Week 03. Computer-Controlled Cutting

Group assignment

- Characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

- document your work (individually or in group)

Individual assignments

- Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf.

- Cut something on the vinylcutter

Have you

- linked to the group assignment page ✓

- Explained how you parametrically designed your files✓

- Documented how you made your press-fit kit ✓

- Documented how you made your vinyl cutting ✓

- Included your original design files ✓

- Included your hero shots ✓

Group Assignment

Here is the link to the group assigment page.

Laser Cutting

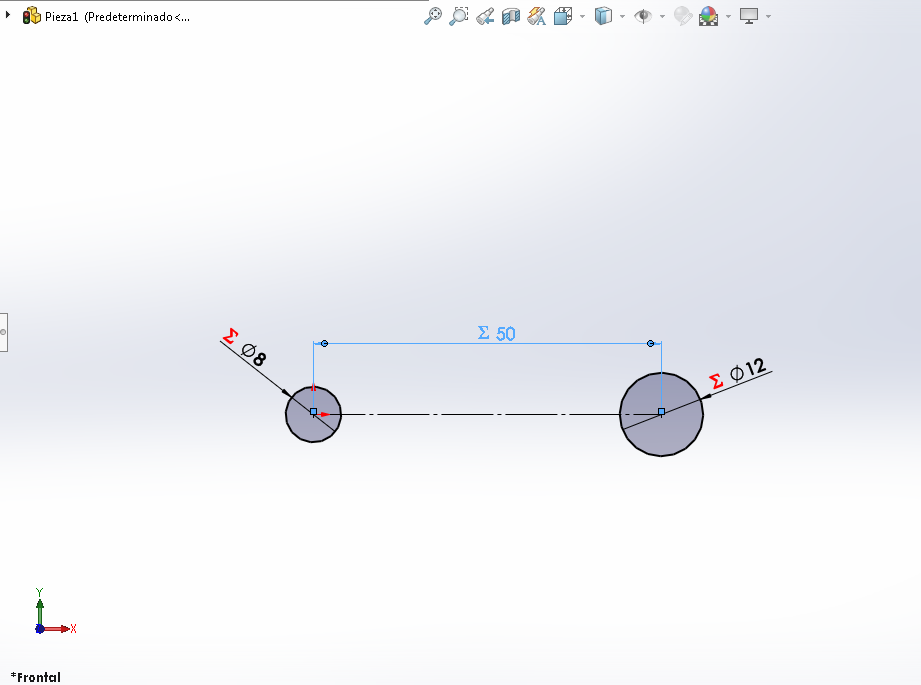

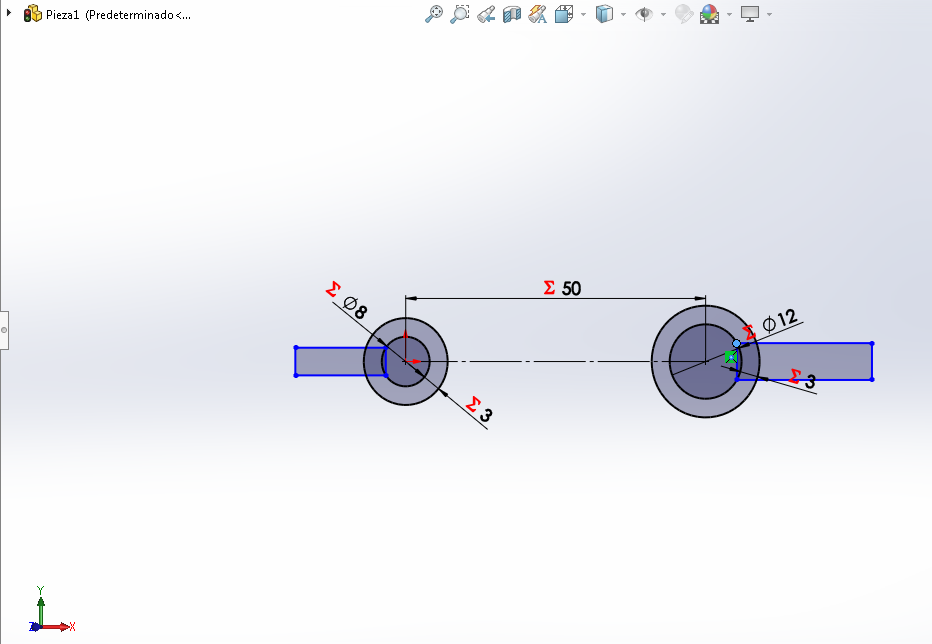

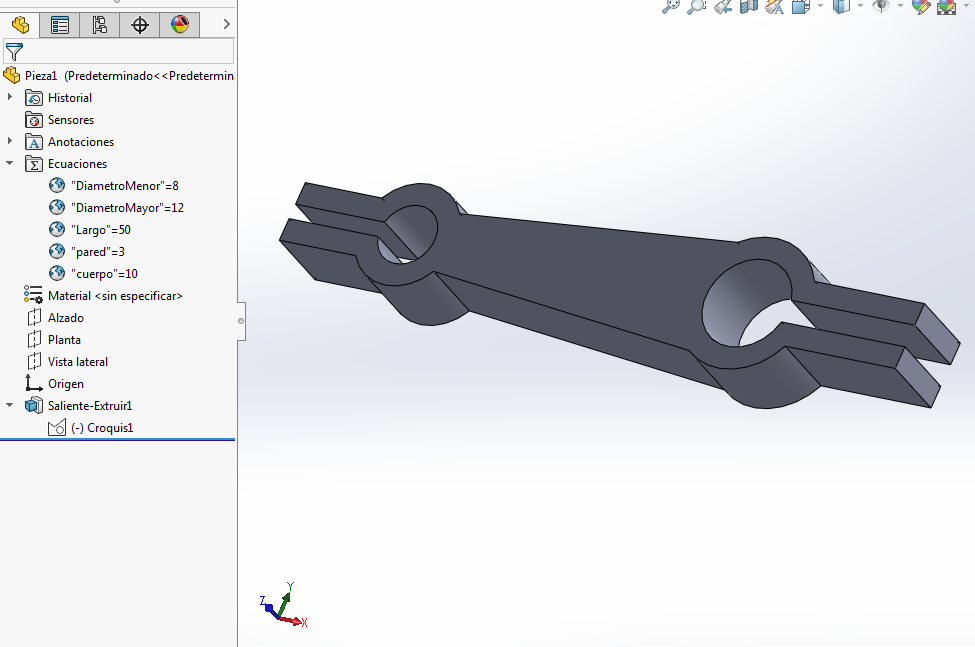

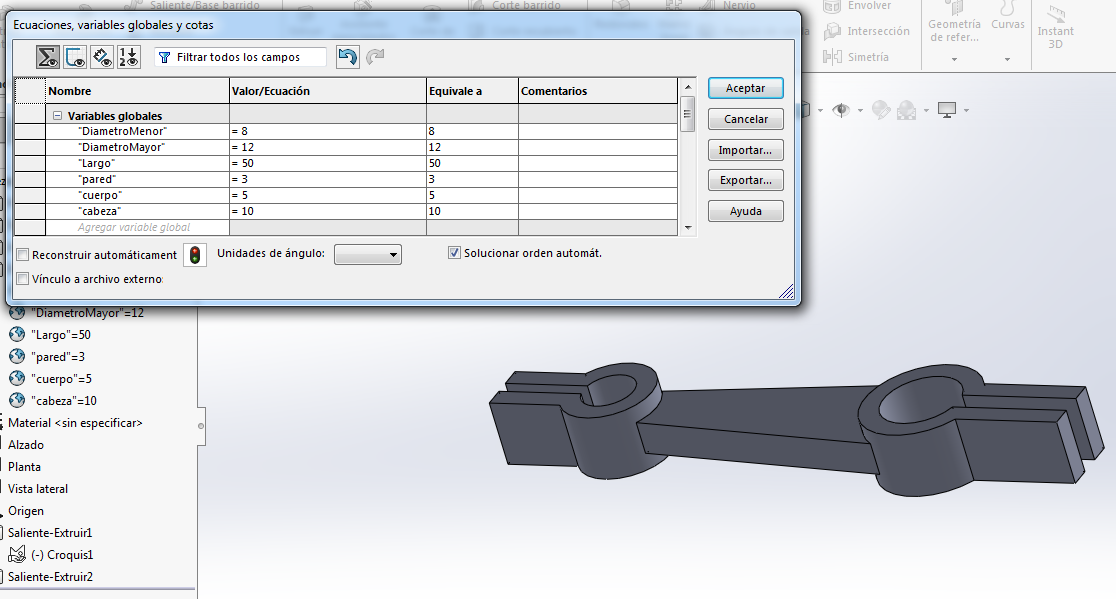

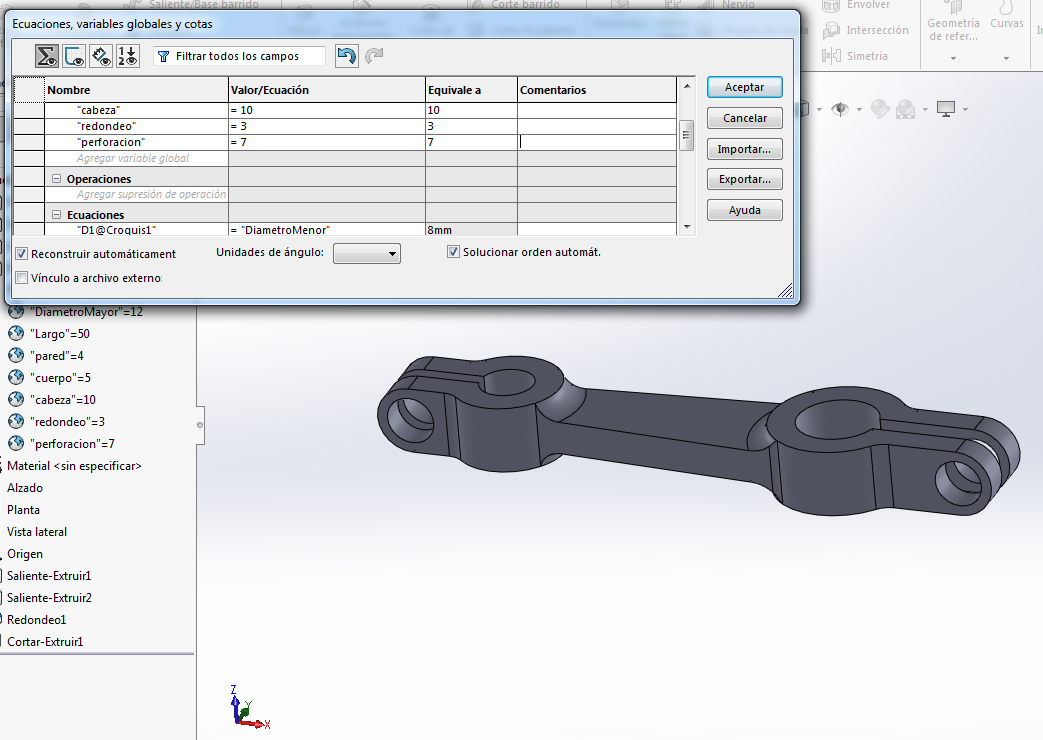

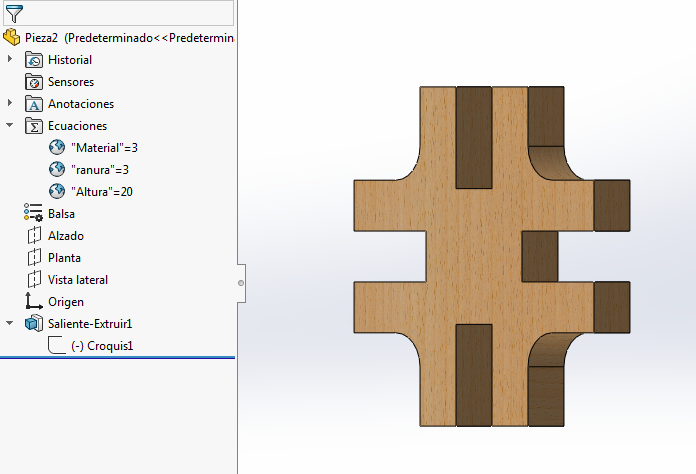

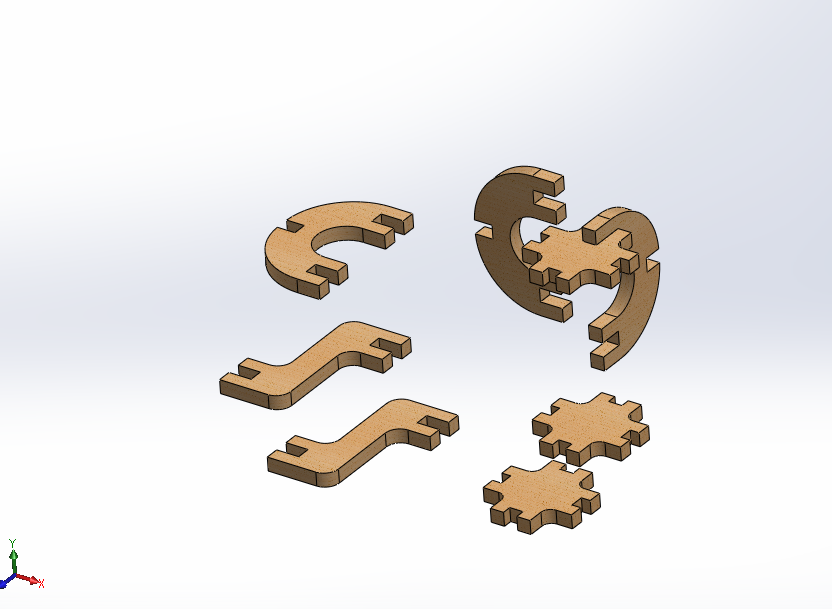

For parametric design I used SolidWorks and I watched this video tutorial to practice the skills needed before to try at my own. The results of this practice are shown in the images below.

After that I review on internet some shapes trying to have some ideas to make the pieces of the puzzle. I din't found anything inspiring so I decided to watched the work of old Fab Academy students, I choose two ramdomly one of them Yeo Gau Siong and the other Cheng Pan. I really like their work on this assigment and open my mind so I wondered some shapes.

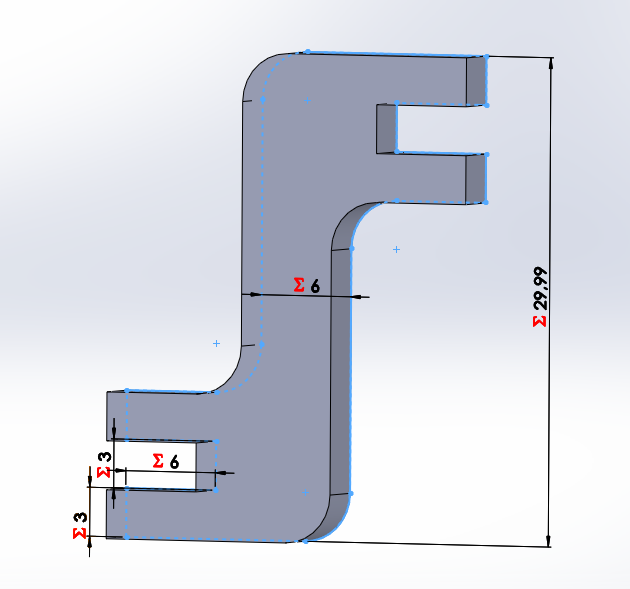

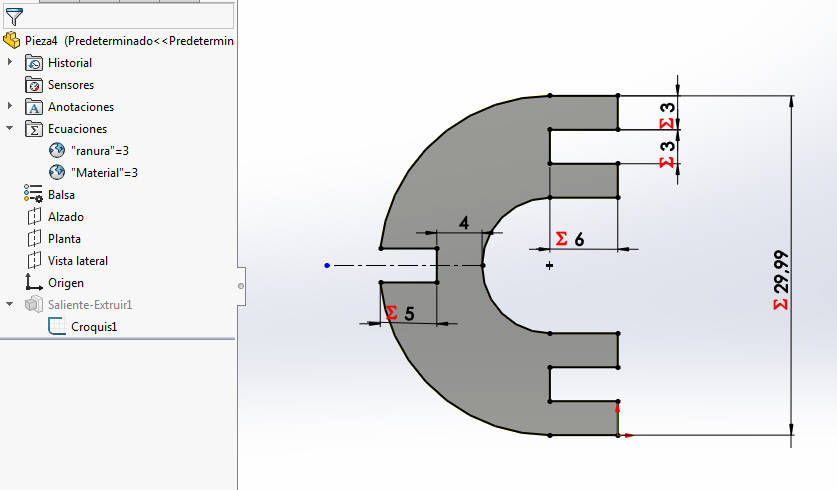

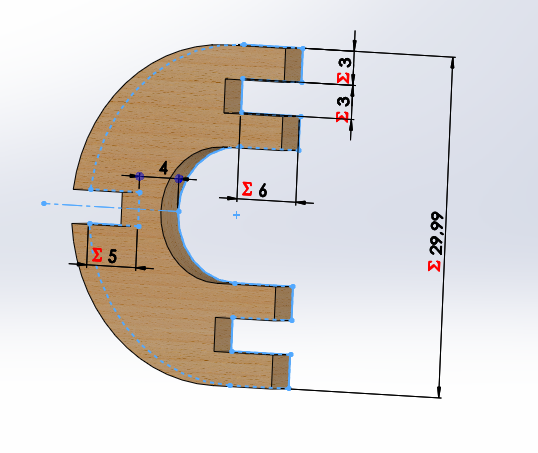

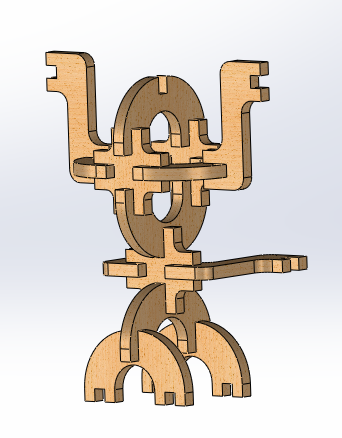

As you can see I put a wood material to give to the pieces a better looking. I decided to do three diferent pieces, the thirth piece is a square shape. Then I did a solidworks assembly to have an idea of how the puzzle will look and propose a shape.

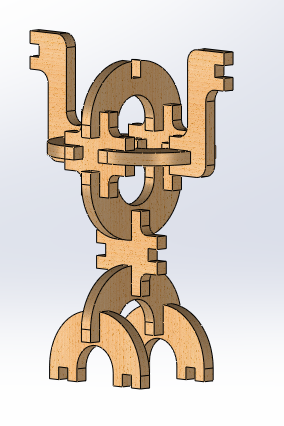

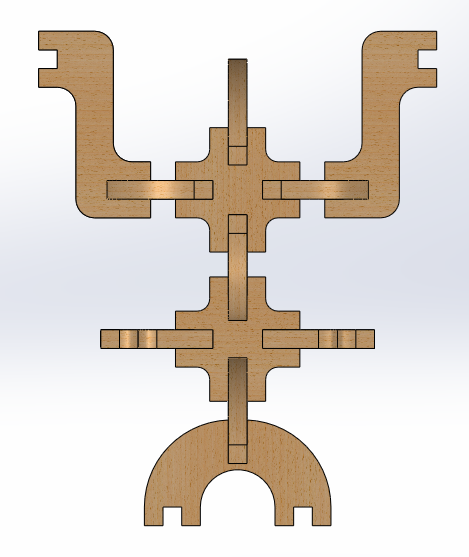

I was thinking in a design that can grow in any direction and also create circular shapes and that was the first intention resulting in a very interesting design wich can be assembly in different ways and also it have an Inca style.

Original Files

Looking for the right parameters

Laser Cutter

The fist thing we did was related with the Group Assigment. In Fab Lab ZOI we used a laser machine made in Ecuador 60x40cm format. The first step to do was measure the material, in this case was 3mm mdf. With this material the kerf was discover by three different tryes until the pieces fit well together.

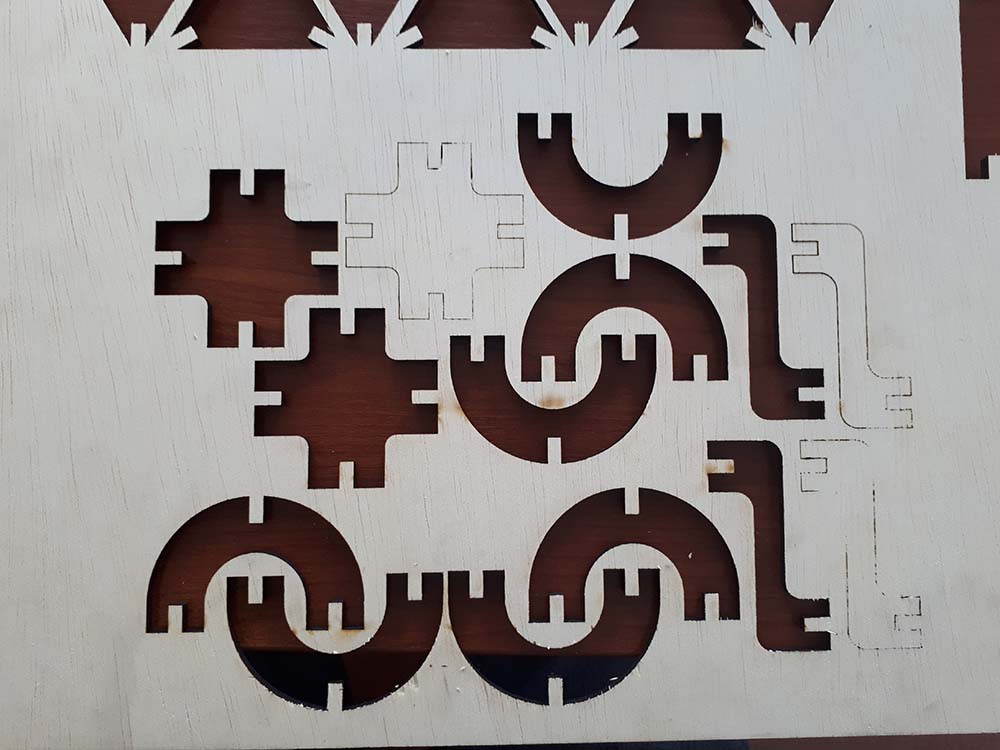

For the cuts of the puzzle pieces Roberto my instructor give us 4mm plywood so the cut parameters were unknown for this material so a few test were needed until the laser cut the material in a way that the piece don't be too burned with a clean cut.

| TRY | MIN POWER (%) | MAX POWER (%) | SPEED (mm/s) | COMMENTS |

|---|---|---|---|---|

| 1 | 65 | 65 | 6 | Laser it's burning the plywood |

| 2 | 55 | 55 | 6 | Borders still burned |

| 3 | 45 | 45 | 6 | It still burning the plywood |

| 4 | 35 | 35 | 15 | This looks good but as the plywood is not straight the laser dind't cut enough in some places. |

| 5 | 40 | 40 | 13 | With these parameters the cut was clean and not too burned. |

The images below are the final cuts with the clean cuts.

Then I did the SolidWorks assembly that I proposed and also another option, there are a lot of possibilities to play with this puzzle.

Vynil Cut

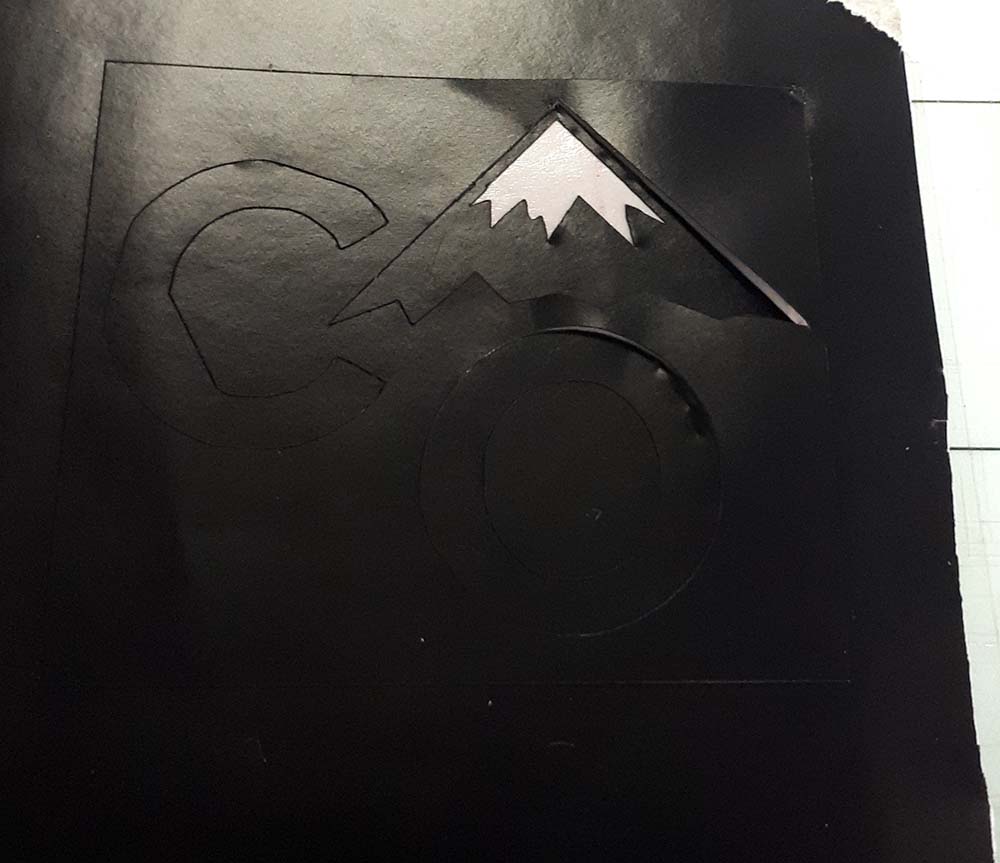

I use a free web page to create a logo, it was really easy to use and usefull, the name is Free Logo Maker. With the logo designed I used INKSCAPE to vectorize the .png logo it was easy to do and I folow this video to know how to use INKSCAPE. Until this point everything okay.

When I import the .svg file to .dxf file to let the Software of the Silhouette Cameo read the file and create the cuts, the import was not succesfull in the sense that the design has some errors even though this one was so simple. This problem doesn't happen with my Fab Academy colleagues, they use Illustrator. The image below are the original desing vs. the one cut.

The parameters used to cut this designs where:

- Blade: #3

- Speed: 6

- Preassure: 3

- Number of passes: 1

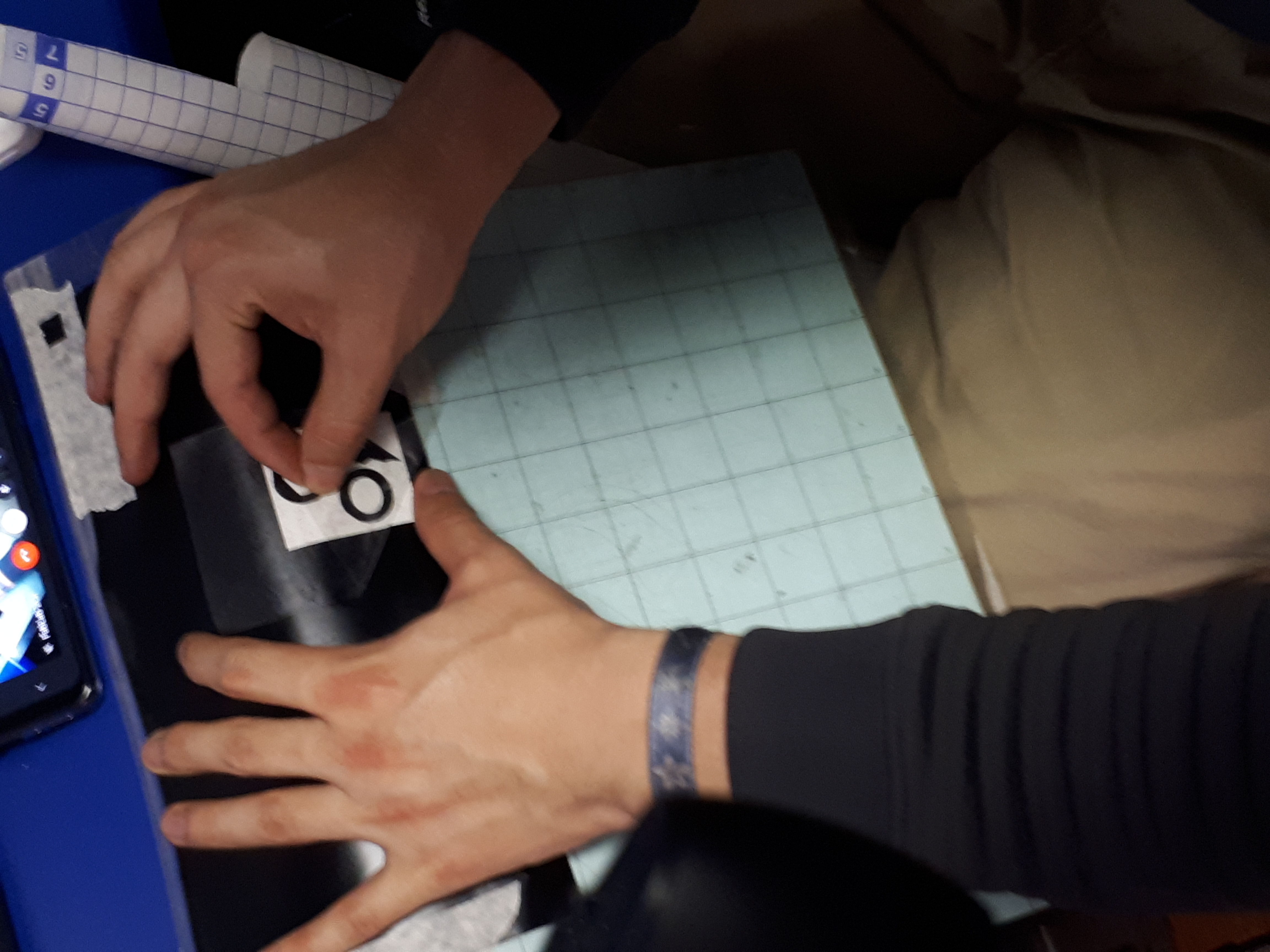

Now some images from the process to cut and paste the designs.

Original Files

I think the problems using diferent software and formats are always there so it's important to know how to avoid them to save time and have a great work done. If we can't avoid the problems at lest we have to learn how to solve them, so in this case I didn't found the solution using Inkscape but there were no problems using Illustrator.