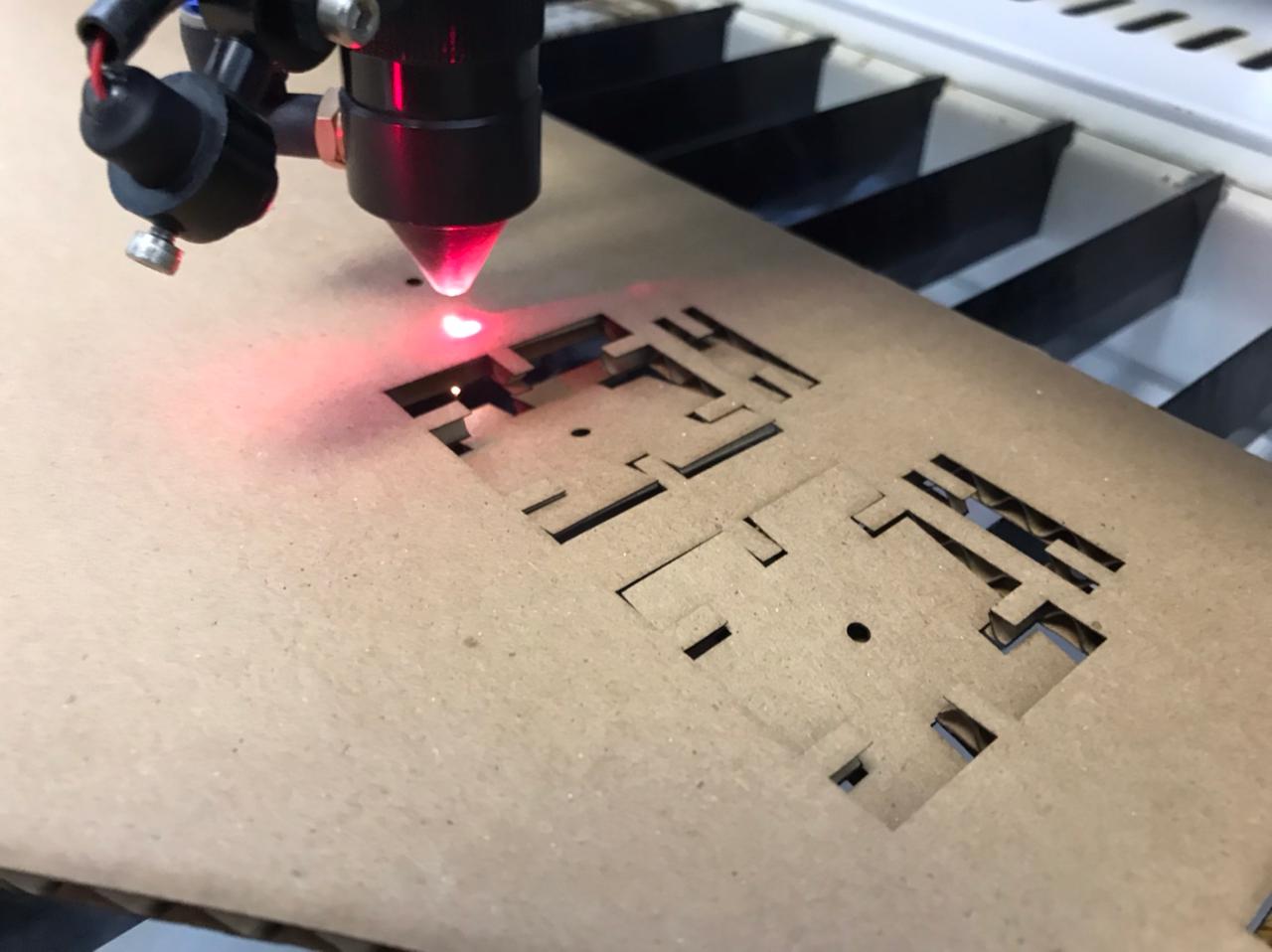

Laser cutting works by focusing the power of a high-power laser onto the surface of the material to be cut. The energy in the laser beam is absorbed into

the surface of material, and the energy of the laser is converted into heat, which melts or vaporizes the material.

Laser cutting is mainly a thermal process in which a focused laser beam is used to melt material in a localised area. A co-axial gas jet is used to eject

the molten material and create a kerf. A continuous cut is produced by moving the laser beam or workpiece under CNC control.

The following video explain how laser works.

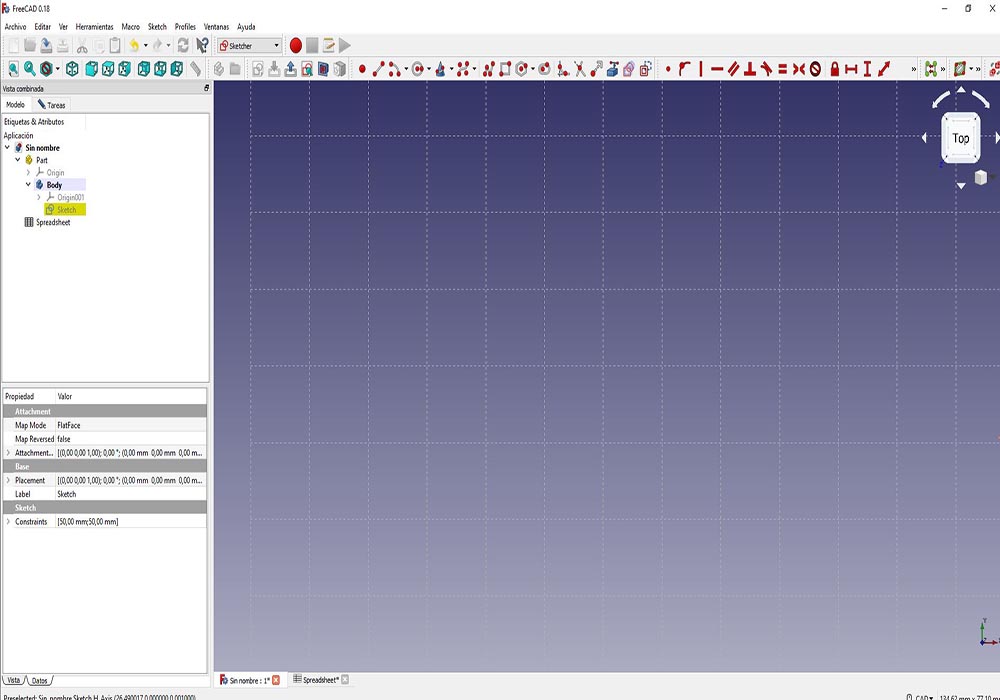

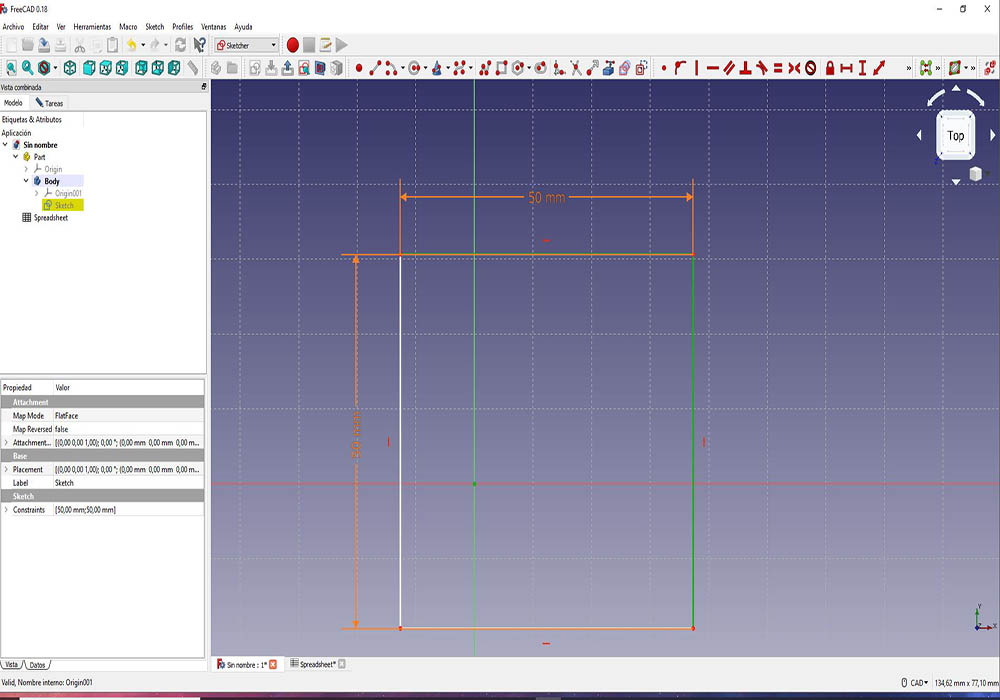

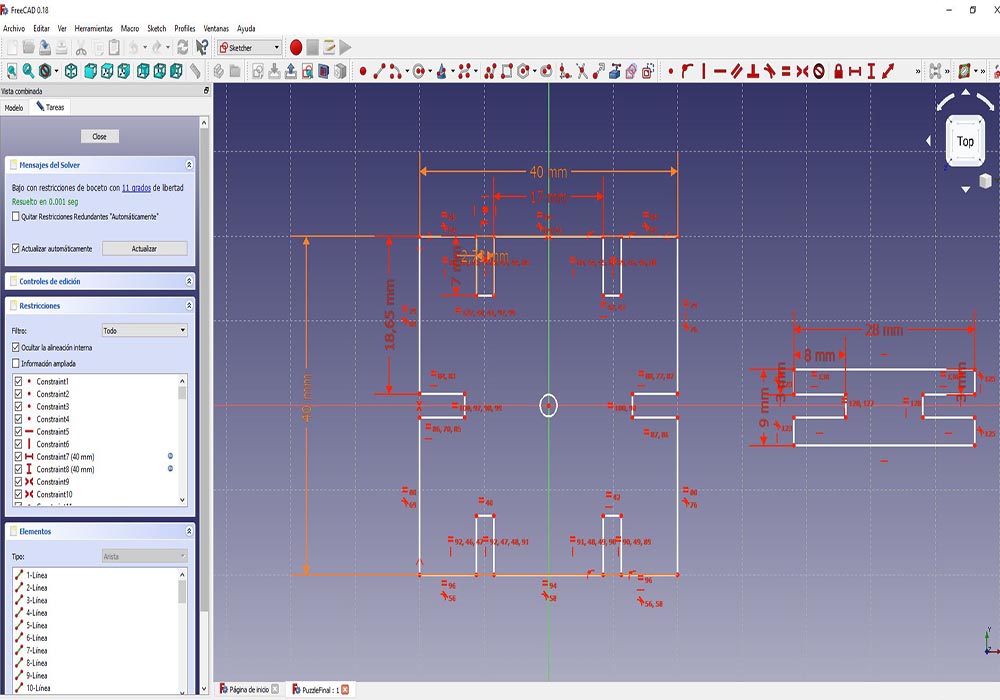

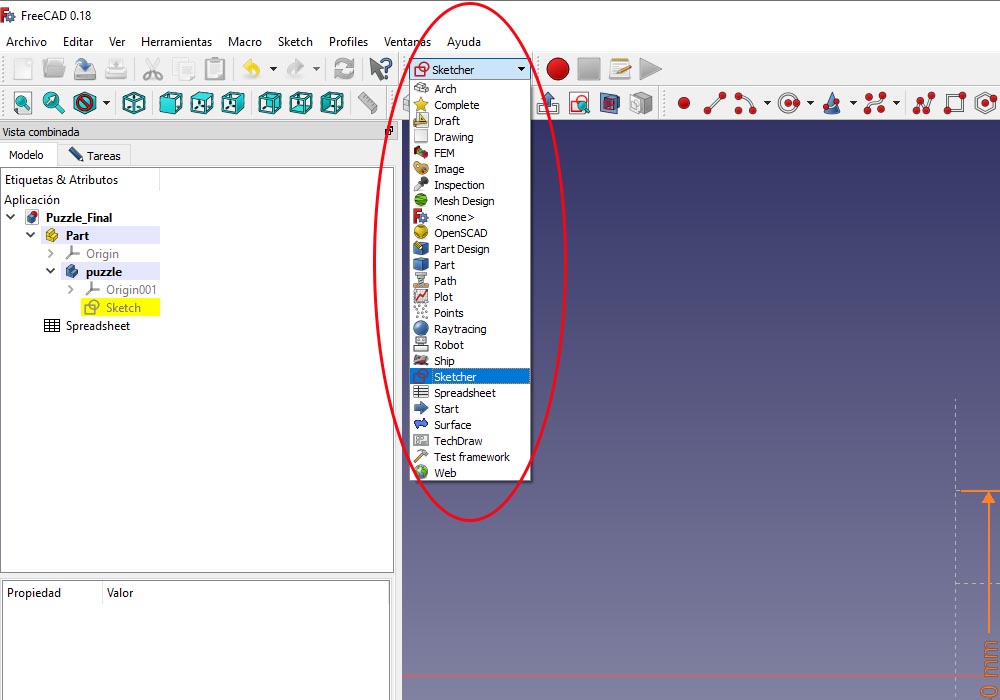

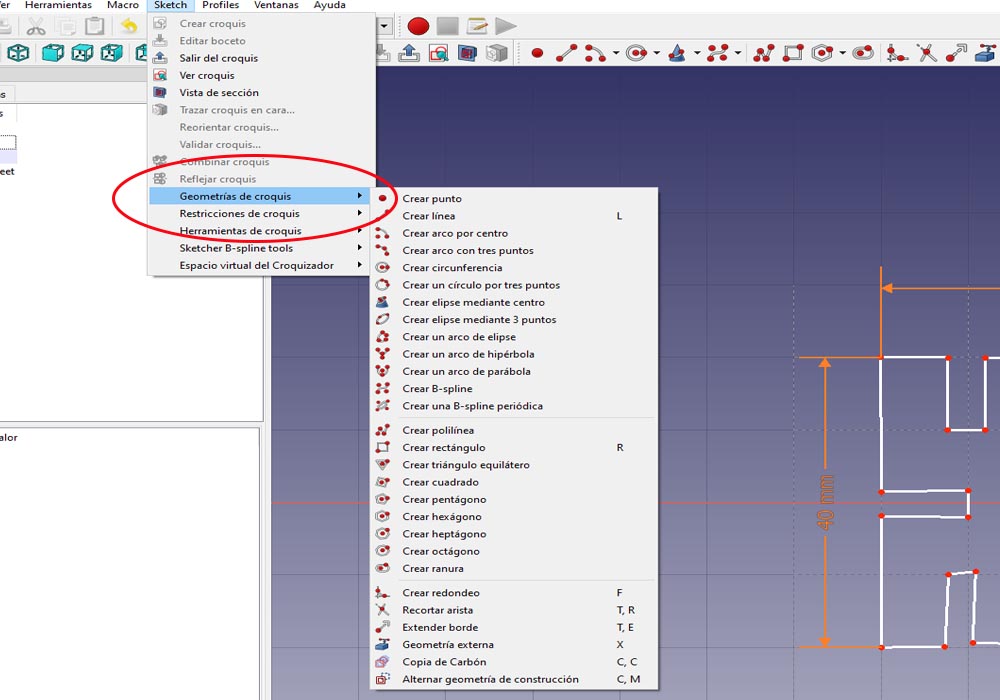

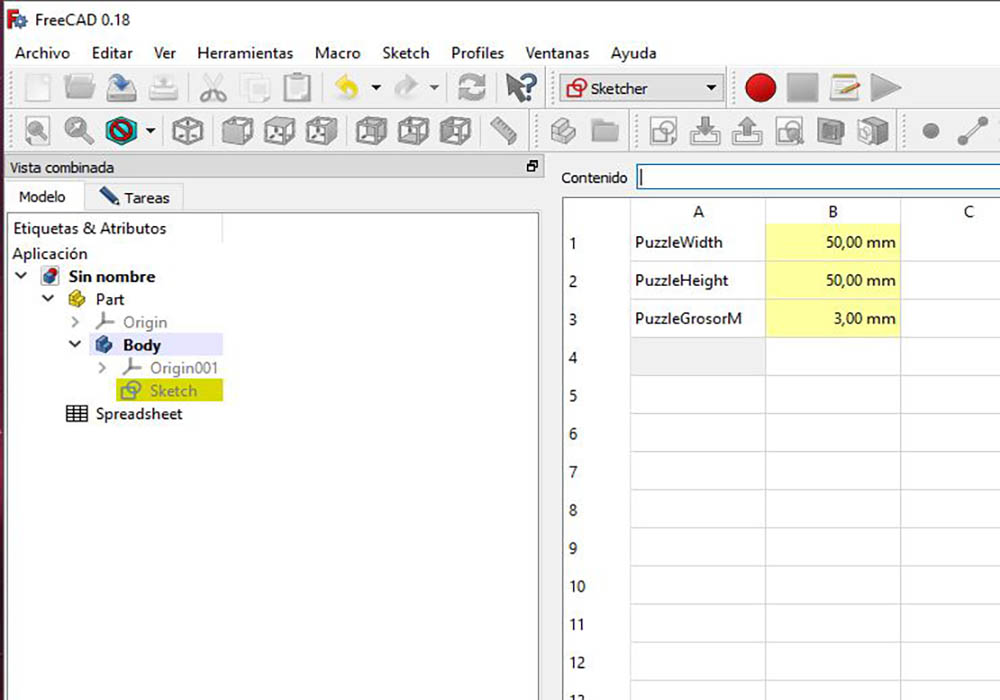

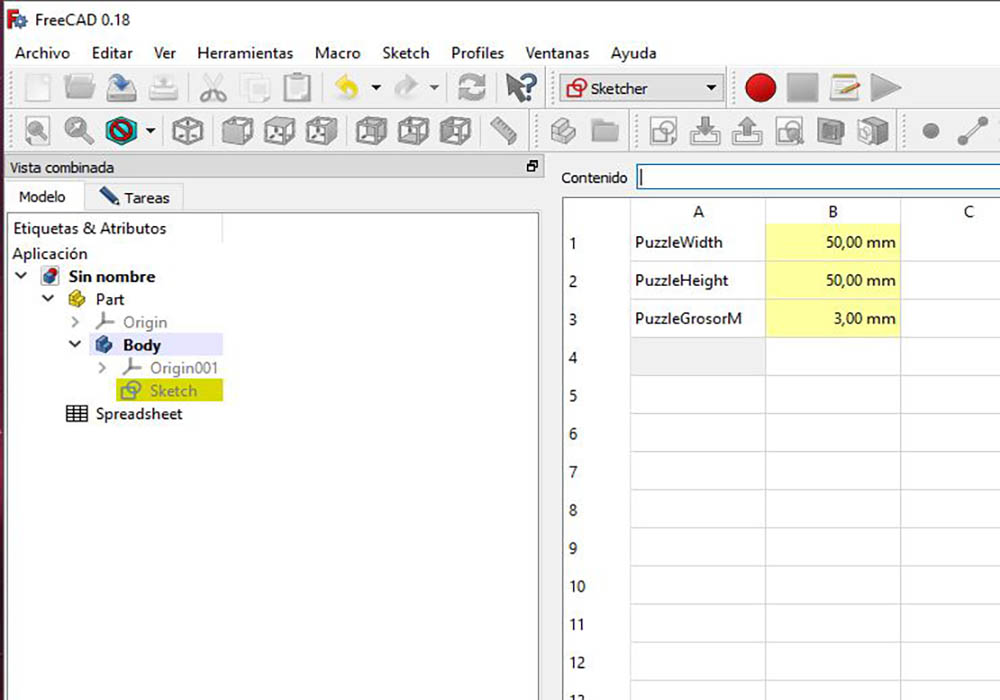

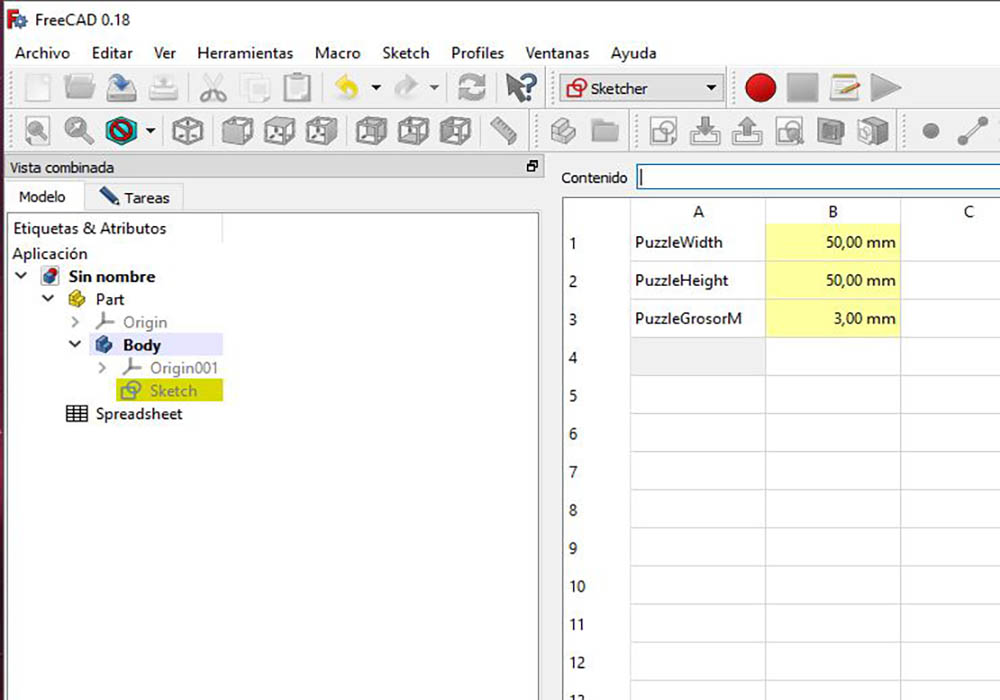

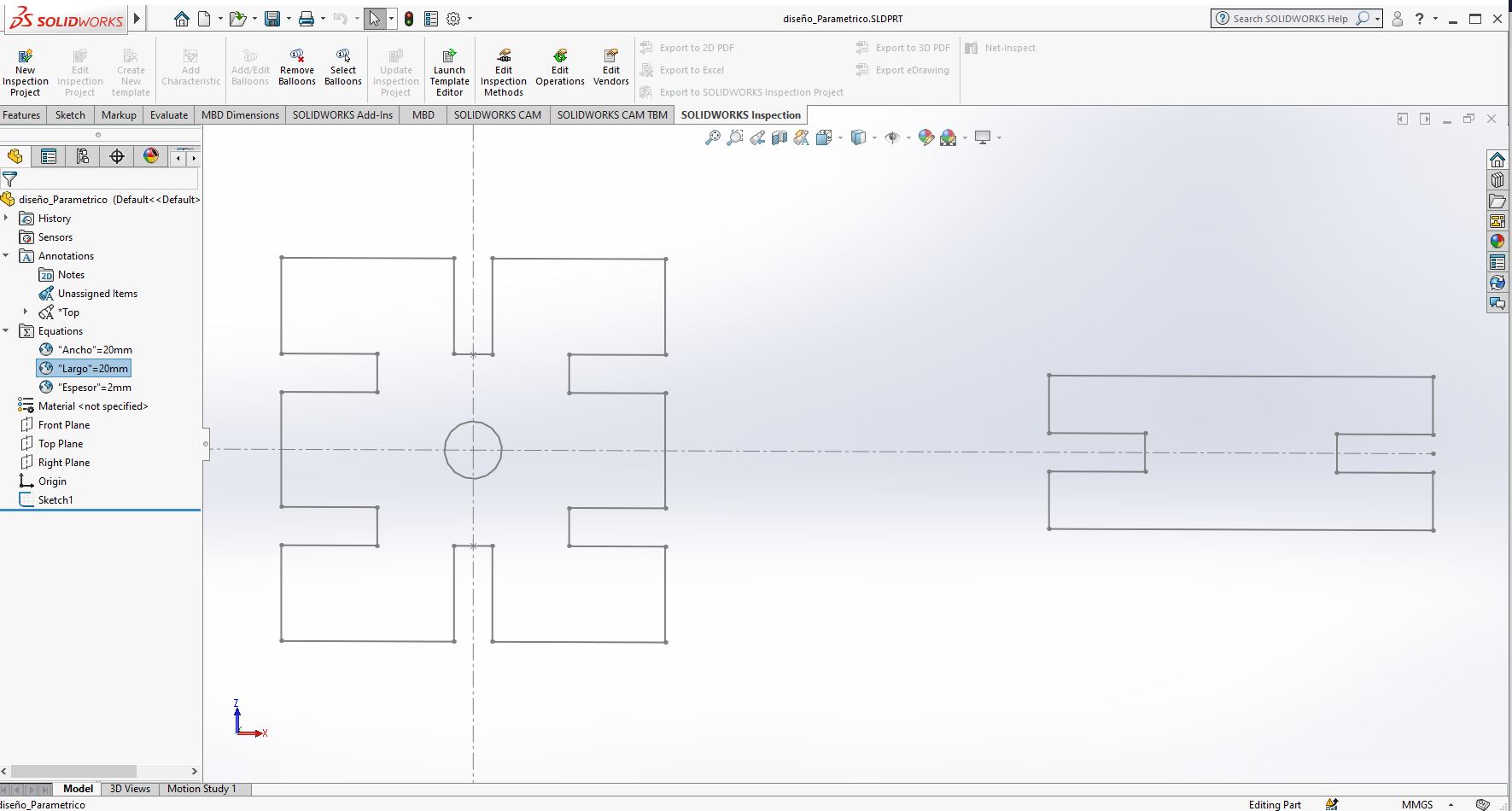

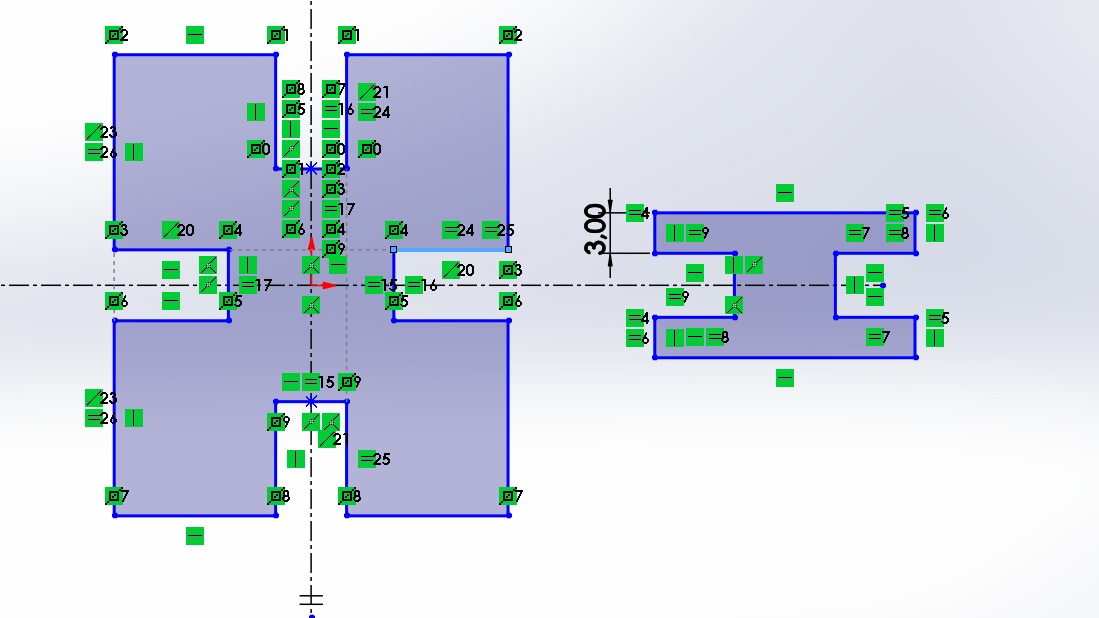

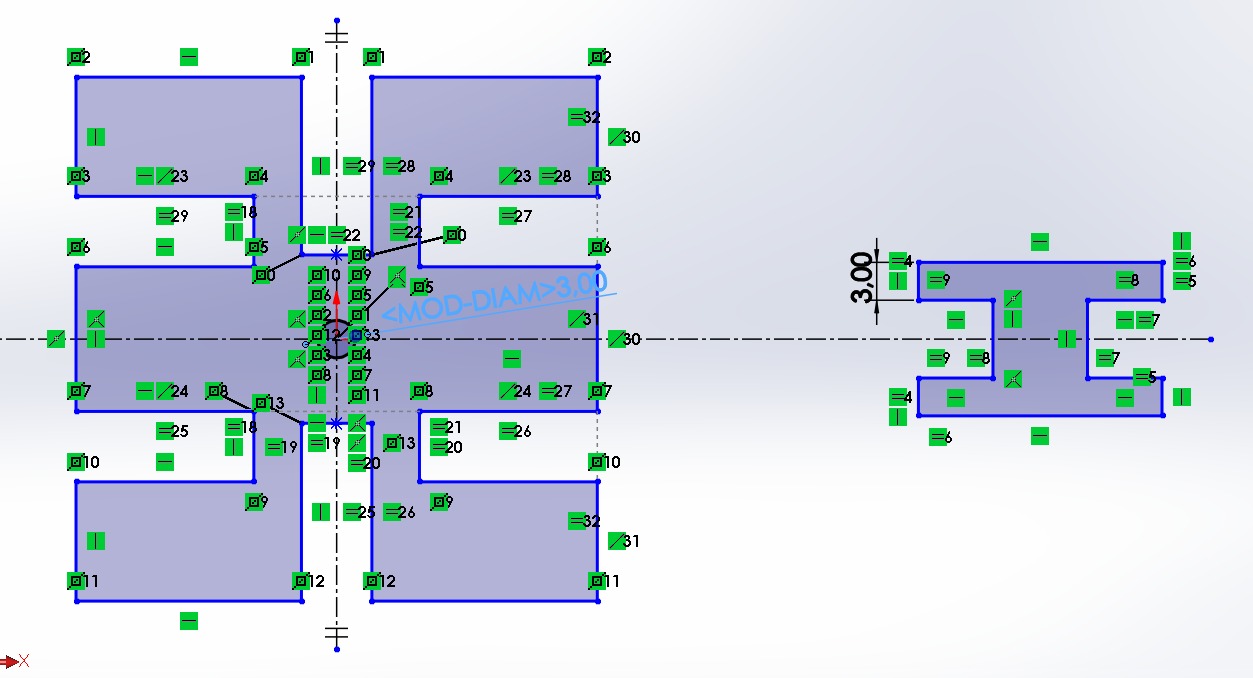

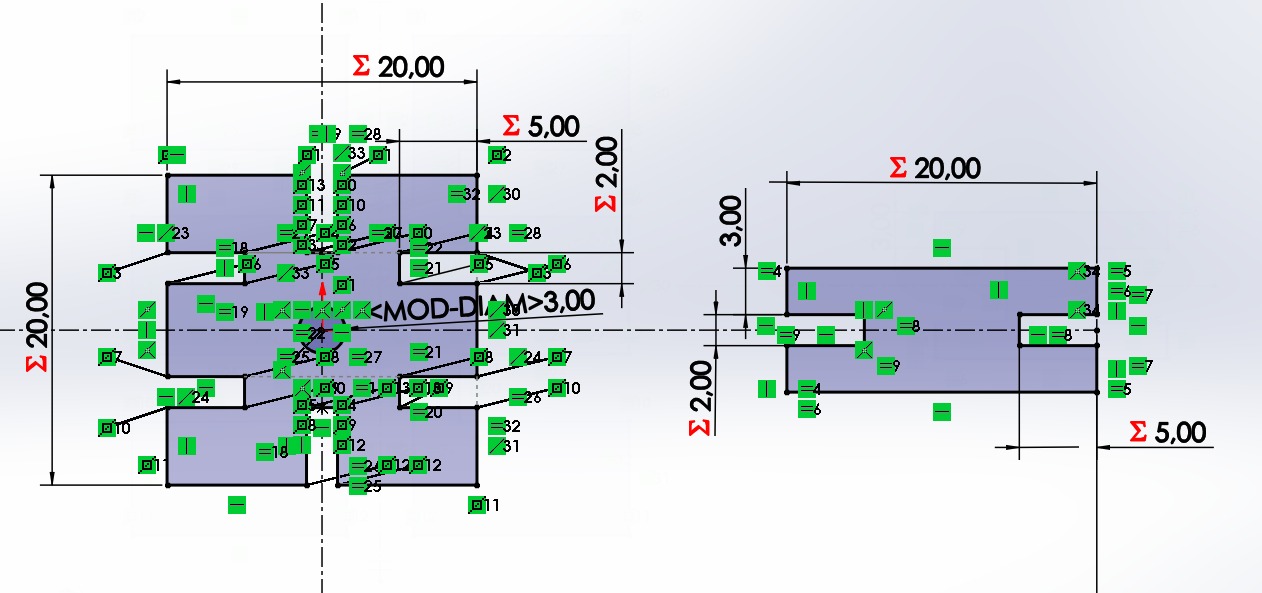

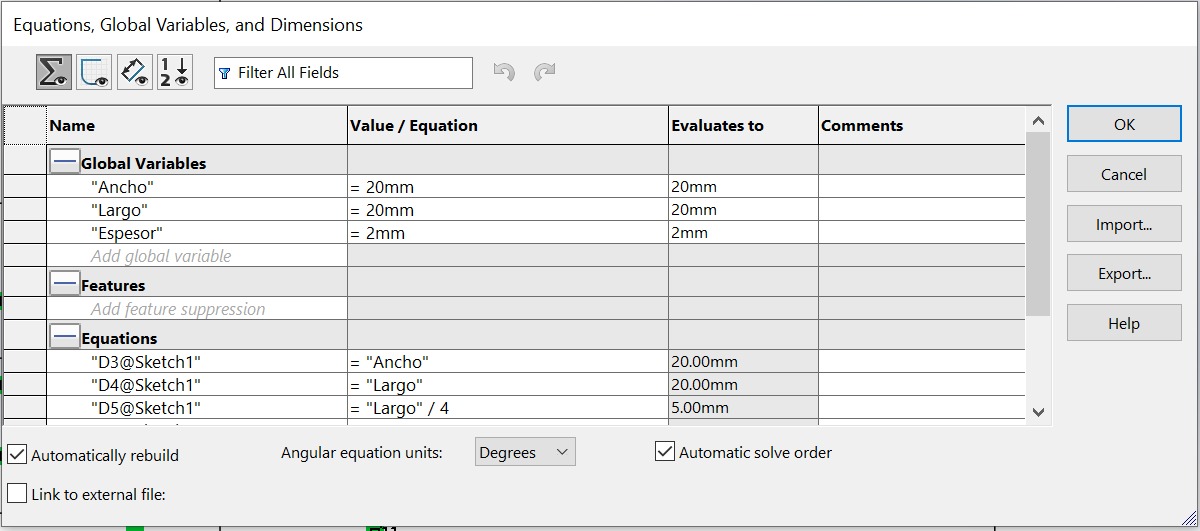

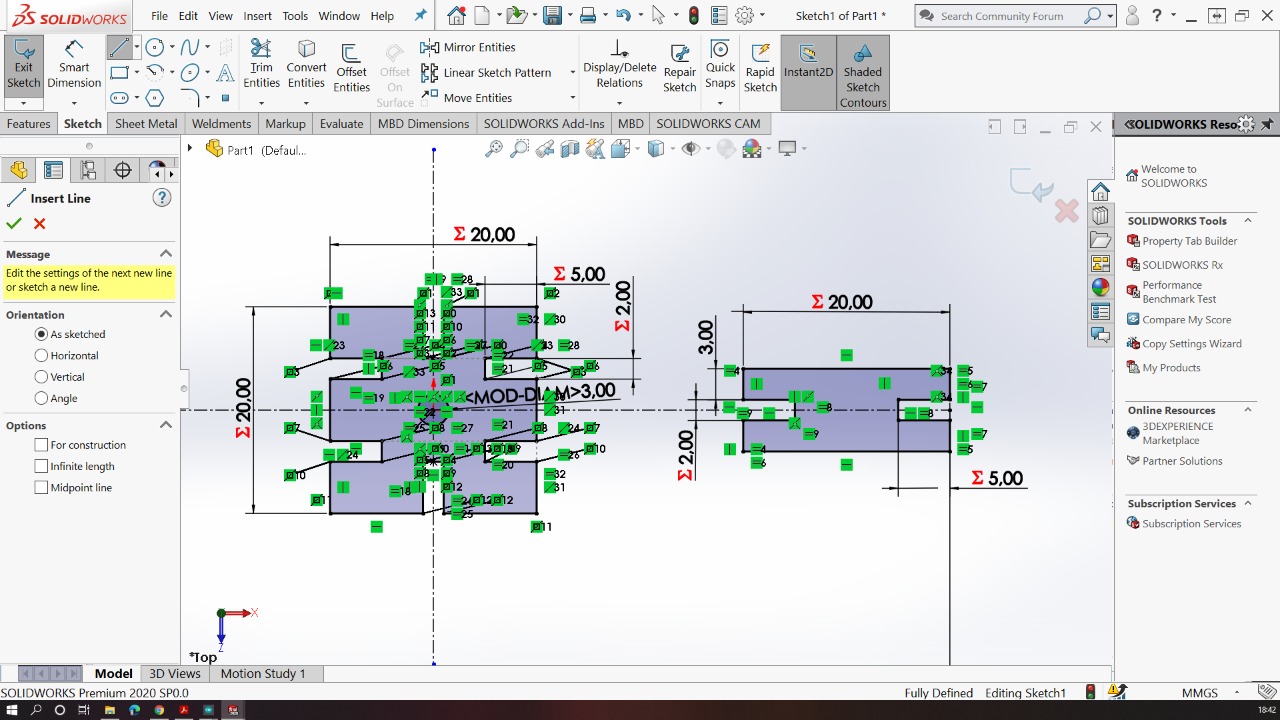

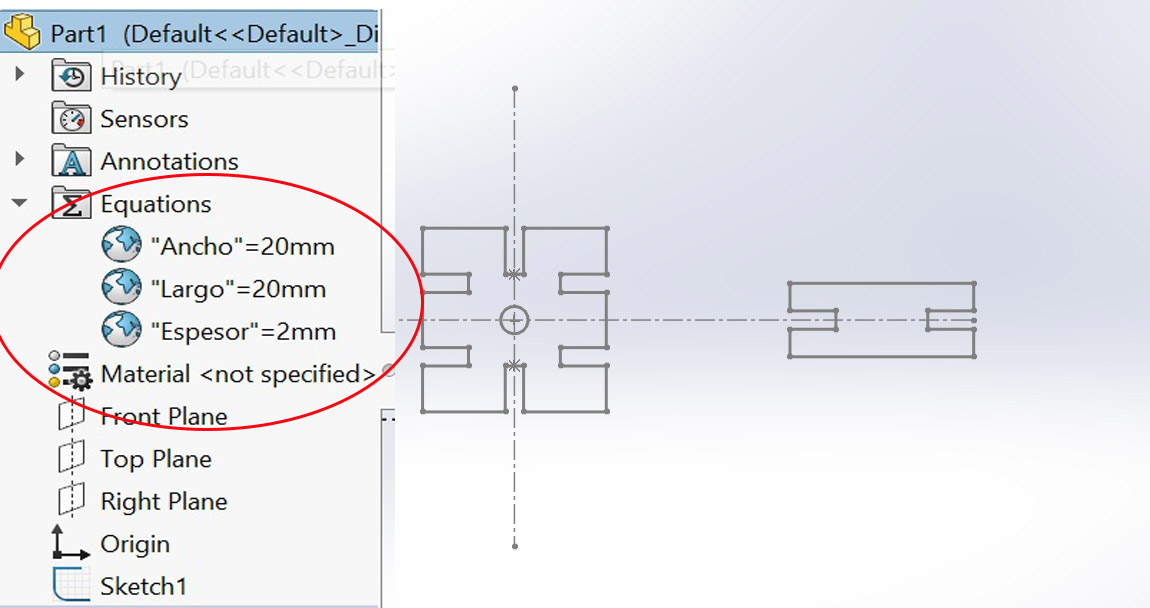

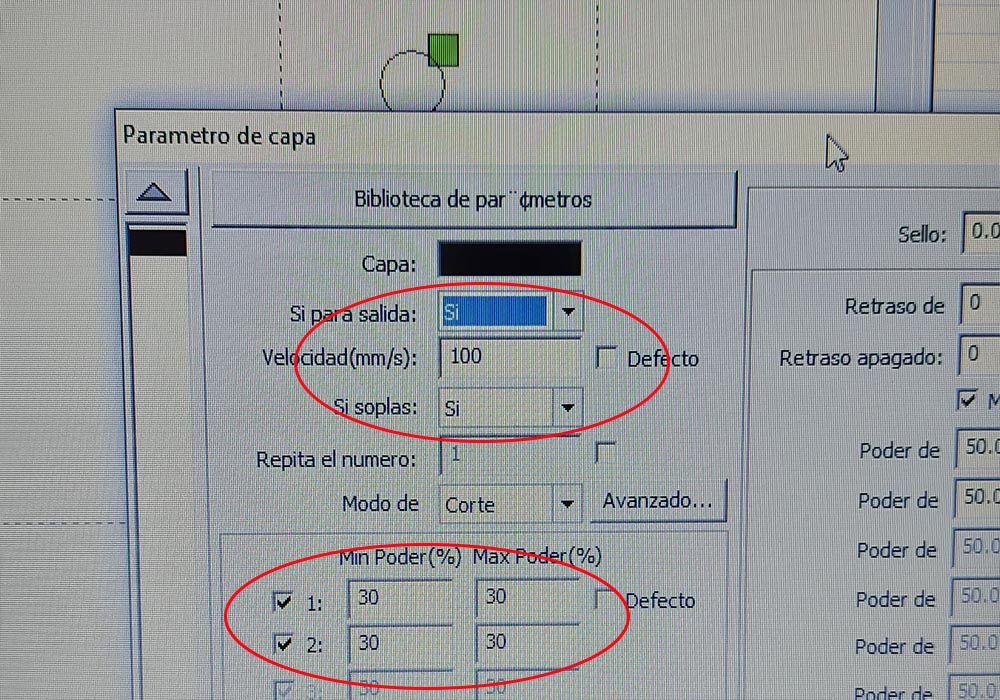

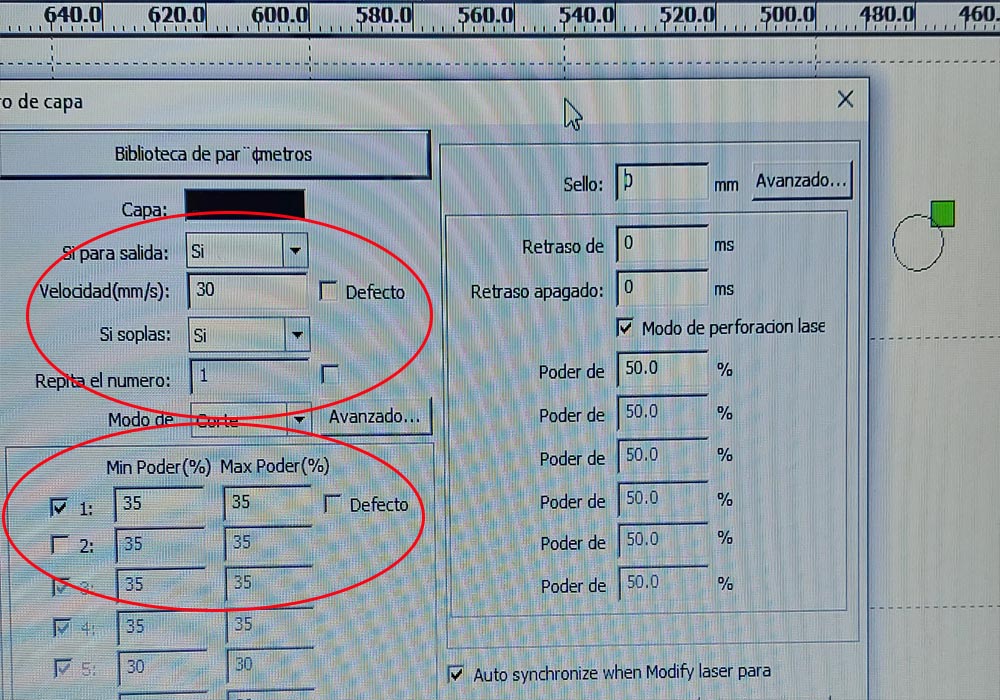

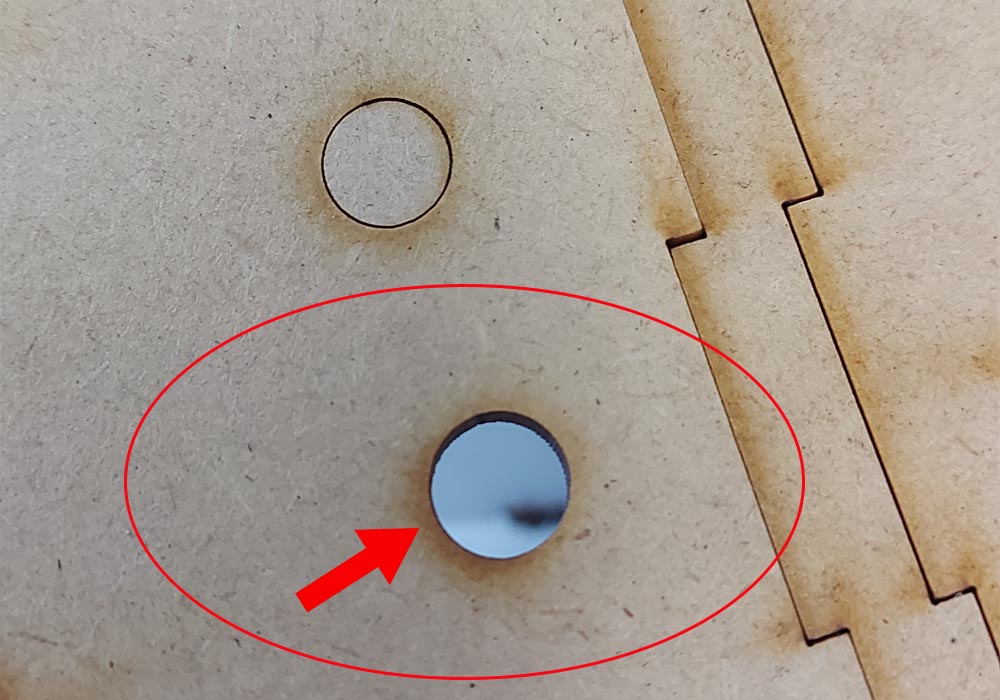

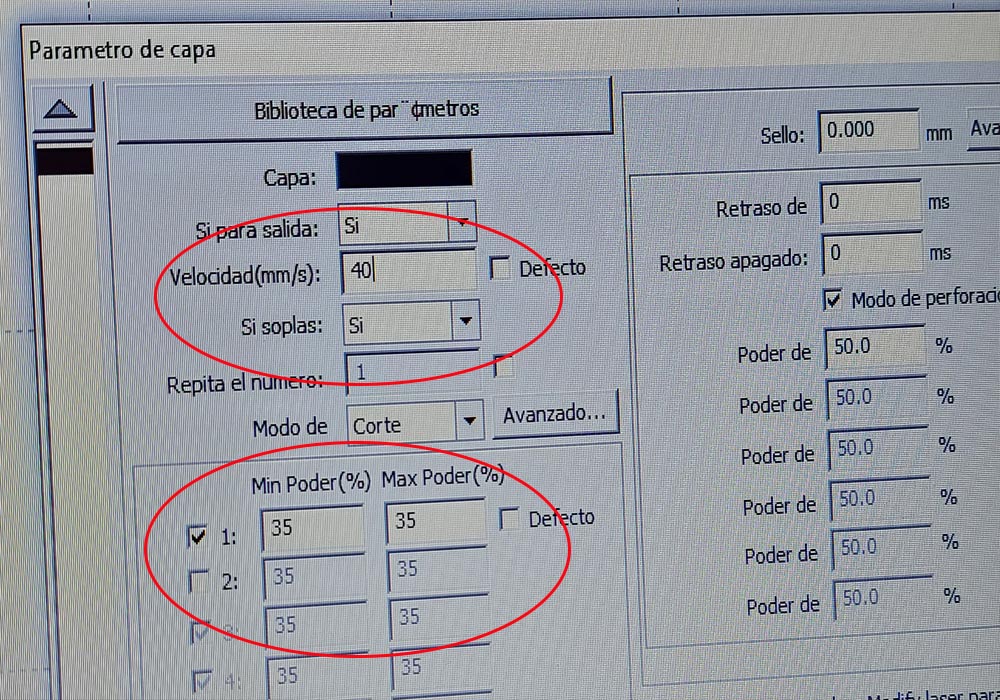

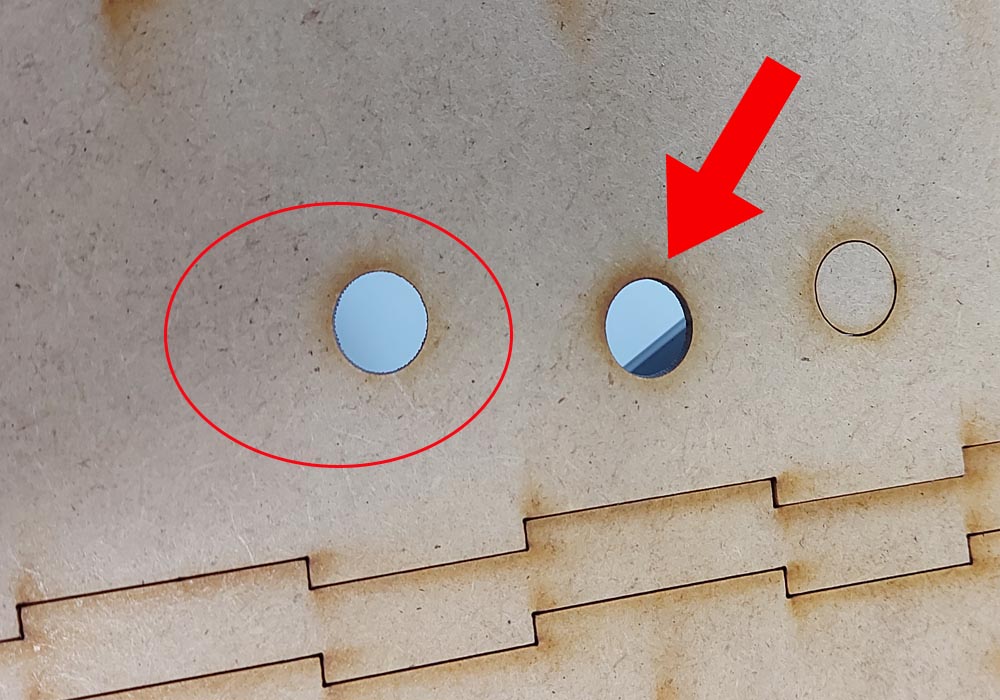

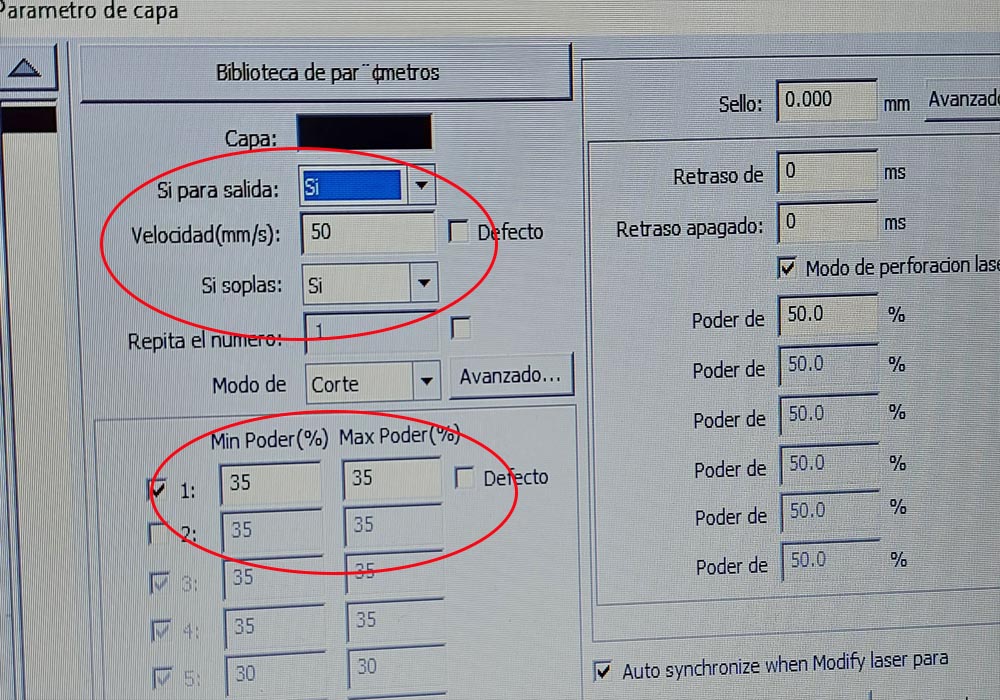

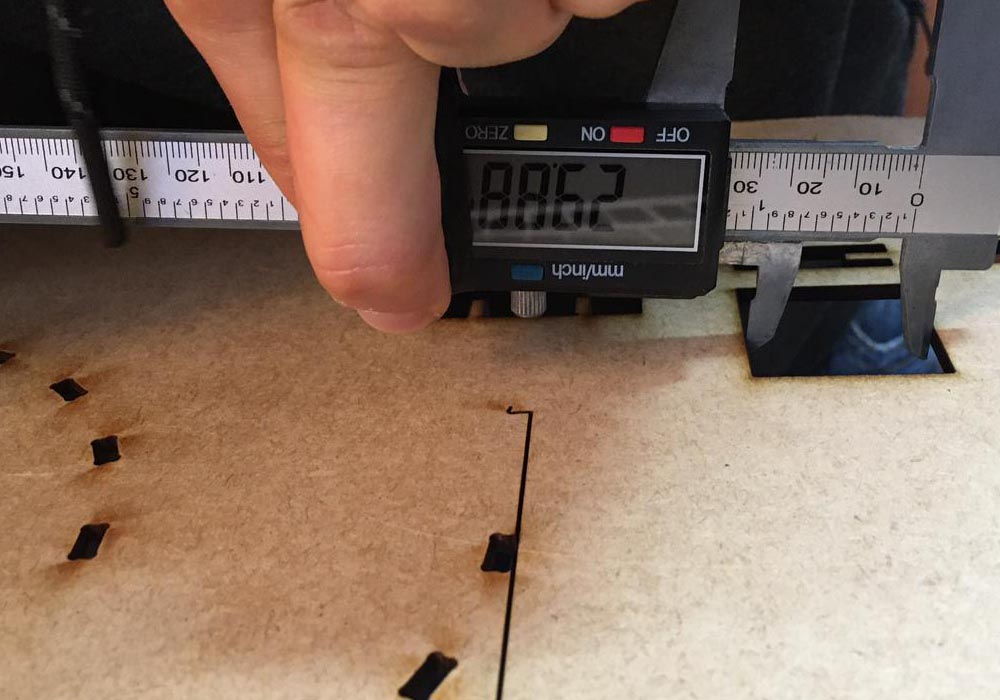

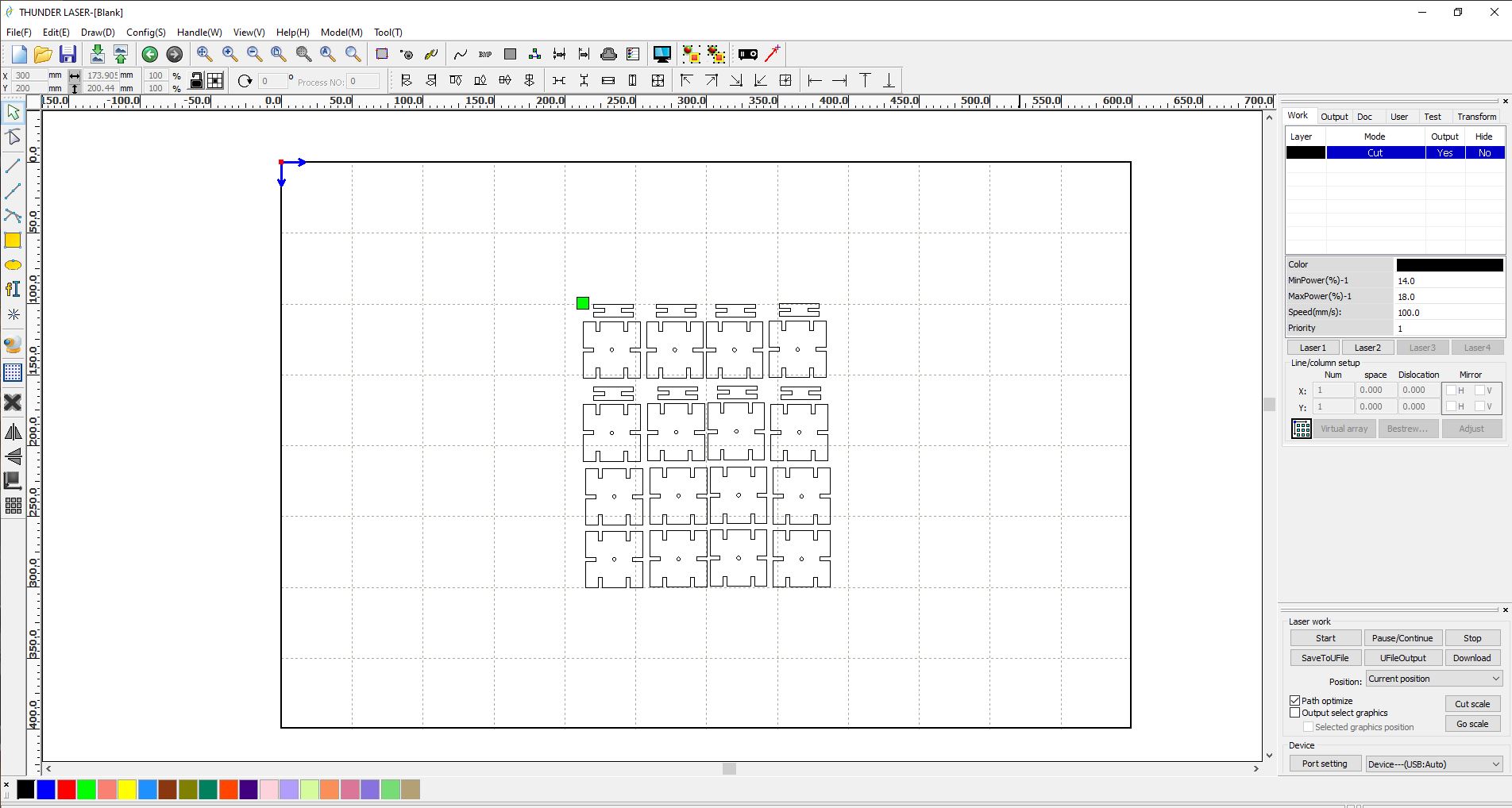

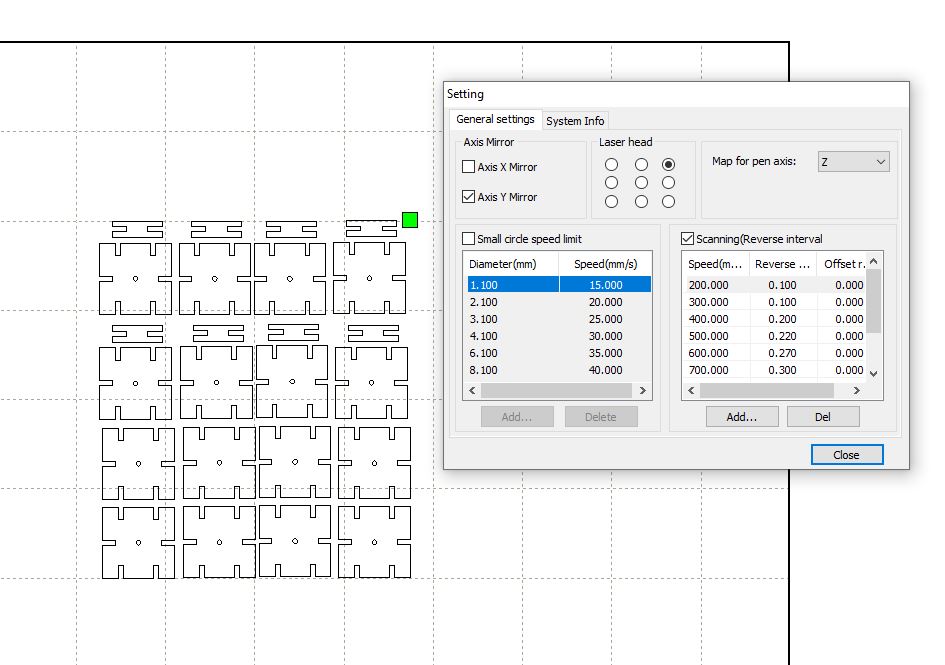

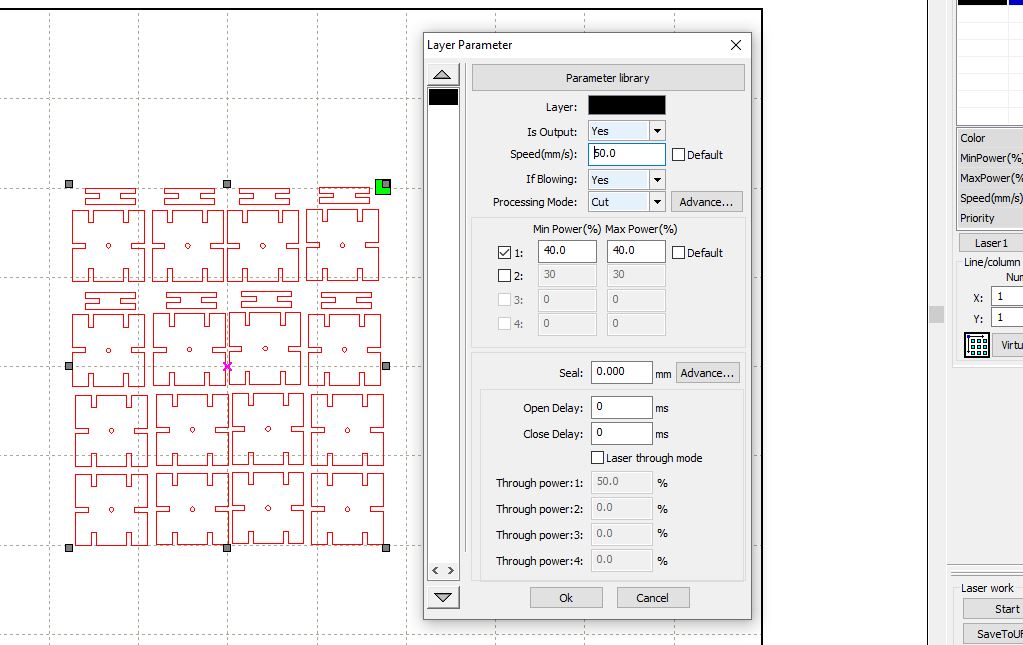

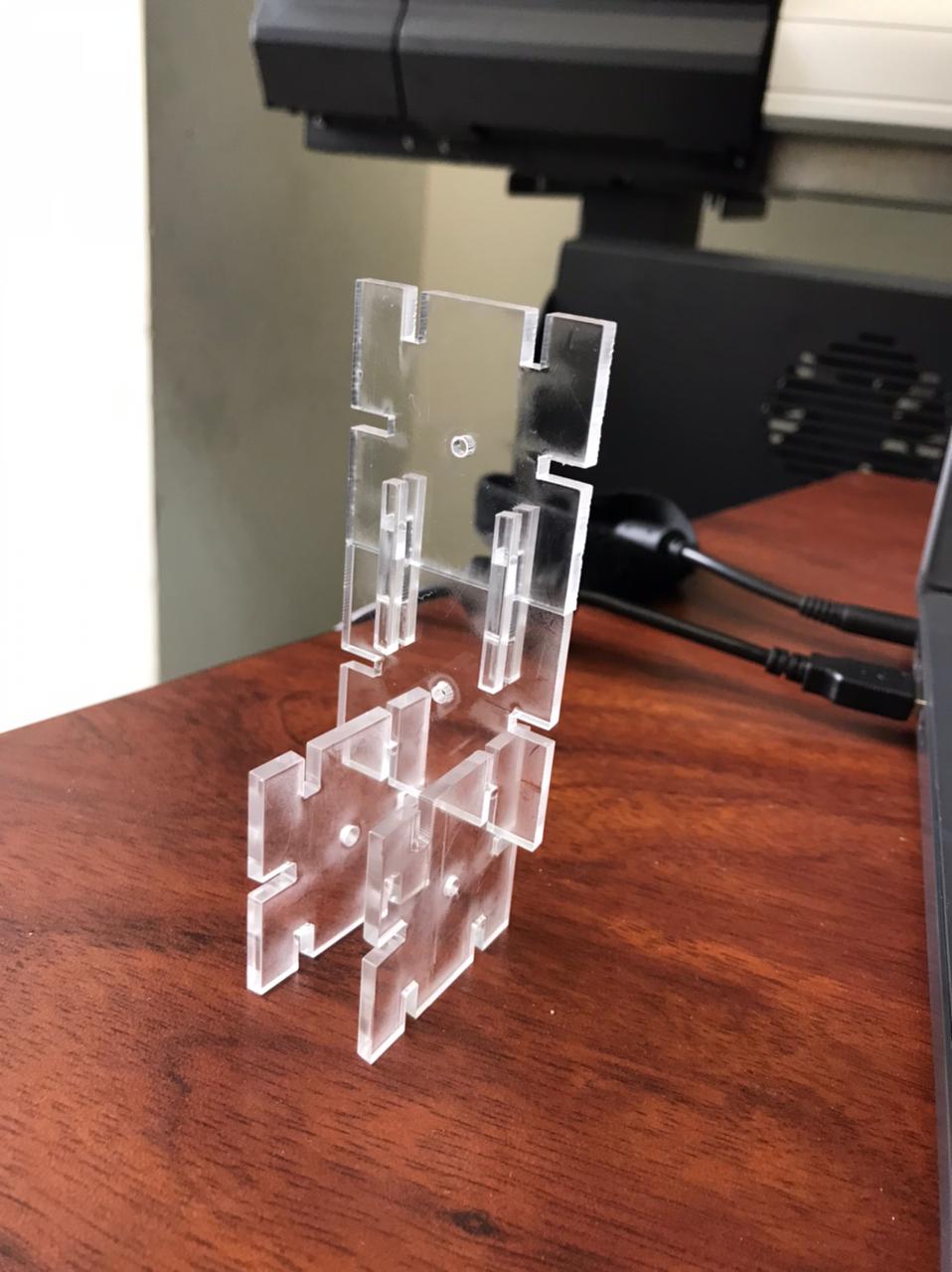

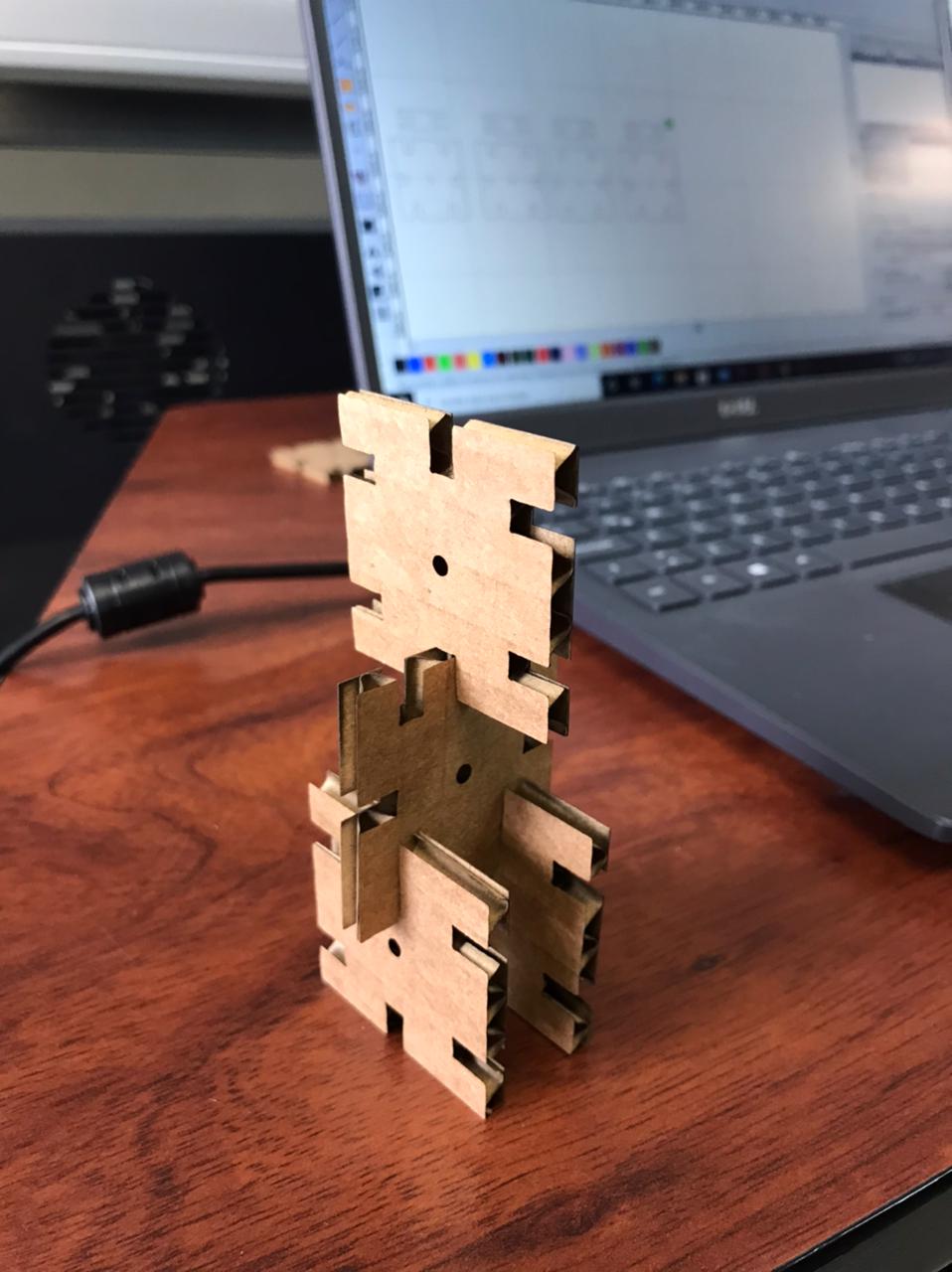

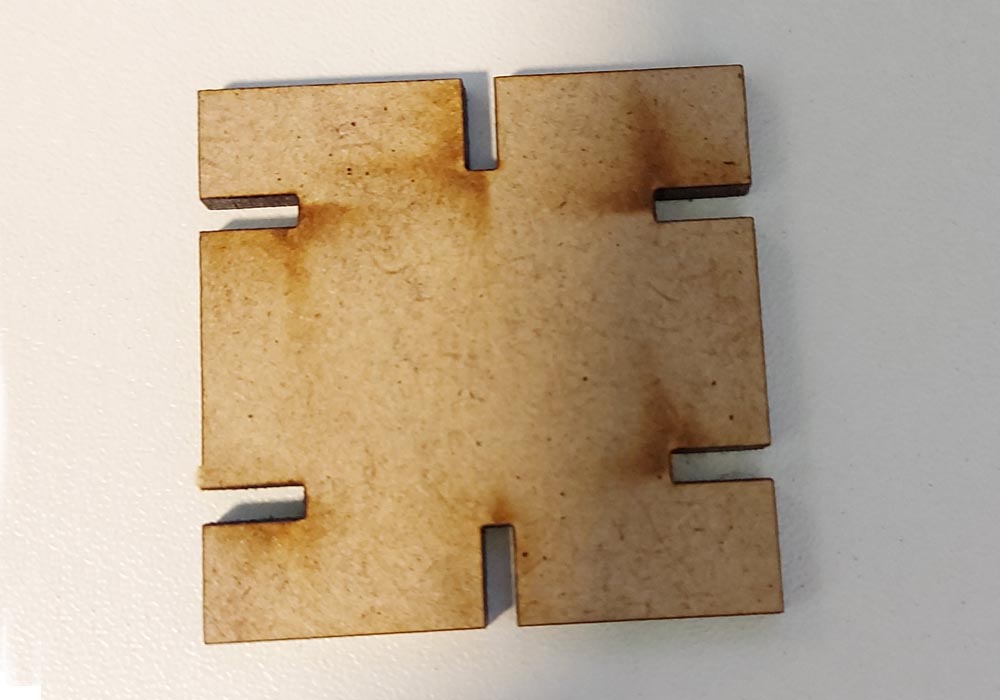

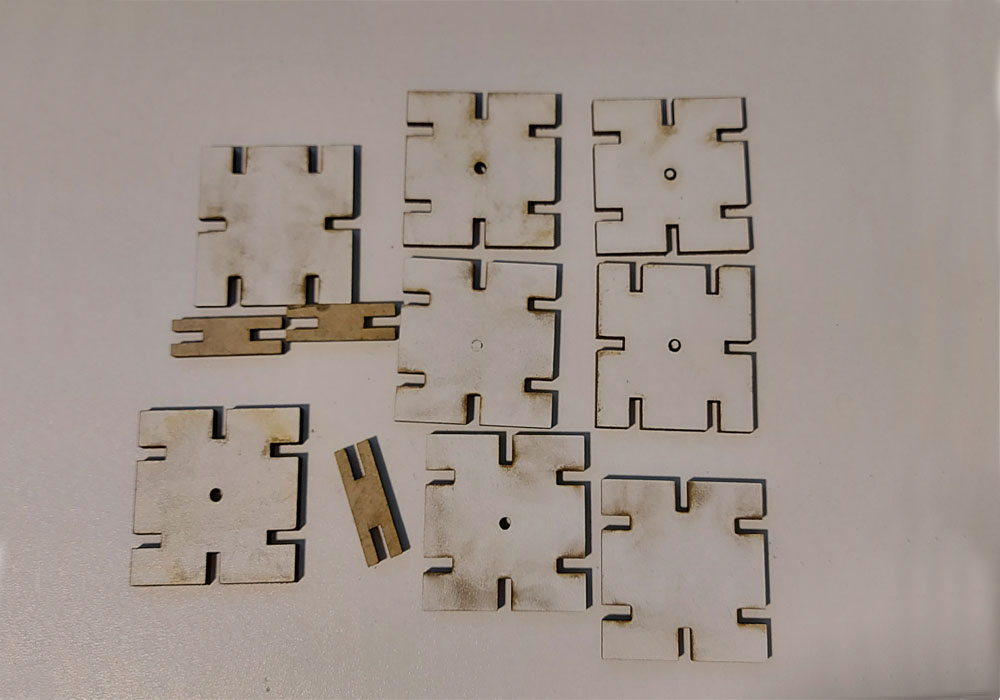

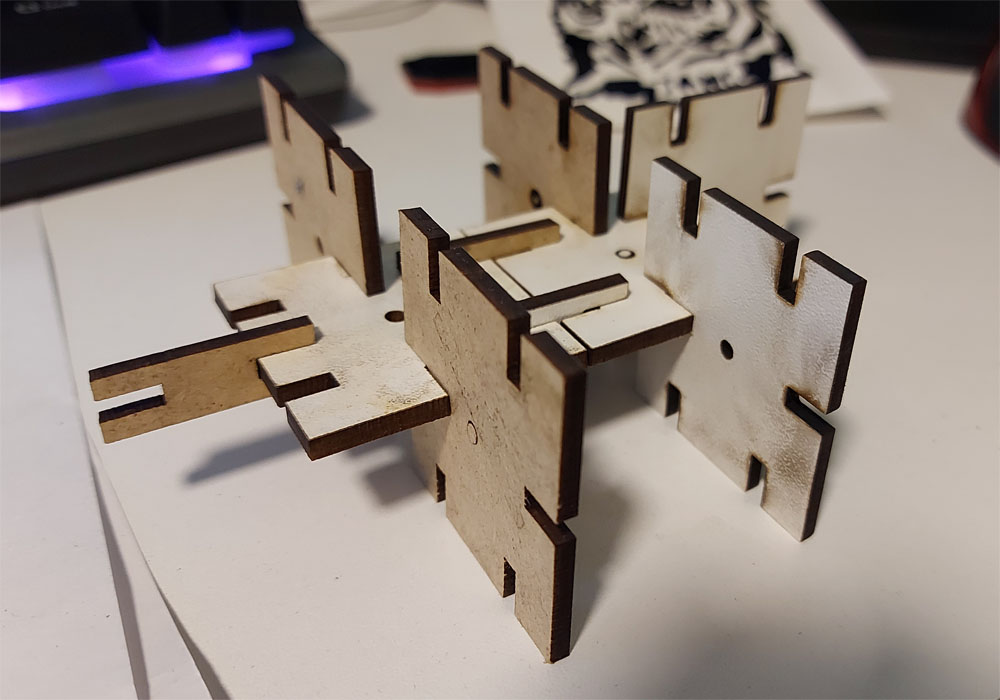

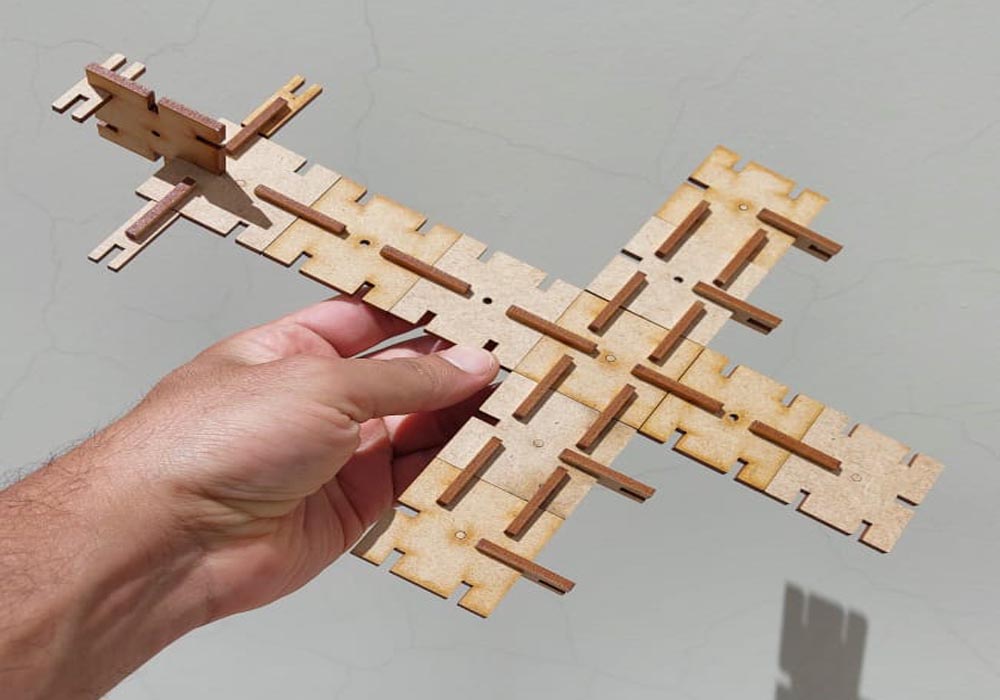

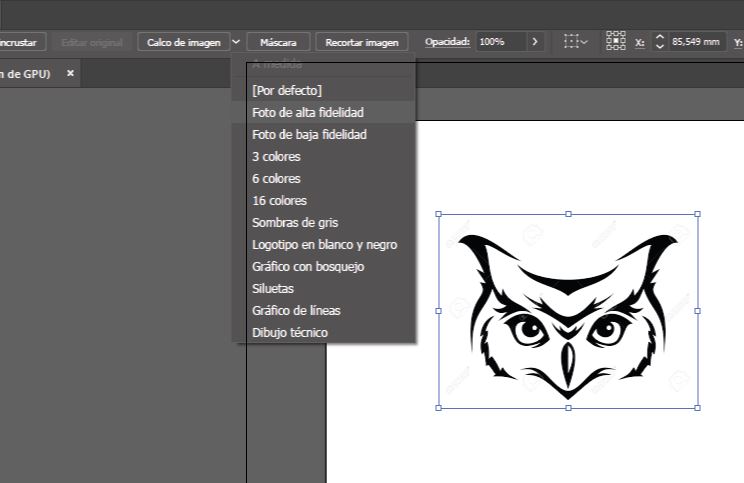

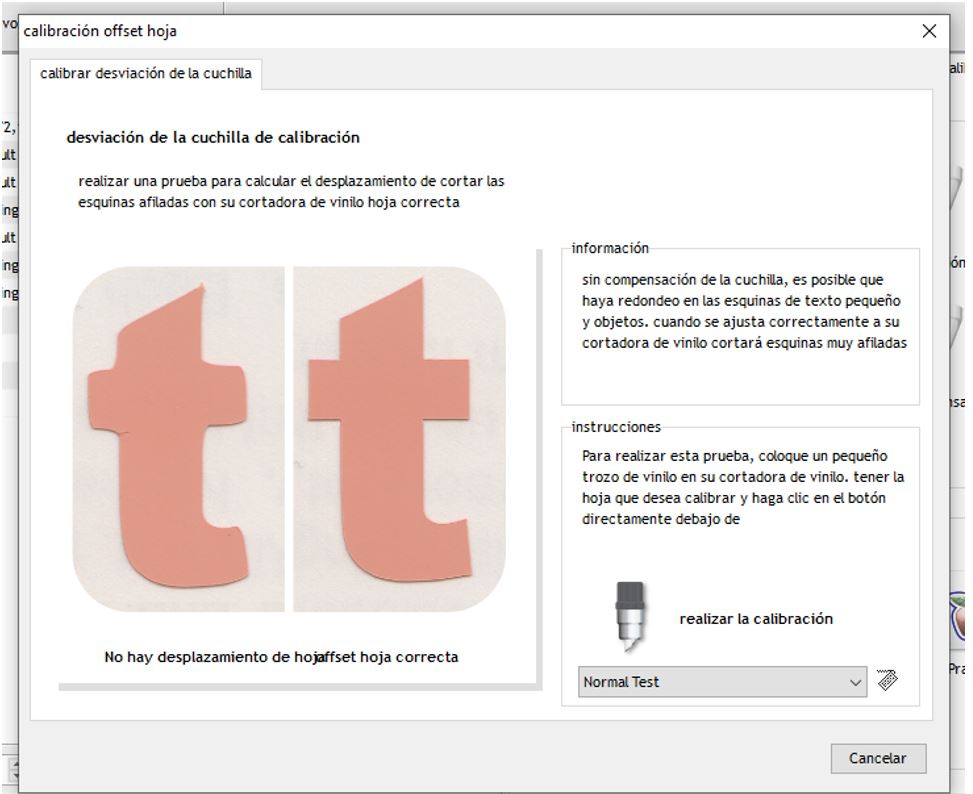

The design of the puzzle piece was parameterized, the thickness of the material was chosen to be able to change and calculate the kerf of the piece at the time of cutting, For this I use the Spreadsheed which is an excel file that allows us to create variables, assign them a unit of measure and an alias, in order to place the restrictions

This week's work was quite interesting and opened the doors to new ideas and design possibilities that I had not explored before, there is a lot to learn in design tools, but expertise is not learned overnight.

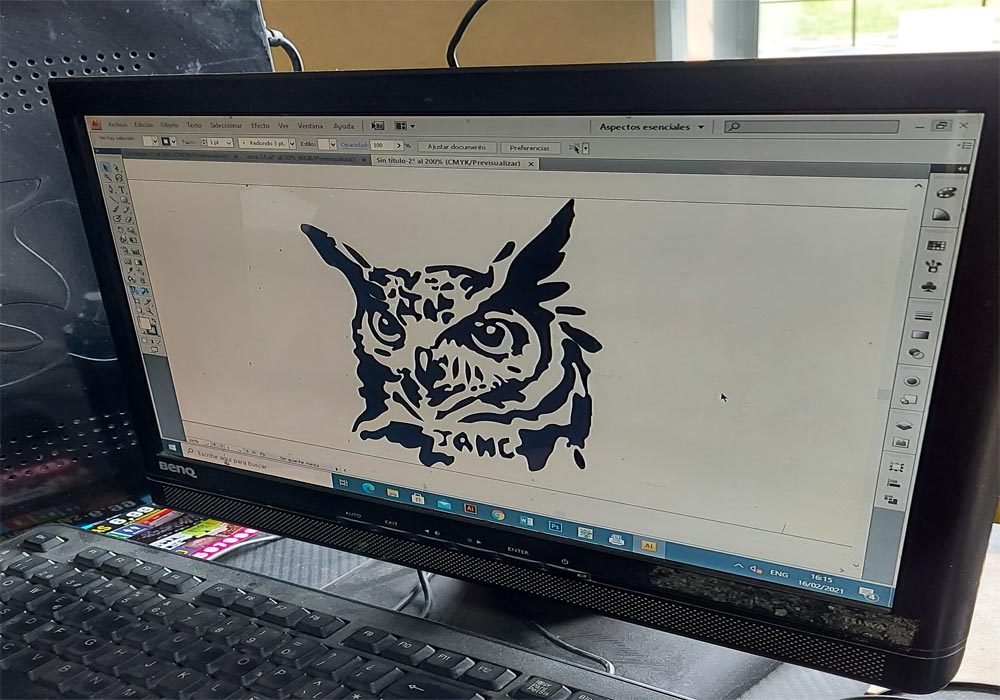

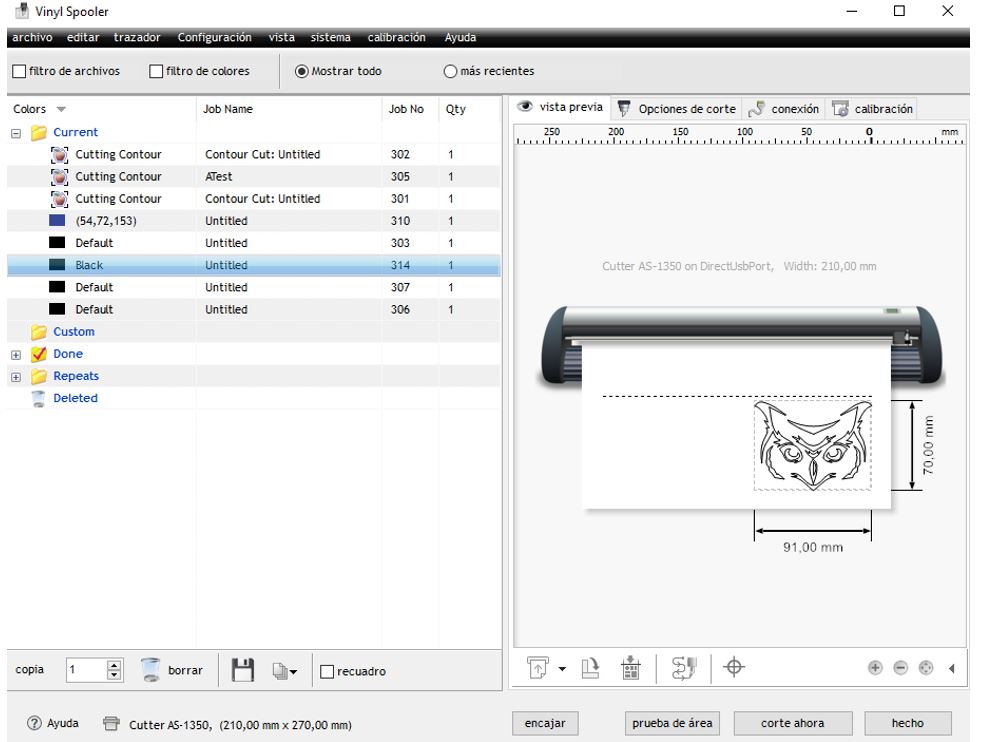

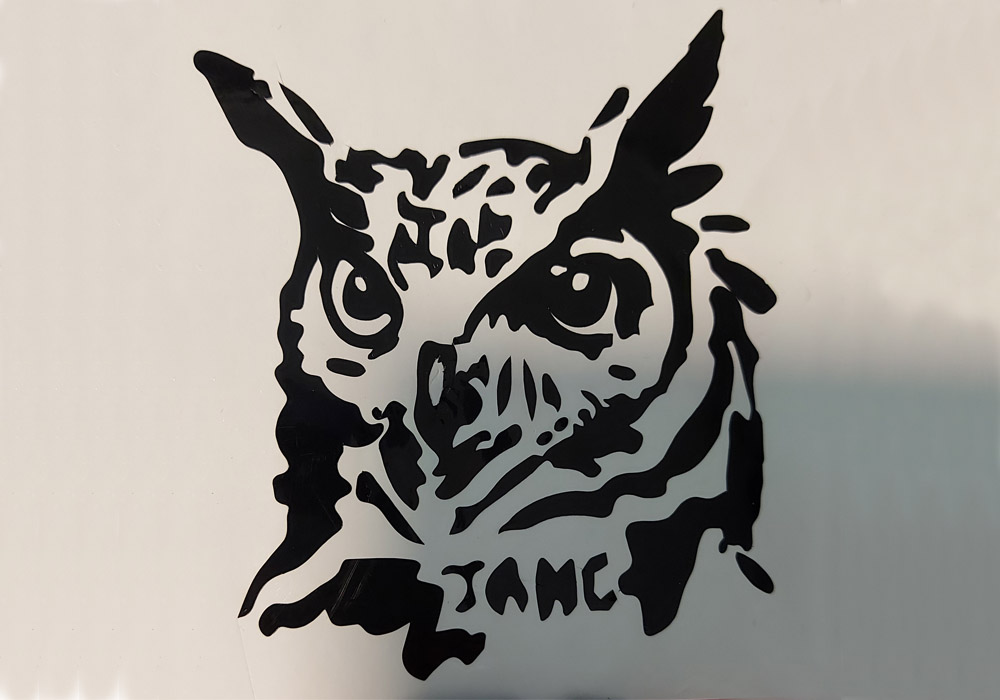

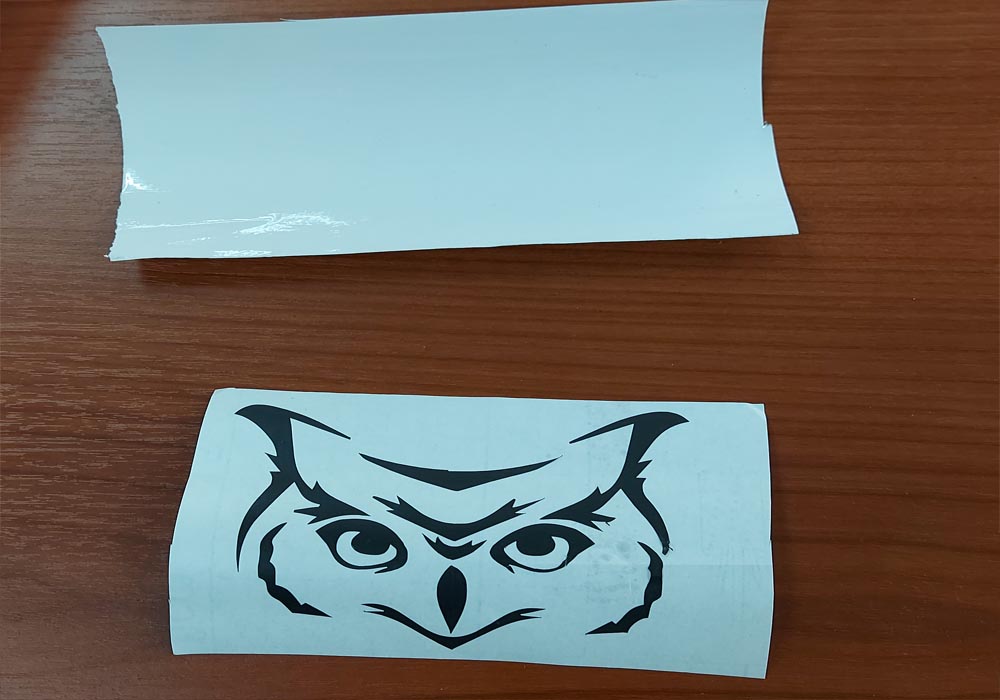

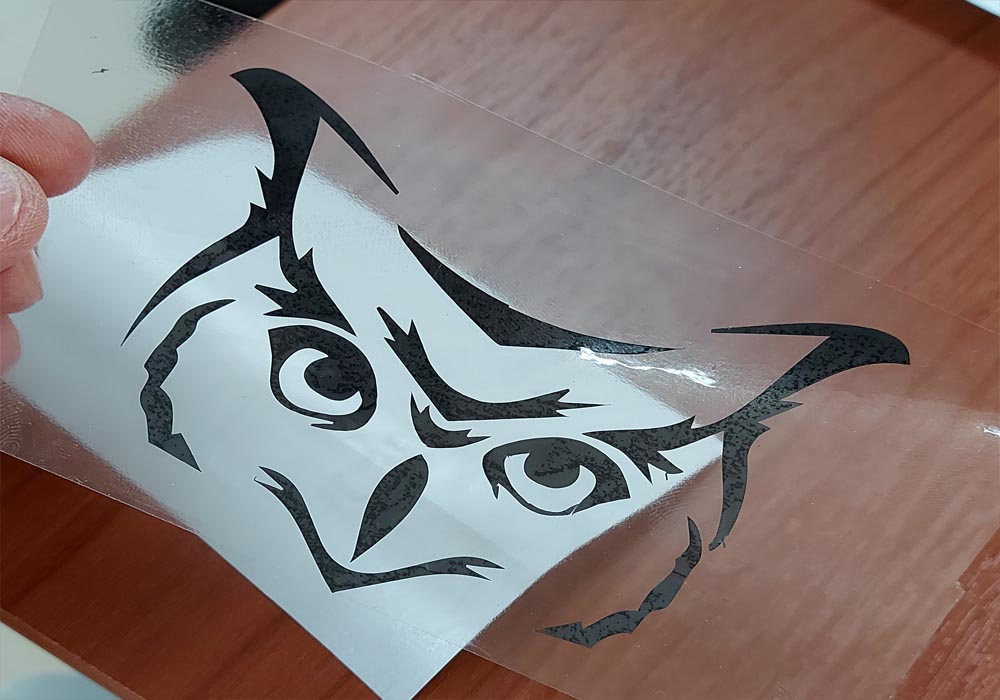

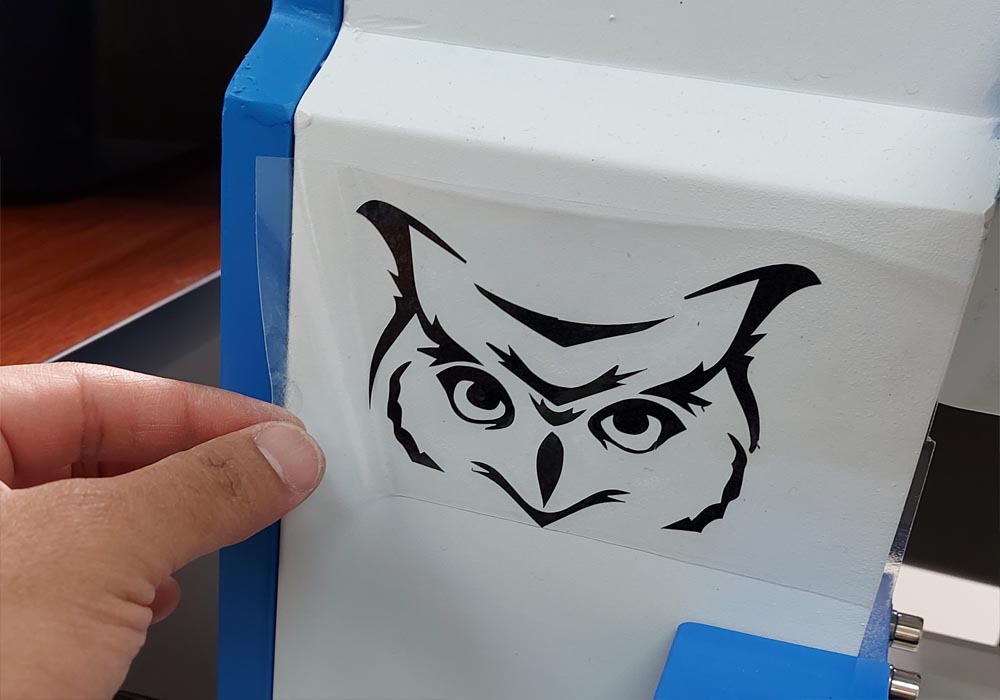

Finally, you have to remember all the safety parameters to make good use of the machines, especially the laser cutter, which can be very dangerous. When it comes to cutting vinyl, it was a lot of fun to be able to make custom stickers, although the job of removing excess material is a bit stressful