Final Project

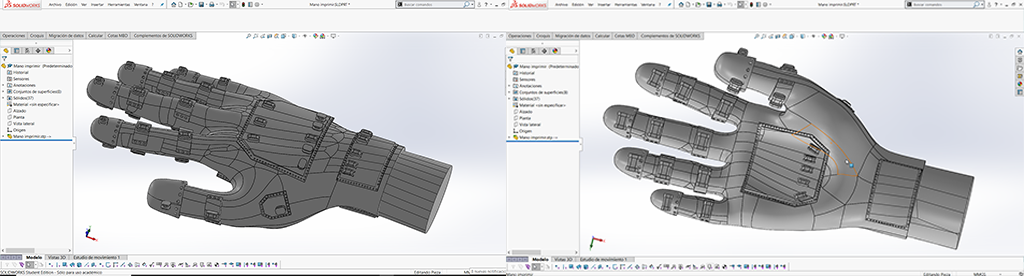

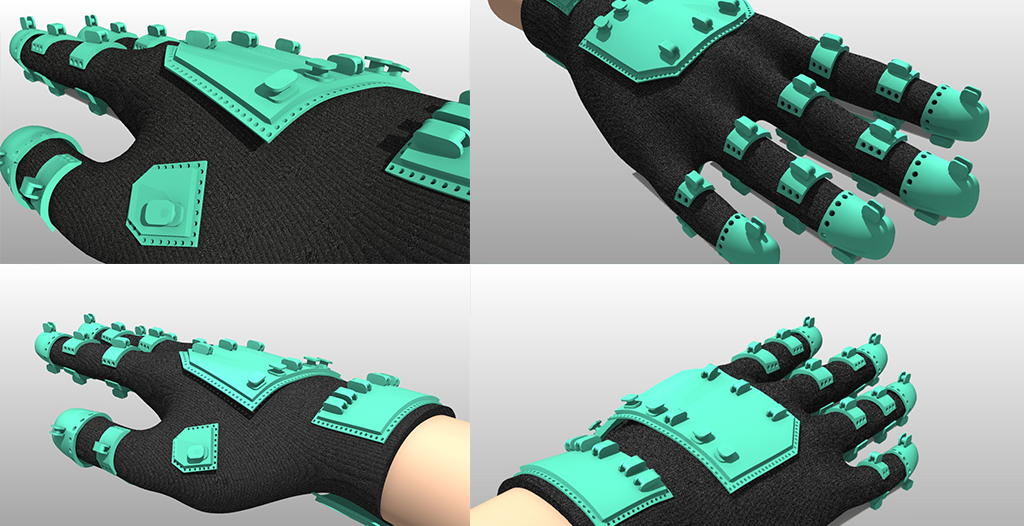

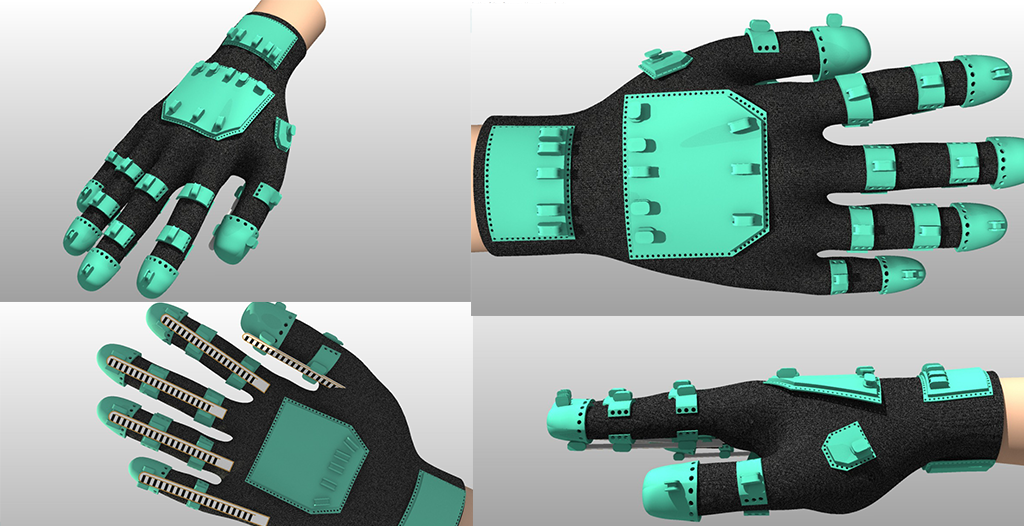

The project involves the development of a hand-held exoskeleton through Computer Aided Design (CAD) software and the use of Rapid Prototyping (RP) technologies to assist Rheumatoid Arteriors (RA) patients in their rehabilitation process. The first prototype was developed thanks to RP techniques and validated by an Occupational Therapist whose objective was the use of a splint that allowed active flexion movement to train joints. The device is made up of the main body printed in 3D on Polylactic Acid (PLA) plastic material that covers the wrist. The digital modeling was performed within the 3D Studio Max ™ software, by obtaining a file in STL format for subsequent printing, and being taken as reference; it was used with the digitized hands in a 3D scanner, in patient OBJ format, in order to replicate the organic shape of the hand, and adapt it to the proposed solution. To generate the tension in the exercise, elastic threads were used according to the distribution in the patient's hand.

The device configuration process was verified in a patient with an incipient state of the disease, where the symptoms presented were associated with loss of polyarticular movement, that is, more than four joints being affected and a slight decrease in joint mobility, with no presence of nodules. The preliminary study started from the verification of the exoskeleton prototype's efficacy by taking into account the degrees of freedom (GDL) necessary for the treatment of the disease, the mechanical analysis of the loads, the main stresses exerted, the resistance as a function of the shape and material, and finally the formal design of the prototype.

Digital tools and RP techniques were used to create a virtual 3D model from the digitization of a hand. It served as a three-dimensional reference to create the rehabilitation device prior to the design of a functional exoskeleton for muscular rehabilitation of the hands. In order to tangibly understand the limitations and scope of this type of techniques, virtual and physical tests were carried out to prepare a prototype of an arthritic hand, establishing real tasks and processes for the generation of a 3D physical model, that would later serve for the implementation of an exoskeleton for muscle rehabilitation. The study's finding suggested, in terms of mobility, that the articular arch of movement improved, reduced stiffness in joints, increased muscle stretching, reduction of pain and a decrease in the pressure around finger movement, which also meant a reduction in the possible appearance of tendon sheaths.

The development of the device began with an innovation to combine digital tools within the use of RP, 3D printing, alongside the possibility of providing a better quality of life for an individual who may require active rehabilitation and further ancillary treatment to their prognosis.

Details

Materials

| Name | Units | Units Price | Total Price |

| PLA filament 200 gr. | 1 | $ 6 | $ 6 |

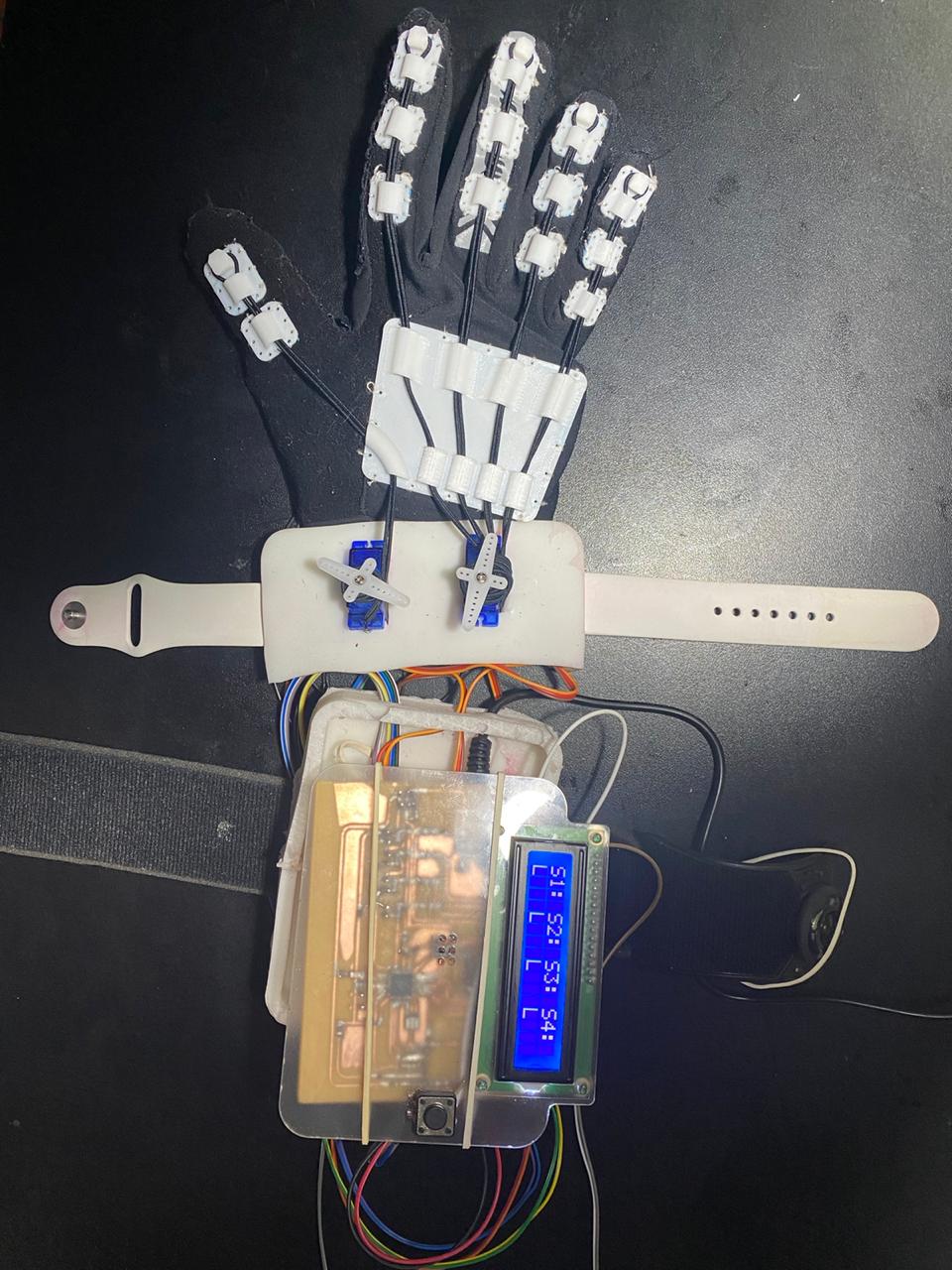

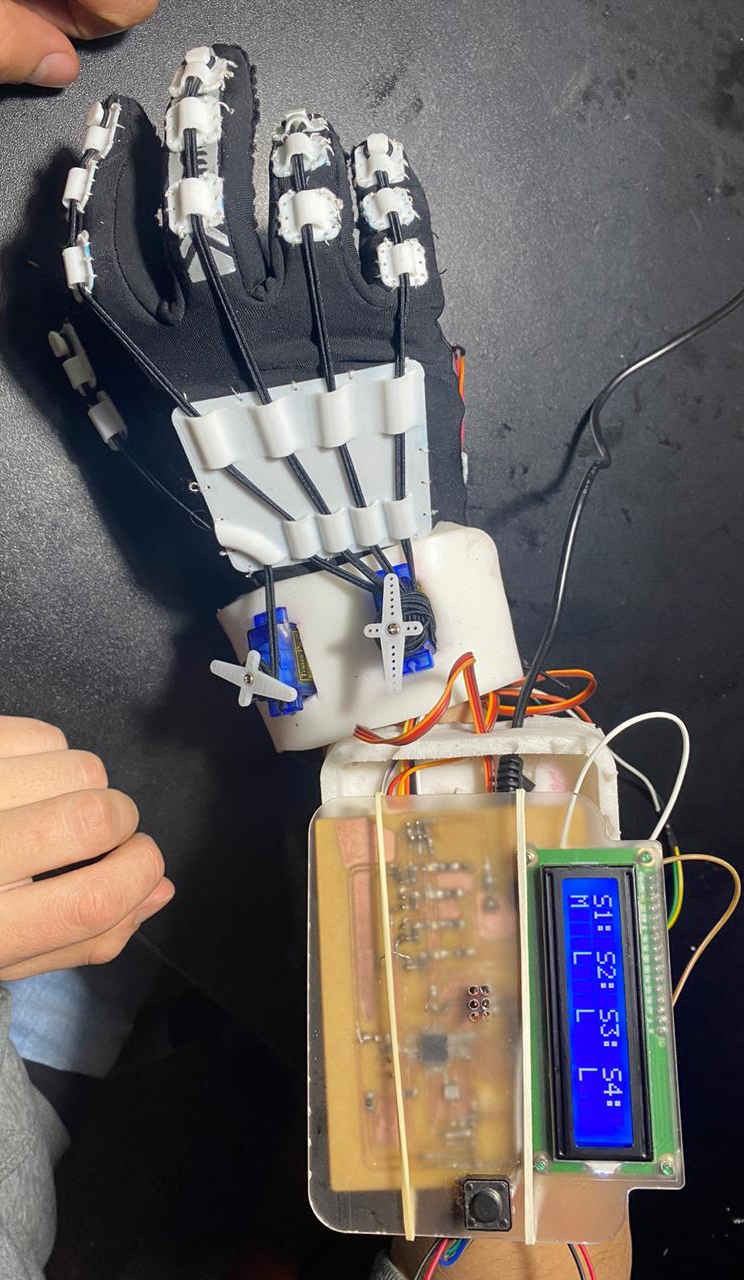

| Servo Motors Torque no less that 1,5 gr. | 2 | $ 5 | $ 10 |

| Pair of gloves | 1 | $ 7 | $ 7 |

| Elastic thread | 1 | $ 10 | $ 10 |

| Flex sensor | 5 | $ 10 | $ 50 |

| Force sensor | 1 | $ 12 | $ 12 |

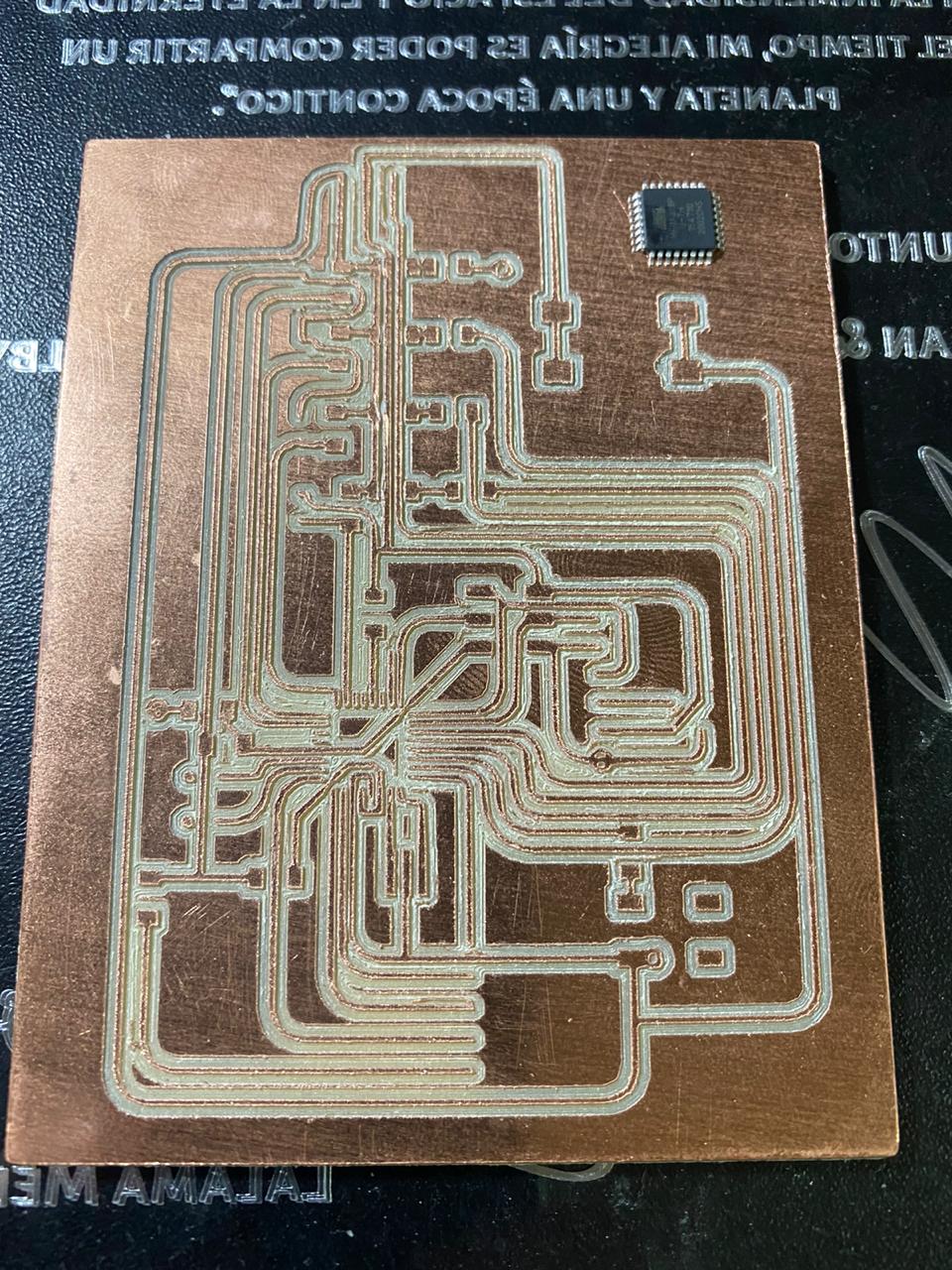

| ATMGA328 AU | 1 | $ 3 | $ 3 |

| Electronics suply SMD | 1 | $ 10 | $ 10 |

| ATtiny3216 | 1 | $ 1 | $ 1 |

| ATtiny412 | 1 | $ 1 | $ 1 |

| Other consumables (leds, tin, cables...) | 1 | $ 5 | $ 5 |

| Total | $ 115 |

It was a hard work but it worth it.

The process is summarized in the scheme presented below: which begins with the identification of a RA patient's hand, then with the use of RP technology, a digital hand is generated for improvement, then materialized to create a rehabilitation piece.

Sketch Process

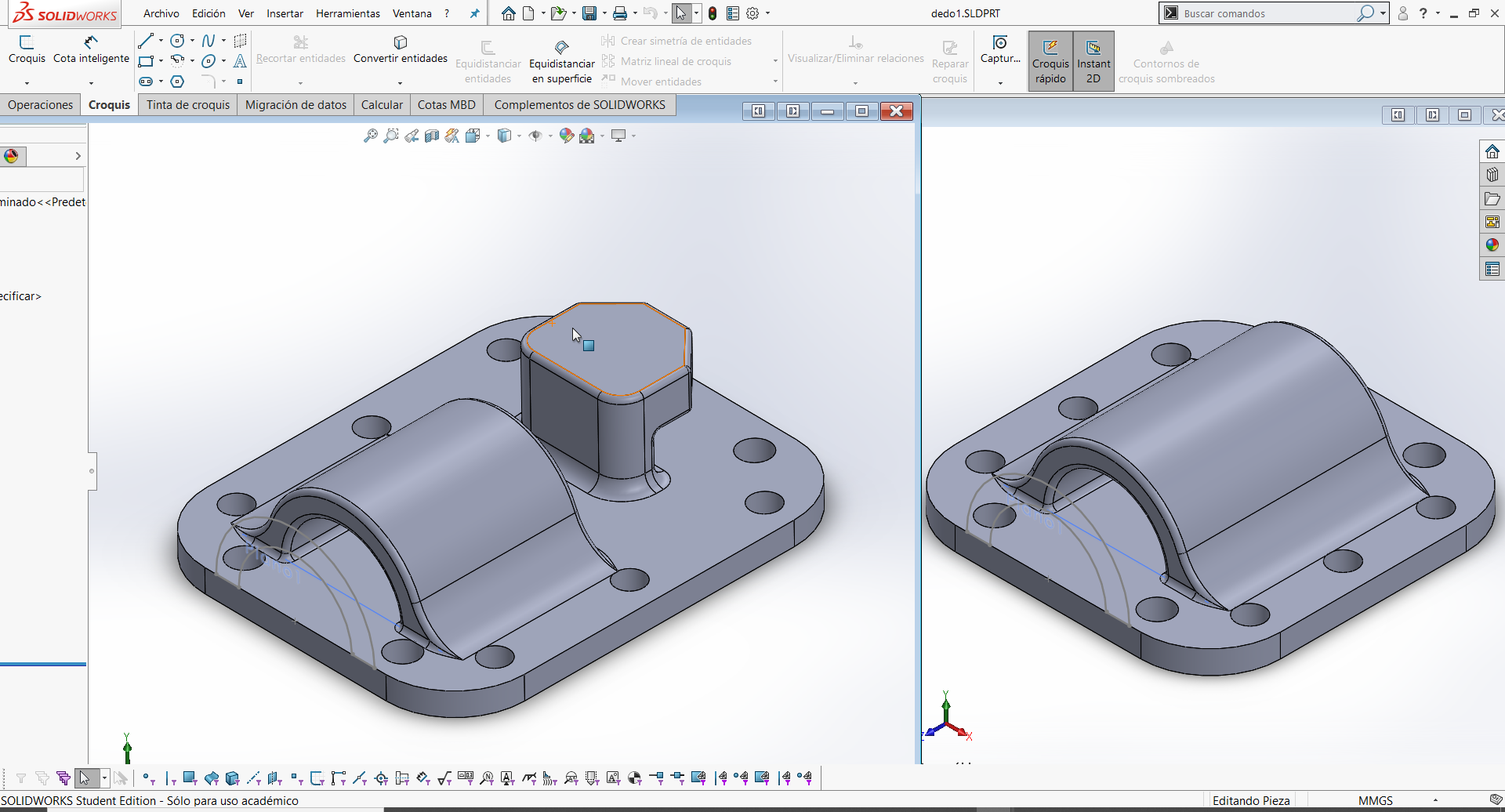

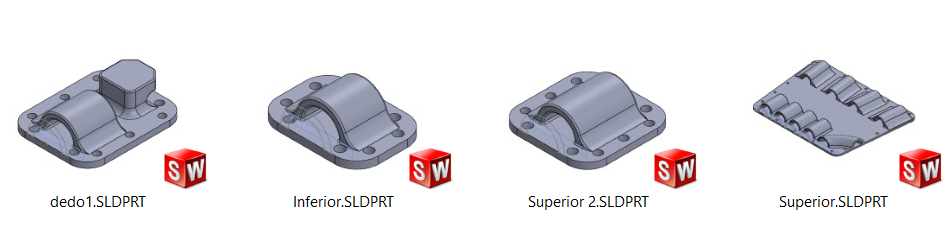

CAD Process

Rendering Process

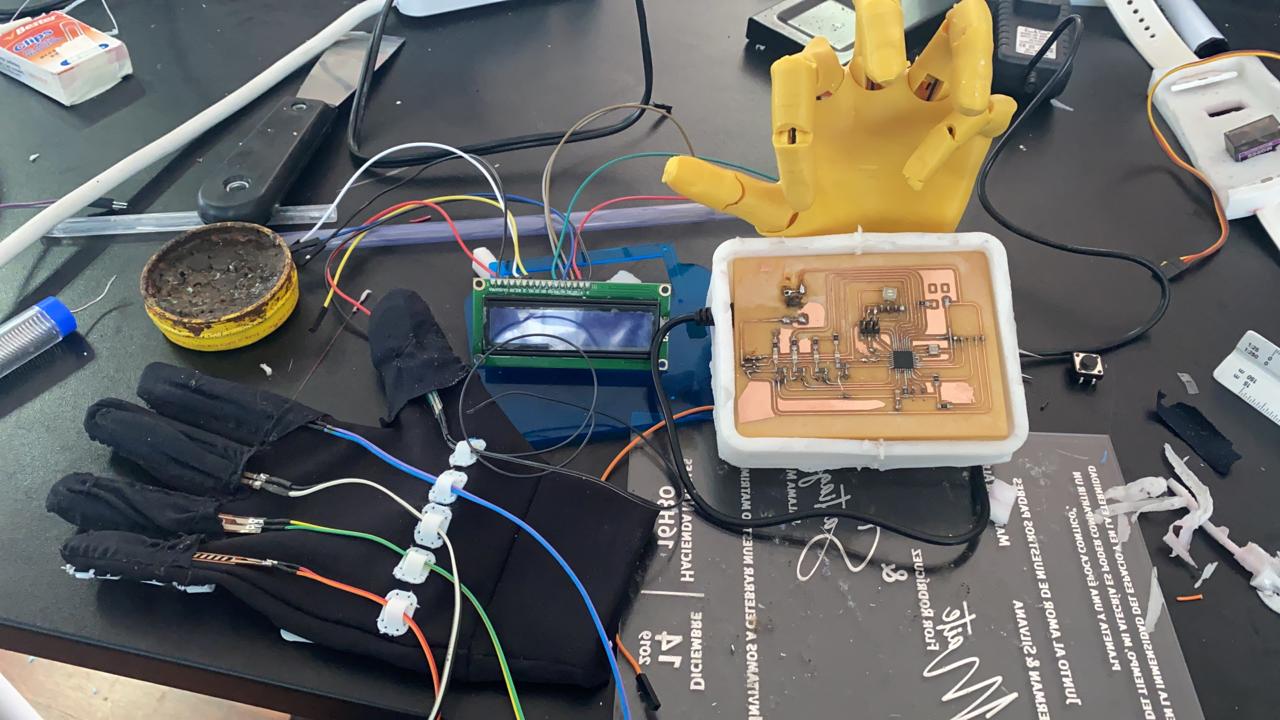

First test

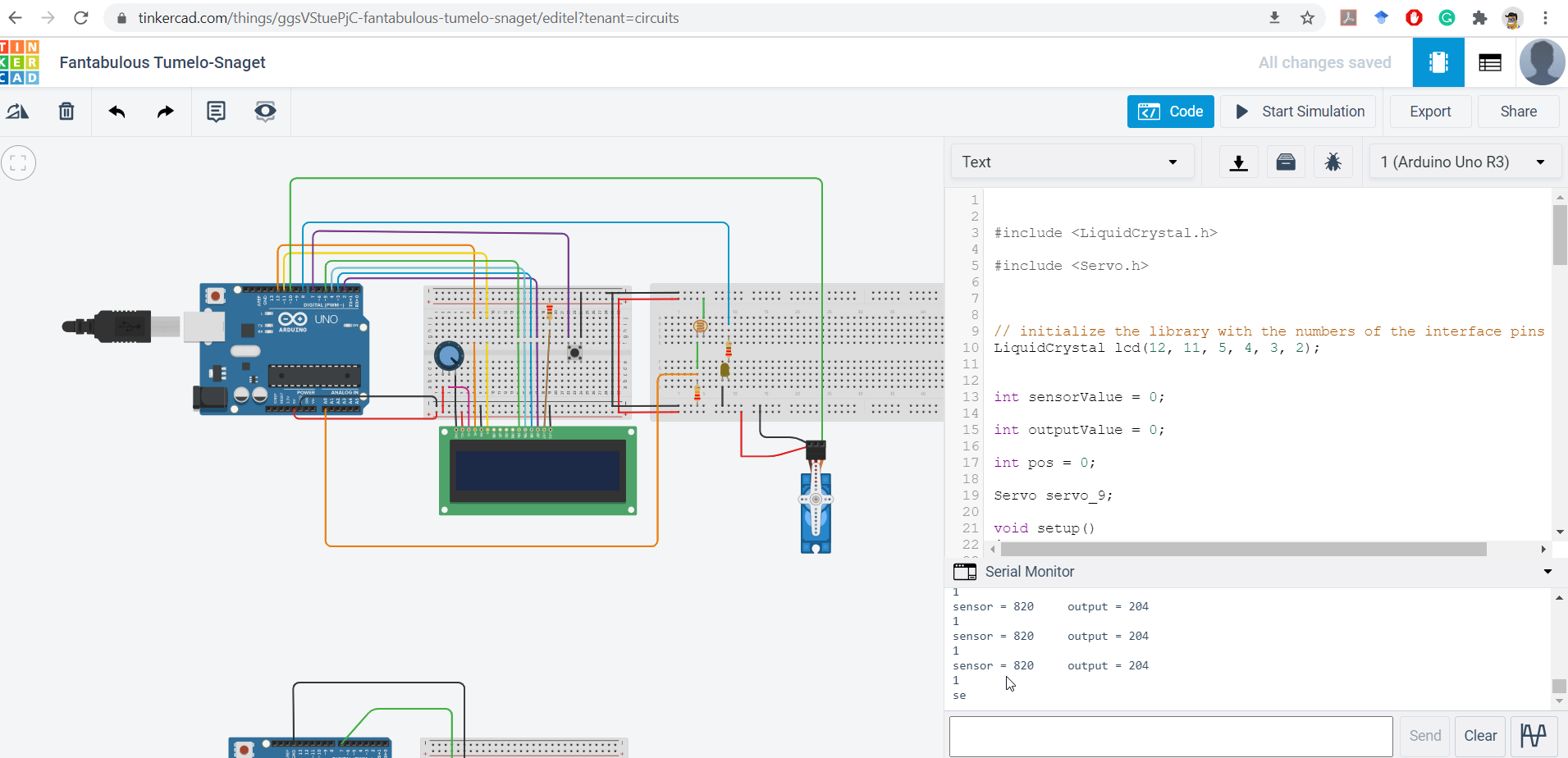

Arduino, LCD, Servo TEST

3D Modeling

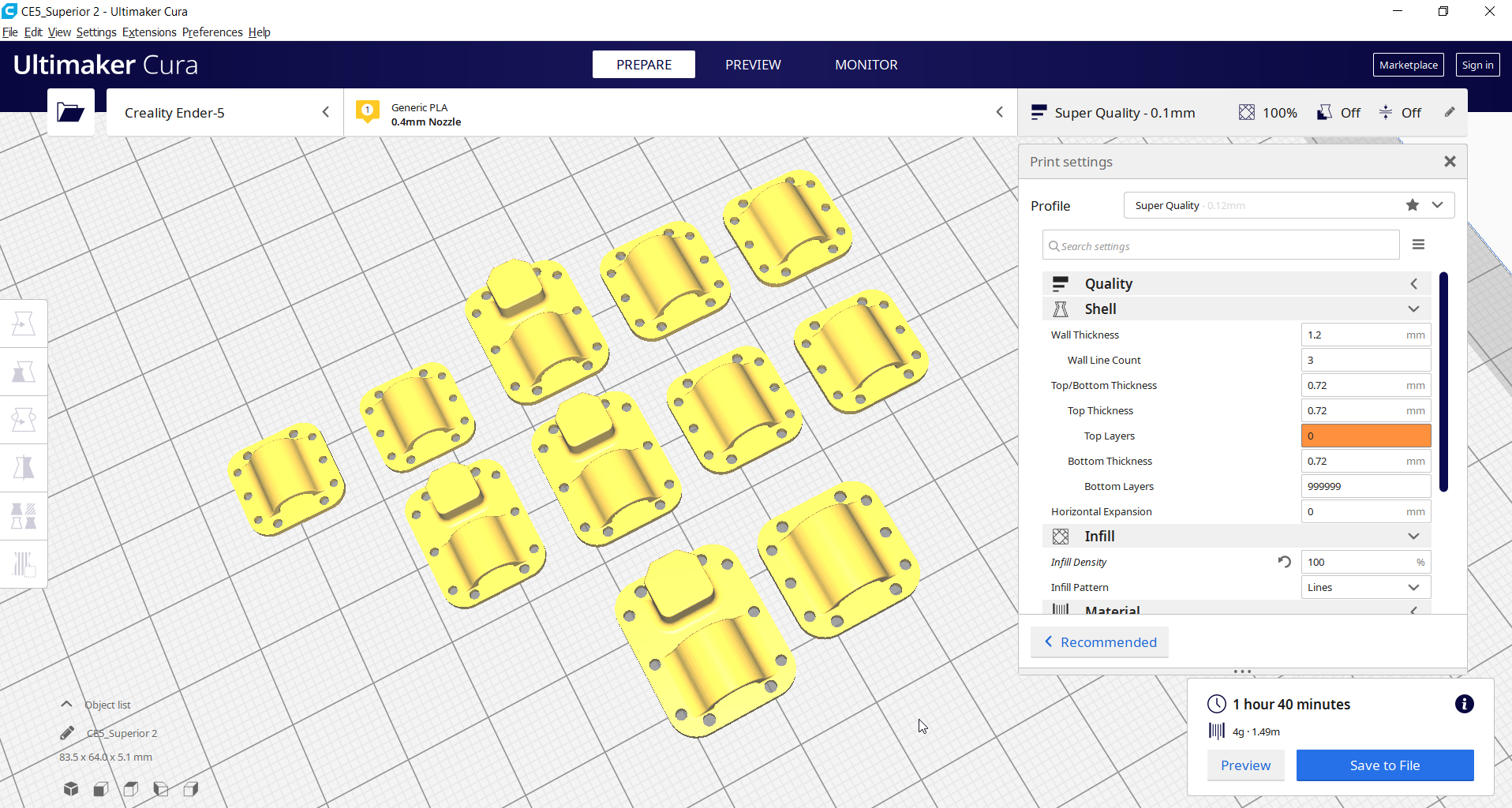

3D Printing

Assembly

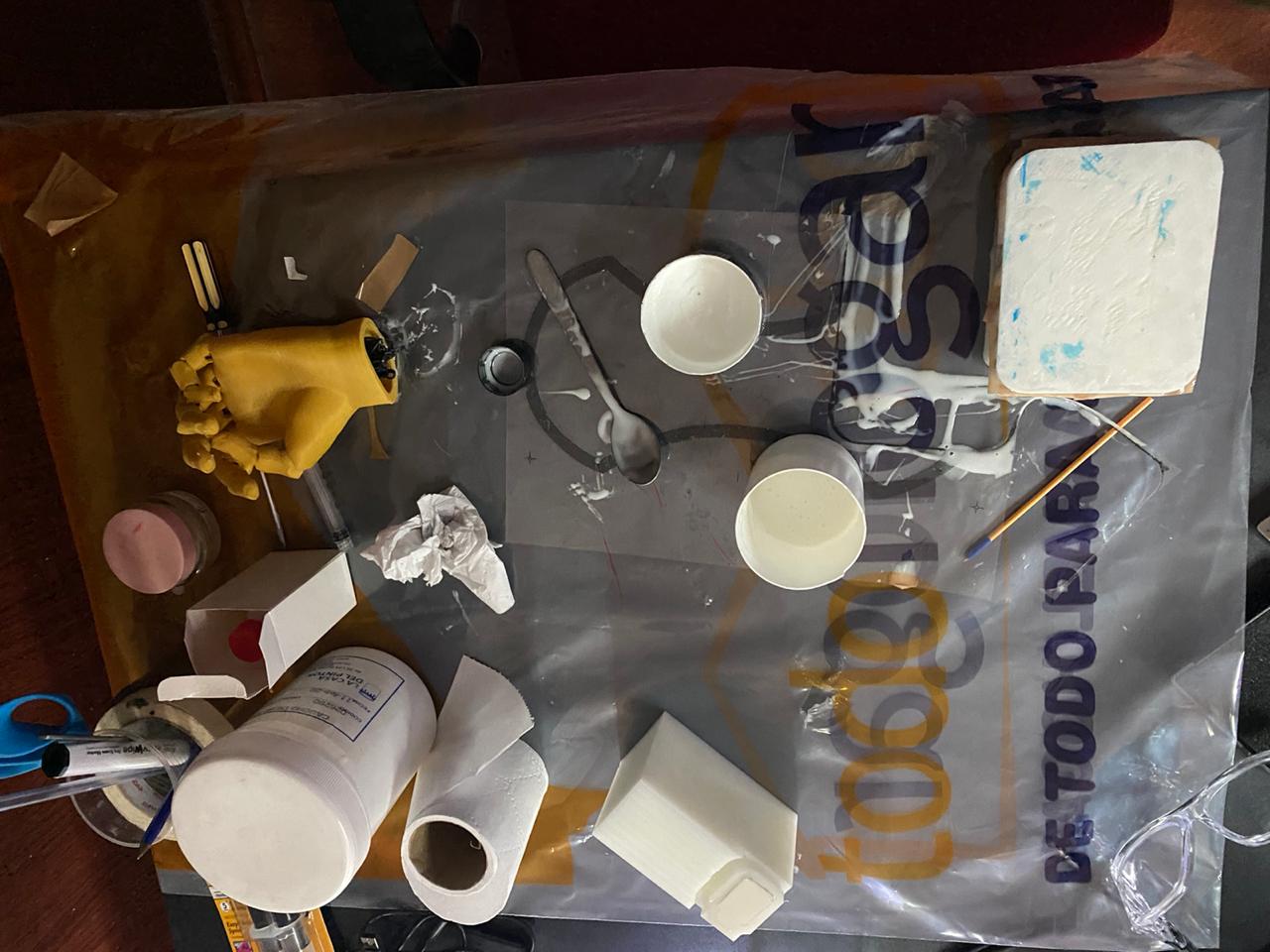

Molding

The creation of a soft container box made of silicone rubber material for the PCB of the hand rehabilitation exoskeleton glove was justified to ensure the protection and safety of the electronic component. This box provided a resilient barrier and shielded the PCB from moisture, dust, and other external elements that could have affected its functionality. Additionally, the silicone rubber material offered cushioning and flexibility properties, minimizing the risk of damage from impacts or abrupt movements. This secure and durable packaging solution ensured the integrity of the PCB and contributed to the optimal performance of the hand rehabilitation exoskeleton glove, providing a reliable and effective solution for the FabAcademy final project.

PCB