Week 15

Wildcard week is made for us students to try new fabrication processes and the fun part it can be anything so since I really like working with laser cutter my instructor suggested that I try to make fiber glass pcbs using the laser cutter. As for the assignment :

Individual assignment:

Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it.

Unfortunately, our fiber glass laser machine is not working so I had to go for plastic welding but you can check out where I reached here.

Learning outcomes

- Demonstrate workflows used in the chosen process.

- Apply different technique and methods of plastic welding.

Plastic Welding:

For my wildcard week I decided to learn plastic welding because it is a very useful process especially for fab academy because I can weld 3d printed material together which gives me a huge advantage , also it is going to help me with my final project because I have a lot of 3d printed stuff.

What is plastic welding?

According to SubStech.com Plastics welding is the technique of connecting two pieces of Thermoplastics under pressure and in a heated condition as a result of polymer molecules cross-linking. With or without filler material, the work parts are fused together.

How strong is it?

According to hotairtools.com plastic welding When done correctly (i.e., the region was appropriately prepped in advance), tested, the right welding rod was picked, and a slew of other criteria were double- and triple-checked, plastic welding can have a parent material strength of up to 98%

What are the processes for plastic welding?

Well there are so many processes you can use to do plastic welding such as:

- Laser Welding or Laser Beam Welding (LBW)

- Ultrasonic Welding

- Hot Plate Welding

- Spin Welding

Welding process:

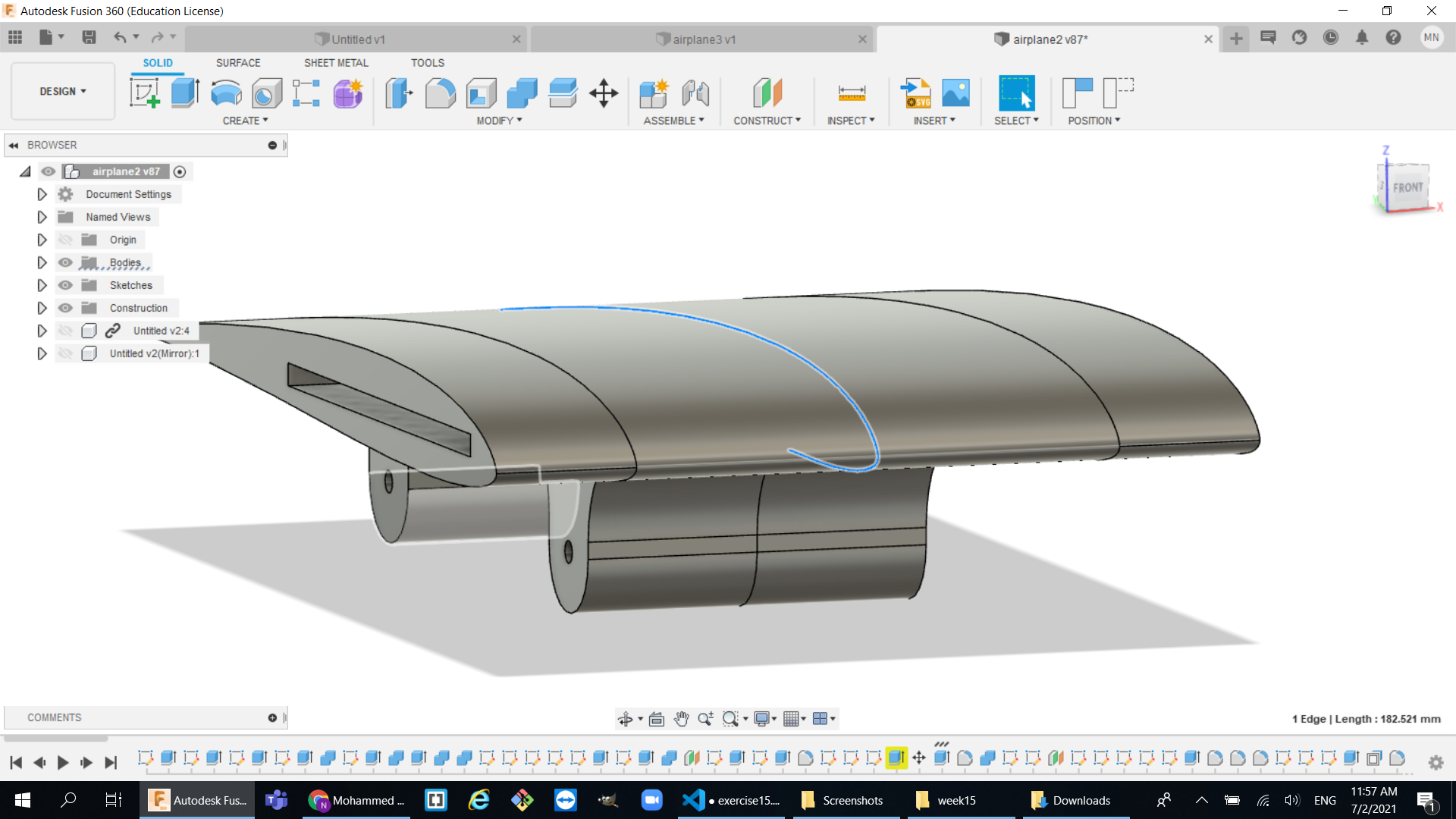

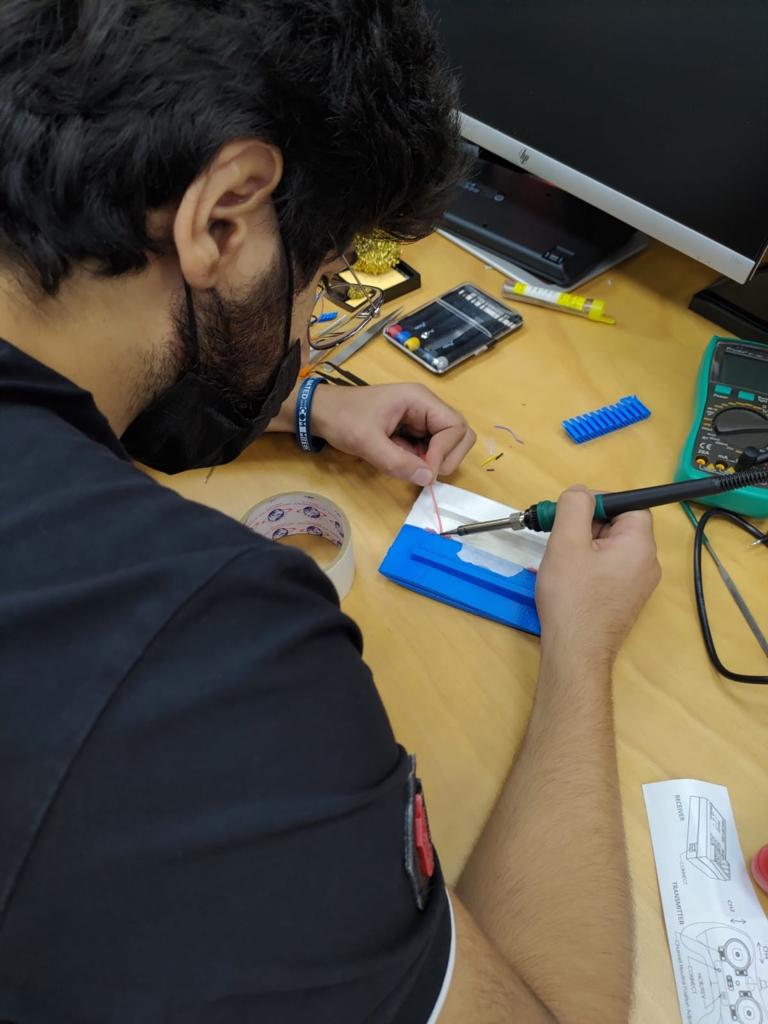

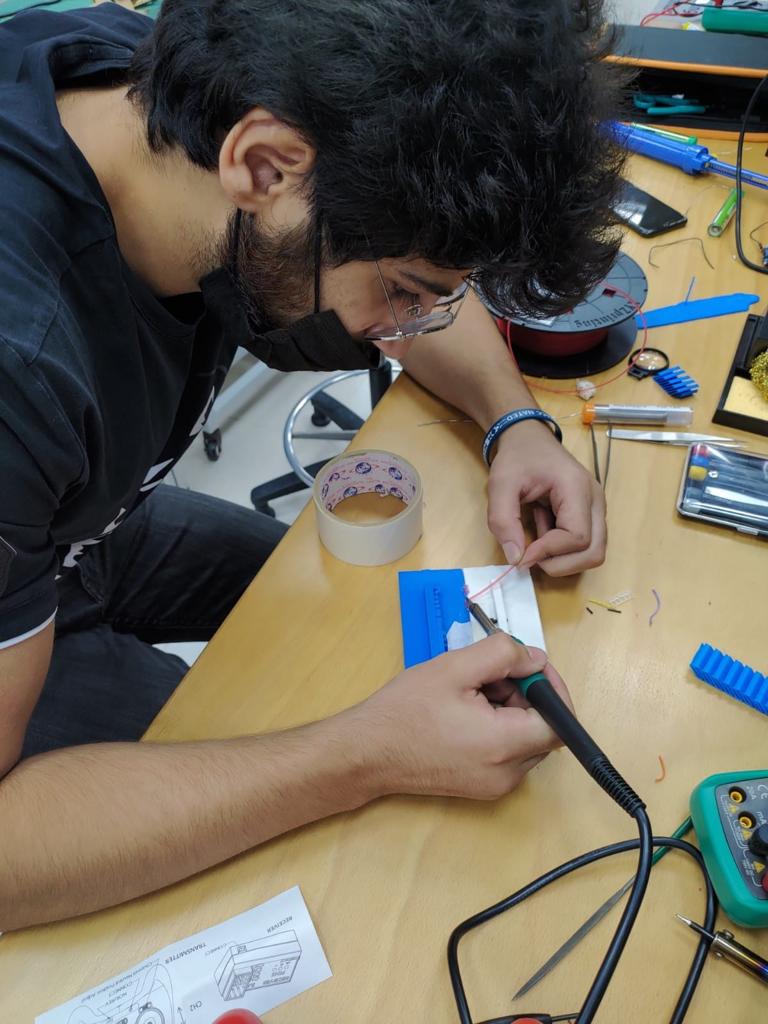

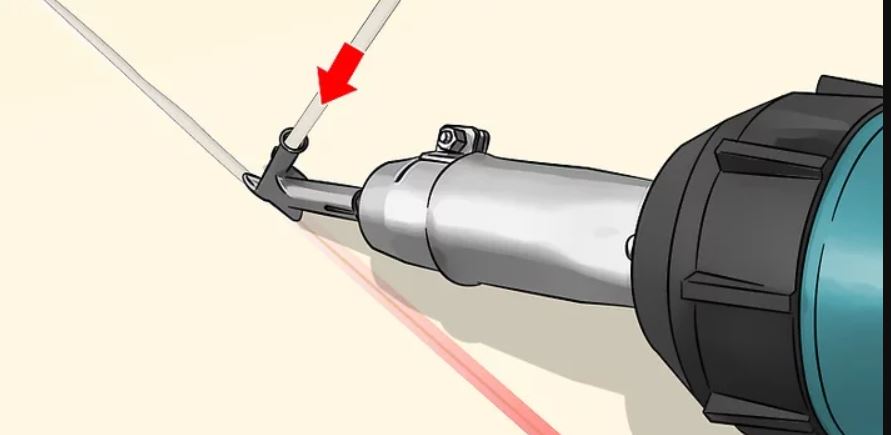

So, after doing some research about plastic welding I concluded that it is a very useful process and also very safe to start practicing with. I mainly wanted to use plastic welding for final project because like I said I have 3d printed material that I wanted to weld together like the wing and the power switch as well as housing for the electronics So, I used the soldering iron to weld with and this some of the tips that I discovered when welding:

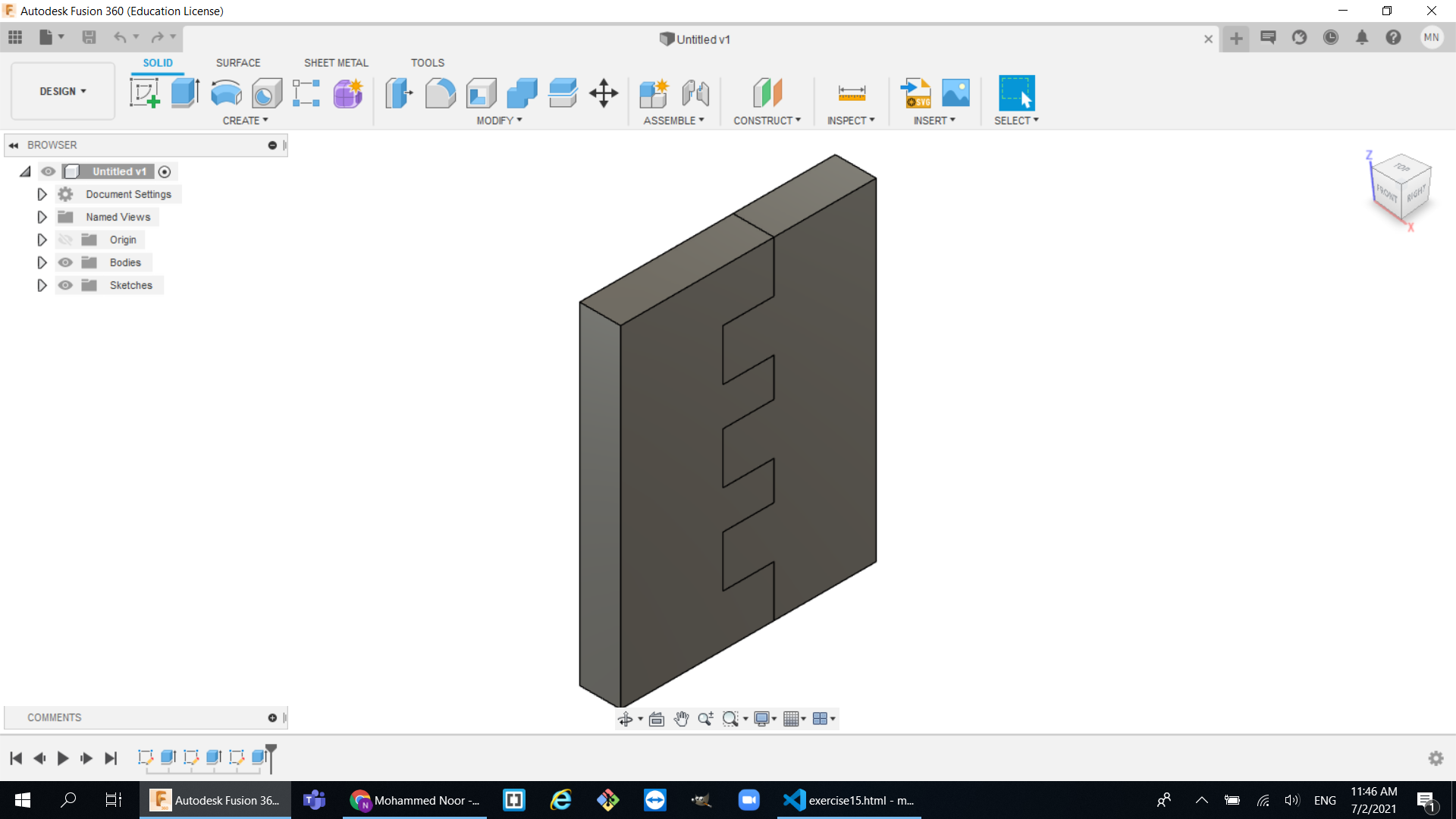

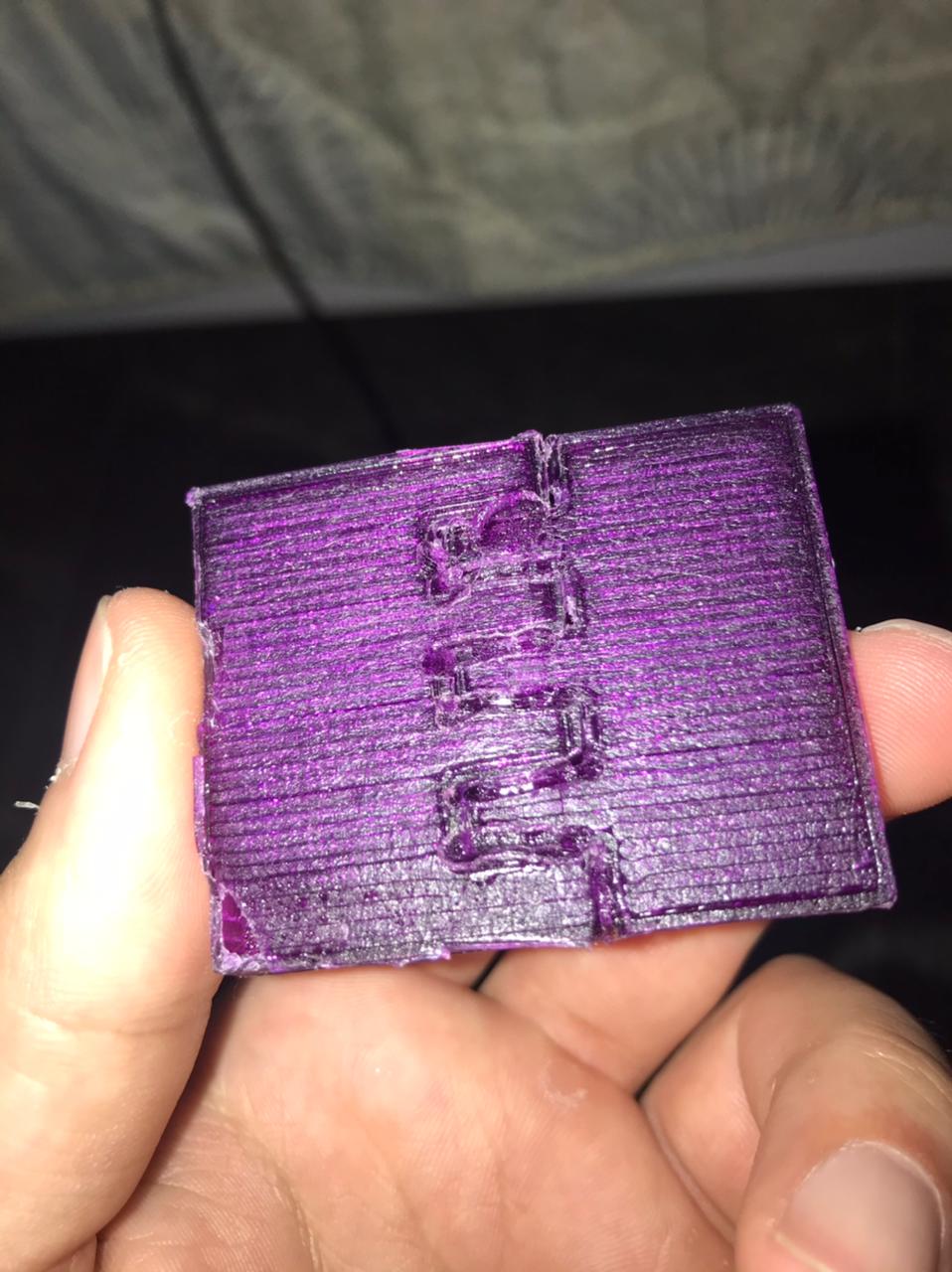

- First I wanted to test how the strength of plastic welding so I made this simple finger joint test with fusion :

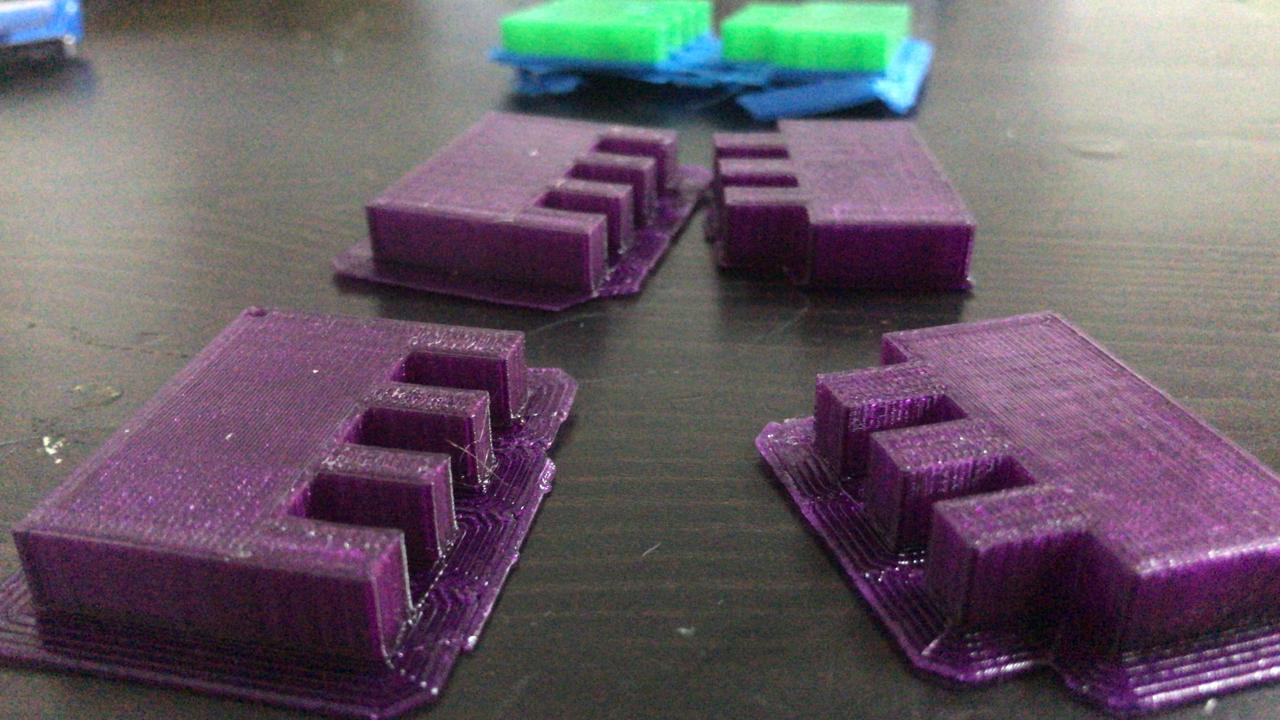

- Then I 3d-printed couple of them and I used PLA filament.

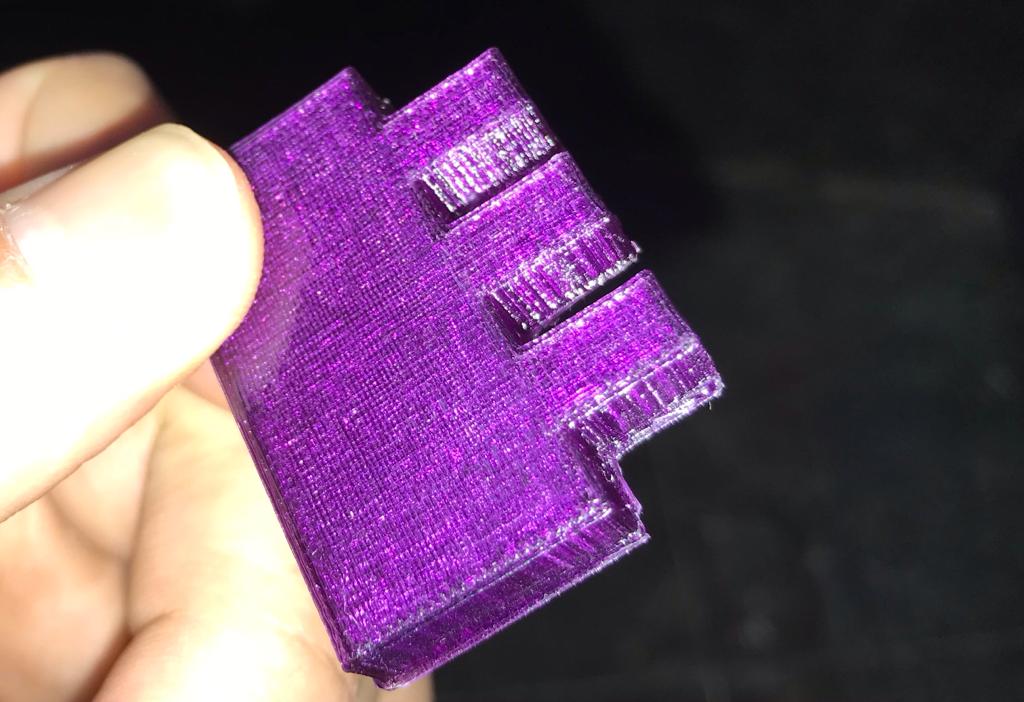

- Before you do anything make sure that the surface for both materials has a good finishing because you want them to be as flat as possible so that both align perfectly.

- Adding filament will make your welding stronger but also you can weld without adding any material

- Best technique I discover is that you run the soldering iron tip along the seam until the two pieces of plastic are partially melted together then follow it directly with the added material so they all melt together.

- Very import make sure that both pieces melt otherwise you will lose a lot of strength

- This video compares between welded fingers and normal fingers you can see it is a much stronger joint:

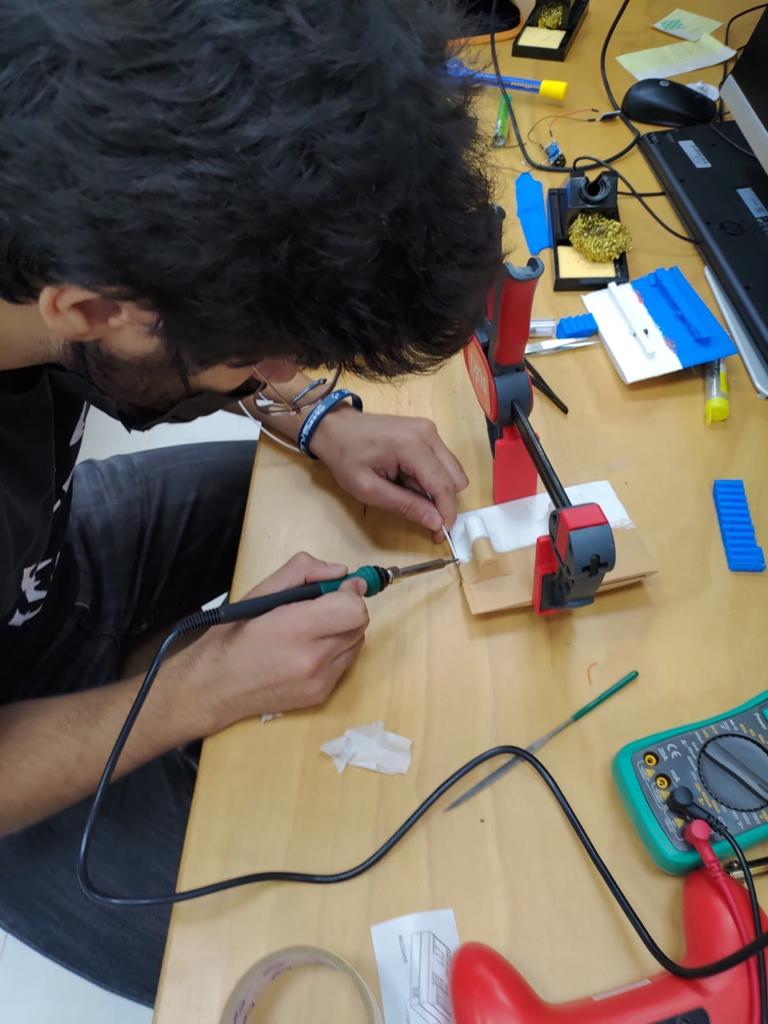

Final project welding:

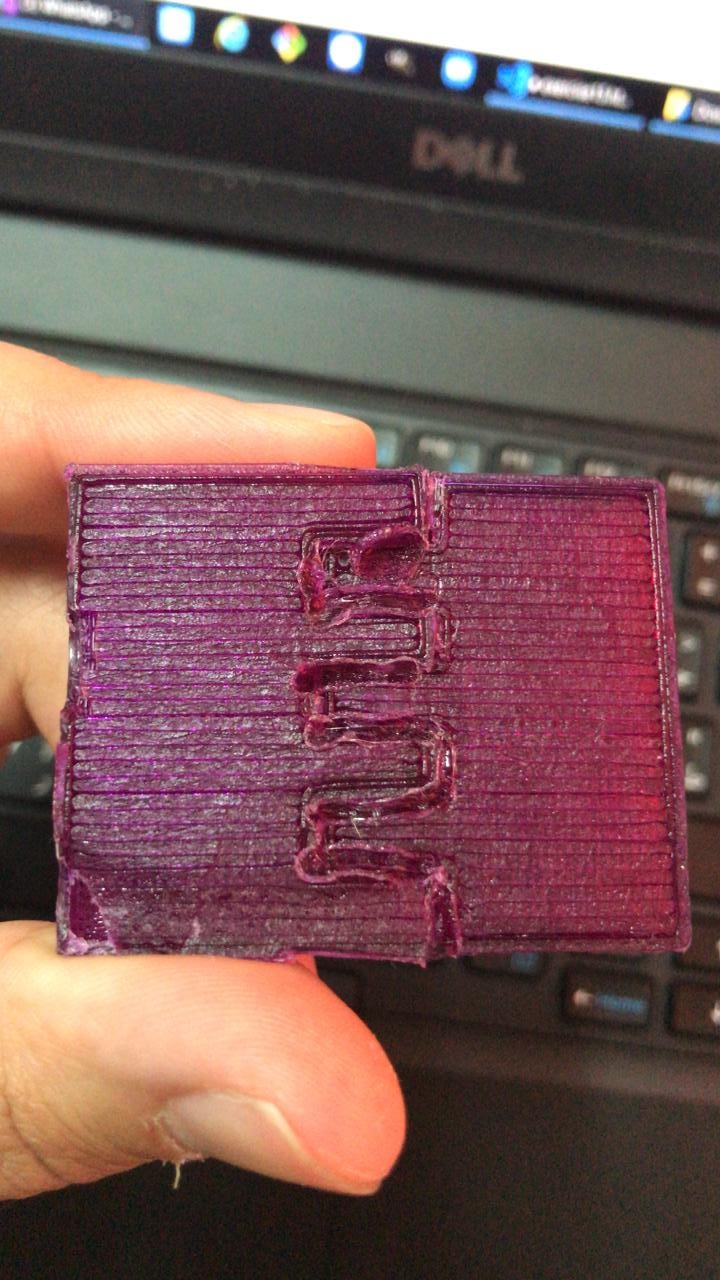

I used plastic welding for my final project as I welded the two connectors that connects the wing with the main frame so I can have the wing as one complete sigment rather than two: