Week 15

Wildcard week is made for us students to try new fabrication processes and the fun part it can be anything so since I really like working with laser cutter my instructor suggested that I try to make fiber glass pcbs using the laser cutter. As for the assignment :

Individual assignment:

Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it.

Unfortunately, our fiber glass laser machine is not working so I had to go for plastic welding but you can check out where I reached here.

Learning outcomes

- Demonstrate workflows used in the chosen process.

- Apply different technique and methods of plastic welding.

File Preparation

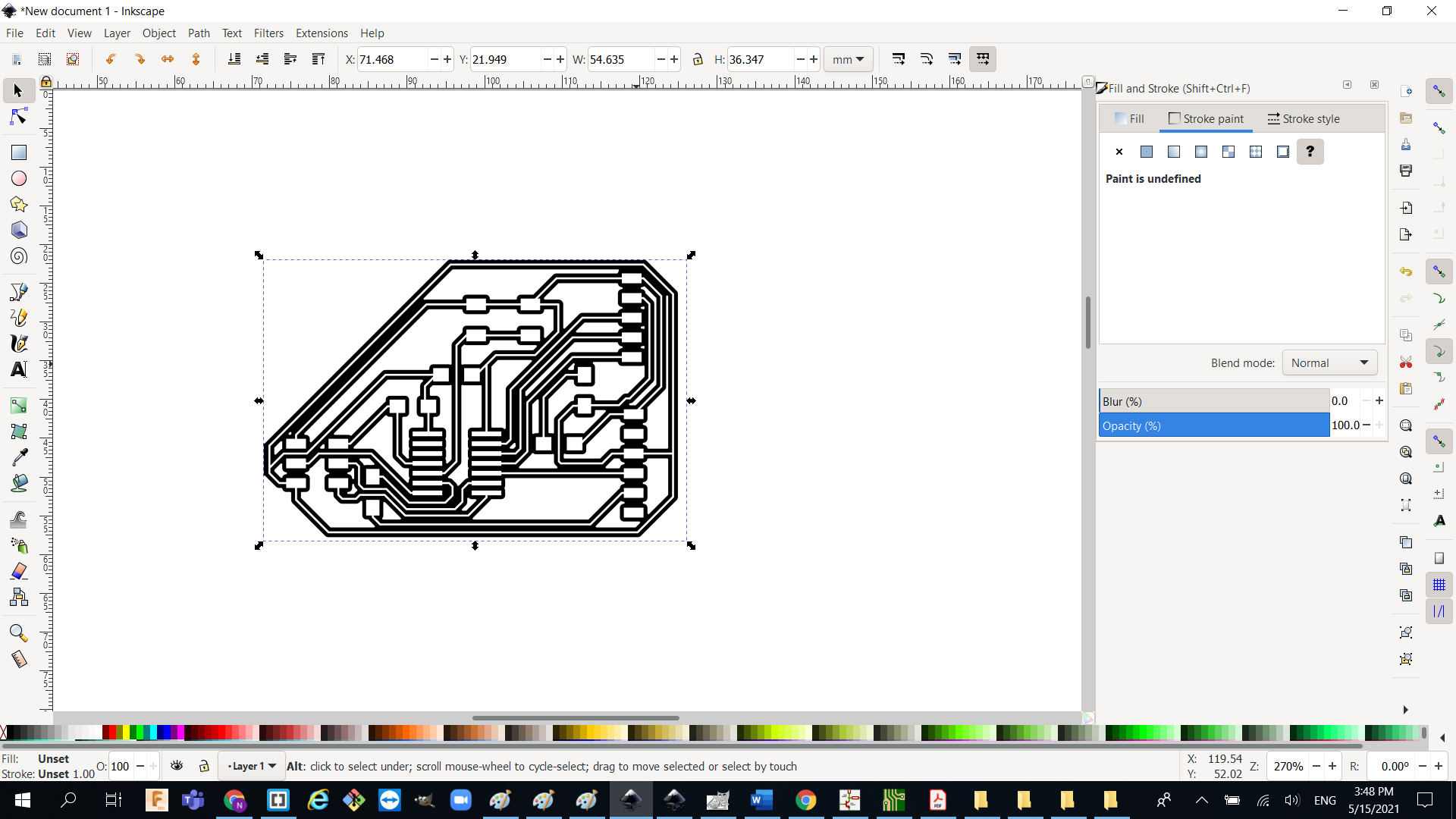

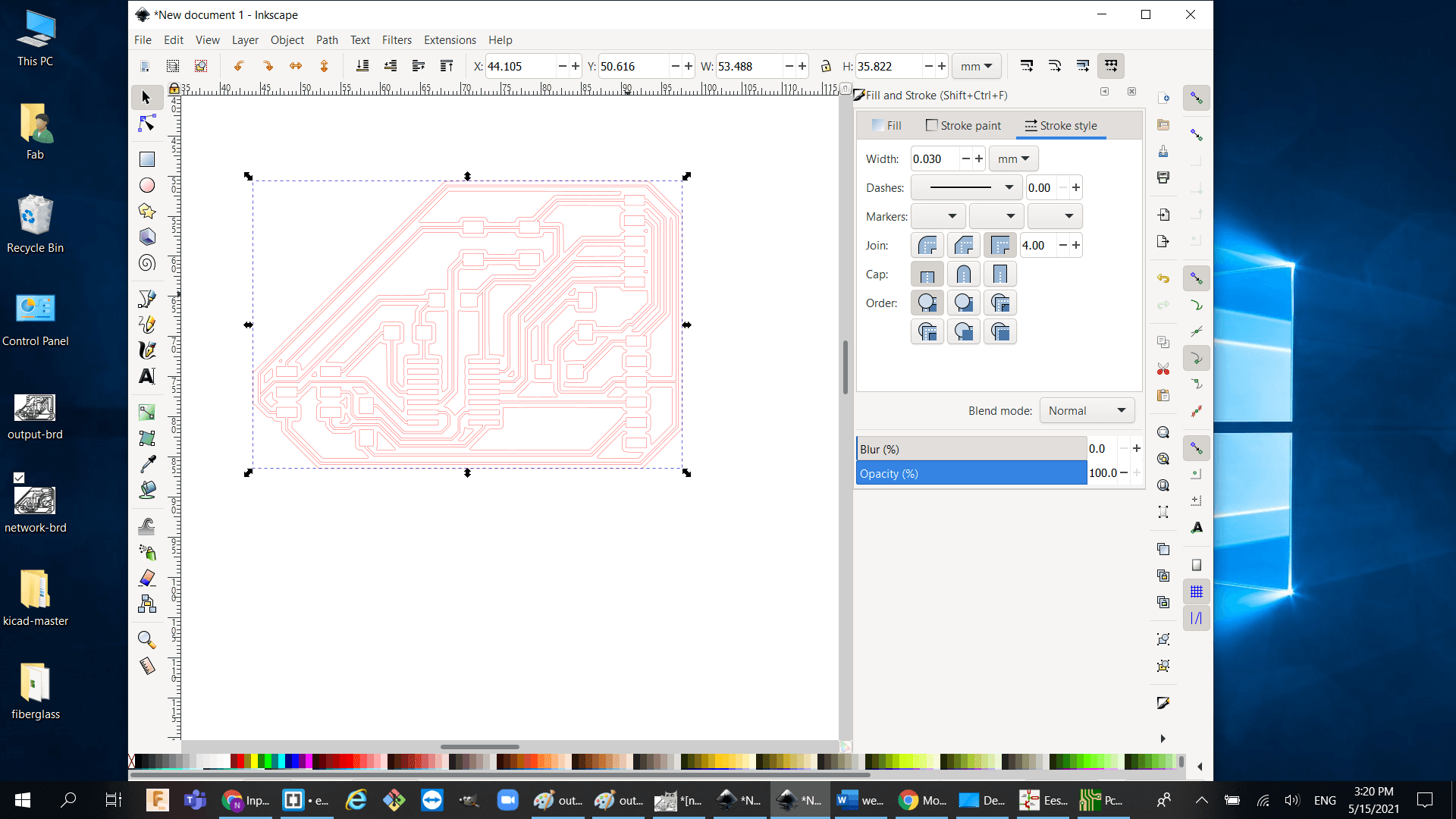

So, to prepare the file for laser cutting in order to make the pcb we need to prepare the file just like we do it with the milling machine, and it’s a similar approach. To prepare the file to the following:

- Use the filled zones tool in kicad to fill the area between the traces

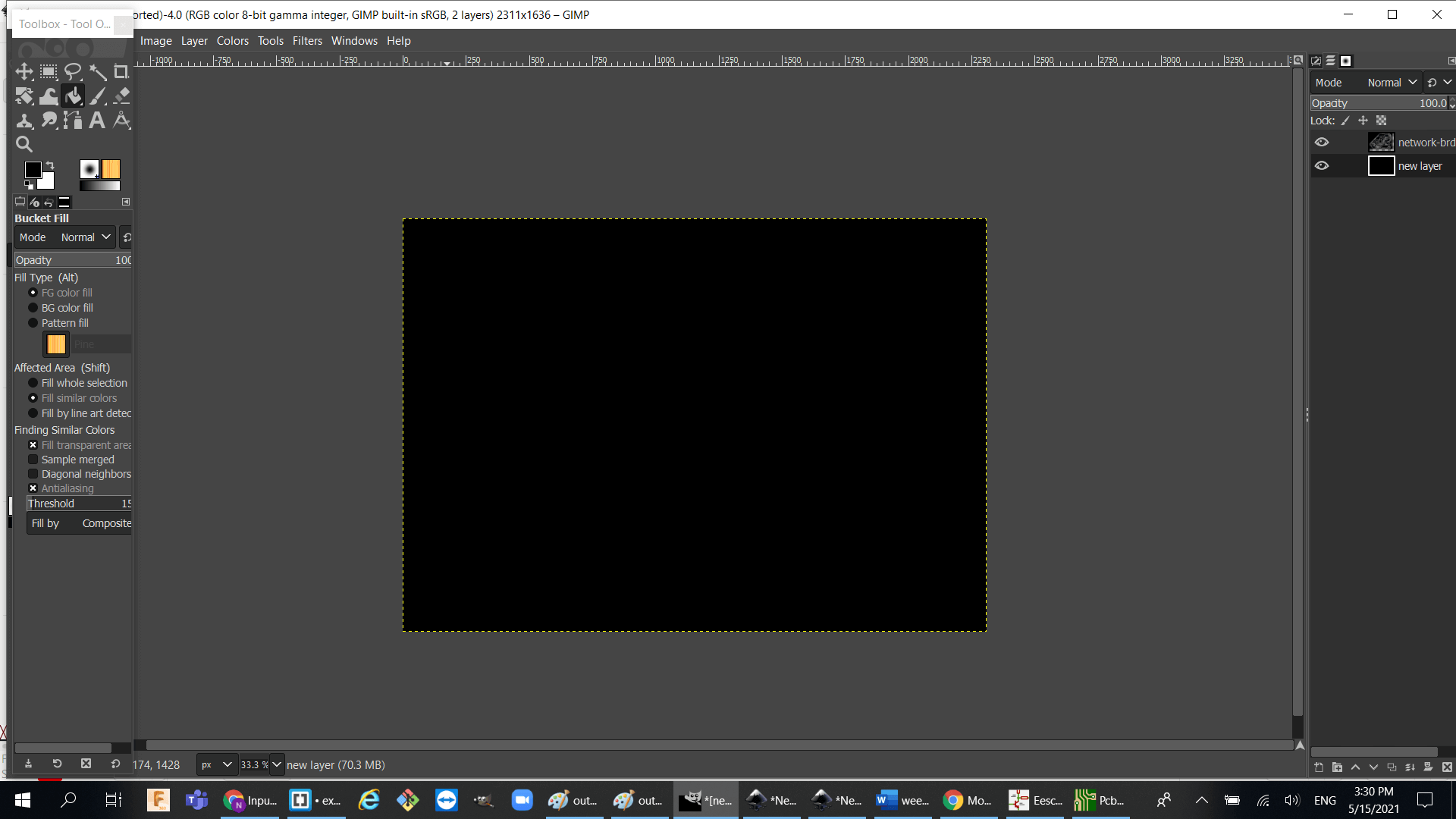

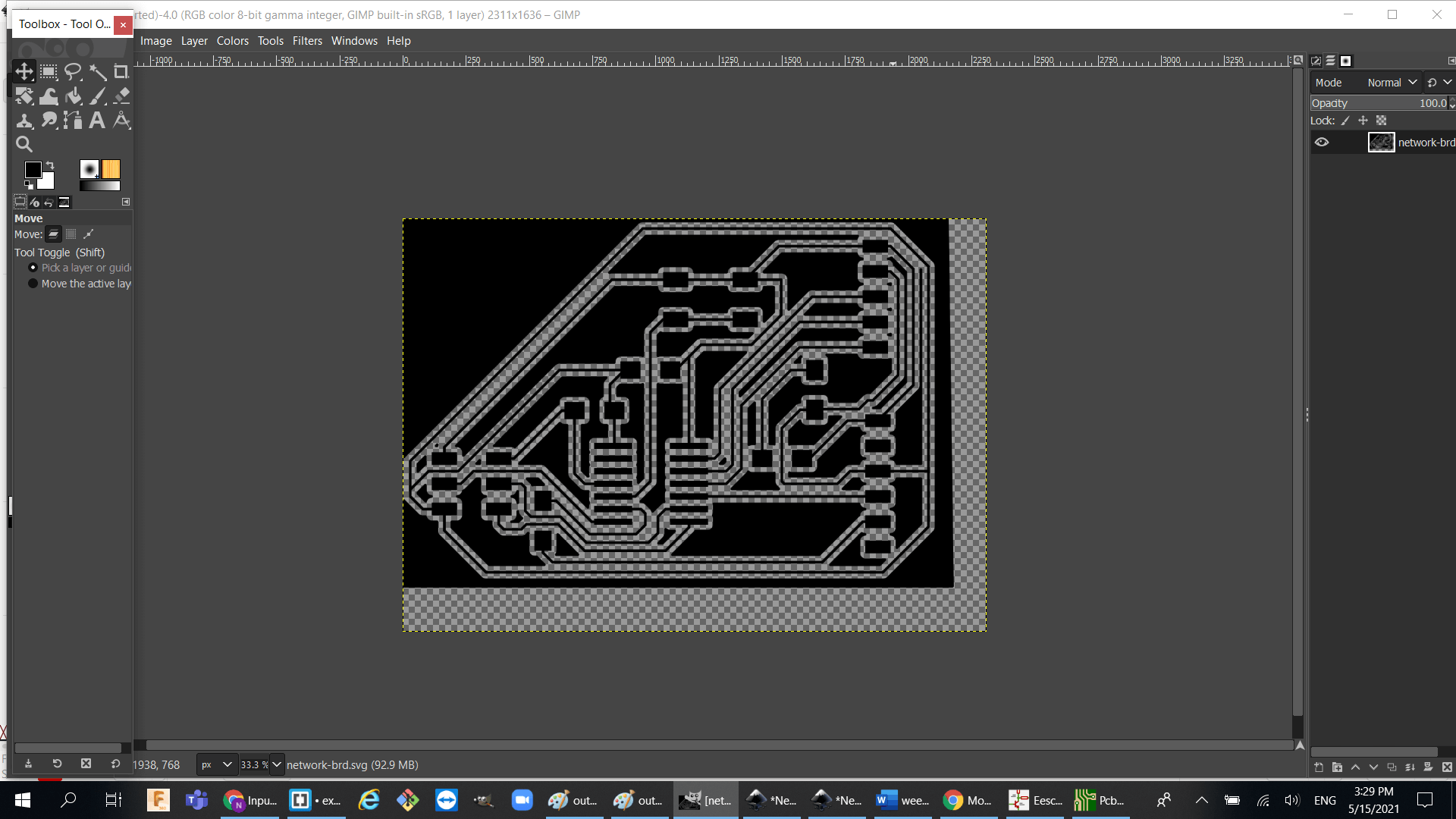

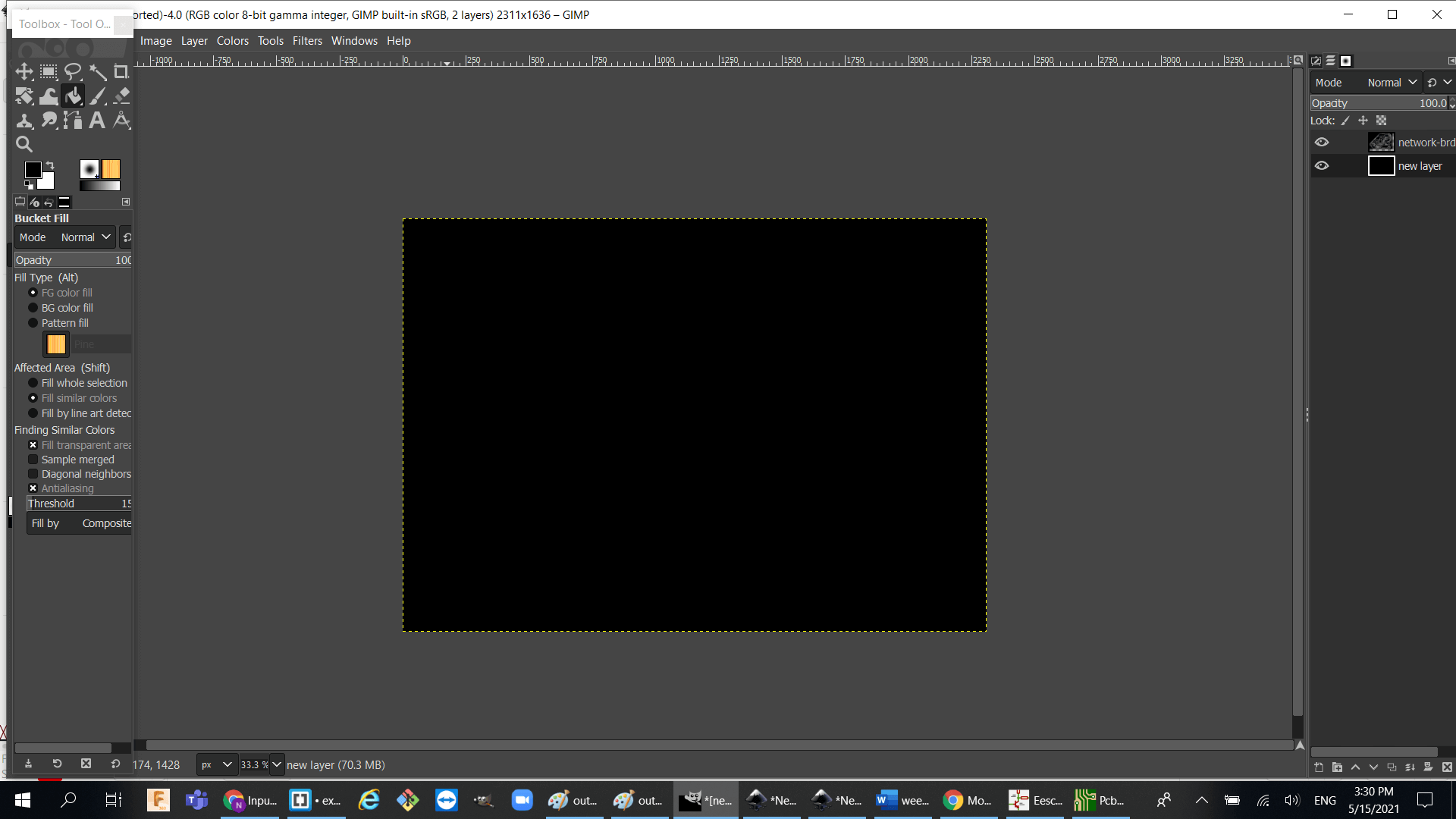

- Export it and open it with gimp

- Make a new layer then fill it

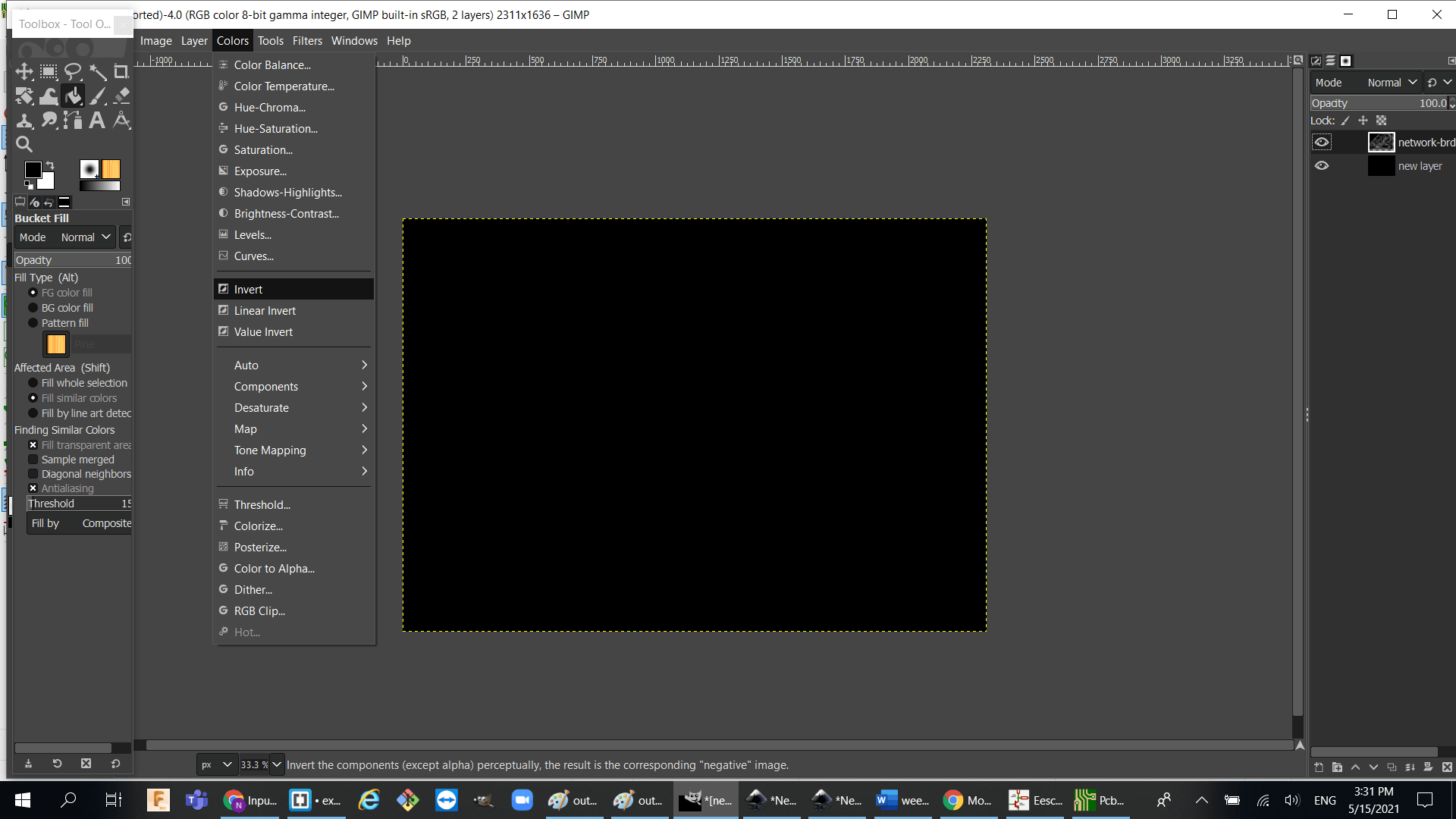

- Now invert the colors of the first layer

- Now export it into a png then open it with InkScape

- Make it a vector then use color mapping to fit your laser cutter

.png)