GROUP ASSIGNMENT

REVIEW THE SAFETY DATA SHEETS FOR EACH OF YOUR MOLDING AND CASTING MATERIALS, THEN MAKE AND COMPARE TEST CASTS WITH EACH OF THEM.

In this week we have study about the Safety tools for the moldeing and Casting,

in our Lab there are different types of materials but we have choose two materails for the Molding we select The MOLDMAX-60,

and for the Casting we selct SMOOTH CAST-305.

Molding Material MOLD MAX-60:

Picture of box and bottle of MOLD MAX 60

Product/Chemical name: MOLD MAX 60 PART A:

Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

Remove source(s) of contamination and move victim to fresh air.

Flush eyes with plenty of water. If irritation persists, seek medical attention.

In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

Do not induce vomiting unless instructed by a physician. Contact physician immediately

300 °F

Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

Store in cool dry, well-ventilated area

Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Product/Chemical Name: Mold Max 60 Part B:

* Hazards Identification

- Harmful if swallowed.

- Irritating to eyes, respiratory system and skin.

- Harmful to aquatic organisms may cause long term adverse effects in the aquatic environment.

* Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

* Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

* Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

* Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

* After first aid, get appropriate in-plant, paramedic, or community medical support.

* Flash Point - 150 °F

* Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

* Storage Requirements - Store in cool dry, well-ventilated area

* Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

* Toxicological Information:

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Smooth-Cast 300 Series Safety DataSheet Review:

picture of Smooth-Cast 305

Product/Chemical Name: Smooth-Cast 305 part A

* Hazards Identification

*Harmful by inhalation.

* Irritating to eyes, respiratory system and skin.

* Limited evidence of a carcinogenic effect

* Harmful; danger of serious damage to health by prolonged exposure through inhalation environment.

* Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

* Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

* Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

* >Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

* After first aid, get appropriate in-plant, paramedic, or community medical support.

* Flash Point - 262 °F

* Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

* Storage Requirements - Store in cool dry, well-ventilated area

* Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

* Toxicological Information:

* Hazardous Component: 4,4’ Methylene, bis(phenylisocyanate)

Product/Chemical Name: Smooth-Cast 305 Part B:

* Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

* Inhalation - Remove source(s) of contamination and move victim to fresh air.

* Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

* Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

* Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

* After first aid, get appropriate in-plant, paramedic, or community medical support.

* Flash Point - 262 °F

* Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

* Storage Requirements - Store in cool dry, well-ventilated area

* Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

* Toxicological Information:

* Acute Inhalation Effects: None Established

* Acute Oral Effects: None Established

* Reproductive Toxicity: None Established

* Mutagenicity: None Established

* Teratogenicity: None Established

* Sensitization: None Established

INDIVIDUAL ASSIGNMENT

DESIGN A MOLD AROUND THE STOCK AND TOOLING THAT YOU'LL BE USING, MILL IT (ROUGH CUT + (AT LEAST) THREE-AXIS FINISH CUT),AND USE IT TO CAST PARTS THEN MAKE AND COMPARE TEST CASTS WITH EACH OF THEM.

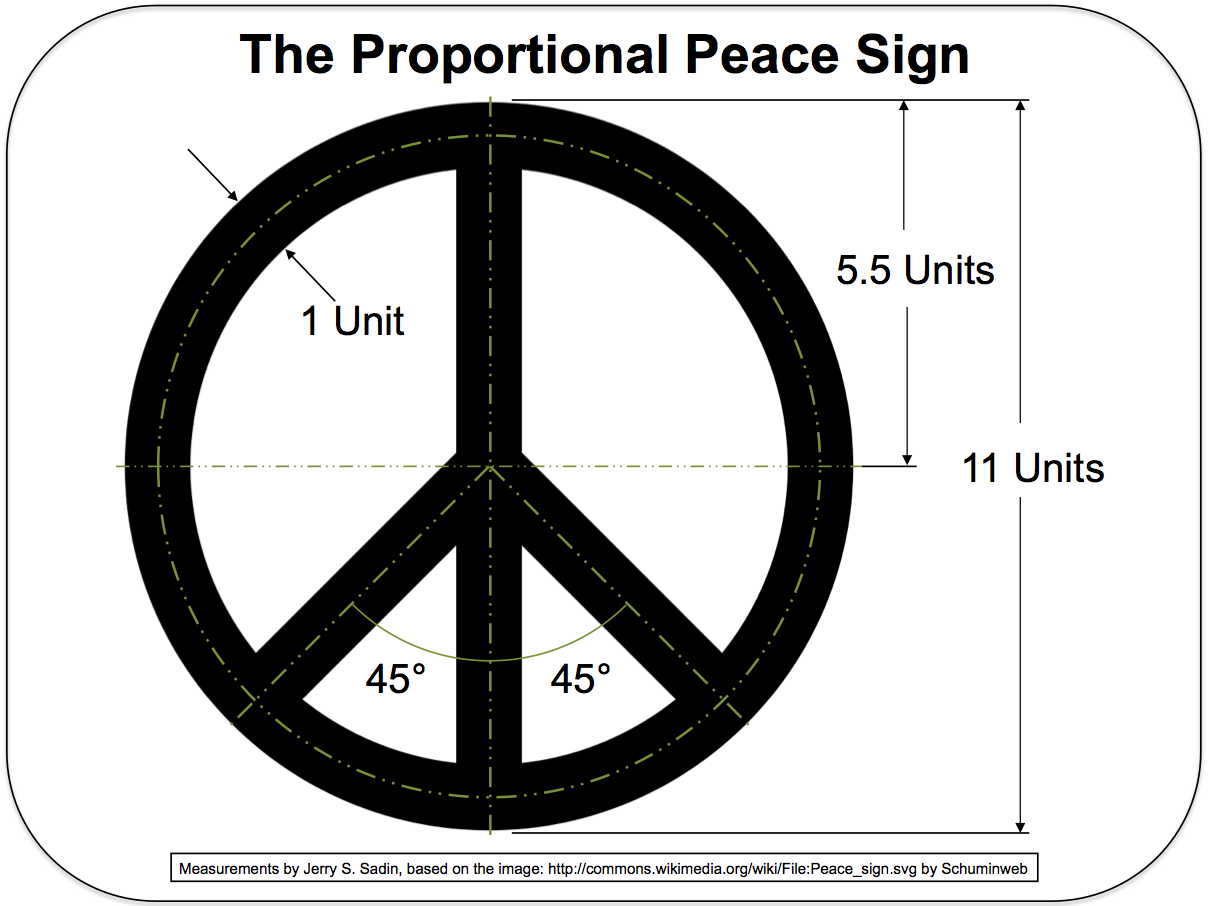

In this week asssignment I want to make the mold of Peace logo in which I will cast both metal and plastic

. First of all I made the design the in the solid work by using the given picture as a reference.

Picture use as a refrence.

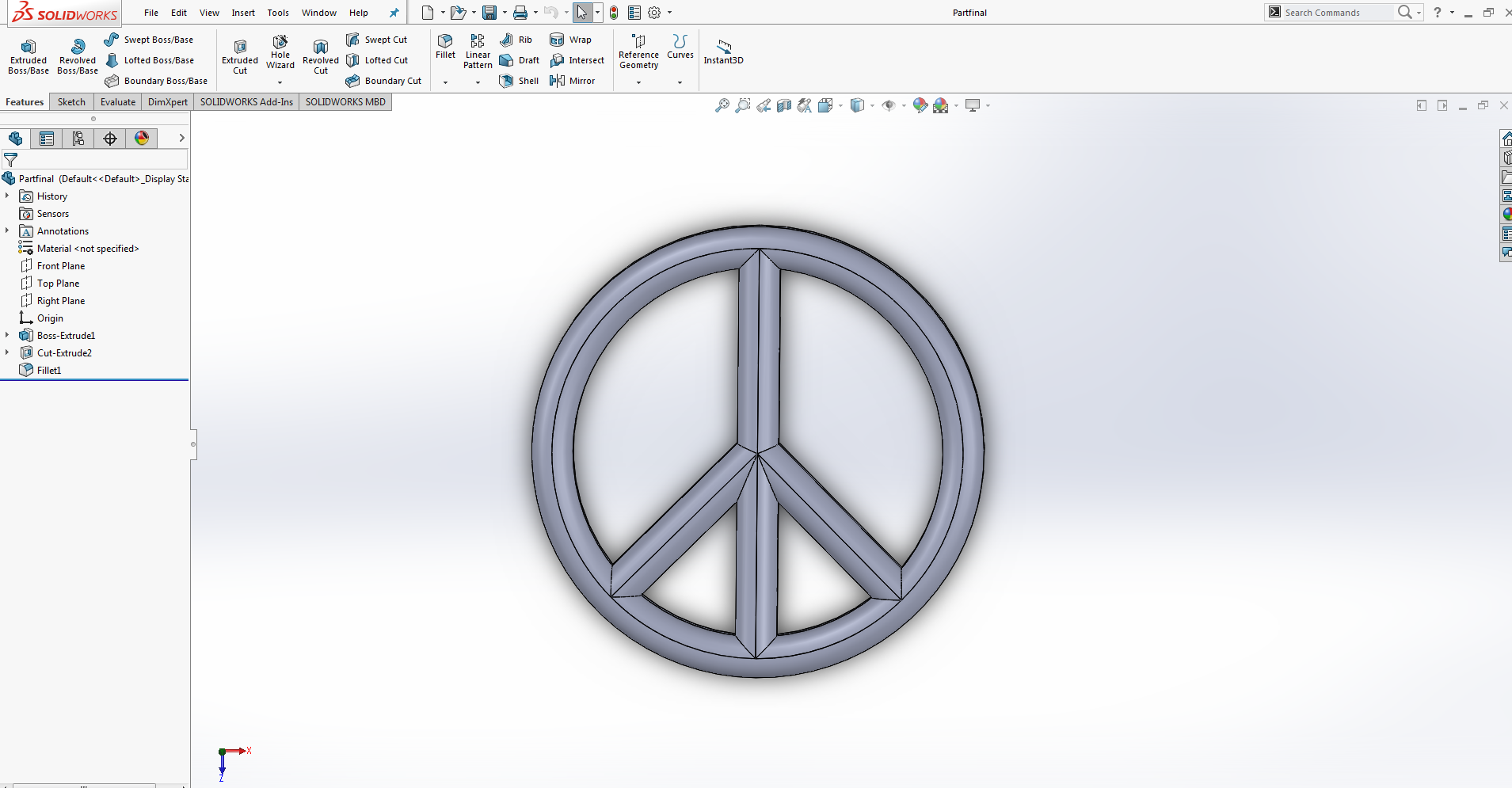

Working on solid work

In solid work i made two different part and then assemble the first part is the logo and the second part is the boundary.In the first part

I use the commands Sketch ,draw a cicrcle extrude dase it and then draw another circle on it.

Making the circle for the logo

After drawing the circle now I draw the lines on the design according to the lines in the refernce picture and then apply the trim

command to have the desire design.

drawing line and applying trim command.

As the lines are according to the required design now I apply extrude cut and fillet commands.

Applying extrude base and fillet commands.

Final design of logo

screen shot of the logo.

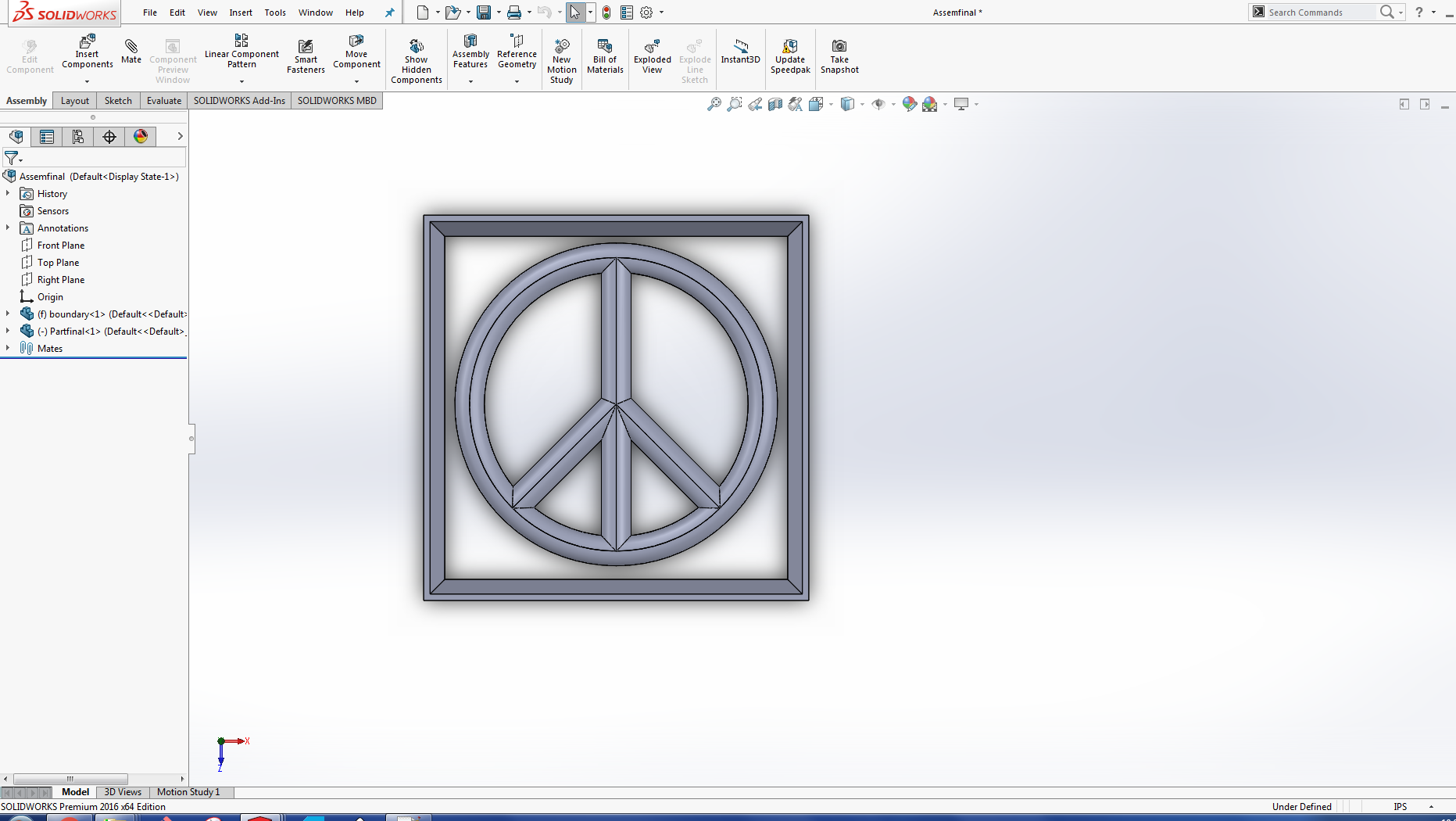

The second part of the design is the boundary for the design For this Use the rectangle and then the extrude command with 45 degree angle and extrude cut command with 18 degree.

designing the boundary.

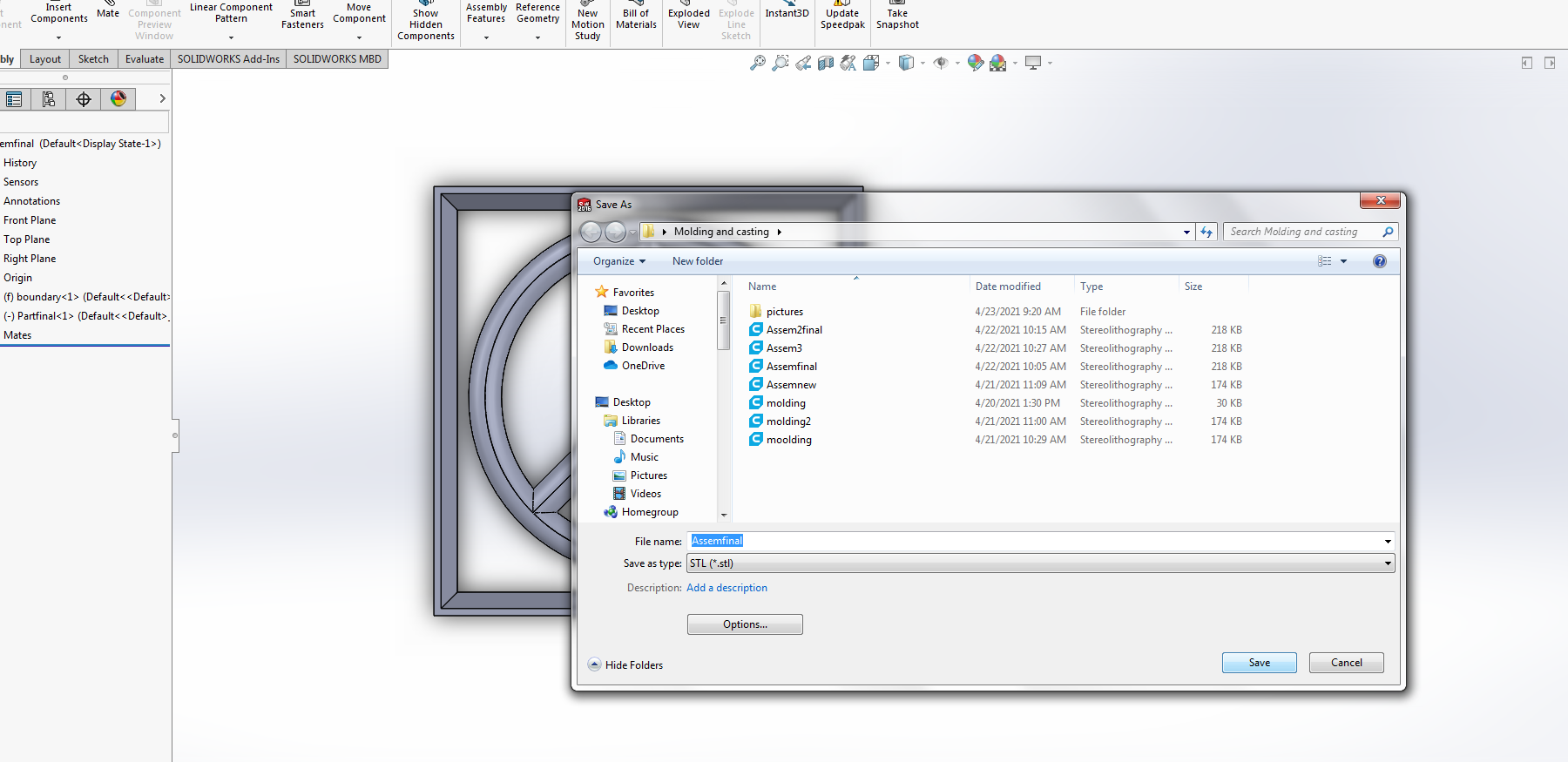

Now at last I assemble the parts and save the file as .stl file

Assembling and saving in stl file.

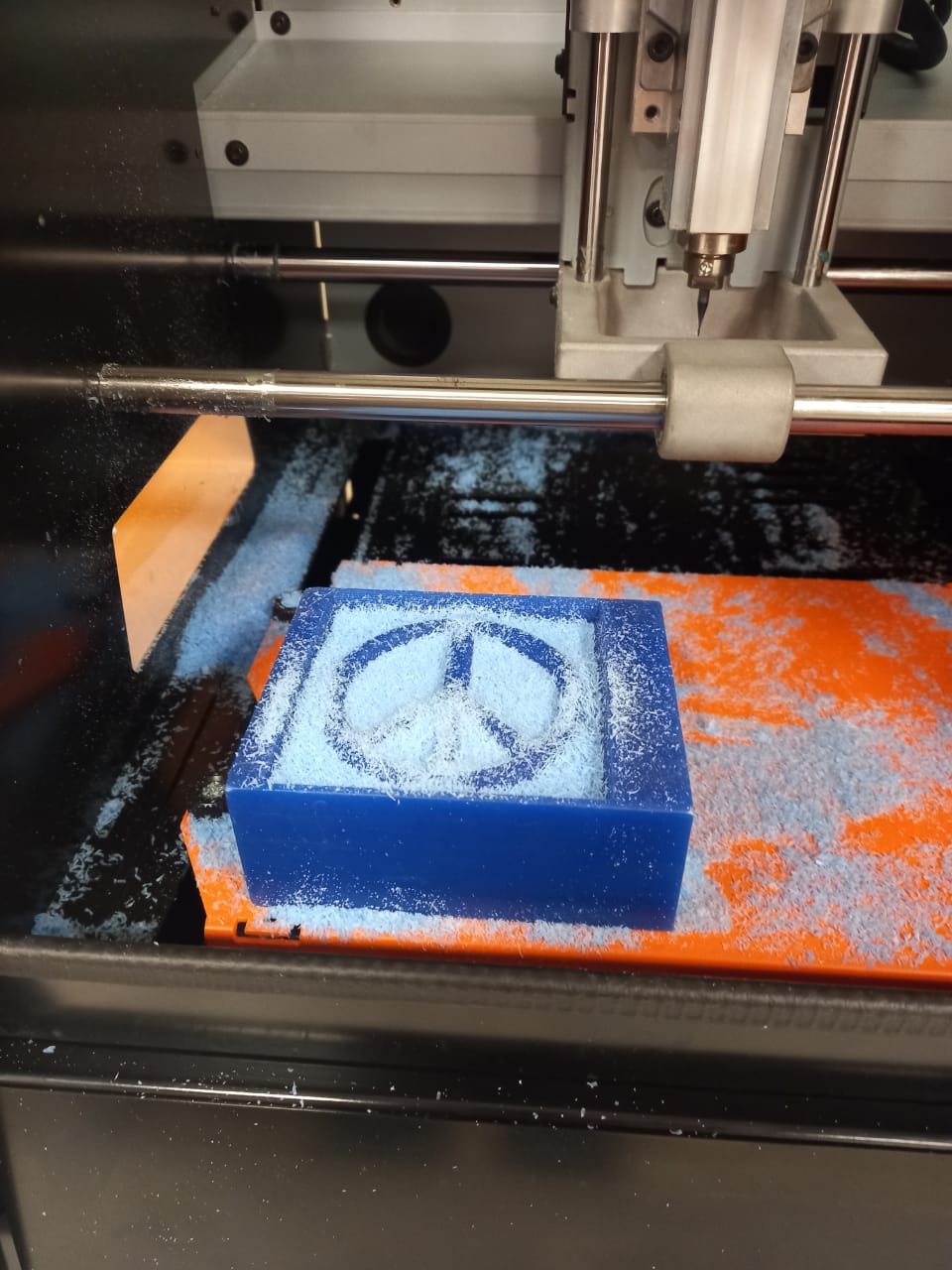

Milling

For milling I am using Rolnad SRM-20 machine and the material to mill is Machinable wax which is used as Rigid Mold here. SRM-20 is worked on .prn format and to generate that I am using MODELA Player 4 a software which came with SRM-20 for making molds.

Process in Modela Player 4

To generate .prn for SRM-20. I followed these steps which I mention below:

* After opening Modela Player 4, click on file and then select machine

selecting machine in MODELA Player 4

* Click on "File> Open" to open .stl file, then click on Solid sphere for Rendering View. Select Material type on right top to Molding Wax

Opening .stl file and setting the view.

* Now I set parameters like origin and boundarie as:

setting the parameters.

* Roughing

As for Milling a wax in Roland SRM-20 there are two tool paths. One is roughing and second is finishing.

We start with Roughing. Select the roughing type. Select the tool width 3mm for roughing.

Set the cutting area by choosing the "Partial" option. Set the "Contour Lines" to Up Cut. Set the " Speed" to 24mm/sec.

Name the process and press the finish button which are as follow.

making the roughing process.

Finishing

After roughing, create tool path for finishing. Repeat the same steps. Only change the tool size to 1mm, scan lines to X+Y and XY speed to 20mm/sec. Which are as under:

making the finishing process.

After Miling and the final result

Final image after milling.

Reason for making the wall around the 3d model tilted

The reason for making the wall tilted for the 3d model is that when ever we cast on it we can remove the negative mold easily without apply any force with may cause to demage the mold and also due to tilted wall the the material we poured in it fill all the side easily. Secondly it improve material distribution. . So for easily and safetly remove of negitive molt and proper material distribution I tilted the wall of the 3d model.

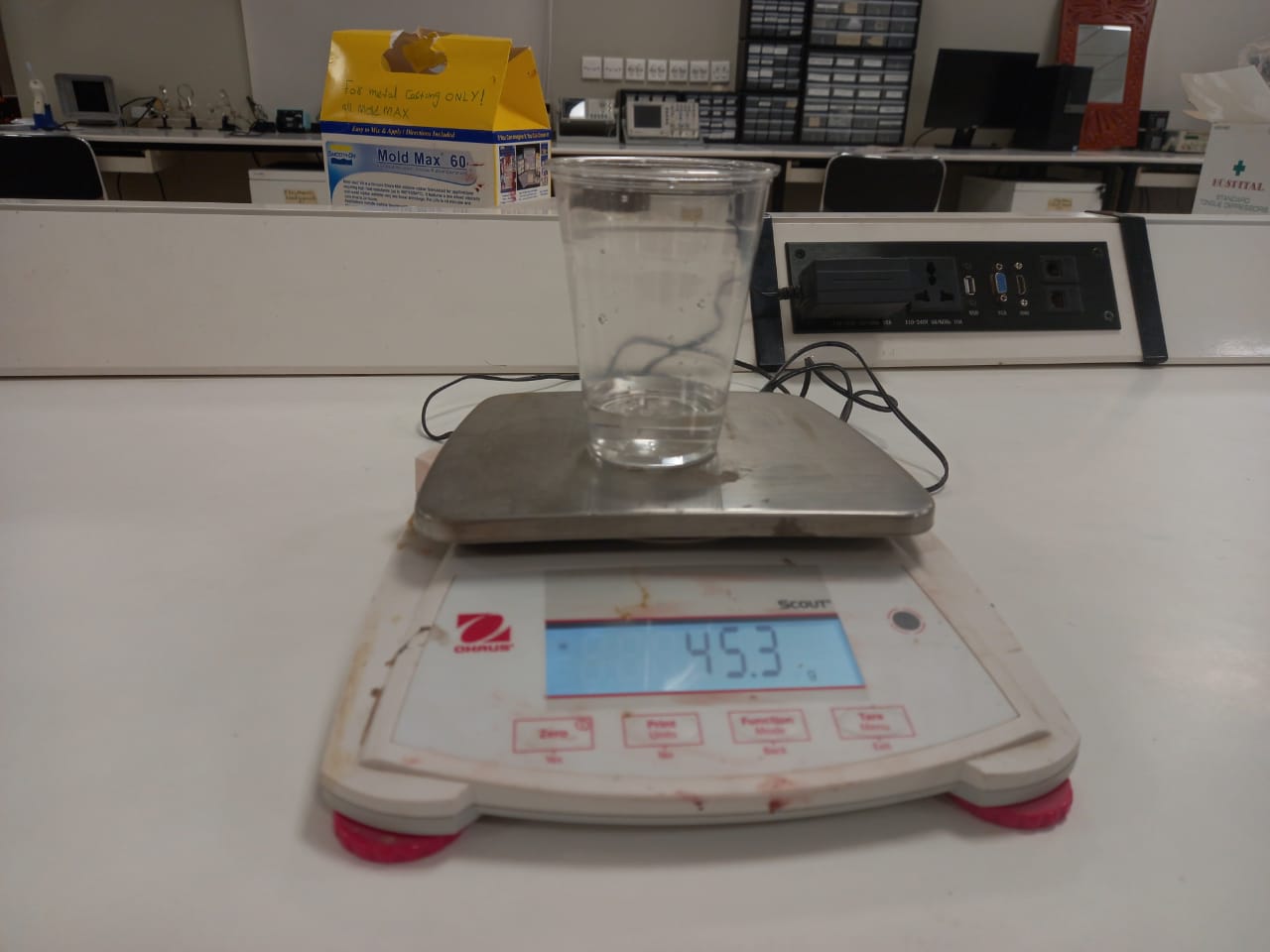

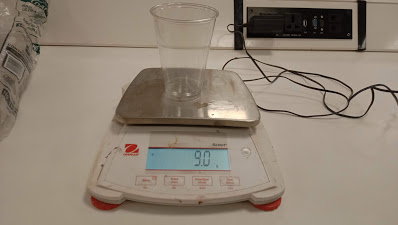

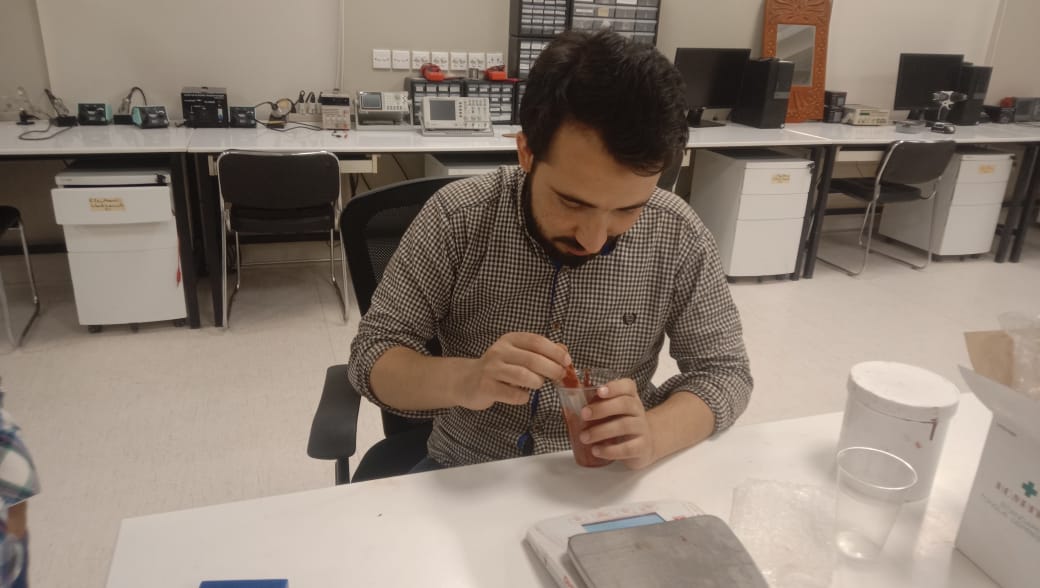

MEASURING THE MATERIAL FOR MOLD

Before making the mold it is necessary to know the exact amount of the material to be used for the mold So for this first I measured

weight of the glass and then the amount of water covered in the mold as:

Measurement for the material.

MAKING FLEXIBLE NEGATIVE MOLD

After making Rigid Mold its time to make flexible mold from it. I am using Mold Max 60 which is used to cast both metal and plastic.

The procedure to make mold is define below:

* Use the material acoording to the measured values.

*Both part A and B are mixed in a ratio which is described in datasheet to get the same gram value measured in water.

Mixing Part A and B.

* After stiring for the 3 to 5 minutes I pour the it into the Hard Mold. And leave it for one day.

After pouring the solution into the hard mold.

* On the next day I take it out from the hard mold. I got the desired result.

The soft mold.

Bubble in Mold

As from the above picture it is shown that there are some bubble in the mold. And I knocked the mold against table surface. This really worked as air bubbles were rising to the surface. As that were not in bulky way that they can effect the result of the mold. My Instructor guide me that the result will good as there are not so many bubble in the mold. We can avoid the bubble in the mold by carefully mixing the material as mixing sometime also caused the bubble to create. After pouring into the mold we can shake to avoid from bubbles. We can also use the vacuum pump remove bubbles.PLASTIC CASTING

For plastic casting we used Smooth-Cast 300. The ratio of part A and B is 1:1.

pouring the plastic casting.

After 10 minutes the results was quite good. It just need little finishing to be perfect.

All process Rigit Mold > Flexible Mold > Cast in one picture.