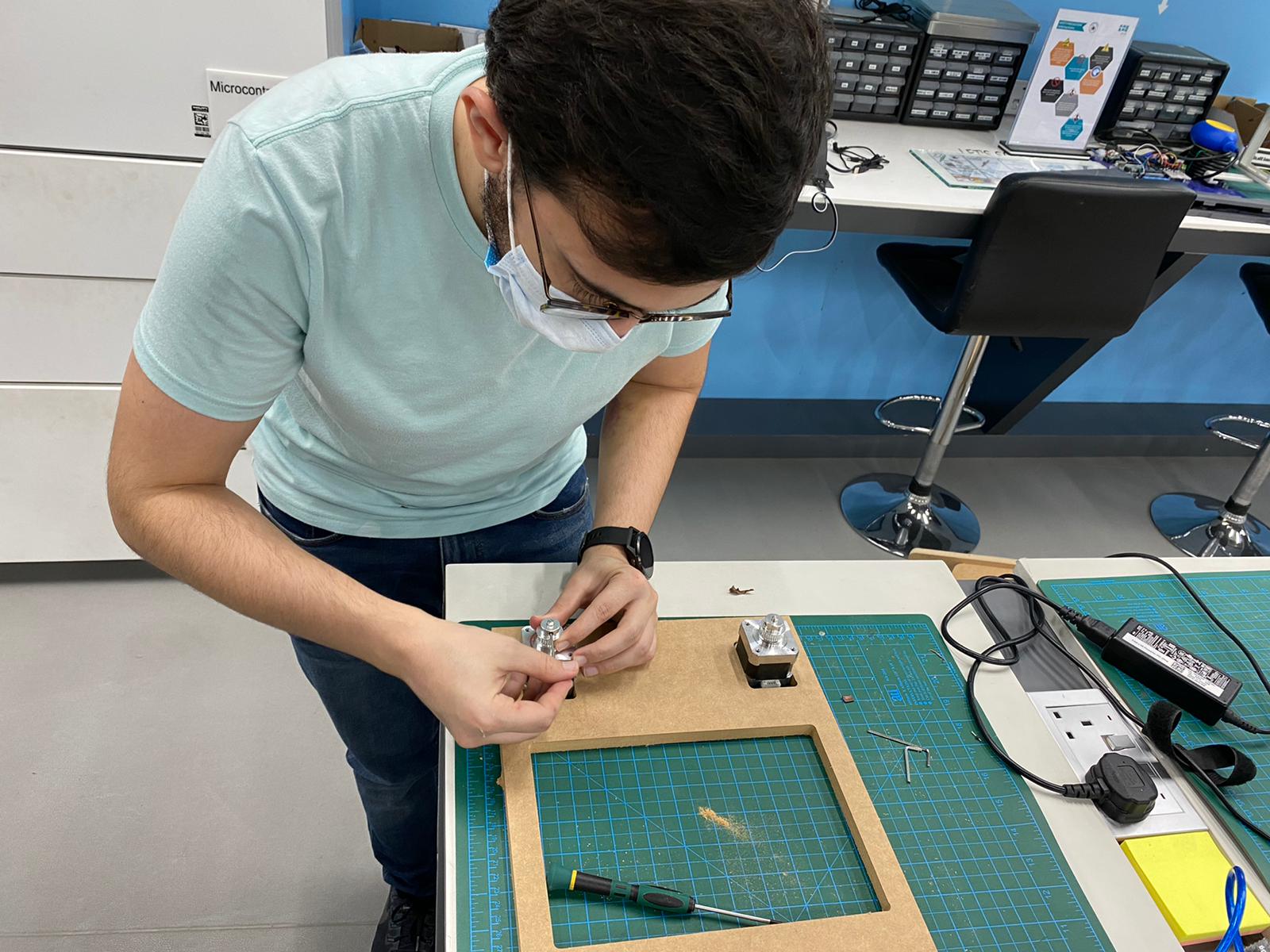

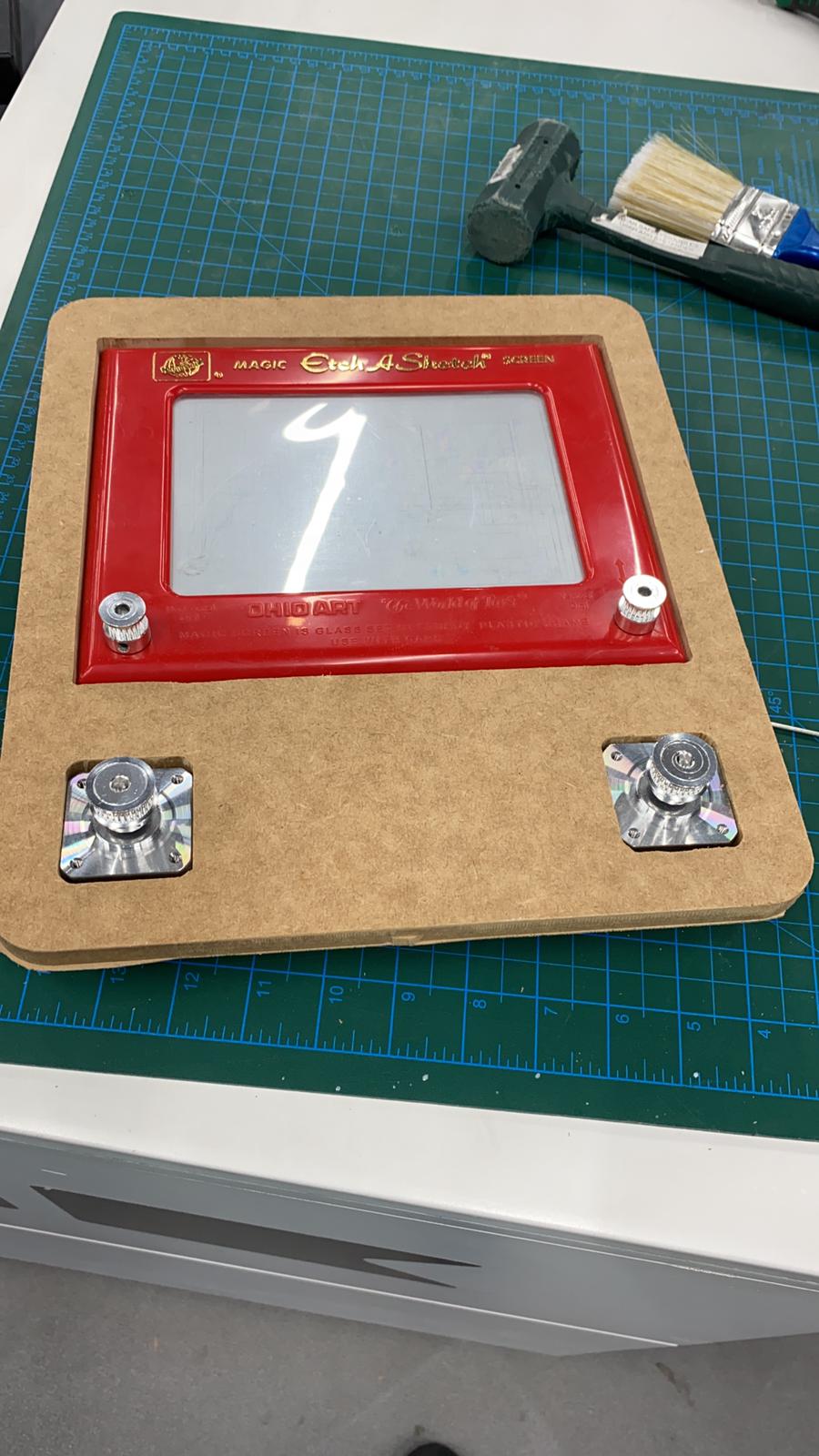

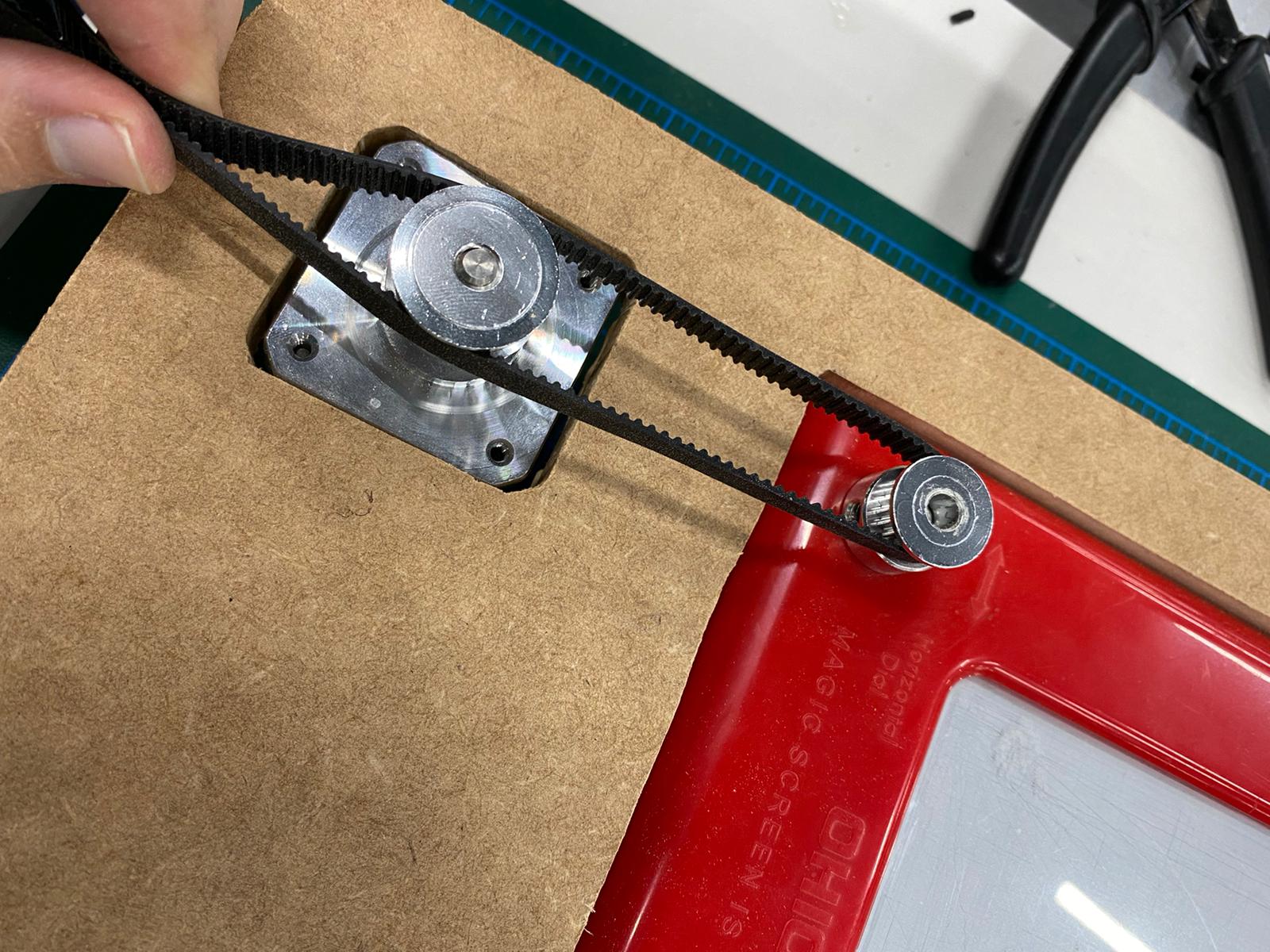

Another fun week in Fabacademy!! This week we explored machines and differen't kind of mechanical designs and actuation systems. The assignment was to design a machine that includes mechanism+actuation+automation. We chose to go with an >Etch-a-Sketch plotter. The Etch A Sketch comes with two knobs, one moves the little needle horizontally (X-axis)and the other moves it Vertically (Y-axis). We have decided to automate the drawings on this toy to produce impressive drawings. face mask and increase human protection.