Week 05. 3D Scanning and Printing

Group assignment

- Test the design rules for your printer(s)

- Document your work and explain what are the limits of your printer(s) (in a group or individually)

Individual assignments

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively

- 3D scan an object, try to prepare it for printing (and optionally print it)

Have you

- linked to the group assignment page ✓

- Explained what you learned from testing the 3D printers✓

- Documented how you designed and made your object and explained why it could not be easily made subtractively✓

- Documented how you scanned and prepared an object (for 3D printing) ✓

- Included your original design files for 3D printing (both CAD and common format for 3D printing)✓

- Included your hero shots ✓

Group Assignment

Here is the link to the group assigment page.

Testing 3D Printers

In Fab lab ZOI there are two 3D Fused Filament Fabrication (FFF) printers the Ultimaker 2 and the Prusa i3, both have similar characteristics but the parameters to print in each one searching the best quality differs. There is also an Stratasys printer we didn't use this time.

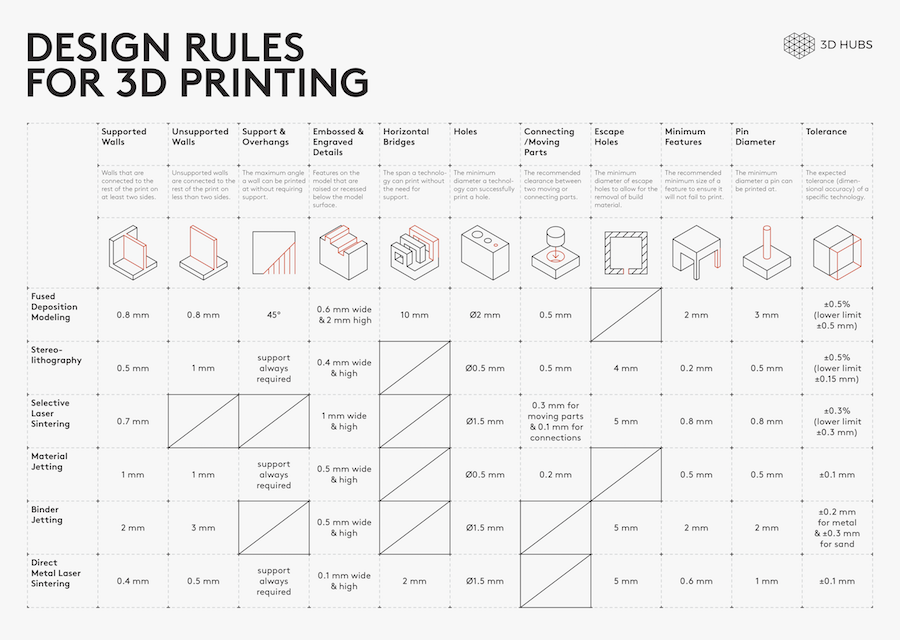

The group assigment consist in test the design rules for the printer(s) so we print an "all in one" model to test the Design Rules for 3D printing.

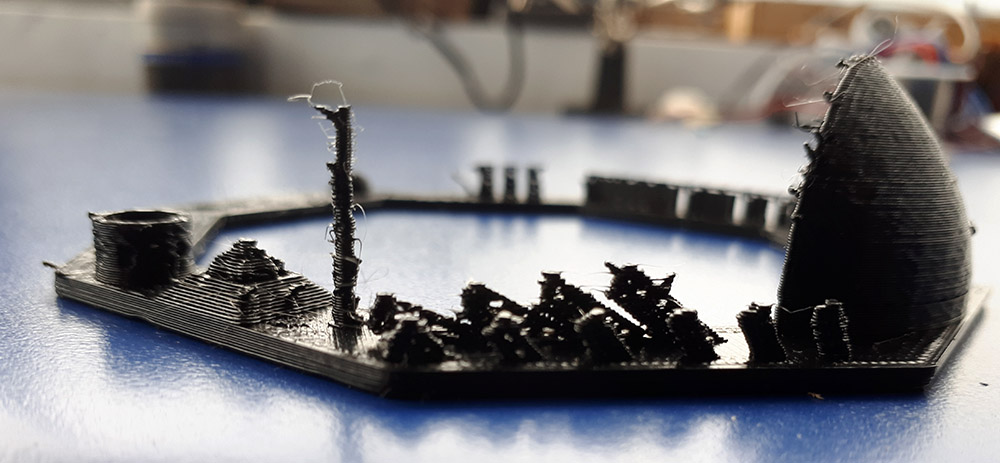

Unfortunately as this test print at the same time with another piece, the supports were active as you can see in the image above. This test are not usefull for example to evaluate overhangs, bridges or minimum features so we watch this in another test.

It's really important that you understand which restrictions the model you want to print have and of course the same with the printer you will use that's the reason this test are important.

If you have resolve this restrictions but have problems in your model you have to analize the parameter on your printing and for that work Diego again have useful informtaion in this link.

Design and 3D print an object that could not be made

Subtractively.

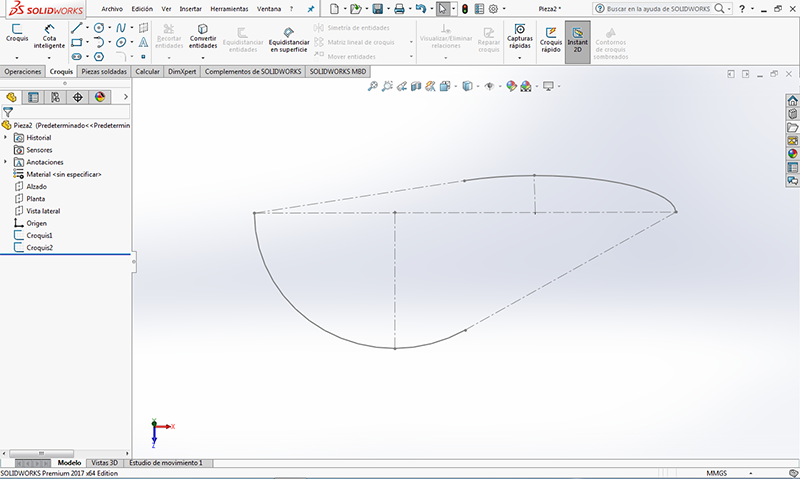

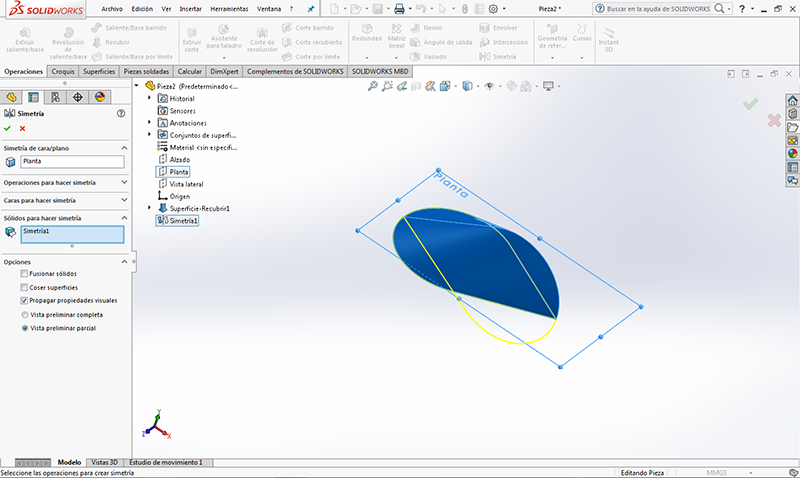

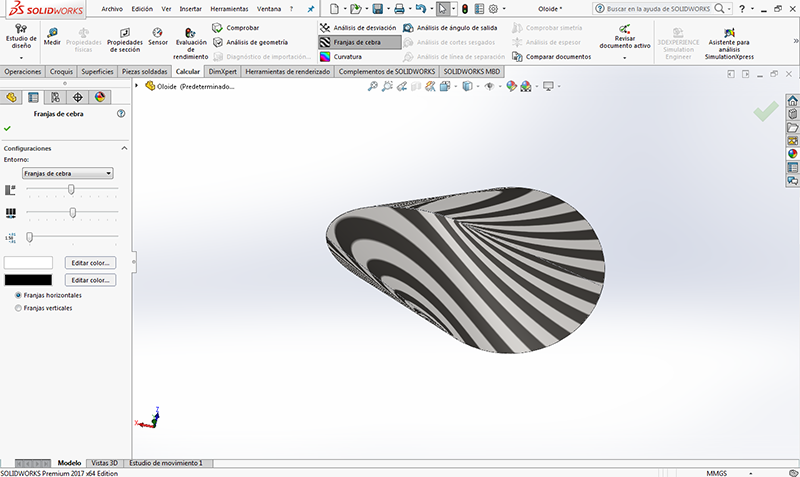

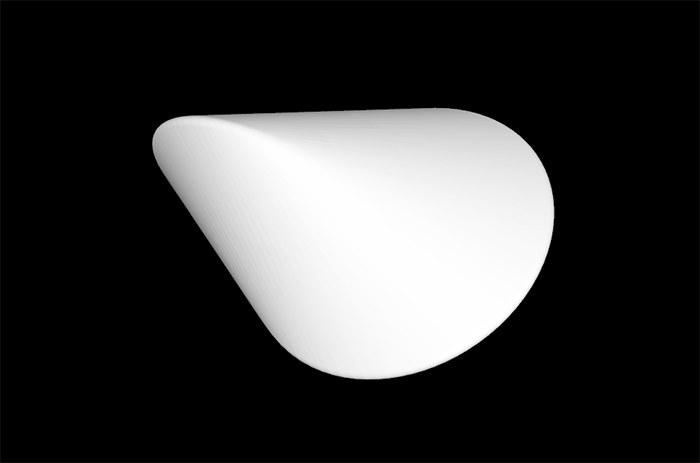

First I was thinking in doing something can move as a hinge but I kwew there are a lot more options so while I was searchi for ideas suddenly I remembrer some years ago I warched a video of 3D printed rolling objects so I start looking for that and try to find that video again, i din't but I find the objects I saw that time this objects are called "Solids of Constant Width." I did an Oloid wich is a three-dimensional curved geometric object. I did it using SolidWorks.

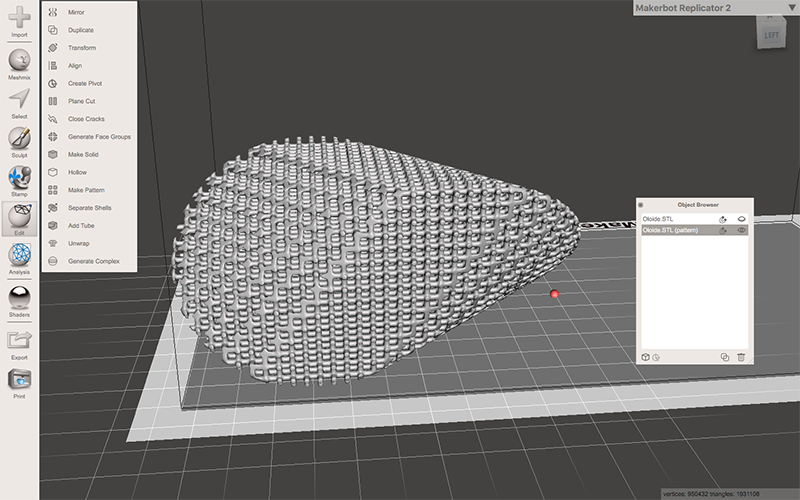

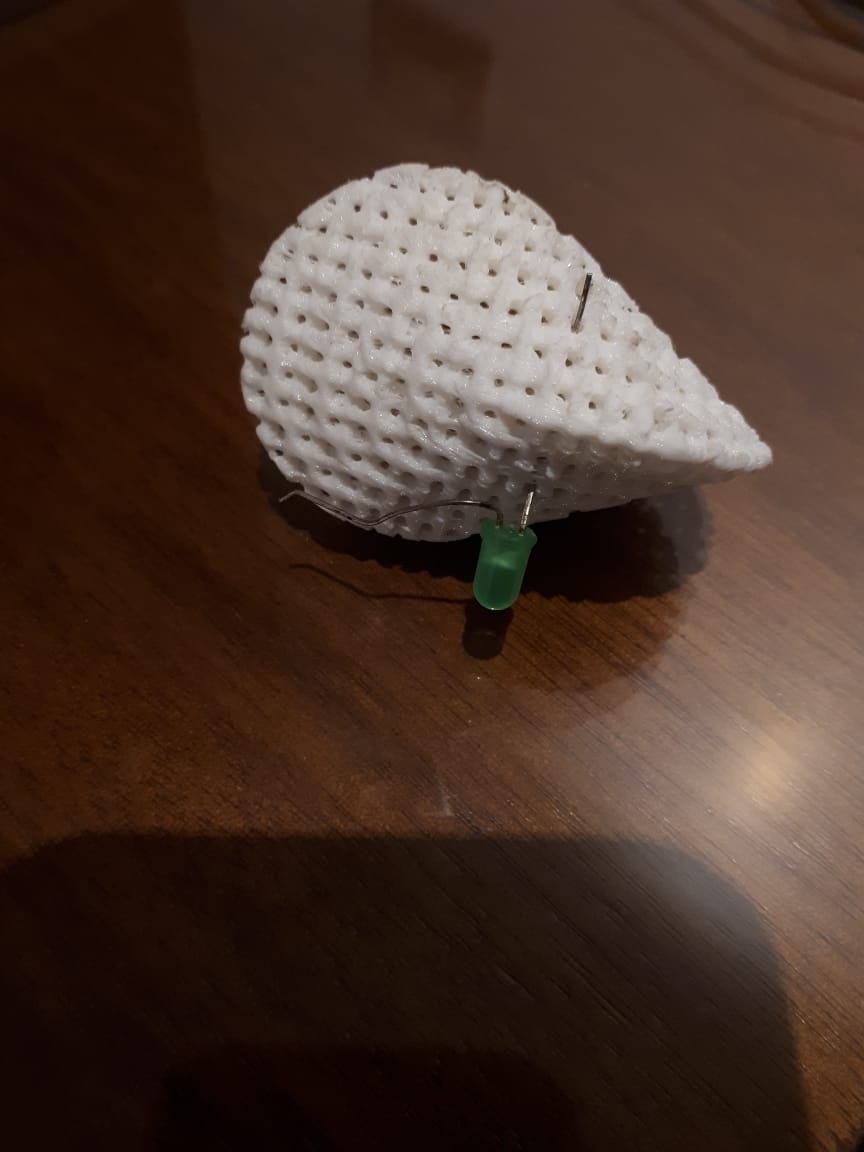

Then I modify the .STL archive in Meshmixer to make a a grid on the design so it will be a unique Oloid. It is an small one with just 60mm width and 40mm height and the grid spacing it's just 2mm in the design.

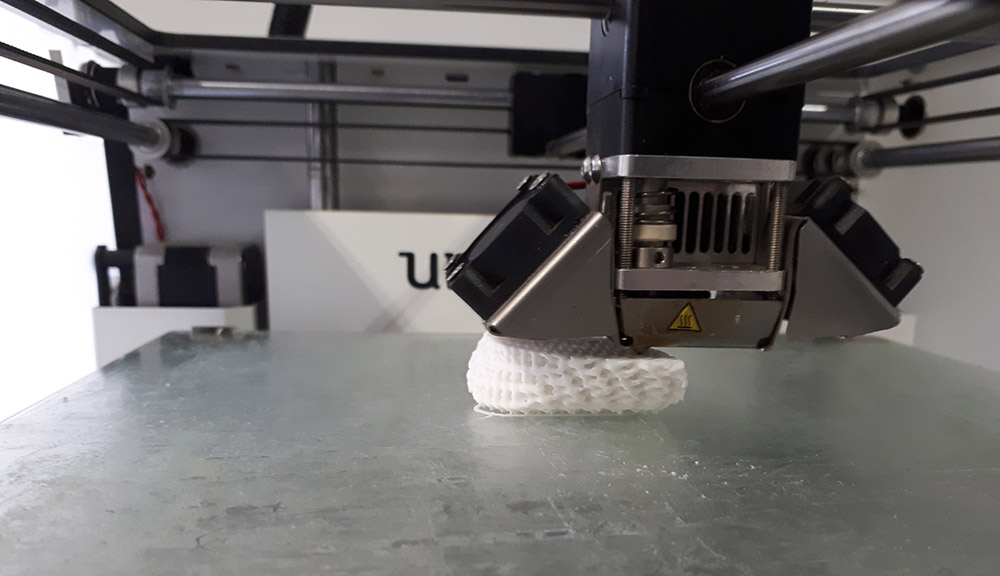

Printing the design using the Ultimaker

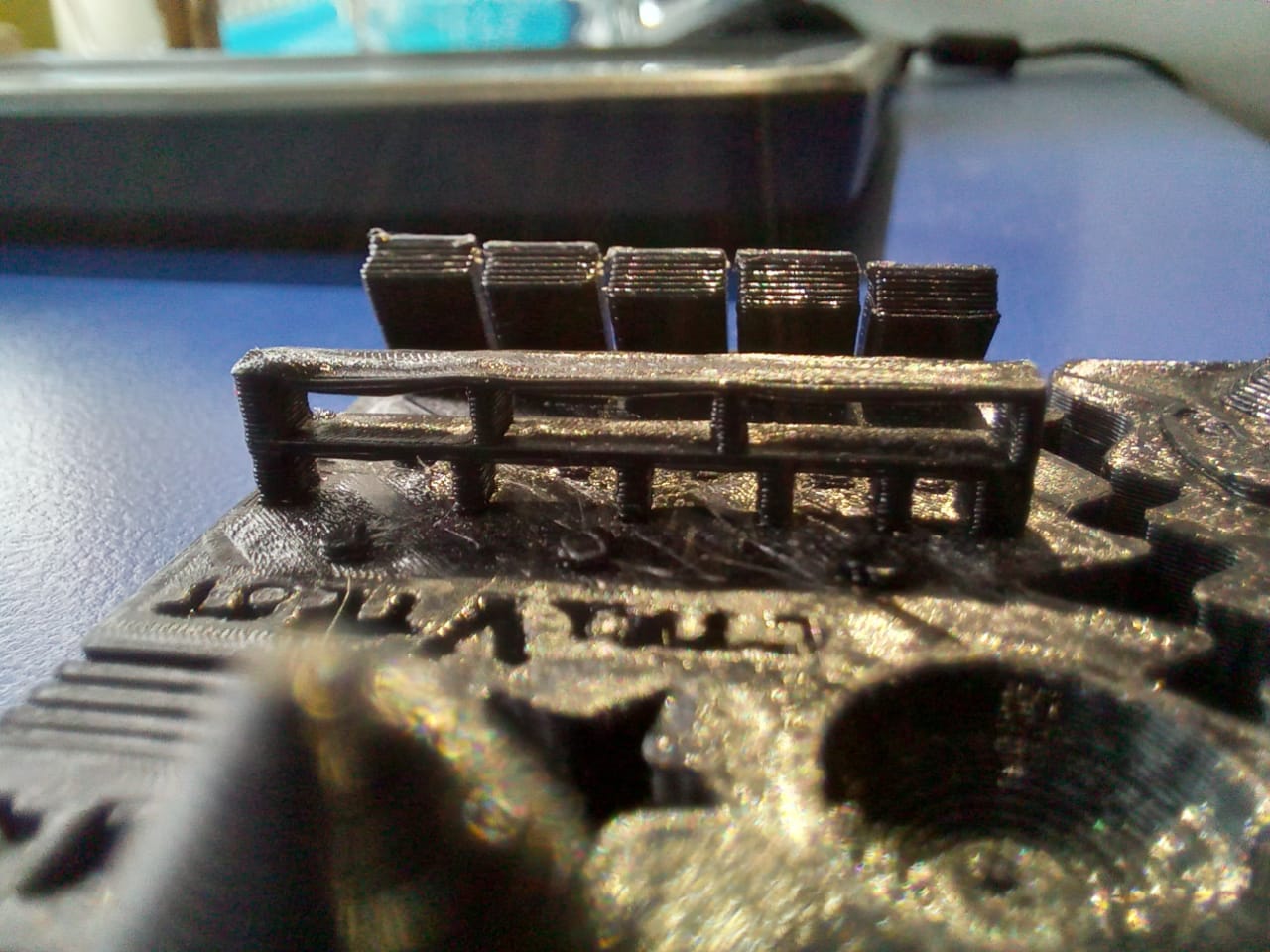

As this design have a lot of overhangs and bridges I was worried about the result of the print but also felt quite secure it will go okay. The more important thing was no use of supports to remain the grid and also a clean finish in the outside.

It looked really good during the process but I was not sure if the grid remains as a grid or the tiny holes are not holes anymore... After the printing another concern I

was about the "funcinality" because it suppose to roll but a center of gravity imbalance could ruin it and also the surface imperfections.

At the end the result it's better than I thought, at least at the first try. And it rolls very well. Also Y really wanted to know if the grid still being a grid bit the holes are just 1mm so I try to go though the holes with an LED as you can see.

Scanning

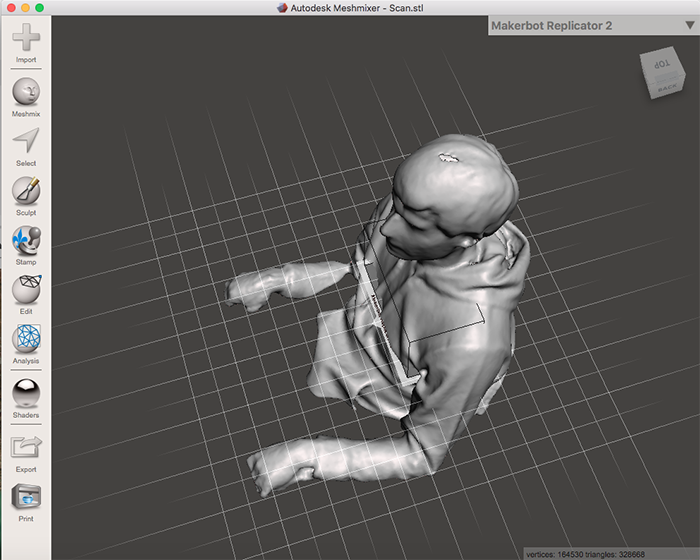

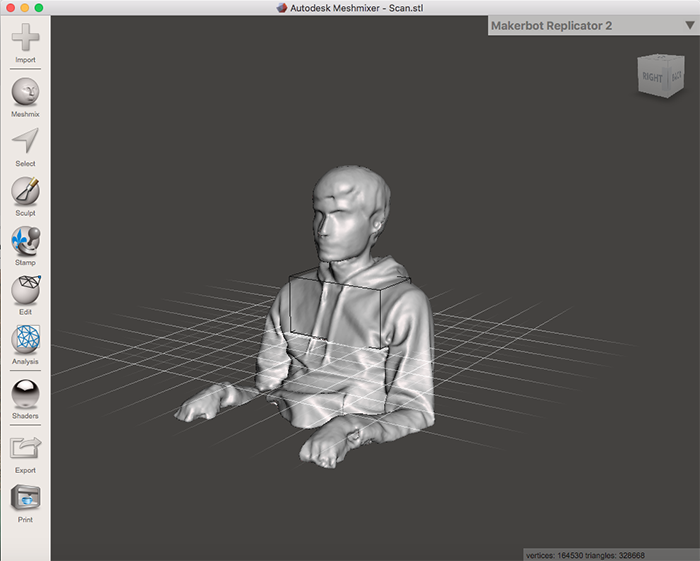

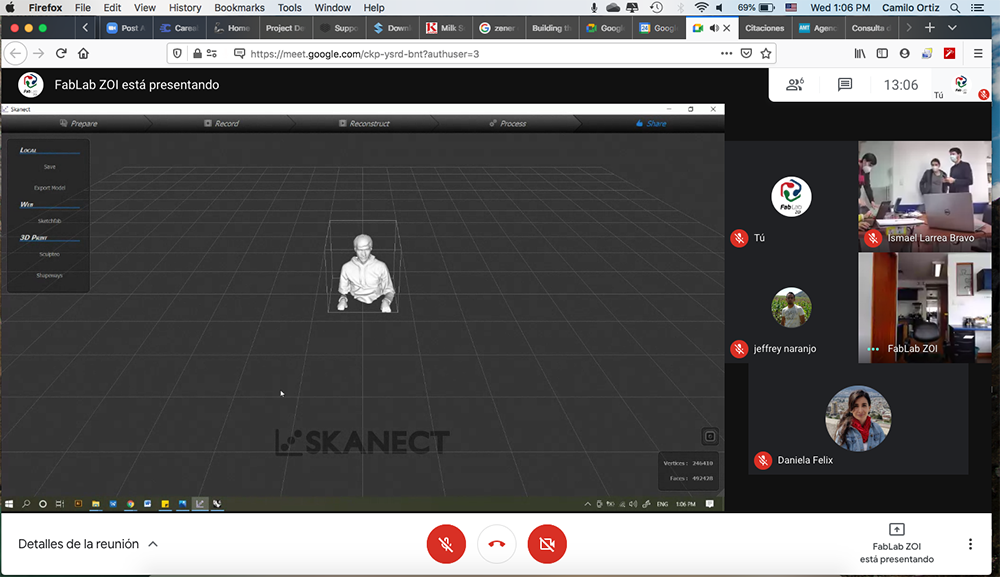

We scan ourselves using KINECT scanner and SKANECT to process the scanned to an .obj archive.

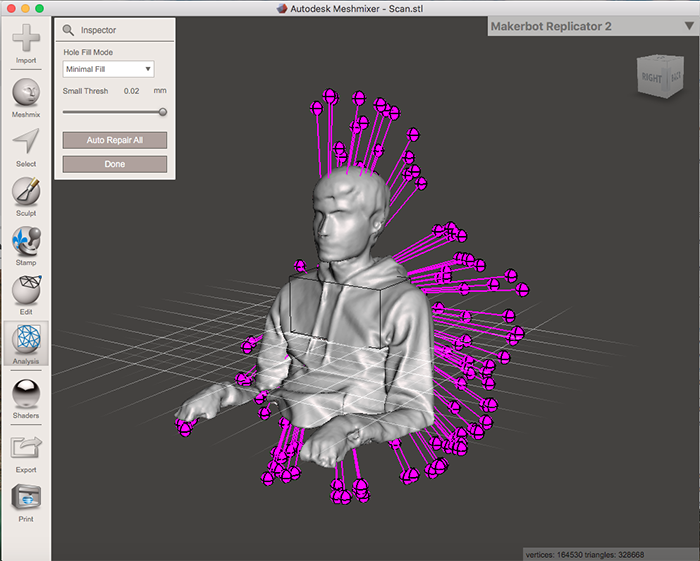

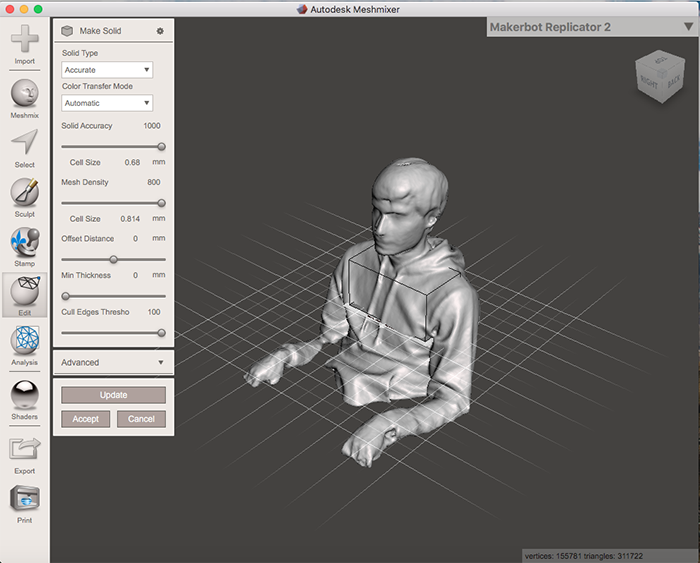

As I use Meshmixer to do the grid of the Oloid I wanted to try if its capable to repair the holes of the object scanned. First I open the .obj in Rhino and export it as .stl to open it in Meshmixer, the try to repair but this didn't work, I try to repair the STL file and also "make solid" but any option worked. In conclution if you need to repair holes or something similar in your file do it using a modeling software to do it right.